The first time I tried cutting concrete with my regular circular saw, I nearly destroyed the blade, choked on a cloud of silica dust, and barely made it halfway through a 4-inch slab before the motor started screaming at me.

I had watched a two-minute YouTube video, figured it looked easy enough, and jumped in without any real preparation. Big mistake.

Cutting concrete isn’t like cutting wood. It’s aggressive, dusty, loud, and genuinely dangerous if you don’t know what you’re doing. But when you have the right blade, the right setup, and the right technique — it’s absolutely something a DIYer can handle on their own.

I’ve since cut dozens of concrete slabs, pavers, stepping stones, and block walls for various projects around my property. This guide shares everything I learned the hard way so you don’t have to.

Table of Contents

- Can You Actually Cut Concrete with a Circular Saw?

- Understanding Concrete Cutting Blades

- Best Blades for Cutting Concrete

- Dry Cutting vs. Wet Cutting: Which Is Better?

- Safety Gear You Absolutely Cannot Skip

- How to Cut Concrete Step by Step

- Common Concrete Cutting Problems (And How to Fix Them)

- Types of Cuts You Can Make

- Blade Comparison Chart

- Final Recommendations

Can You Actually Cut Concrete with a Regular Circular Saw?

Short answer: yes, but with the right blade.

Your standard wood-cutting blade will last about three seconds on concrete before it’s completely destroyed. Concrete is incredibly abrasive and dense — it’ll eat through regular carbide teeth like they’re butter.

What you need is a diamond blade or a abrasive masonry blade designed specifically for cutting concrete, brick, stone, and similar materials.

Here’s the honest truth though: a standard circular saw isn’t the ideal tool for cutting concrete. Dedicated concrete saws and angle grinders work better for many jobs. But for occasional cuts on slabs, pavers, stepping stones, blocks, or concrete board — a circular saw with the right blade works perfectly fine.

What a circular saw can handle:

- Concrete pavers and stepping stones

- Concrete board (Hardieboard, cement board)

- Thin concrete slabs up to 3-4 inches

- Decorative concrete cuts

- Brick and block

- Scored expansion joints

What’s beyond a circular saw:

- Very thick reinforced concrete (6+ inches)

- Cutting rebar-heavy structural slabs

- Deep expansion joints in commercial work

- High-volume professional cutting jobs

For most homeowner projects, a 7-1/4″ circular saw with a quality diamond blade will do exactly what you need.

Understanding Concrete Cutting Blades

Before buying a blade, you need to understand what you’re dealing with.

Diamond Blades

These are what you want for serious concrete cutting. Despite the name, they don’t have sharp cutting edges. Instead, the rim is embedded with tiny diamond particles bonded in a metal matrix.

As the blade spins, those diamond particles grind through the concrete. The metal matrix gradually wears away, exposing fresh diamond particles to keep cutting. It’s more like grinding than slicing.

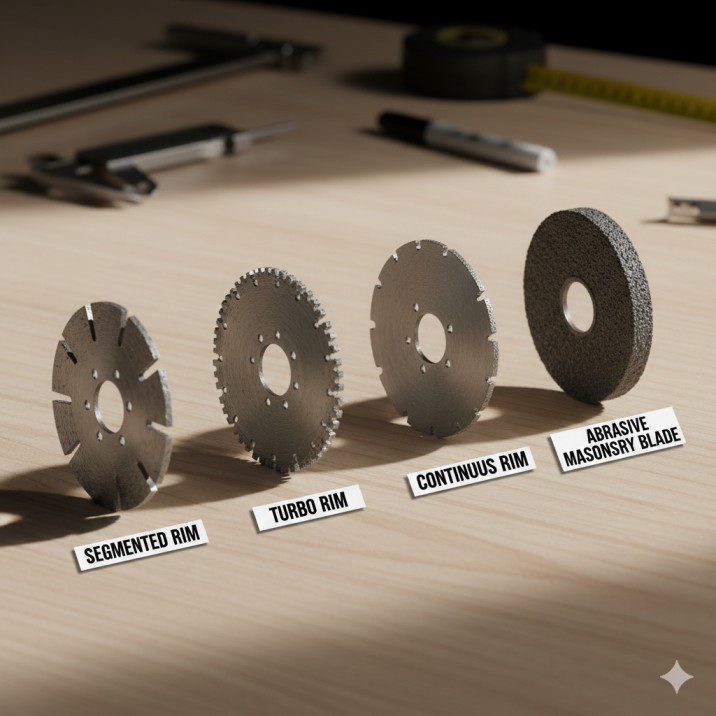

Two types of diamond blades:

Segmented rim blades have gaps cut around the rim. These gaps serve two purposes — they cool the blade and remove debris. Segmented blades cut faster but leave slightly rougher edges. They’re best for general concrete cutting, slabs, and block work.

Continuous rim blades have a solid rim with no gaps. They cut smoother and cleaner, which matters for tile, decorative concrete, and visible edges. They cut slower and require water cooling or frequent breaks.

Turbo rim blades fall in between — they have serrated patterns on a continuous rim for faster cutting than continuous rims with smoother cuts than segmented blades. These are a good all-around choice.

Abrasive Masonry Blades

These are the cheap silicon carbide wheels that look like grinding discs. They cut concrete by wearing away aggressively and also wear away themselves — fast.

I used one of these on my first attempt. In about 20 minutes of cutting, the blade had worn down from 7-1/4″ to barely 6″. They also generate insane amounts of dust and heat.

My honest take on abrasive masonry blades:

They work for very occasional cuts on light materials like concrete board or a single paver. But for anything more than that, spend the extra money on a diamond blade. The difference in performance, dust, and blade life is massive.

Blade Arbor and Size

Most circular saws use 7-1/4″ blades with a 5/8″ arbor. Always check your saw’s specifications before buying. Using a blade that doesn’t fit is dangerous.

Some diamond blades come with a 5/8″ – 7/8″ diamond knockout arbor that fits both common sizes.

Best Blades for Cutting Concrete with a Circular Saw in 2026

These blades are all currently available and proven performers for concrete work.

1. Diablo DBD070070H01F 7″ Diamond Blade

Diablo Diamond Continuous Rim Masonry Cuf-Off Disc for Granite, Marble, Porcelain and Tile – 7" Diameter, 5/8" Arbor, 1.6mm Kerf – DMADC0700

- Smooth, Precise Cutting – Achieve up to 60 Percent smoother cuts resulting in chip-free cuts without burn marks, perfect for tile, granite, marble, and porcelain.

- Durable Design – Industrial-grade diamond rim with a hardened disc body delivers lasting durability and maximizes cutting quality in hardened materials even in extreme applications.

- Ultra-Thin Rim – Utlra-thin constant contact continuous turbo rim design provides precise cuts at high rates of speed.

Best all-around concrete cutting blade

Diablo makes some of the best value blades on the market, and their diamond blades are no exception. This segmented rim blade handles everything from concrete pavers to block walls.

Real-world experience: I used this blade to cut about 30 concrete stepping stones for a garden path. Clean cuts, reasonable speed, and after all those cuts the blade barely looked worn. The segmented design handled heat well without water — I just gave it a few seconds to cool between cuts.

Pros:

- Excellent value for performance

- Segmented rim stays cool during dry cutting

- Works on concrete, brick, block, and stone

- Cuts faster than most budget blades

- Widely available at hardware stores

Cons:

- Leaves slightly rougher edges than continuous rim

- Not ideal for super clean decorative cuts

- Some heat buildup on longer cuts

Price range: $15-25

2. DEWALT DW4712B 7-1/4″ Segmented Diamond Blade

DEWALT Diamond Blade for Masonry, High Performance, 7-Inch (DW4712B)

- The product is 7″, high performance masonry blade, 5/8″ Diamond knock out arbor

- Easy to use

- The product is manufactured in China

Best for durability on tough concrete

DEWALT’s diamond blade is built tough and holds up well on hard concrete and cinder block. It’s one of the most popular blades among contractors who need reliable performance.

Real-world experience: A contractor friend uses these almost exclusively for jobsite concrete work. He cuts everything from expansion joints to block walls. He tells me he gets significantly more life out of DEWALT blades versus cheaper alternatives, which matters when you’re cutting all day.

I borrowed one for a patio demolition project — cutting through a cracked 3.5-inch concrete slab to remove sections. The blade powered through without complaining.

Pros:

- Excellent longevity on hard materials

- Handles reinforced concrete well

- Good heat management

- Consistent cut depth throughout blade life

- DEWALT warranty backing

Cons:

- Slightly more expensive than Diablo

- Segmented cut isn’t the smoothest

- Overkill for light occasional use

Price range: $20-30

3. Diablo DMADST0700 — 7″ Segmented Turbo Masonry Blade

Best all-around balance of speed and cut quality

Diablo Diamond Segmented Turbo Masonry Cut-Off Blade for Concrete, Brick and Block – 4" Diameter, 2.4mm Kerf, 15250 Max RPM – DMADST0400

- Longer Lifespan – 60% taller segments containing superior quality diamonds along with an ultra-durable bond to the disc body for up to 4X longer life.

- Faster Cutting Speed – Diamond segment SPEED-Edge slot design reduces vibration, providing high cutting speeds that deliver up to 30% faster cuts than standard segmented diamond discs.

- Impact Resistance – Hardened disc body absorbs vibration and increases impact resistance to deliver superior quality cuts in hardened materials.

The turbo design gives you the best of both worlds — faster cutting than a pure continuous rim blade, with cleaner results than a basic segmented blade. If you want one blade that handles most concrete jobs well, this is a strong pick.

What it’s good for: General concrete, pavers, brick, block — anything where you want a middle ground between speed and cut quality.

Pros:

- SPEED-Edge slot design cuts up to 30% faster than standard segmented

- 60% taller diamond segments for longer blade life

- Hardened body absorbs vibration for smoother cuts

- Dry and wet use compatible

- Compatible with 7/8″, 20mm, and 5/8″ arbors

Cons:

- Slightly more expensive than the basic segmented version

- Not quite as smooth as a full continuous rim on decorative work

Price range: $18–30

4. Archer USA 7-1/4″ Turbo Diamond Blade

Archer Pro 10" in. General Purpose Diamond Saw Blades for Fast Cutting Concrete, Stone, Masonry, Pavers, Bricks, Blocks

- CONCRETE SAW ✔️ Ideal for both professional contractors and DIY users.

- DIAMOND BLADE 👑 Laser welded segments and Grade A diamond crystals for highest performance.

- SAW BLADES 💪 Medium bond for aggressive cutting of a wide range of construction materials.

Best value for occasional DIY use

Turbo rim blades are the sweet spot between segmented and continuous rim. This Archer blade gives you faster cutting than a continuous rim with smoother results than a segmented.

Real-world experience: This was my first diamond blade purchase after ruining that abrasive disc. I used it to cut patio blocks for a backyard project — about 40 cuts total. It handled the job cleanly and the edges were good enough that I didn’t need to do any cleanup work.

For a DIYer who cuts concrete a few times a year, this blade is all you need.

Pros:

- Good balance of speed and cut quality

- More affordable than premium brands

- Works on dry or wet cutting

- Decent longevity for occasional use

Cons:

- Doesn’t last as long as Diablo or DEWALT

- Slight vibration at higher speeds

- Not for heavy professional use

Price range: $10-18

5. MK Diamond MK-99 7″ Premium Segmented Blade

M.K. Diamond Prod. 167022 Mk-99 Diamond Blade with Turbo Rim

- The item is M.K. Diamond Diamond Blade Mk-99, Turbo Rim Wet/Dry 7 ” Diax0.080 ” Wxdm-5/8 “

- Used for Power Tool Accessories, Blades – Diamond

- The product is manufactured in United States

Best for professional-level work

MK Diamond is a brand many professional concrete cutters rely on. This blade is built for serious work on hard concrete, cured slabs, and block.

Real-world experience: I borrowed one of these from a mason friend when cutting expansion joints in a new patio slab. The difference over my usual Diablo blade was noticeable on fresh, hard concrete — it cut faster and seemed to stay cooler. If I was cutting concrete regularly, this would be my go-to.

Pros:

- Premium diamond quality for demanding work

- Excellent on very hard or cured concrete

- Longer blade life than mid-range options

- Stays consistent from first cut to last

Cons:

- Higher price point

- Overkill for light DIY projects

- Takes time to break in on new cuts

Price range: $35-55

Dry Cutting vs. Wet Cutting: Which Is Better?

This is one of the most common questions about cutting concrete, and the answer depends on your situation.

Dry Cutting

Most DIYers cut concrete dry. No water setup needed, easier to set up and move around, and most diamond blades support dry cutting.

The catch: Dry cutting generates a massive amount of fine silica dust. This dust is genuinely dangerous to breathe — it causes silicosis, a serious and permanent lung disease. More on this in the safety section.

How to dry cut safely:

- Always wear an N95 or P100 respirator (not just a dust mask)

- Cut outdoors or with excellent ventilation

- Use a vacuum or dust collection near the cut

- Take breaks between cuts so the blade cools

- Keep cuts short — 30 seconds max before pausing

For dry cutting: Use segmented or turbo rim blades. They have gaps that help cool the blade through airflow.

Wet Cutting

Wet cutting involves running water over the blade while cutting. This eliminates virtually all dust and dramatically extends blade life.

Professional concrete saws have built-in water systems. On a circular saw, you’d need a helper with a garden hose or a wet-cutting attachment.

Benefits of wet cutting:

- Almost zero dust

- Blade stays much cooler

- Longer blade life

- Smoother cuts possible

Drawbacks of wet cutting:

- Messy and complicated setup

- Creates concrete slurry that needs cleanup

- Can’t use near electrical panels or in tight indoor spaces

- Continuous rim blades required (not segmented)

My honest recommendation:

For outdoor work, dry cutting with a good respirator is fine for most DIY projects. If you’re cutting indoors, near living spaces, or doing a large amount of concrete cutting, wet cutting is worth the hassle. The dust from dry cutting is just too dangerous to ignore in enclosed spaces.

Safety Gear You Absolutely Cannot Skip

I want to be blunt here: cutting concrete is one of the most hazardous DIY tasks you can do. Not because of the saw itself, but because of what cutting concrete creates.

Silica dust is invisible and deadly. Concrete contains crystalline silica, and when you cut it, you create fine particles that go deep into your lungs. You won’t feel anything at the time — the damage builds up over years. Silicosis is irreversible and can be fatal.

Please take this seriously. Here’s the gear you need:

Respirator (Non-Negotiable)

A regular dust mask is NOT enough for silica dust. You need at minimum an N95 respirator that seals around your face. For any significant concrete cutting, use a P100 half-face respirator.

I bought a 3M half-face respirator with P100 filters for about $30. It’s uncomfortable but I wear it every single time I cut concrete. No exceptions.

Safety Glasses or Full Face Shield

Concrete chips and blade fragments travel fast. Safety glasses protect your eyes, but a full face shield is better for concrete work because chips fly in all directions.

I’ve been hit in the cheek by concrete fragments while wearing safety glasses. Now I wear a face shield for any significant concrete cutting.

Hearing Protection

Circular saws are loud on their own. Cutting concrete adds grinding noise and vibration that’s significantly worse. Foam earplugs or earmuff-style hearing protection are essential.

Long exposure to this kind of noise causes permanent hearing damage. I started wearing hearing protection consistently after noticing ringing in my ears after a big project.

Heavy Work Gloves

Concrete dust is caustic and rough. It irritates and dries your skin with prolonged contact. Heavy leather or cut-resistant work gloves protect your hands.

Also, if the blade catches and the saw kicks back, gloves won’t fully protect you — but bare hands are much worse.

Knee Pads (If Cutting at Ground Level)

Most concrete cutting happens at ground level on slabs and pavers. Kneeling on rough concrete for extended periods tears up your knees fast. Thick foam knee pads make the job much more bearable.

Work Boots

Concrete chips and saw kickback can injure your feet badly. Steel-toed boots are ideal. At minimum, wear solid leather work boots — no sneakers near a circular saw cutting concrete.

How to Cut Concrete with a Circular Saw: Step by Step

Follow this process and your cuts will be clean, safe, and accurate.

Step 1: Mark Your Cut Line

Use a chalk line or pencil to mark exactly where you want to cut. For straight cuts on pavers or slabs, use a straight edge and marker.

Make the line visible — you’ll be following it through dust and noise.

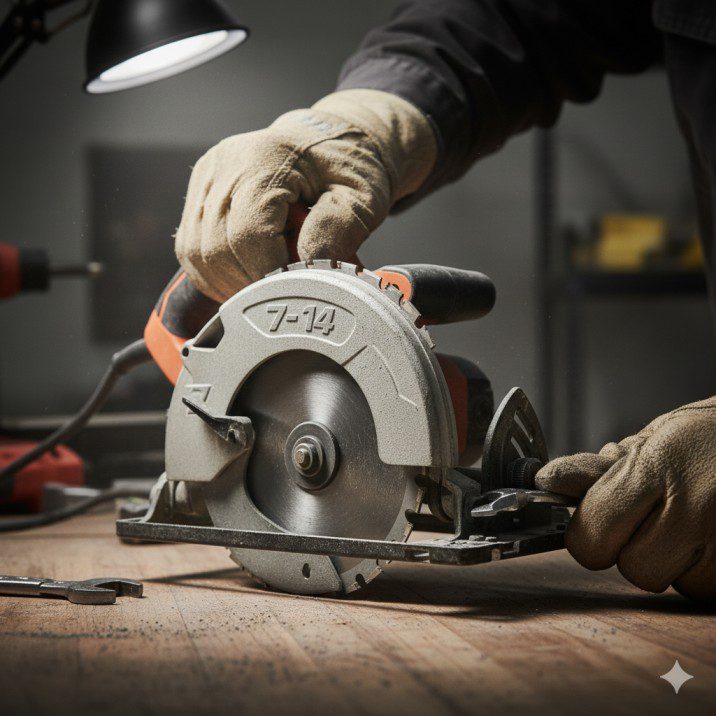

Step 2: Install Your Diamond Blade

Remove your wood blade and install your diamond blade. Check that the blade direction is correct — the arrows on the blade should match the direction of rotation on your saw.

Tighten the arbor bolt firmly. A loose blade on concrete is extremely dangerous.

Check your blade depth. Set it so the blade extends about 1/4″ deeper than the thickness of the material you’re cutting. Don’t expose more blade than needed.

Step 3: Put On All Your Safety Gear

Respirator, eye protection, hearing protection, gloves, boots. Do this before you make any cuts. No exceptions, no “just this one quick cut” without protection.

Step 4: Set Up Your Workspace

If cutting outdoors, position yourself so the dust blows away from you (check wind direction).

For concrete pavers or blocks: secure the piece so it won’t shift during cutting. I use sandbags on either side or have a helper hold the piece (not near the cutting line obviously).

For slab cuts: make sure you’re not going to cut through anything underneath — pipes, wires, or rebar in unexpected places can be a nasty surprise.

Step 5: Make a Scoring Pass First

Don’t try to cut to full depth on the first pass. Start with a shallow scoring cut — about 1/4″ to 1/2″ deep — along your entire cut line.

This creates a guide channel that keeps your blade on track for deeper passes. It also reduces blade wander on the first cut.

I used to skip this step and paid for it with wandering cuts. Now I always score first.

Step 6: Cut in Multiple Passes

Increase your blade depth in stages. For a 3-inch slab, I typically make 3-4 passes:

- Pass 1: Score at 1/2″

- Pass 2: 1-1/4″

- Pass 3: 2-1/4″

- Pass 4: Full depth (3″ + 1/4″ extra)

Don’t rush. Move the saw at a steady, moderate pace. Let the blade do the work — don’t push it. If the saw is bogging down, you’re going too fast or the blade is dull.

Step 7: Cool the Blade Between Passes

For dry cutting, give your blade 30-60 seconds between passes. Let it spin freely in the air to cool down. Running a diamond blade too hot ruins it fast.

If the blade is smoking or you smell burning, stop immediately and let it cool fully before continuing.

Step 8: Complete the Cut and Clean Up

Once you’ve cut to full depth, let the piece break cleanly or use a chisel and hammer for any remaining section.

Clean up concrete dust immediately while it’s still contained. Use a shop vacuum with a HEPA filter — a regular vacuum will blow the fine dust back into the air.

Common Concrete Cutting Problems and How to Fix Them

Here’s what goes wrong and how to fix it:

Blade Wandering Off the Line

Cause: Going too fast, blade too hot, or not using a guide.

Fix: Slow down. Use a straight edge clamped to the concrete as a guide fence. Make a scoring pass first to create a channel.

Blade Overheating and Smoking

Cause: Cutting too fast, not enough cooling breaks, wrong blade for the material.

Fix: Stop immediately. Let the blade cool completely. Cut in shorter passes with cooling breaks between each one. If it keeps happening, your blade might be wrong for the material.

Blade Stalling or Saw Bogging Down

Cause: Too much depth per pass, dull blade, or motor not powerful enough.

Fix: Reduce your cutting depth per pass. Make more passes at shallower depths. A dull diamond blade can sometimes be revived by cutting through a soft abrasive brick to re-expose fresh diamonds.

Ragged, Chipped Edges

Cause: Wrong blade type (segmented when you need continuous rim), dull blade, cutting too fast.

Fix: Switch to a continuous rim or turbo blade. Slow your feed rate. For visible edges on pavers, wet cutting gives the cleanest results.

Saw Kickback

Cause: Blade pinching in the cut, bad technique, trying to cut curves.

Fix: Support your workpiece so the cut doesn’t close up and pinch the blade. Always cut in straight lines only — circular saws aren’t designed for curved cuts in concrete. Never force the saw.

This is dangerous territory. If you experience kickback, stop immediately, assess what went wrong, and correct it before continuing.

Vibration and Rough Cutting

Cause: Damaged blade, loose arbor bolt, or warped blade from overheating.

Fix: Check the arbor bolt is tight. Inspect the blade for damage — chips, cracks, or bent segments. A damaged diamond blade should be replaced immediately. Never run a visibly damaged blade.

Types of Concrete Cuts You Can Make

Understanding what type of cut you’re making helps you choose the right blade and technique.

Straight Through-Cuts

Cutting pavers, blocks, or slabs completely through. The most common DIY concrete cut. Use a segmented or turbo diamond blade. Score first, then cut to full depth in multiple passes.

Control Joints and Expansion Joints

Cutting shallow grooves into a slab to control where cracking occurs. You only need to cut 1/4 to 1/3 of the slab thickness deep. A segmented blade works well here.

Time these cuts correctly — fresh concrete should be cut within 4-12 hours of finishing, before it fully cures.

Concrete Board Cutting

Cutting cement board (HardieBacker, Durock, etc.) for tile installations. This is much thinner and softer than slab concrete. A continuous rim blade or even an abrasive blade works here.

I actually prefer scoring and snapping cement board for straight cuts — mark the line, score with a utility knife or segmented blade, then snap it like drywall. It’s faster and cleaner for long straight cuts.

Demolition Cuts

Cutting sections of existing slabs for removal — like breaking up a section of driveway or patio. Use an aggressive segmented blade. Cut depth isn’t about cleanliness here, just penetration. Then use a sledgehammer or demo saw to break the pieces loose.

Decorative Scoring

Cutting patterns into decorative concrete. Use a continuous rim blade for cleanest edges, or better yet, an angle grinder with a diamond cup wheel for finer detail work.

Blade Comparison Chart

| Blade | Type | Best For | Cut Quality | Speed | Dry / Wet |

|---|---|---|---|---|---|

| Diablo DBD070070H01F | Segmented | General concrete, pavers, block | Good | Fast | Dry |

| DEWALT DW4712B | Segmented | Hard concrete, pro work | Good | Fast | Dry |

| Diablo Diamond Segmented Turbo | Turbo | Concrete, brick, masonry | Very Good | Fast | Dry |

| Archer Turbo | Turbo | All-around DIY | Very Good | Medium | Dry |

| MK Diamond MK-99 | Segmented | Heavy professional use | Very Good | Fast | Dry |

Final Recommendations

After cutting concrete on a dozen different projects, here’s my straightforward advice:

For most DIY homeowners: The Diablo DBD070070H01F is the best starting point. It handles pavers, blocks, slabs, and light demolition work at a price that makes sense for occasional use. It’s the blade I’d buy first.

For reliable performance on tough concrete: Go with DEWALT DW4712B. It costs a bit more but the longevity is worth it if you’re doing more than just a couple of projects per year.

For cement board and clean visible cuts: The Freud CD007 continuous rim blade gives you the smoothest edges. Essential for tile work and decorative concrete.

On a tight budget for one small job: The Archer turbo blade does the job at a price that makes sense if you’re only making a handful of cuts.

For serious or professional-level work: Spend the money on MK Diamond MK-99. The premium diamond quality pays off in speed, consistency, and blade life.

My Most Important Advice

Protect your lungs. No cut, no project, no deadline is worth silicosis. Buy a proper P100 respirator before you buy a blade. Wear it every single time.

Work slowly and let the blade do the work. Don’t force the saw through concrete — you’ll overheat the blade, ruin your cut, and create dangerous kickback situations.

If the job feels too big or complex, rent a dedicated concrete saw or hire a professional. There’s no shame in knowing your limits. A circular saw handles typical DIY concrete work just fine, but big demolition or deep structural cuts deserve proper equipment.

For more tips on using saws safely and effectively, check out our complete how-to guide for power saws.

Frequently Asked Questions

Q: Can any circular saw cut concrete, or do I need a special saw?

A: Any circular saw can cut concrete as long as you use the right blade — a diamond blade designed for masonry. The saw itself doesn’t need to be special, but more powerful saws (15-amp corded) handle thick concrete better than underpowered ones. Cordless saws can work for light cuts on pavers and cement board, but a corded saw is better for thick slabs.

Q: How long does a diamond blade last when cutting concrete?

A: It depends heavily on the blade quality and material you’re cutting. Budget turbo blades might last through 20-30 cuts on hard concrete. Mid-range blades like Diablo can handle dozens of feet of cutting. Premium blades can last hundreds of cuts if used correctly — with cooling breaks during dry cutting and without overheating. The #1 way to kill a diamond blade early is overheating it.

Q: Do I really need to make multiple passes instead of cutting to full depth at once?

A: Yes, absolutely. Trying to cut a 3-4 inch slab in one pass overloads your saw, overheats the blade, and produces a wandering cut. Multiple shallow passes are faster overall, produce cleaner cuts, and extend blade life dramatically. I learned this the hard way by burning through a blade in one aggressive pass.

Q: Is it safe to cut concrete indoors with a circular saw?

A: It’s risky due to silica dust. If you must cut indoors, wet cutting is far safer because it eliminates most airborne dust. If dry cutting indoors is unavoidable, use the strongest ventilation possible, seal off other rooms, wear a P100 respirator, and clean up with a HEPA vacuum immediately. Honestly, if the cut can wait until you can move the work outdoors, do that instead.

Q: Can I use a concrete-cutting diamond blade on my regular circular saw without any modifications?

A: In most cases, yes. Diamond blades for concrete come in standard sizes (7-1/4″ is the most common) with standard arbor sizes (5/8″ is typical). As long as the blade fits your saw’s spindle and the RPM rating on the blade exceeds your saw’s RPM, you’re good. Always check both the blade’s rated RPM and your saw’s max RPM before cutting.

Disclosure: This article contains affiliate links. Purchases made through these links may earn us a small commission at no extra cost to you. We only recommend products based on real use and honest research.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.