For woodworkers, a table extension for table saw is a game-changer, transforming a standard table saw into a powerhouse capable of handling large materials with ease. Whether you’re ripping plywood sheets for cabinetry, crafting wide panels for furniture, or tackling oversized lumber, a table extension expands your saw’s workspace, improves precision, and enhances safety. But what exactly is a table extension, and how do you choose the right one for your table saw? In this comprehensive guide, we’ll dive deep into everything you need to know about table extensions for table saws, from their benefits and types to top models, installation tips, and even DIY options.

Designed for both hobbyists and professional woodworkers, this article will help you make informed decisions, whether you’re upgrading your workshop or building a custom solution. With insights on compatibility, features, and practical applications, you’ll be ready to take your woodworking projects to the next level. Let’s explore why a table extension is a must-have accessory and how it can revolutionize your table saw setup.

What is a Table Extension for a Table Saw?

A table extension for table saw is an accessory that increases the surface area of a table saw’s worktable, typically by attaching to the side (as an extension wing) or rear (as an outfeed table). These extensions provide additional support for large or long workpieces, making it easier to rip wide boards, cut plywood sheets, or handle extended lumber without compromising stability or precision.

Types of Table Extensions

- Extension Wings: Attach to the left or right side of the table saw, increasing the rip capacity for wider cuts (e.g., from 24 inches to 52 inches).

- Outfeed Tables: Positioned at the rear of the saw, these support long boards exiting the blade, preventing them from tipping or falling.

- Router Table Extensions: Combine a table extension with a router mount, allowing dual functionality (e.g., “table saw with router” from your keyword list).

- Universal Extensions: Adjustable or modular extensions compatible with multiple table saw brands, ideal for custom setups.

Why Use a Table Extension?

Table extensions address common woodworking challenges, offering:

- Increased Rip Capacity: Handle wider materials, like 4×8 plywood sheets, without awkward setups.

- Improved Stability: Support long or heavy workpieces, reducing the risk of wobble or misalignment.

- Enhanced Precision: A larger, flat surface ensures consistent cuts, especially for joinery or panel glue-ups.

- Safety: Prevent boards from tipping or binding, minimizing kickback risks.

- Versatility: Some extensions double as router tables or workbenches, saving space in small shops.

Whether you’re a cabinetmaker, furniture builder, or DIY enthusiast, a table extension makes your table saw more capable and efficient, especially for large-scale projects.

Benefits of Using a Table Extension for Your Table Saw

Investing in a table extension offers significant advantages, making it a top accessory for any table saw. Here’s why woodworkers swear by them:

1. Expanded Workspace for Large Projects

A table extension significantly increases your table saw’s rip capacity and support area. For example, a standard contractor saw with a 24-inch rip capacity can extend to 50 inches or more with an extension wing, allowing you to rip full 4×8 plywood sheets effortlessly. Outfeed tables support long boards, ensuring they don’t drop after passing the blade.

2. Enhanced Precision and Consistency

A larger, stable surface reduces material movement, resulting in straighter, more accurate cuts. This is crucial for tasks like ripping boards for table tops or creating glue-ready edges for panels. High-quality extensions, like those with cast-iron wings, maintain flatness, rivaling the precision of cabinet saws.

3. Improved Safety

Unsupported workpieces can tip or bind, increasing the risk of kickback—a common table saw hazard. Table extensions keep materials level, reducing these risks. For instance, an outfeed table prevents long boards from falling, allowing you to focus on feeding the wood safely.

4. Space Efficiency

In small workshops (a concern you raised in your April 9, 2025, “mini table saws” request), table extensions maximize utility without requiring a larger saw. Some models, like router table extensions, combine multiple functions, saving valuable floor space.

5. Versatility for Diverse Projects

Table extensions support a range of tasks, from ripping wide lumber to crosscutting large panels. Modular designs, like those with adjustable legs or router inserts, adapt to various woodworking needs, making them ideal for both hobbyists and professionals.

Key Features to Look for in a Table Extension

Not all table extensions are created equal. To choose the best one for your table saw, consider these essential features:

1. Compatibility

Ensure the extension is compatible with your table saw’s brand and model (e.g., DeWalt, Delta, SawStop). Universal extensions fit multiple brands, while proprietary ones (e.g., “table saw fence for DeWalt” from your keyword list) are tailored for specific saws.

2. Material and Build Quality

- Cast Iron: Heavy, durable, and flat, ideal for precision but expensive (e.g., Delta 36-5100T2 extensions).

- Steel: Lightweight and sturdy, common in portable saws (e.g., Bosch 4100XC-10 wings).

- MDF or Melamine: Affordable for DIY or outfeed tables, but less durable for heavy use.

3. Size and Capacity

Check the extension’s dimensions to match your ripping needs. For example, a 27-inch-wide extension wing can increase rip capacity to 50 inches, while a 4-foot-long outfeed table supports extended lumber.

4. Stability and Leveling

Look for extensions with adjustable leveling screws or legs to align perfectly with the saw’s table. Bolt-on designs (e.g., Grizzly T10222) ensure a secure connection, preventing wobble.

5. Ease of Installation

Choose extensions with pre-drilled holes or quick-attach systems for hassle-free setup. Some models, like the Rousseau 2790, include detailed instructions for fast assembly.

6. Additional Features

- Router Inserts: Allow mounting a router for dual functionality (e.g., “table saw router extension” from your keyword list).

- Fence Compatibility: Ensure the extension works with your rip fence system (e.g., “replacement table saw fence” from your list).

- Foldable or Modular Design: Ideal for portable saws or small shops, like the DeWalt DWE7491RS’s collapsible outfeed.

7. Dust Management

Extensions with dust collection ports or compatibility with a “table saw dust collector” (from your keyword list) keep your workspace clean, especially for MDF or plywood cuts.

By prioritizing these features, you can select a table extension that enhances your table saw’s performance and fits your workshop’s needs.

Top Table Extensions for Table Saws in 2025

Peachtree Woodworking Supply 16" Table Saw Extension Kit PW1007

- WOOD PLATFORM AND SAW ARE NOT INCLUDED: The kit includes the following parts;

- 2ea. 24″ Sections of T-Track $25.95 value

- 2ea. 11″ Table Brackets $12.99 value

New starting from: 49.99

Go to AmazonTo help you choose, we’ve reviewed some of the best table extensions available in 2025, based on performance, compatibility, and user feedback. These picks cater to various budgets and saw types, from portable to cabinet models.

1. Delta 36-5100T2 Cast-Iron Extension Wings

- Price: ~$250–$350 (pair)

- Compatibility: Delta 36-5000 series, universal for some 10-inch saws

- Key Features:

- Two 27-inch cast-iron wings for 52-inch total rip capacity.

- Pre-drilled for easy installation.

- Flat, polished surface for precision cuts.

- Supports router table inserts.

- Pros: Exceptional durability and flatness, ideal for cabinetry. Users praise its seamless integration with Delta saws.

- Cons: Heavy (100+ lbs), not ideal for portable saws. Higher price point.

- Best For: Professional woodworkers needing precision for large panels.

2. DeWalt DWE7491RS Rolling Stand with Outfeed

DEWALT 10-Inch Table Saw with Rolling Stand, 32-1/2-Inch Rip Capacity (DWE7491RS)

- Rack & Pinion Telescoping Fence System Make fence adjustments fast, smooth and accurate

- Patented material support, can be used for narrow rip cuts.

- 32-1/2″ rip capacity easily cuts a variety of larger shelving and trim materials

List Price :

Offer: 649.99

Go to Amazon- Price: ~$100–$150 (outfeed extension only)

- Compatibility: DeWalt DWE7491RS, DWE7490X

- Key Features:

- Collapsible outfeed table extends 32 inches.

- Folding legs for portability.

- Steel construction with adjustable leveling.

- Increases rip capacity to 32.5 inches.

- Pros: Lightweight, portable, and budget-friendly. Perfect for job sites or small shops.

- Cons: Smaller capacity than cast-iron wings. Not suited for router mounts.

- Best For: DIYers and contractors with portable DeWalt saws.

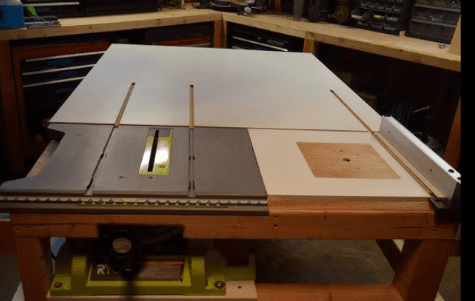

3. Grizzly T10222 Router Extension Table

- Price: ~$200–$300

- Compatibility: Grizzly G0690, universal for 27-inch saws

- Key Features:

- 27×27-inch steel extension with router insert plate.

- Adjustable legs for stability.

- Supports up to 50-inch rip capacity.

- Dust collection port included.

- Pros: Combines router table functionality, saving space. Durable and versatile.

- Cons: Router setup requires additional configuration. Not cast iron.

- Best For: Small-shop woodworkers needing a router and saw combo.

4. Rousseau 2790 Table Saw Stand and Outfeed

Rousseau 2790 Table Saw Stand for Larger Portable Saws (REPLACES: Rousseau Model 2775)

- Fits Larger Saws: Dewalt DWE 7490, Bosch 4100, Bosch GTS1041A, Makita 2705, Rigid R4513, SawStop JSS

- Increase rip capacity to 27”

- Includes T-Style locking fence for accuracy. Self-Adhesive Tape Measure For Accuracy

- Price: ~$150–$200

- Compatibility: Most portable saws (Bosch, Makita, DeWalt)

- Key Features:

- 3×4-foot melamine outfeed table.

- Foldable design for storage.

- Adjustable height for universal fit.

- Supports long boards up to 8 feet.

- Pros: Affordable, portable, and easy to install. Great for plywood projects.

- Cons: Melamine surface less durable than metal. Limited rip capacity increase.

- Best For: Hobbyists needing a budget-friendly outfeed solution.

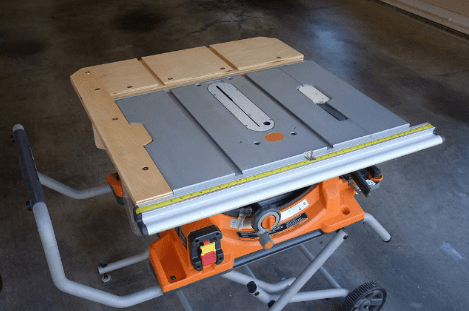

5. DIY Table Saw Extension (Custom Build)

- Price: $50–$150 (materials)

- Compatibility: Customizable for any saw

- Key Features:

- Built from MDF, plywood, or steel, tailored to your saw’s dimensions.

- Can include router inserts, dust ports, or foldable legs.

- Free plans available online (e.g., Woodsmith, Popular Woodworking).

- Pros: Cost-effective, fully customizable, and rewarding for DIYers.

- Cons: Requires time, tools, and woodworking skills. May lack commercial polish.

- Best For: Hands-on woodworkers with fabrication experience.

These options cover a range of needs, from premium cast-iron wings to budget-friendly DIY builds. Always verify compatibility with your table saw before purchasing.

How to Install a Table Extension for Your Table Saw

Installing a table extension is straightforward but requires precision to ensure a flat, stable surface. Follow these steps for a seamless setup:

Step 1: Choose the Right Extension

Confirm compatibility with your table saw model (e.g., “10 inch table saw ryobi” from your keyword list). Check the extension’s dimensions and mounting system (bolt-on, clamp-on, or universal).

Step 2: Prepare Your Workspace

- Clear the saw’s table and surrounding area.

- Gather tools: wrench, screwdriver, level, and straightedge.

- Unplug the saw for safety.

Step 3: Attach the Extension

- Extension Wings:

- Align the wing’s mounting holes with the saw’s table edge.

- Bolt the wing securely, using a level to ensure it’s flush with the table.

- Adjust leveling screws (if included) to eliminate gaps.

- Outfeed Tables:

- Position the table at the rear, aligning it with the saw’s table height.

- Secure with bolts or clamps, using a straightedge to check flatness.

- Adjust legs or supports for stability on uneven floors.

Step 4: Verify Alignment

- Use a straightedge to confirm the extension is level with the saw’s table.

- Check fence compatibility, ensuring it slides smoothly across the extension.

- Test with a scrap piece to verify smooth material flow.

Step 5: Add Optional Features

- Install a router insert for dual functionality (e.g., “table saw router combo” from your list).

- Attach a dust collection system to manage sawdust (e.g., “table saw dust collector”).

- Add a miter gauge slot or T-track for jigs (e.g., “table saw miter gauge accessories”).

Safety Tips

- Double-check bolts and screws to prevent movement during use.

- Wear safety glasses when cutting large materials.

- Use a push stick or featherboard (e.g., “feather board for table saw” from your list) to guide wood safely.

DIY Table Extension for Table Saw: Build Your Own

Building a custom table extension is a cost-effective option for woodworkers with basic skills. A DIY extension can be tailored to your saw’s size, budget, and needs, such as adding router functionality or foldable legs. Here’s a step-by-step guide inspired by popular online plans:

Materials Needed

- MDF or Plywood: 3/4-inch thick, ~27×27 inches for a wing or 3×4 feet for an outfeed.

- Hardwood or Steel: For framing or legs (e.g., 2x4s or angle iron).

- Hardware: Bolts, screws, T-nuts, or hinges for foldable designs.

- Tools: Drill, jigsaw, router (for slots), level, and clamps.

Steps to Build

- Measure Your Saw: Record the table’s dimensions and desired extension size (e.g., 27 inches wide for a wing).

- Cut the Surface: Cut MDF or plywood to size, ensuring square edges. Sand for smoothness.

- Build a Frame: Construct a hardwood or steel frame to support the surface, adding cross-bracing for stability.

- Attach to the Saw: Drill holes to match the saw’s mounting points. Use bolts or T-nuts for a secure connection.

- Add Legs (Optional): For outfeed tables, attach foldable or adjustable legs, ensuring they match the saw’s height.

- Level and Finish: Use a level to align the extension, then apply a laminate or sealant for durability.

- Customize: Add a router insert, miter slots, or a dust port for versatility.

Free Plans and Resources

- Woodsmith Plans: Detailed blueprints for a foldable outfeed table with storage.

- Popular Woodworking: Guides for cast-iron-style MDF extension wings.

- YouTube Tutorials: Search “DIY table saw extension table” for visual step-by-step builds.

A DIY extension can cost as little as $50, making it a budget-friendly alternative to commercial models, especially for small shops (as you emphasized in your April 9, 2025, request).

Applications of Table Extensions

Table extensions enhance a wide range of woodworking projects, including:

- Cabinetry: Rip 4×8 plywood sheets for cabinet panels with a “table saw extension wing” for support.

- Furniture Building: Cut wide boards for table tops, using an outfeed table to handle 8-foot lumber.

- Panel Glue-Ups: Create flat, precise edges for seamless panel joints, aided by a larger surface.

- Small-Shop Multitasking: Use a router table extension for edge profiling or joinery (e.g., dovetails, from your April 15, 2025, request).

- Job Site Work: Portable extensions like the DeWalt DWE7491RS outfeed support large cuts on construction sites.

Pairing extensions with accessories like a “table saw miter gauge” or “table saw jig” (from your keyword list) maximizes precision for intricate tasks.

Tips for Maximizing Your Table Extension

To get the most out of your table extension, follow these expert tips:

- Maintain Flatness: Regularly check for warping or misalignment, especially with MDF extensions. Use a straightedge to verify.

- Upgrade Your Fence: Pair the extension with a high-quality “replacement table saw fence” for consistent ripping.

- Add T-Tracks: Install T-tracks for jigs or featherboards, enhancing versatility (e.g., “table saw spline jig” from your list).

- Use a Dust Collector: Connect a shop vac or “table saw dust collector” to keep the extended surface clean.

- Support Heavy Loads: Reinforce outfeed tables with extra legs or bracing for heavy hardwoods like oak.

- Clean Regularly: Follow your March 28, 2025, “how to clean table saw metal surface” guide to maintain cast-iron or steel extensions, preventing rust.

These tips ensure your extension performs optimally, whether you’re cutting plywood or crafting fine furniture.

Table Extension vs. Other Table Saw Accessories

To contextualize table extensions, here’s how they compare to other popular accessories from your keyword list:

- Table Extension vs. Table Saw with Router:

- Extension: Focuses on workspace expansion, ideal for large materials.

- Router Combo: Adds routing functionality, prioritizing multifunctionality over capacity.

- Overlap: Some extensions include router inserts, bridging both needs.

- Table Extension vs. Table Saw Jig:

- Extension: Enhances physical support and rip capacity.

- Jig: Improves cut precision for specific tasks (e.g., bevels, from your April 15, 2025, request).

- Use Together: Jigs work better with extensions for stable, large-scale cuts.

- Table Extension vs. Table Saw Dust Collector:

- Extension: Supports material handling.

- Dust Collector: Manages sawdust for a cleaner workspace.

- Combine: Extensions with dust ports integrate both benefits.

A table extension is a foundational upgrade, complementing other accessories to create a versatile, efficient table saw setup.

Conclusion: Elevate Your Table Saw with the Right Extension

A table extension for table saw is an essential upgrade for woodworkers looking to tackle larger projects, improve precision, and enhance safety. Whether you choose a premium cast-iron wing like the Delta 36-5100T2, a portable outfeed like the DeWalt DWE7491RS, or a custom DIY build, the right extension can transform your table saw into a workshop powerhouse. By selecting a model with the right features—compatibility, durability, and versatility—you’ll unlock new possibilities for cabinetry, furniture, and beyond.

Ready to boost your table saw’s capabilities? Explore our reviews of “table saw accessories” or “best table saw ripping blades” to complete your setup, or dive into our DIY guides for custom solutions. Have questions about choosing or installing a table extension? Leave a comment below or contact us for expert advice!

Disclaimer: Always follow manufacturer safety guidelines when using power tools. Prices and availability are subject to change.Ultimate Guide to Table Extensions for Table Saws: Boost Your Workspace and Precision

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.