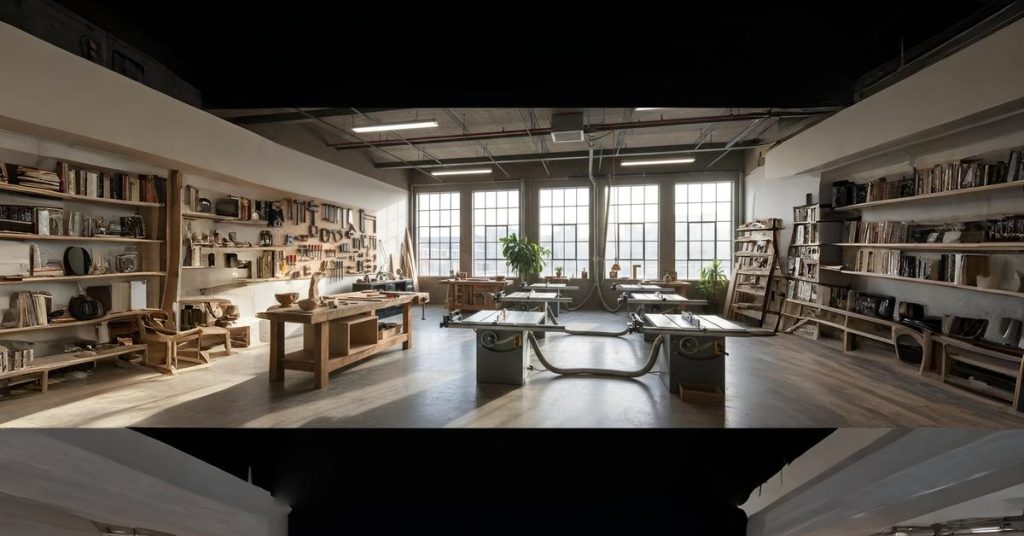

Choosing the right table saw isn’t just about cutting wood—it’s about investing in safety, precision, and the long-term success of every project you tackle. Whether you’re building custom furniture, framing houses, or just making weekend repairs, the table saw you choose will become the backbone of your workshop. A quality saw delivers clean, accurate cuts that save time and material. A poor choice? You’ll fight tear-out, binding, and alignment issues that make even simple cuts frustrating.

We’ve spent years testing table saws across every price range and workshop scenario. We know what separates a reliable workhorse from a money pit, and we understand that choosing your first—or next—table saw can feel overwhelming. Should you prioritize portability or power? Is a $400 jobsite saw enough, or do you need a $2,000 cabinet model? What about safety features like riving knives and blade guards?

This comprehensive 2025 table saw buying guide cuts through the marketing noise and gives you practical, workshop-tested advice. We’ll walk you through the different types of table saws, what features actually matter, how to match your saw to your budget and workspace, and where to find the best models for your specific needs. Whether you’re a weekend DIYer or a full-time craftsman, you’ll finish this guide knowing exactly which saw belongs in your shop—and why.

Understanding Table Saw Types

Not all table saws are created equal. The type you choose depends on where you work, what you build, and how much you’re willing to invest. Let’s break down the main categories so you can narrow your search from the start.

Portable Table Saws

BOSCH GTS15-10 10 Inch Portable Jobsite Table Saw with Gravity-Rise Wheeled Stand, 15 Amp, 32-1/8 Inch Rip Capacity, 4 HP

- 15-Amp saw with 3,800 rpm for rip-cutting and cross-cutting of fine and hard wood materials

- CONVENIENCE BRAKE: Helps blade stop in approximately three seconds, increasing productivity

- CLAMPZONE AREAS :Allow tabletop to be used as a light-duty, secondary work surface

List Price :

Offer: 649.00

Go to AmazonPortable saws (also called jobsite saws) are lightweight, compact, and designed for contractors who move between locations. Most weigh 45-70 pounds and feature folding stands or wheeled bases. They typically run on 15-amp motors and handle everyday cutting tasks like framing lumber, trim work, and sheet goods.

The tradeoff? You sacrifice table size, fence precision, and dust collection compared to stationary models. But if you need something you can load into a truck or store in a small garage, portables are unbeatable. If you need something portable for job sites or tight spaces, check out our guide to the Best Portable Table Saws for the Money. We also cover ultra-affordable options in our Best Portable Table Saw Under $500 and Best Portable Table Saw Under $300 roundups.

Best for: Contractors, DIYers with limited space, anyone who needs mobility over maximum precision.

Hybrid Table Saws

DEWALT 10-Inch Table Saw with Rolling Stand, 32-1/2-Inch Rip Capacity (DWE7491RS)

- Rack & Pinion Telescoping Fence System Make fence adjustments fast, smooth and accurate

- Patented material support, can be used for narrow rip cuts.

- 32-1/2″ rip capacity easily cuts a variety of larger shelving and trim materials

List Price :

Offer: 649.99

Go to AmazonHybrid saws bridge the gap between portable and cabinet models. They feature enclosed bases (reducing dust and noise), more powerful motors (usually 1.5-2 HP), and heavier construction for improved stability—all while staying under 400 pounds and fitting a 120V outlet in most cases.

These saws deliver near-cabinet-grade performance at mid-range prices, making them incredibly popular with serious hobbyists and small shop owners. Hybrid table saws combine power and precision without requiring 220V wiring—explore our Best Hybrid Table Saws Under $1000 for top recommendations.

Best for: Home workshops, weekend woodworkers upgrading from portable saws, small professional shops.

Cabinet Table Saws

Grizzly Industrial G0771Z – 10" 2 HP 120V Hybrid Table Saw with T-Shaped Fence

- Includes full manufacturer warranty

- Includes full manufacturer warranty

- Includes full manufacturer warranty

New starting from: 1599.00

Go to AmazonCabinet saws are the gold standard for professional woodworkers. These stationary beasts weigh 400-700+ pounds, run on 3-5 HP motors (usually 220V), and feature cast-iron tables, precision fence systems, and superior dust collection. The fully enclosed cabinet houses the motor and trunnions, improving cut quality and dramatically reducing sawdust in your shop.

Yes, they’re expensive and require dedicated floor space. But if accuracy, power, and repeatability matter to your work, nothing else compares. For professionals who demand unmatched stability and power, cabinet saws are the ultimate investment—see our Best Cabinet Table Saw guide for detailed comparisons.

Best for: Professional woodworkers, production shops, anyone who values precision above portability.

Compact and Mini Table Saws

Mini table saws have exploded in popularity among crafters, model builders, and hobbyists working with smaller materials. These 8.5″ to 10″ blade models sit on your workbench and handle everything from balsa wood to thin hardwoods. They’re quieter, safer for beginners, and cost a fraction of full-size saws.

Don’t expect to rip 2x4s all day—these are specialized tools for detailed work. But if you’re building dollhouses, cutting acrylic, or crafting small projects, they’re perfect. Check out our Best Mini Table Saws for Crafts and Woodworking if you work with smaller materials.

Best for: Crafters, model makers, hobbyists working with thin stock and small projects.

Table Saws by Budget

Your budget often determines which type of saw you’ll bring home. But price isn’t everything—even budget saws can deliver excellent value if you know what to look for. Here’s how to think about table saw pricing in 2025.

Under $500: Entry-Level and Portable Models

At this price point, you’re shopping for portable saws with basic features. Expect 15-amp motors, rack-and-pinion fences, and aluminum tables. These saws handle DIY projects, home repairs, and light construction work just fine. You won’t get the refinement of pricier models, but you also won’t break the bank.

The key is finding models with decent fence systems and adequate dust ports. Cheap fences drift during cuts, and poor dust collection turns your workspace into a sawdust blizzard. If you’re shopping on a budget, our detailed guide to the Best Budget Table Saw highlights reliable entry-level models that punch above their price tag.

What to expect: Adequate power for most cuts, acceptable accuracy, compromises on dust collection and build quality.

Who should buy: First-time buyers, casual DIYers, anyone who needs a functional saw without premium features.

Under $1,000: The Sweet Spot for Serious Hobbyists

This is where table saws get genuinely good. At $600-$1,000, you can afford quality hybrid saws or high-end portables with better fences, larger tables, and improved motors. Some models in this range include T-square fences, cast-iron extensions, and even mobile bases.

We’ve tested dozens of saws in this category, and the performance jump from $300 to $800 is dramatic. Cuts are cleaner, adjustments hold longer, and features like riving knives and better guards actually make these saws safer. Our Best Table Saws Under $1000 guide covers the models that deliver professional-level results without the professional price tag.

What to expect: Reliable accuracy, solid construction, enough power for hardwoods and sheet goods, decent dust collection.

Who should buy: Dedicated hobbyists, weekend woodworkers tackling furniture projects, anyone who wants a saw they won’t outgrow.

Over $1,000: Professional-Grade Cabinet Saws

Once you cross the $1,000 threshold, you’re shopping for cabinet saws, premium hybrids, or specialty models with advanced safety systems. These saws feature superior fence systems, massive cast-iron tables, powerful induction motors, and first-rate dust collection. Many include features like SawStop’s blade-brake technology, which stops the blade in milliseconds if it contacts skin.

Yes, it’s a significant investment. But if woodworking is your profession—or serious passion—these saws pay for themselves through improved cut quality, reduced waste, and enhanced safety. Plus, they last decades with proper maintenance.

What to expect: Exceptional accuracy, smooth operation, advanced safety features, professional build quality.

Who should buy: Professional woodworkers, serious hobbyists with dedicated workshops, anyone who prioritizes safety and precision.

Key Features to Consider

Knowing which features actually matter will save you from expensive buyer’s remorse. Here’s what we look for when evaluating table saws—and what you should prioritize based on your needs.

Motor Power: HP and Performance

Table saw motors range from 15-amp (roughly 1.5-2 HP) on portable models to 3-5 HP on cabinet saws. More power means you can cut thicker hardwoods without bogging down, but it’s not just about horsepower. Motor quality, blade speed (measured in RPM), and how the saw handles sustained cutting all matter.

A 1.75 HP motor is adequate for most DIY work. If you regularly rip thick hardwoods or cut dense materials, aim for 2+ HP. Professional shops should consider 3 HP or higher, especially if you’re working with exotic hardwoods or production runs.

Pro tip: Don’t assume higher HP always means better performance. A well-designed 2 HP motor often outperforms a cheap 3 HP motor.

Blade Size and Type

Most table saws use 10″ blades, which handle cuts up to 3.5″ deep at 90 degrees. Some contractor saws use 8.25″ blades (lighter, less expensive), while premium models occasionally offer 12″ blades for deeper cuts.

The blade itself matters as much as the saw. A cheap saw with a premium blade will outperform an expensive saw with a garbage blade. We always recommend investing in quality blades matched to your most common tasks—ripping blades for breaking down lumber, crosscut blades for trim work, and combination blades for general use. For detailed blade recommendations, check out our guide to the Best Table Saw Blade

What to look for: Standard 5/8″ arbor, at least 4,000 RPM blade speed, compatibility with dado blade sets if you cut joinery.

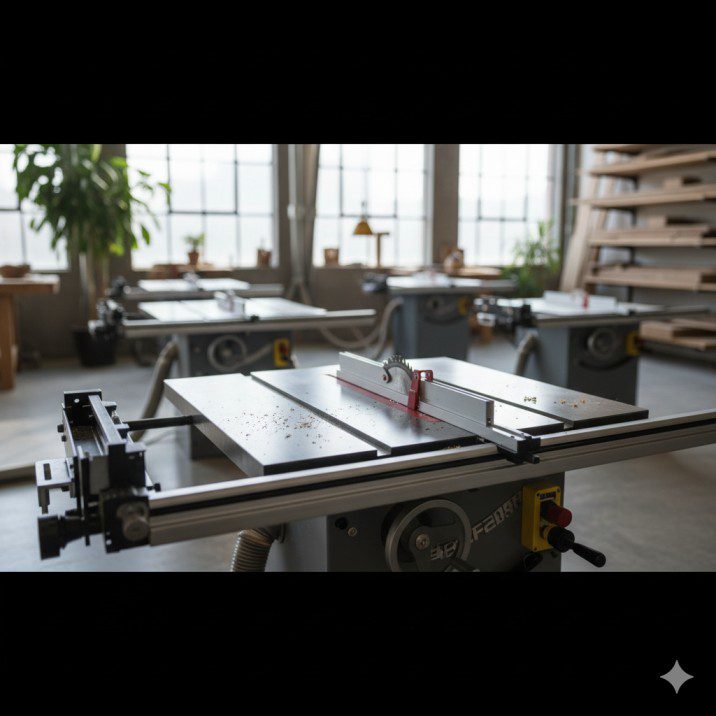

Fence System: The Make-or-Break Feature

Your fence determines whether cuts are accurate or frustrating. We’ve tested saws with fences so bad they drift mid-cut, and we’ve used T-square fence systems that lock perfectly every single time.

Look for fences that lock parallel to the blade, stay square under pressure, and adjust smoothly across the full table width. T-square fences (like Biesemeyer-style systems) are the gold standard—they mount to both the front and rear rails, ensuring parallel alignment.

A precise fence system can make or break your cuts—we always recommend testing the alignment before buying. If you’re shopping online, read reviews carefully. Fence complaints are the #1 reason people return table saws.

Miter Gauge Quality

Most stock miter gauges are mediocre at best. They wobble in the slots, lack positive stops at common angles, and don’t support workpieces adequately. If precision crosscuts matter, plan to upgrade to an aftermarket miter gauge or crosscut sled.

That said, some higher-end saws include better miter gauges with adjustable faces, flip stops, and solid construction. It’s a nice bonus, but not a dealbreaker if missing.

Table Size and Extensions

Larger tables provide better workpiece support, especially when cutting full sheets of plywood. Portable saws typically have 20″ x 26″ tables. Hybrid and cabinet saws range from 27″ x 40″ to massive 30″ x 52″ surfaces with extensions.

If you regularly work with sheet goods, consider models with cast-iron extension wings or invest in outfeed support. Tipping a 4×8 sheet because your table is too small is dangerous—and maddening. Our Ultimate Guide to Table Extension for Table Saw (coming soon) covers how to expand your workspace safely.

Pro tip: Cast-iron extensions are worth the weight. They add mass (reducing vibration) and provide dead-flat support. Stamped steel extensions flex and warp.

Dust Collection Systems

Table saws create mountains of sawdust. Without proper dust collection, your shop becomes hazardous—sawdust is a respiratory risk, fire hazard, and slipping hazard all at once.

Look for saws with 2.5″ or 4″ dust ports and enclosed blade housings. Portable saws struggle with dust collection because their open stands let sawdust escape everywhere. Cabinet and hybrid saws capture far more dust due to their enclosed bases. For our top picks with superior dust collection, see Best Table Saws with Dust Collectors.

Real-world advice: Even the best table saw dust collection captures only 80-90% of sawdust. Connect your saw to a shop vacuum or dust collector, and wear a respirator for fine dust.

Portability and Build Quality

If you’re moving your saw regularly, weight and portability matter. Look for folding stands, wheeled bases, or compact designs. If your saw stays put, prioritize stability and build quality instead.

Cast-iron tops are flatter, more durable, and dampen vibration better than aluminum. Thicker materials resist warping and provide smoother surfaces for sliding workpieces. Heavier saws stay planted during aggressive cuts, reducing blade deflection and improving safety.

Safety Features You Shouldn’t Ignore

Table saws are powerful, unforgiving tools. Every year, thousands of woodworkers suffer serious injuries—many preventable with proper safety features.

Must-have safety features:

- Riving knife: Prevents kickback by keeping the kerf open behind the blade. Unlike old-style splitters, riving knives move with the blade during height adjustments.

- Blade guard: Shields your hands from the spinning blade. Yes, you’ll remove it for certain cuts, but use it whenever possible.

- Anti-kickback pawls: Grab the workpiece if it tries to shoot backward. Essential for ripping operations.

- Push sticks and push blocks: Keep your hands away from the blade. Always use them for narrow cuts.

- Emergency stop switch: Should be large, red, and easily accessible. Paddle-style switches are ideal—you can hit them with your knee if needed.

Advanced saws offer SawStop technology, which uses electrical conductivity to detect skin contact and stop the blade in milliseconds. It’s expensive (roughly $1,200+), but if you value your fingers, it’s worth considering.

For comprehensive safety guidance, read our How to Use a Table Saw for Beginners guide before making your first cut.

Table Saw Safety and Maintenance

Buying the right saw is only half the battle. Keeping it safe, accurate, and running smoothly requires regular maintenance and proper technique.

Essential Safety Practices

We can’t stress this enough: table saws demand respect. Follow these non-negotiable rules:

- Always use the riving knife and blade guard unless the cut physically prevents it. Remove them only when necessary, and reinstall immediately after.

- Stand to the side of the blade, never directly behind it. Kickback can launch workpieces like missiles.

- Keep your hands at least 6″ from the blade. Use push sticks, push blocks, or featherboards for narrow cuts.

- Unplug the saw before changing blades or making adjustments. Accidental starts cause injuries.

- Never reach over or behind a spinning blade. Wait for the blade to stop completely.

- Wear safety glasses and hearing protection. Table saws are loud, and sawdust will find your eyes.

- Keep your work area clean. Sawdust and offcuts create tripping hazards and interfere with cuts.

- Don’t cut freehand. Always use the fence or miter gauge—never both simultaneously (it causes binding and kickback).

If you’re new to table saws, our How to Use a Table Saw for Beginners guide walks through proper technique, common mistakes, and setup procedures in detail.

Routine Maintenance Tasks

Proper maintenance keeps your saw cutting accurately and prevents premature wear:

- Clean the table surface regularly. Sawdust, pitch buildup, and rust create friction that ruins cuts. Learn How to Clean a Table Saw Metal Surface (coming soon) for detailed cleaning methods.

- Remove rust immediately. Even light surface rust affects workpiece sliding and cut quality. Our How to Remove Rust from Table Saw (coming soon) guide covers safe rust removal techniques.

- Check fence alignment monthly. Even quality fences drift over time. Adjust as needed to maintain parallel alignment with the blade.

- Inspect the blade for damage. Chipped or dull teeth cause tear-out, burning, and dangerous kickback. Replace or sharpen blades when performance drops.

- Sharpen or replace blades as needed. Dull blades force you to push harder, increasing kickback risk and burning wood. See our guide on How to Sharpen Table Saw Blades (coming soon).

- Lubricate moving parts. Apply dry lubricant to the blade raising mechanism, fence rails, and extension slide. Avoid oil-based products—they attract sawdust.

- Empty dust collection regularly. Full dust ports reduce suction and increase fire risk.

- Check belts for wear. On belt-driven saws, worn belts slip and reduce power. Replace annually or as needed.

A well-maintained saw lasts decades. Neglected saws become safety hazards and accuracy nightmares.

Choosing by Use Case

Different projects demand different saws. Here’s how to match your saw to your specific woodworking needs.

For Small Workshops and Tight Spaces

Limited square footage doesn’t mean settling for poor performance. Hybrid saws with mobile bases, compact portables with folding stands, and benchtop models all deliver excellent results in small shops.

Focus on models with efficient footprints, good dust collection (small shops get dusty fast), and mobile bases so you can move the saw when needed. Our Best Table Saws for Small Workshops guide highlights saws that maximize performance without eating your entire garage.

Pro tip: Wall-mounted fold-down tables and outfeed supports save floor space while improving safety and accuracy.

For Hobbyists and Weekend Woodworkers

If woodworking is your primary hobby, you need a saw that balances performance, features, and budget. You’re building furniture, cutting joinery, and tackling projects that demand accuracy—but you’re not running a production shop.

Hybrid saws, high-end portables, and budget cabinet saws all fit this category. Look for solid fence systems, adequate power, and expandability (like accepting dado blade sets). Check out our 7 Best Table Saws for Hobbyists (2025 Guide) for saws that hit the sweet spot between features and value.

For Fine Woodworking and Furniture Building

Precision is everything when building heirloom furniture. You need dead-flat tables, micro-adjustable fences, smooth blade raising mechanisms, and powerful motors that maintain consistent RPM through hardwoods.

Cabinet saws dominate this category, though premium hybrids can deliver similar results. Expect to invest in quality blades, zero-clearance inserts, and accurate measurement systems. Our Best Table Saw for Fine Woodworking guide covers the saws that deliver show-quality results.

For Dado Cuts and Joinery Work

Cutting dados, rabbets, and grooves requires saws that accept stacked dado blade sets (typically 8″ diameter, up to 13/16″ wide). Not all saws support dados—many portable models lack the arbor length or throat plate compatibility.

If you often cut intricate joints, check out our guide to the Best Table Saws for Dado Cuts—we cover the exact blade setup, power requirements, and safety considerations for dado work.

Critical note: Always use a zero-clearance insert with dado blades. Standard throat plates allow thin workpieces to catch and jam.

For Home Use and DIY Projects

Home projects vary wildly—one week you’re building a deck, the next you’re assembling cabinets. You need versatility, not specialization. Look for saws with good fence systems, adequate power for 2x lumber and plywood, and portability if you work in different locations.

Mid-range portables and budget hybrids excel here. They handle everything from cutting trim to ripping hardwoods without breaking the bank. See our Best Table Saw for DIY Woodworking for versatile models that tackle diverse projects.

For Beginners Just Getting Started

Your first table saw should emphasize safety, ease of use, and affordability. You don’t need every feature—you need a saw that’s forgiving while you learn proper technique.

Look for models with excellent safety features (riving knives, blade guards, emergency stops), simple fence adjustments, and clear depth/angle markings. Avoid complex saws with confusing controls or finicky adjustments. If you’re new to woodworking, our Best Table Saws for Beginners post covers safe and easy-to-use models that build confidence without causing frustration.

Top Table Saw Brands

Brand matters more than many woodworkers realize. The best manufacturers back their saws with solid warranties, readily available parts, and responsive customer service. Here are the brands we trust—and what makes each unique.

DeWalt

DeWalt dominates the portable and jobsite saw market. Their saws are rugged, reliable, and designed for contractors who abuse equipment daily. The DW745 and DWE7491RS are industry standards for good reason—they deliver consistent performance, feature decent fence systems, and survive years of job site punishment.

Known for: Durability, portability, contractor-grade features, widespread parts availability.

Best for: Contractors, DIYers who prioritize toughness over precision, anyone who needs a saw that travels.

Bosch

Bosch brings European engineering to table saws, resulting in innovative features like their gravity-rise stands and patented safety systems. Their saws balance portability with precision, making them popular with craftsmen who demand quality cuts from jobsite equipment.

Known for: Innovation, build quality, excellent dust collection (for portables), smart design features.

Best for: Professional contractors, woodworkers who want portable saws with hybrid-level accuracy.

Read our Bosch Table Saw Reviews (coming soon) for in-depth testing results.

Makita

Makita focuses on power and refinement. Their saws feature smooth adjustments, reliable motors, and excellent ergonomics. While they’re not as widely distributed as DeWalt, Makita’s build quality and performance earn loyal followers.

Known for: Powerful motors, smooth operation, quality construction, Japanese engineering standards.

Best for: Woodworkers who value refined performance, professionals willing to pay for quality.

Check out our Makita Table Saw Reviews (coming soon) for our hands-on impressions.

Delta

Delta practically invented the modern table saw, and their legacy shows in cabinet models like the Unisaw. While their portable offerings are less impressive, Delta’s cabinet saws remain benchmarks for accuracy, power, and longevity. Many professional shops still run decades-old Delta saws.

Known for: Cabinet saw excellence, legendary Unisaw models, American manufacturing heritage, precision fence systems.

Best for: Professional woodworkers, serious hobbyists investing in forever saws.

Our Delta Table Saw Reviews (coming soon) cover both vintage and modern models.

Ridgid

Ridgid offers incredible value for hobbyists and budget-conscious buyers. Their saws won’t match premium brands in refinement, but they deliver solid performance at aggressive price points. Plus, Ridgid backs their tools with lifetime service agreements (with registration).

Known for: Value pricing, lifetime warranties, decent features for the money, Home Depot exclusivity.

Best for: Budget shoppers, first-time buyers, DIYers who want warranty protection.

Read our Ridgid Table Saw Reviews (coming soon) to see how they stack up.

Other Notable Brands

- SawStop: Industry-leading safety technology. Their flesh-detection system stops blades in milliseconds, preventing catastrophic injuries. Expensive, but potentially life-saving.

- Jet: Premium cabinet saws with excellent fit and finish. Popular in professional shops.

- Grizzly: Direct-sale industrial saws at competitive prices. Heavy, powerful, and designed for production work.

- Laguna: High-end hybrids and cabinet saws with Italian-inspired design. Excellent fences and smooth operation.

- Powermatic: Professional-grade cabinet saws with legendary durability. Built for decades of daily use.

For a comprehensive brand comparison, see our guide to the Best Table Saw Brands.

Comparison Snapshot

Here’s a quick reference to help you visualize how different saw types stack up:

| Type | Ideal For | Avg. Price | Motor Power | Weight | Portability |

|---|---|---|---|---|---|

| Portable/Jobsite | Contractors, small shops, DIYers | $300–$600 | 15A (1.5-2 HP) | 45-70 lbs | Excellent |

| Benchtop/Mini | Crafters, small projects | $150–$400 | 10-15A | 20-45 lbs | Excellent |

| Hybrid | Serious hobbyists, small pros | $700–$1,200 | 1.5-2 HP | 250-400 lbs | Poor (mobile base helps) |

| Cabinet | Professional woodworkers | $1,500–$5,000+ | 3-5 HP | 400-700+ lbs | None (stationary) |

Key Takeaways:

- Portables sacrifice precision for mobility—great for contractors, limiting for fine woodwork.

- Hybrids offer the best bang-for-buck if you have a dedicated workshop space.

- Cabinet saws are overkill for casual DIYers but essential for professional results.

- Mini saws are specialized tools—perfect for their niche, inadequate for general woodworking.

Conclusion

Choosing the right table saw comes down to honest self-assessment: What will you build? Where will you work? What’s your realistic budget? A contractor framing houses needs a different saw than a furniture maker building jewelry boxes. There’s no universal “best” table saw—only the best saw for your specific needs.

Start by defining your use case and budget. If you’re a beginner exploring woodworking, a reliable portable or hybrid saw under $600 will serve you well for years. If you’re ready to invest in your craft, premium hybrids and cabinet saws deliver professional results that justify their cost. And if space or budget is tight, modern portables and mini saws offer surprising capability in compact packages.

Remember: The saw is just one piece of the puzzle. Quality blades, proper technique, and regular maintenance matter as much as the saw itself. A $400 saw with a $50 blade and good habits will outperform a $2,000 saw with a dull blade and sloppy technique every time.

Now that you understand what to look for—saw types, essential features, safety considerations, and brand differences—you’re ready to make an informed decision. Explore our full Table Saw Reviews to find in-depth comparisons, real-world test results, and hands-on impressions of specific models. We’ve done the testing so you can shop with confidence.

Whether you’re cutting your first board or your ten-thousandth, the right table saw makes all the difference. Choose wisely, cut safely, and build something amazing.