If you’ve ever finished a cutting session only to find every surface in your shop coated with fine sawdust—including your lungs—you know why dust collection matters. I learned this the hard way after spending three years coughing through projects before finally investing in proper dust collection.

The transformation was immediate. Cleaner shop, better visibility during cuts, and I stopped leaving work feeling like I’d been breathing sandpaper. My wife was happier too—I stopped tracking sawdust through the house.

A table saw dust collection system captures sawdust and fine particles at the source, preventing them from spreading throughout your workspace and into your respiratory system. According to the Occupational Safety and Health Administration (OSHA), wood dust exposure can cause respiratory issues, skin irritation, and long-term health problems. Their 2024 standards mandate specific exposure limits for commercial woodworking operations.

In this guide, I’ll show you everything you need to know about table saw dust collection—from understanding why basic collection falls short to choosing the right system or building an effective DIY solution that actually works.

Why Standard Dust Ports Aren’t Enough

Most table saws come with a dust port beneath the blade—a 2.5 or 4-inch opening that promises to collect sawdust. In reality, these factory ports typically capture only 50-60% of the dust created during cutting. The rest escapes into your shop air.

The Two-Source Problem

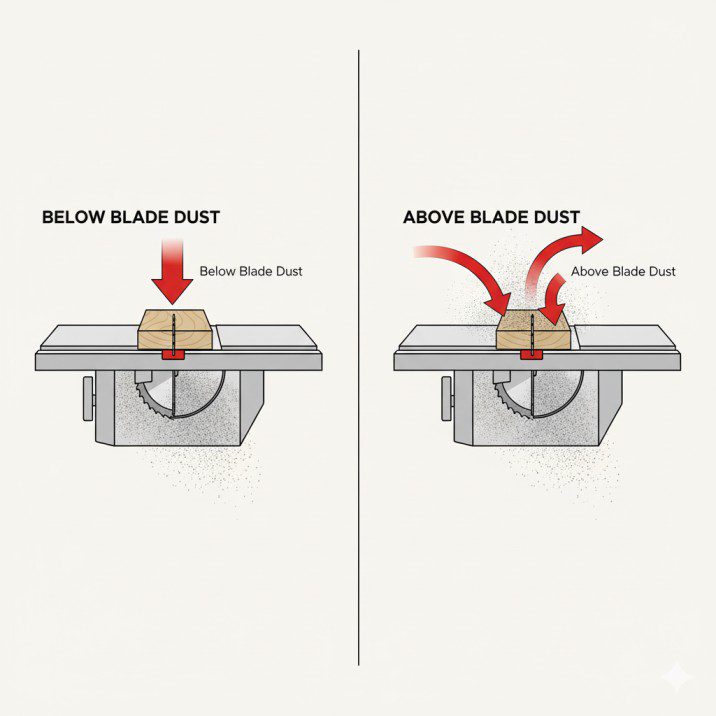

Table saws create dust at two distinct locations:

Below the blade: Dust falls through the throat plate into the cabinet. Factory ports target this area but often have poor shroud design that allows dust to bounce around inside before escaping through gaps.

Above the blade: As the blade exits the wood, it flings dust upward and forward—directly toward your face and chest. This is often the majority of visible dust, and standard ports don’t address it at all.

I noticed this clearly when I added my first shop vacuum to the standard port. The dust inside the cabinet reduced, but I still had a cloud of fine particles hanging in the air after every cut. That’s when I realized effective collection requires a dual approach.

Health Implications You Can’t Ignore

Fine wood dust particles (under 10 microns) are small enough to bypass your body’s natural filters and lodge deep in your lungs. The American Lung Association reports that prolonged exposure to wood dust increases risks of respiratory diseases, asthma, and even nasal cancer.

Beyond health concerns, accumulated dust creates fire hazards. Sawdust is highly combustible—many shop fires start from dust buildup near electrical motors or hot surfaces. Professional shops follow strict dust management protocols not just for health but for safety compliance.

Types of Dust Collection Systems

Understanding your options helps you choose the right system for your budget, shop size, and typical workload.

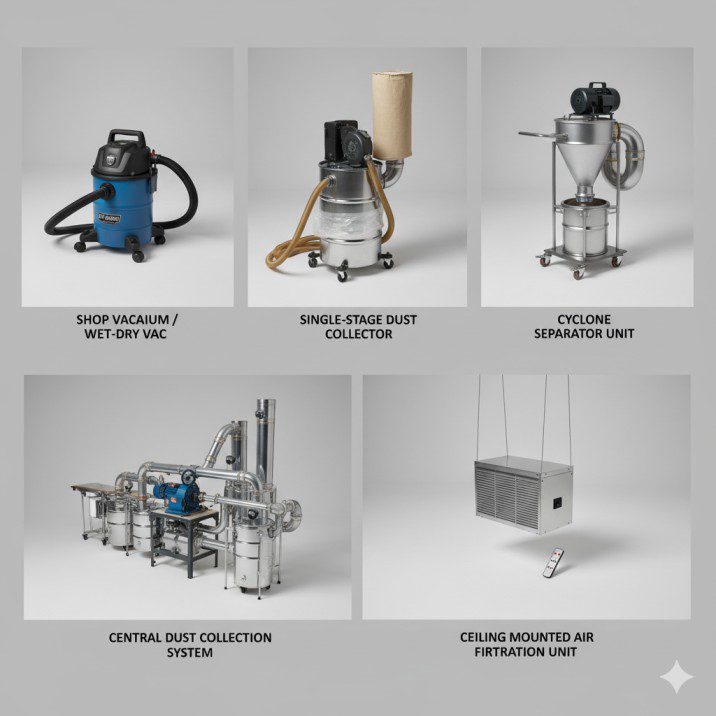

Shop Vacuums (Wet/Dry Vacs)

Standard shop vacuums work for light-duty collection if you’re an occasional woodworker making a few cuts per month.

Pros: Affordable ($50-$150), portable, multi-purpose use, readily available

Cons: Small capacity requires frequent emptying, motors not designed for continuous use, limited airflow (CFM), loud operation, fine dust clogs filters quickly

Shop vacs suit weekend hobbyists doing small projects but struggle with production work or regular shop use. I burned through two shop vac motors before upgrading to a proper system.

Single-Stage Dust Collectors

These dedicated machines use an impeller to pull dust through a filter bag or canister. They’re the standard choice for home workshops.

Pros: High airflow (400-1,200 CFM), larger collection capacity, designed for continuous operation, relatively affordable ($200-$600)

Cons: Require floor space, noise level around 80-90 dB, fine dust can pass through standard bags, need regular filter cleaning

The 1.5 HP models with 650+ CFM provide adequate suction for table saws and can service multiple machines through ducting.

Cyclone Separators

Cyclones use centrifugal force to separate dust from airflow before it reaches the filter. This dramatically improves efficiency and reduces filter maintenance.

Pros: Superior separation (95-99%), minimal filter loading, handles both chips and fine dust, longer motor life, can be added to existing systems

Cons: Higher cost ($300-$1,200 for complete systems), requires more height clearance, additional floor space

After adding a cyclone separator to my single-stage collector, filter cleaning went from weekly to monthly. The investment paid for itself in reduced filter replacement costs.

Central Dust Collection Systems

Large, permanently installed systems with ducting running throughout the shop to multiple machines.

Pros: Professional-level performance, convenience (always ready), powerful motors (2-5 HP), quiet operation in remote location

Cons: Expensive ($1,000-$3,000+), complex installation, requires dedicated space, permanent commitment

These suit serious woodworkers with dedicated shop spaces and multiple stationary tools. For most home shops, a good single-stage collector with cyclone separator delivers 90% of the performance at 40% of the cost.

HEPA and Air Filtration Units

Ceiling or wall-mounted units that filter ambient shop air, capturing particles that escape primary collection.

Pros: Removes fine airborne dust, improves overall air quality, quiet operation, low maintenance

Cons: Doesn’t collect bulk dust (not a substitute for primary collection), filters require periodic replacement

I run both primary collection at the saw and an ambient air filter. Together, they keep my shop air remarkably clean—I no longer see dust floating in light beams after cutting sessions.

Check our table saw accessories page for compatible collection options.

Key Features of Effective Dust Collection

Whether buying or building, certain features separate systems that work from those that disappoint.

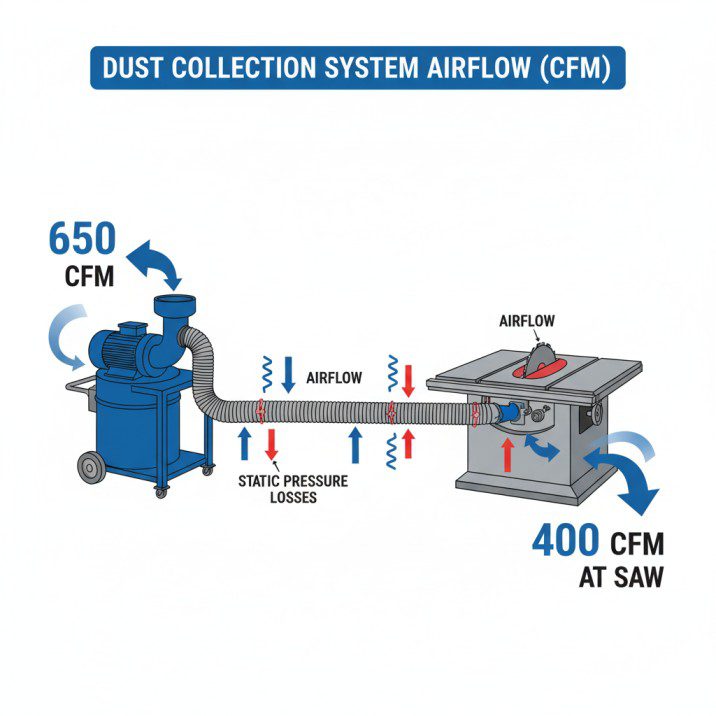

Airflow (CFM) and Static Pressure

Cubic Feet per Minute (CFM) measures how much air the system moves. Table saws typically require 350-450 CFM at the dust port for effective collection.

However, CFM alone doesn’t tell the whole story. Static pressure—the system’s ability to pull air through hoses, fittings, and filters—matters equally. A system rated at 650 CFM might deliver only 350 CFM at your saw after accounting for resistance.

Rules of thumb:

- Minimum 350 CFM at the tool for basic collection

- 500+ CFM for excellent results

- Shorter, larger diameter hoses maintain CFM better

- Every elbow joint reduces effective airflow by approximately 10%

Filter Quality and Micron Rating

Standard fabric bags on budget collectors filter particles down to 30-50 microns. That sounds fine until you learn that harmful dust particles are 10 microns and smaller—invisible to the eye but devastating to lungs.

Quality systems use:

- Pleated filters: More surface area means better airflow and finer filtration

- Canister filters: Superior to bags for fine dust capture

- HEPA filters: Capture 99.97% of particles 0.3 microns and larger (overkill for most shops but excellent for health-conscious woodworkers)

I upgraded from a standard bag to a canister filter rated at 1 micron. The difference was immediately visible—much less fine dust settling on surfaces after running the collector.

Collection Capacity and Ease of Emptying

Larger capacity means less frequent emptying, but only if the system actually fills the bag rather than clogging the filter first.

Clear collection bins or bags let you monitor capacity at a glance. Bottom-opening designs with quick-release mechanisms make emptying far less messy than systems requiring bag removal.

My cyclone setup drops chips into a clear 20-gallon drum. I can see when it’s 80% full and empty it in 30 seconds without creating dust clouds.

Blast Gates and Multi-Tool Capability

If you’ll connect multiple tools to one collector, blast gates (manual or automatic) let you direct suction to the active tool. This maintains maximum CFM where needed and prevents unnecessary suction at idle machines.

I installed manual blast gates at my table saw, router table, and miter saw. Takes two seconds to open the gate at the tool I’m using and ensures full suction power isn’t divided across multiple points.

Visit our table saw buying guide to understand how dust collection integrates with saw selection.

Top Commercial Systems in 2025

Based on current market analysis and extensive user feedback, here are the leading systems for table saw dust collection.

| Model | Price Range | CFM Rating | Type | Best For | Key Feature |

|---|---|---|---|---|---|

| Shop Fox W1727 | $380-$450 | 700 CFM | Single-stage | Home workshops | 1 HP motor, 1-micron canister filter |

| WEN 3401 | $280-$340 | 660 CFM | Single-stage | Budget-conscious | Affordable, reliable, bottom collection |

| Oneida Dust Deputy Deluxe | $160-$200 | N/A (separator only) | Cyclone add-on | Upgrade existing vac | 99% separation efficiency |

| Grizzly G0548ZP | $550-$650 | 1,200 CFM | Cyclone combo | Serious woodworkers | 2 HP, true cyclone design |

| JET DC-650 | $420-$500 | 650 CFM | Single-stage | Small shops | Compact, mobile, canister filter |

Shop Fox W1727: My consistent recommendation for dedicated dust collectors. The 1-micron canister filter captures fine dust that basic systems miss, and the 700 CFM provides strong suction for table saws. The mobile base means you can move it around small shops.

SHOP FOX Portable W1727 1 HP Dust Collector

- Motor: 1 HP, 120V/240V, single-phase, prewired 110V

- Motor amp draw: 9A/4.5A

- Air suction capacity: 800 CFM

New starting from: 409.00

Go to AmazonOneida Dust Deputy: If you’re starting with a shop vac and want dramatic improvement without buying a complete system, this cyclone separator transforms performance. Attach it between your vac and tool—it captures 99% of debris before it reaches your vacuum, preventing filter clogging and maintaining suction.

WEN Woodworking Dust Collector, 5.7-Amp Motor with 12-Gallon Bag, Mobile Base, and Optional Wall Mount (DC3401)

- 5.7-amp brushed motor combined with the 6-inch impeller moves up to 660 cubic feet of air per minute

- 4-inch dust port allows for connection to your favorite woodworking tools

- Compact design includes an onboard carrying handle for easy storage and transportation

List Price :

Offer: 126.35

Go to AmazonGrizzly G0548ZP: For woodworkers ready to invest in professional-grade collection, this true cyclone system delivers exceptional performance. The 1,200 CFM rating provides enough power to service multiple tools through ducting, and the cyclone design means minimal filter maintenance.

Learn about overall saw performance in our best table saw reviews.

Building an Effective DIY Solution

You can create highly effective dust collection on modest budgets by understanding the principles and building smart solutions.

The Shop Vac + Cyclone Separator Combo

For under $200 total, this setup rivals systems costing $500+.

What you need:

- Quality shop vacuum (6+ HP peak, 12+ gallon capacity): $100-$130

- Cyclone separator kit (Dust Deputy or similar): $60-$100

- 5-gallon bucket with lid (separator collection): $10

- Quality 2.5″ hose and adapters: $25-$40

Assembly: Mount the cyclone separator on the bucket lid. Connect your tool to the cyclone inlet, cyclone outlet to shop vac inlet. Dust and chips spin into the bucket; only fine particles reach the vacuum filter.

This setup transformed my portable collection capability. The vacuum filter stays clean 10x longer, and I empty the bucket instead of struggling with vacuum bags.

Improving Factory Dust Ports

Most table saws have poorly designed factory shrouds that allow dust to escape. Simple modifications dramatically improve capture:

Lower port improvement:

- Seal all cabinet gaps and openings with foam tape or caulk

- Build a better-fitting shroud around the blade using thin plywood or MDF

- Replace small dust ports with larger 4-inch connections

- Ensure smooth airflow paths without sharp corners

Upper blade guard collection: Add an overhead blade guard with integrated dust collection. These mount to your saw and position a collection hood directly over the blade exit point where most visible dust originates.

I built an overhead guard from clear polycarbonate and connected it to my dust system through flexible hose. It captures approximately 80% of above-blade dust that previously escaped into the shop air.

The Thien Baffle Separator

This DIY cyclone design uses simple plywood construction and performs nearly as well as commercial cyclones.

Construction: Build a round baffle that fits inside a collection drum (typically a 20-gallon metal trash can). The baffle creates a cyclonic path that drops debris into the drum while clean air exits to your vacuum or dust collector.

Plans are widely available online, and total material costs run $30-$50. I built one in an afternoon, and it’s been separating dust efficiently for four years.

Zero-Clearance Insert Modification

Replace your standard throat plate with a zero-clearance insert that fits tightly around the blade. This simple upgrade keeps more dust from escaping upward through gaps around the blade.

Cut the insert from 1/2″ MDF or hardboard, and ensure it sits perfectly flush with your saw table. The tight blade clearance alone improves dust capture by approximately 15-20%.

For more techniques, visit our table saw how-to guide.

Setup and Optimization Tips

Proper installation and adjustment maximize any dust collection system’s performance.

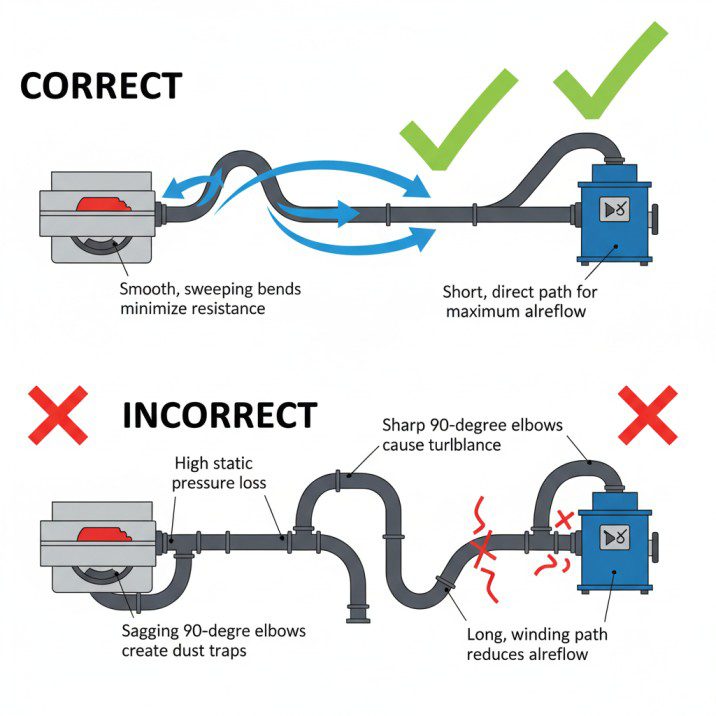

Hose Sizing and Routing

Use the largest diameter practical: 4-inch hoses move more air with less resistance than 2.5-inch hoses. Only step down at the final tool connection if necessary.

Keep hoses as short as possible: Every foot of hose reduces effective CFM. Position your collector close to your saw.

Minimize bends: Each 90-degree elbow reduces airflow by approximately 10%. Use gentle sweeping bends instead of sharp elbows when possible.

Support hoses properly: Sagging hoses create low spots where debris accumulates and restricts airflow. Use hangers or overhead routing to maintain gentle slopes toward the collector.

Filter Maintenance Schedule

Clean or replace filters based on use frequency:

- Heavy use (daily): Clean weekly, replace every 6 months

- Regular use (3-4 times/week): Clean bi-weekly, replace annually

- Occasional use (weekly): Clean monthly, replace every 2 years

Set calendar reminders—clogged filters destroy collection efficiency. I clean my canister filter every Sunday evening after weekend shop time.

Testing Collection Effectiveness

Verify your system works properly:

Visual test: Make a cut and observe dust behavior. You should see minimal dust escaping into the air or landing on surrounding surfaces.

Paper test: Hold tissue paper near your dust port while the collector runs. Strong suction should pull the paper firmly against the opening.

Shop cleanliness: After a cutting session, surfaces should remain relatively dust-free. If everything is coated in fine powder, your collection is inadequate.

Frequently Asked Questions

What CFM do I need for a table saw? Minimum 350 CFM at the tool for basic collection; 500+ CFM for excellent results. Account for resistance in hoses and fittings when sizing your system.

Can I use a shop vac for dust collection? Yes, for light occasional use. Add a cyclone separator to prevent filter clogging. For regular woodworking, invest in a dedicated dust collector for better performance and motor longevity.

Do I need both lower and upper collection? Ideally, yes. Lower ports capture dust falling through the table; upper guards collect dust thrown upward by the blade. Dual collection typically captures 90%+ of total dust versus 50-60% with lower only.

How often should I empty my dust collector? Empty when 60-70% full. Overfilling reduces separation efficiency in cyclones and can damage impellers if debris reaches the fan.

What’s better: bag or canister filter? Canister filters offer more surface area, better fine dust capture, and easier cleaning than bags. They cost more initially but provide superior performance and durability.

Can one collector serve multiple tools? Yes, with proper CFM capacity and blast gate system. Add approximately 350-400 CFM requirement per tool. A 1,200 CFM collector can service 2-3 tools if you use blast gates to direct suction.

Final Thoughts

Investing in proper dust collection ranks among the most important decisions you’ll make for your workshop. Unlike tools that improve your work quality, dust collection protects your health—something far more valuable than any project.

Whether you start with a $150 shop vac and cyclone combo or invest in a $600 dedicated system, any collection beats breathing sawdust. I started with basic shop vacuum collection and gradually upgraded as my woodworking increased. Each improvement was immediately noticeable in air quality and shop cleanliness.

The “best” system is the one you’ll actually use consistently. A mid-range collector that’s easy to operate gets used every time; an elaborate system that’s cumbersome to set up gets ignored. Prioritize convenience alongside performance.

Start by assessing your current dust situation. Make one cut and observe where dust goes. That tells you what needs improvement. Add collection at the worst spots first, then expand coverage gradually.

Most importantly, don’t skip dust collection thinking you’ll “add it later.” The damage to your respiratory system accumulates with every dust-filled cutting session. Protect your health now—your lungs will thank you decades from now.

Action Steps:

- Evaluate your current dust situation—where does dust escape during typical cuts?

- Determine budget and shop space available for collection equipment

- Choose between shop vac combo (under $200) or dedicated collector ($300-$600)

- Prioritize both lower cabinet and upper blade collection for complete coverage

- Maintain filters regularly and monitor collection effectiveness

- Consider ambient air filtration as secondary protection

Your health and shop environment deserve the same attention you give to cutting accuracy and finish quality. Clean air makes woodworking more enjoyable and sustainable for the long term.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.