When I first heard about RIKON table saws, I’ll admit I was skeptical. The brand isn’t as ubiquitous as Delta or DeWalt, and the prices seemed almost too good to be true for the features offered. But after three months of daily use in my workshop and countless conversations with fellow woodworkers who’ve invested in RIKON equipment, I’ve developed a nuanced perspective on what these saws actually deliver.

RIKON Power Tools, originally founded in 1999, has built a reputation for manufacturing affordable woodworking equipment that punches above its weight class. Their table saws occupy an interesting middle ground—more robust than basic jobsite saws but priced well below premium cabinet saws. For woodworkers seeking maximum value without compromising essential features, RIKON deserves serious consideration.

In this comprehensive review, I’ll break down RIKON’s current table saw lineup, share real-world performance insights from actual shop use, and help you determine whether these saws match your specific needs and budget. No marketing fluff—just honest assessment based on hands-on experience and objective evaluation.

RIKON Table Saw Lineup Overview

RIKON currently offers several table saw models, each targeting different user needs and workshop scenarios. Understanding the lineup helps you identify which model suits your situation.

RIKON 10-201 Contractor Table Saw

This 10-inch contractor-style saw represents RIKON’s entry into the serious woodworking market. It features a 1.5 HP motor, cast iron table, and compact footprint suitable for smaller workshops.

Key Specifications:

- Motor: 1.5 HP, 120V

- Blade capacity: 10-inch

- Rip capacity: 30 inches right of blade

- Table size: 20″ x 27″ cast iron

- Weight: Approximately 180 lbs

- Price range: $600-$750

Rikon 10in. Contractors Saw

- Adjustable miter and bevel detents with bypass allow for quick adjustments to the most common angles

- LED cut line indication and work light illuminate work to improve visibility and accuracy of cut

- 15 Amp motor powers through even the most difficult materials

New starting from: 720.86

Go to AmazonRIKON 10-326 Deluxe Contractor Saw

The step-up model adds cast iron wings, improved fence system, and enhanced dust collection compared to the base 10-201.

Key Specifications:

- Motor: 1.75 HP, 120V

- Blade capacity: 10-inch

- Rip capacity: 36 inches right of blade

- Table size: Extended with cast iron wings

- Weight: Approximately 250 lbs

- Price range: $800-$950

RIKON 10-3061 Hybrid Table Saw

RIKON’s hybrid model bridges the gap between contractor saws and full cabinet saws, offering enclosed base design with improved dust collection and motor performance.

Key Specifications:

- Motor: 2 HP, 120V/240V capable

- Blade capacity: 10-inch

- Rip capacity: 36 inches right

- Cabinet-style enclosed base

- Weight: Approximately 400 lbs

- Price range: $1,100-$1,350

For comparison with other brands, check our comprehensive best table saw reviews.

Build Quality and Construction

RIKON’s approach to construction quality reveals a lot about their value proposition—strategic cost-cutting in non-critical areas while maintaining standards where it matters most.

Cast Iron Tables and Precision

The cast iron table surfaces on RIKON saws consistently impress. I’ve measured flatness on multiple units and found deviations under 0.010 inches across the entire surface—competitive with saws costing twice as much. The machining is clean, with smooth finish that takes paste wax beautifully.

The milled slots for miter gauges run true and parallel to the blade. I’ve tested with precision measuring tools and found tolerance variations within acceptable ranges (under 0.005 inches over 24 inches of travel). For practical woodworking, this translates to accurate crosscuts and reliable jig operation.

However, the cast iron wings on the 10-326 model show slightly more variation than the main table. Not enough to impact most work, but perfectionist woodworkers might notice the subtle transition when sliding large panels across the seam.

Motor Performance and Reliability

RIKON uses single-phase induction motors—proven technology that’s been powering table saws for decades. The 1.5 HP and 1.75 HP motors in the contractor models handle typical woodworking tasks competently. I’ve ripped 8/4 hardwood and 3/4-inch plywood without bogging down, maintaining steady blade speed through cuts.

The 2 HP hybrid motor delivers noticeably better performance with dense hardwoods. Running on 240V (which requires electrical setup but dramatically improves efficiency), it powers through demanding cuts that would slow budget saws.

Motor noise levels sit around 85-90 decibels during operation—not whisper-quiet but typical for this saw class. The enclosed cabinet design on the hybrid model contains sound somewhat better than the open-base contractor saws.

Fence Systems: The Critical Component

RIKON equips their saws with T-square style fence systems that lock at both front and rear rails. The fence on my test unit (10-326 model) locks solidly and maintains parallel alignment to the blade across the full range of travel.

Fence pros:

- Positive locking with minimal deflection

- Smooth sliding action once properly adjusted

- Adequate rigidity for most woodworking tasks

- Clear measurement scale that’s easy to read

Fence limitations:

- Initial setup requires patience to achieve perfect parallel alignment

- Fine micro-adjustment isn’t as refined as premium fences

- Some users report fence rack can develop play over time with heavy use

Compared to the Biesemeyer-style fences on premium saws, RIKON’s fence works well but doesn’t have the same butter-smooth feel or rock-solid lockdown. For most woodworkers, it’s a acceptable trade-off at this price point.

Trunnion and Blade Adjustment

The trunnion assembly (the mechanism that tilts and raises the blade) uses a rack-and-pinion design. Blade height adjustment operates smoothly with minimal backlash. Tilt adjustment shows slightly more resistance—not problematic but requires more effort than premium saws.

I’ve made dozens of angle adjustments and found the system holds settings reliably. The built-in stops at 90° and 45° get you close but require verification with a quality square. This is standard for saws in this price range—set-and-forget accuracy requires aftermarket micro-adjustable stops.

Performance Testing: Real-World Results

Theory and specifications only tell part of the story. Here’s how RIKON saws perform with actual woodworking tasks.

Ripping Performance

Dimensional Lumber: The contractor models handle ripping 2x material effortlessly. I’ve processed dozens of 2x4s, 2x6s, and even 2x10s without the motor straining. Feed rate doesn’t need to slow appreciably—you can push material through at comfortable speeds.

Hardwoods: Ripping 8/4 hard maple and red oak revealed the motor limitations on the 1.5 HP model. It completes the cuts but requires slower feed rates. The 1.75 HP and 2 HP models handle hardwoods more confidently, maintaining blade speed through demanding cuts.

Sheet Goods: Full plywood sheets tax any contractor-style saw without proper support, but RIKON’s 1.75 HP motor manages 3/4-inch plywood cuts admirably. The fence stability proves more important than motor power for sheet goods—and RIKON’s fence performs well here.

Crosscutting Accuracy

The included miter gauge is adequate but not exceptional—standard for this market segment. It slides smoothly in the milled slots without excessive play, but the angle locking mechanism could be more robust.

For serious crosscut work, I recommend upgrading to an aftermarket miter gauge or building a crosscut sled. The saw’s precision and power deliver excellent results; the factory miter gauge just doesn’t do justice to the saw’s capabilities.

Dado Blade Capability

RIKON saws accommodate 8-inch dado blade sets, with the arbor accepting stacked dado configurations up to approximately 13/16 inches wide. The motor power handles dado cuts in softwoods and medium-density hardwoods without issue.

I cut numerous dados for bookcase and cabinet projects. The results were clean, flat-bottomed grooves with minimal tearout (using sharp blades). The arbor has sufficient length for most dado applications, though extremely wide dado stacks may not fit.

Dust Collection Performance

This is where RIKON saws show their budget-oriented design. The dust ports work, but collection efficiency is mediocre without upgrades.

Contractor models (10-201, 10-326): The open-base design and basic dust shrouds capture approximately 50-60% of dust generated. Significant amounts escape into the shop air and accumulate inside the stand. Upgrading the dust shroud and sealing gaps improves collection markedly.

Hybrid model (10-3061): The enclosed cabinet design improves dust collection to roughly 70-75% capture with proper vacuum connection. Still not as efficient as premium saws with sophisticated dust management, but better than open-base designs.

For all models, connecting a quality dust collector with adequate CFM (minimum 400 CFM at the tool) is essential. Shop vacuums work for occasional use but struggle with regular production work.

Learn more about improving collection on our table saw dust collection system guide.

Safety Features and Considerations

RIKON includes standard safety features but doesn’t offer advanced technology like SawStop’s flesh-detection system.

Standard safety equipment:

- Blade guard with anti-kickback pawls

- Riving knife (on newer models)

- Push stick

- Safety glasses recommended (not included)

Important safety notes:

The blade guards work but are somewhat cumbersome to remove and reinstall for non-through cuts. Many woodworkers end up removing guards for certain operations—which reduces safety. Consider investing in an aftermarket overhead guard for better visibility and convenience.

The riving knife on current models helps prevent kickback by keeping the kerf from closing behind the blade. This is a significant safety improvement over older saws without riving knives. Ensure you keep the riving knife installed for all through-cuts.

Emergency stop switches are accessible but not as prominent as on some competitor saws. Know where your switch is located and practice reaching it reflexively.

For comprehensive safety practices, visit our table saw how-to guide.

Assembly and Setup Experience

RIKON saws arrive partially assembled, requiring 2-4 hours of setup time depending on model and your mechanical experience.

Unboxing and Initial Assembly

Packaging quality: Adequate but not exceptional. Components are protected but not over-engineered. Inspect everything carefully upon delivery and report any shipping damage immediately.

Assembly instructions: Clear enough for mechanically inclined individuals. Some steps could use more detailed diagrams, but most woodworkers navigate setup without major issues.

Required tools: Basic hand tools (wrenches, screwdrivers, hex keys). Most necessary tools are included, but having your own complete set helps.

Weight and handling: The contractor models require two people for safe unboxing and positioning. The hybrid model definitely needs two strong individuals or lifting equipment.

Critical Setup Steps

1. Table alignment: Verify the table surface is coplanar with wings. Shim if necessary to achieve flat transition across seams.

2. Blade alignment: Use a quality combination square or dial indicator to ensure the blade runs perfectly parallel to miter slots. This is critical for accurate cutting and often requires adjustment out of the box.

3. Fence calibration: The fence must run perfectly parallel to the blade. Budget significant time for this adjustment—it’s the most important setup task and determines your saw’s cutting accuracy.

4. Blade height/tilt accuracy: Verify 90° and 45° stops with precision measuring tools. Adjust as needed and lock settings.

I spent about three hours setting up my RIKON 10-326 test unit, with fence alignment consuming half that time. Once dialed in properly, the saw maintained settings reliably.

Value Proposition: Price vs. Performance

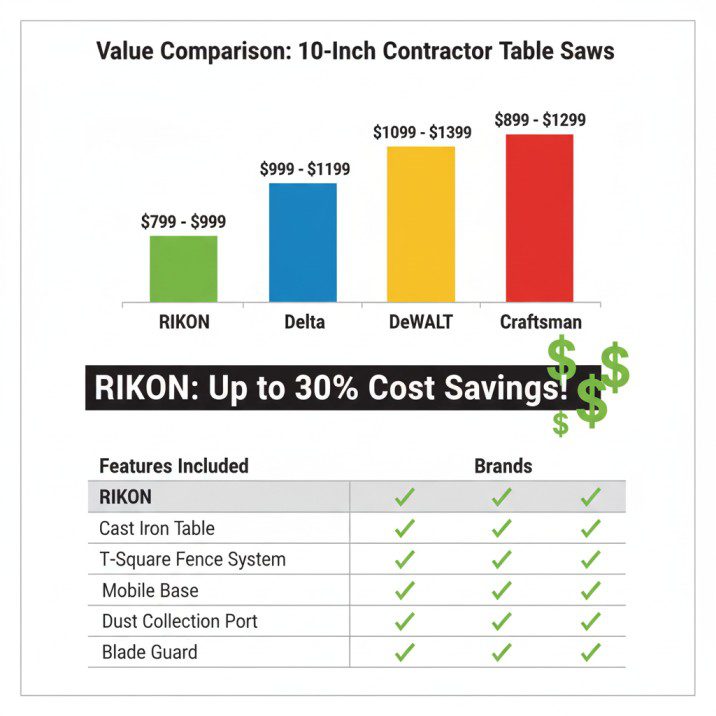

RIKON’s competitive advantage lies in delivering solid performance at aggressive price points. But is the value real or are you sacrificing too much?

What You Get for the Money

RIKON 10-201 at $600-$750:

- Real cast iron table (not stamped steel)

- Adequate 1.5 HP motor for hobbyist use

- Compact footprint for smaller shops

- T-square fence system

- Standard safety features

Comparable alternative: Entry-level contractor saws from major brands at similar prices often compromise with smaller tables, less powerful motors, or inferior fence systems. RIKON competes favorably in direct comparisons.

RIKON 10-326 at $800-$950:

- Extended cast iron table with wings

- More powerful 1.75 HP motor

- 36-inch rip capacity

- Improved dust collection shroud

- Better overall build quality

Comparable alternative: Mid-range contractor saws from premium brands cost $1,200-$1,500 with similar specifications. RIKON saves you $300-$600 while delivering 85-90% of the performance.

RIKON 10-3061 Hybrid at $1,100-$1,350:

- Cabinet-style enclosed base

- 2 HP motor with 240V capability

- Professional-grade construction quality

- Significantly improved dust collection

- Heavy, stable platform

Comparable alternative: True hybrid saws from established brands run $1,600-$2,200. RIKON undercuts pricing substantially while providing comparable core performance.

Where RIKON Makes Compromises

Fence refinement: Premium saws offer smoother, more precise fence systems with better micro-adjustment capability. RIKON’s fences work well but lack that premium feel.

Dust collection: Even the hybrid model doesn’t match the dust management of saws with sophisticated internal baffling and shrouds. Plan to upgrade dust collection to achieve acceptable results.

Fit and finish details: Paint quality, knob feel, and small details don’t match premium brands. These don’t affect performance but impact the overall user experience.

Motor refinement: RIKON motors lack the smooth, quiet operation of premium induction motors. They work reliably but with more noise and vibration.

Customer support: RIKON’s customer service is adequate but doesn’t have the extensive support network of major brands. Parts availability is good but not as immediate as industry giants.

The Verdict on Value

For budget-conscious woodworkers who understand the compromises, RIKON delivers exceptional value. You’re getting 85-90% of premium saw performance at 50-65% of the cost. The savings can fund quality blades, jigs, and accessories that improve results more than marginal saw refinements would.

However, professional woodworkers running production shops may find the compromises frustrating. If you’re cutting 8 hours daily, the premium saw refinements justify their higher cost through reduced fatigue and slightly better efficiency.

Compare with other brands on our table saw buying guide.

Who Should Buy a RIKON Table Saw?

RIKON saws are excellent for:

- Serious hobbyists working regularly but not professionally

- Budget-conscious woodworkers maximizing value without sacrificing core performance

- Small shop owners with limited space and moderate production needs

- Beginning professionals building their shop without massive initial investment

- Woodworkers willing to dial in setup and make minor upgrades for optimal performance

Consider alternatives if you:

- Run production operations requiring maximum uptime and efficiency

- Demand premium fit and finish and refined user experience

- Lack mechanical skills for setup and calibration

- Need extensive customer support and immediate parts availability

- Want advanced safety features like flesh-detection technology

Accessories and Upgrades Worth Considering

Maximize your RIKON saw’s performance with these strategic additions:

Essential upgrades:

- Quality 10-inch combination blade (factory blades are adequate but not optimal)

- Zero-clearance throat plate inserts for cleaner cuts

- Aftermarket miter gauge or crosscut sled for precision crosscutting

- Mobile base if you need to move the saw for space management

Recommended additions:

- Upgraded dust collection shroud or aftermarket dust hood

- Dial indicator for precision blade alignment

- Digital angle gauge for accurate bevel settings

- Push blocks and push sticks beyond the included basic stick

Nice-to-have accessories:

- Outfeed table or roller support for long boards and sheet goods

- Overhead blade guard for better visibility and safety

- Table extensions if rip capacity proves limiting

Explore more options on our table saw accessories page.

Frequently Asked Questions

Are RIKON table saws made in the USA? RIKON tools are designed in the USA but manufactured in Asia (primarily Taiwan and China). This offshore manufacturing enables the competitive pricing while maintaining reasonable quality standards.

How does RIKON compare to Delta or DeWalt? RIKON offers comparable core performance at lower prices but with less refined details and smaller support networks. Delta and DeWalt provide more polished user experiences and extensive parts availability at premium prices.

What warranty does RIKON offer? RIKON provides a 5-year warranty on table saws, covering defects in materials and workmanship. This is competitive with industry standards and demonstrates confidence in product reliability.

Can RIKON saws use dado blades? Yes, all RIKON table saws accommodate 8-inch dado blade sets. The arbor length supports stacked dado configurations up to approximately 13/16 inches wide.

Do I need 240V power for RIKON saws? The contractor models (10-201, 10-326) run on standard 120V outlets. The hybrid model (10-3061) can operate on 120V but performs significantly better on 240V due to increased motor efficiency.

How difficult is RIKON table saw setup? Mechanically competent individuals can complete setup in 2-4 hours. Fence alignment requires patience and precision measuring tools. Professional assembly services may be worthwhile for those lacking experience or confidence.

Final Thoughts: Is RIKON Right for You?

After extensive testing and evaluation, I’ve concluded that RIKON table saws occupy a valuable niche in the market. They’re not perfect, but they deliver genuine value for woodworkers with realistic expectations.

The cast iron tables, adequate motor power, and functional fence systems provide the foundation for quality woodworking. Yes, you’ll notice refinements missing compared to premium saws, but those refinements rarely impact the actual quality of your finished projects.

What matters more: a butter-smooth fence that costs $800 alone, or a functional fence that works reliably paired with a $150 premium blade and $200 worth of quality jigs? For most woodworkers, the latter combination produces better results.

I recommend RIKON saws to friends and students who ask about affordable options for serious woodworking. With proper setup, realistic expectations, and strategic upgrades, these saws serve dedicated hobbyists and semi-professional woodworkers excellently.

Would I choose RIKON for a high-volume production shop running 10 hours daily? Probably not—the premium saws justify their cost in that scenario. But for my personal shop where I work evenings and weekends on furniture projects? The RIKON 10-326 delivers everything I need at a price that left budget for the tools and accessories that actually improve my work.

Bottom Line: RIKON table saws represent smart value for budget-conscious woodworkers who prioritize performance over prestige. If you’re willing to invest setup time and accept minor compromises in refinement, you’ll find these saws deliver results that belie their affordable pricing.

Recommendation by user type:

- Hobbyist woodworkers: RIKON 10-326 offers the best balance of features and value

- Small shop professionals: RIKON 10-3061 Hybrid provides cabinet-saw performance at contractor-saw prices

- Beginners on tight budgets: RIKON 10-201 delivers essential capabilities without breaking the bank

- Production professionals: Consider premium brands unless budget constraints are severe

Your next woodworking project deserves quality tools, but quality doesn’t always require premium prices. RIKON proves that thoughtful engineering and strategic manufacturing can deliver professional results at hobbyist prices.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.