When I first upgraded from my contractor table saw to a cabinet saw three years ago, I thought I was just getting “a bigger table saw.” I couldn’t have been more wrong. The difference in vibration, cut quality, and sheer power completely changed how I approached my woodworking projects. But here’s the thing—a cabinet saw isn’t always the right choice, and understanding the real differences can save you thousands of dollars and workshop frustration.

The cabinet saw vs table saw debate isn’t just about size or price. It’s about matching the right tool to your specific needs, workspace, and woodworking ambitions. Whether you’re a weekend hobbyist working in a garage or a professional furniture maker planning your dream workshop, this guide will help you make the right decision based on real-world experience and current 2025 standards.

Understanding the Fundamental Differences Between Cabinet Saws and Table Saws

Let’s clear up some confusion right away. When most people say “table saw,” they’re actually referring to contractor or hybrid table saws—the mid-range options you’ll find at most home improvement stores. Cabinet saws are technically table saws too, but they represent the premium tier of stationary woodworking equipment.

What Defines a Cabinet Saw?

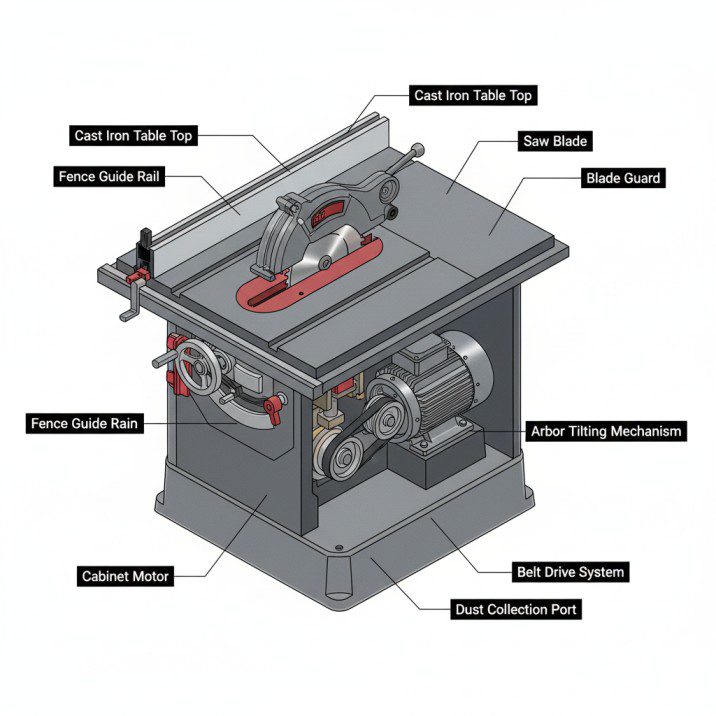

A cabinet saw features a completely enclosed base cabinet that houses the motor, belts, and dust collection system. The motor hangs inside this cabinet, typically ranging from 3 to 5 horsepower, and drives the blade through multiple belts. These saws are built on cast iron tables and trunnions, making them incredibly stable and vibration-free during operation.

I remember the first time I ripped a 12-foot piece of 8/4 hard maple on my cabinet saw. The motor didn’t even strain—it just powered through like butter. That’s the kind of performance you get when engineering doesn’t compromise on any component.

Standard Table Saw Characteristics

When we talk about standard table saws in the cabinet saw vs table saw comparison, we’re usually discussing contractor saws and hybrid models. These feature motors mounted on the back or partially enclosed designs. They typically run on 1.5 to 2 horsepower motors and use lighter-weight construction materials.

Contractor saws earned their name because they’re portable enough to move between job sites while still delivering decent cutting power. Hybrid saws try to split the difference, offering some enclosed cabinet benefits while maintaining a more accessible price point.

Power and Performance Comparison: Where the Rubber Meets the Road

The performance gap between cabinet saws and standard table saws becomes obvious the moment you start cutting hardwoods or making repeated cuts in thick stock.

Motor Specifications and Real-World Performance

Cabinet saws typically feature 3HP to 5HP motors running on 220-volt circuits. This isn’t just about raw power—it’s about sustained performance under load. When I’m doing production runs of cabinet doors, my 5HP cabinet saw maintains consistent blade speed even through dense materials like hard maple or white oak.

Standard table saws with 1.5HP to 2HP motors work great for softwoods, plywood, and occasional hardwood projects. But push them hard, and you’ll notice blade slowdown, motor strain, and potential safety issues. I’ve burned up two contractor saw motors over the years by pushing them beyond their designed capacity.

According to 2025 performance data from woodworking equipment manufacturers, cabinet saws maintain blade speed within 2% of optimal RPM even under heavy loads, while contractor saws can experience 10-15% speed reduction when cutting 2-inch hardwoods.

Cutting Capacity and Versatility

The cabinet saw vs table saw comparison really highlights differences in cutting capacity. Most cabinet saws offer 50-52 inch rip capacities with their standard fence systems, and the powerful motors handle dados, tenoning jigs, and other heavy-duty accessories without complaint.

My Delta Unisaw (a classic cabinet saw) can stack a full 3/4-inch dado set and plow through hardwood like it’s nothing. When I tried the same operation on my old contractor saw, it would bog down and I’d have to make multiple passes—wasting time and increasing the risk of tearout.

Precision and Cut Quality Analysis: The Details That Matter

If you’re serious about furniture making or precision woodworking, cut quality isn’t just a nice-to-have—it’s essential. This is where cabinet saws truly justify their premium pricing.

Vibration Control and Accuracy

The massive cast iron construction of cabinet saws essentially eliminates vibration during operation. I can measure the runout on my cabinet saw blade at 0.001 inches or less—that’s barely measurable. This translates to smoother cuts, less tearout, and edges that often need minimal sanding.

Standard table saws, with their lighter construction and direct-drive or belt-drive systems mounted externally, produce noticeably more vibration. You’ll see this in the cut quality, especially on crosscuts and when working with figured woods. The vibration shows up as slight blade marks that require additional cleanup work.

Fence Systems and Adjustment Precision

Cabinet saws typically come with premium fence systems like Biesemeyer or similar designs that lock down with bank-vault precision. My fence can be set and reset to within 1/64 inch accuracy, and it stays square to the blade indefinitely.

I’ve used contractor saws with decent fences, but they require more frequent checking and adjustment. The lighter tables also mean the fence rails can flex slightly under pressure, affecting accuracy in critical cuts.

For anyone interested in maximizing accuracy across different saw types, check out our comprehensive table saw accessories guide for upgrade options.

Workspace and Portability Considerations: Size Really Does Matter

This is where the cabinet saw vs table saw decision becomes very personal. Your workspace limitations might make the choice for you, regardless of performance preferences.

Footprint and Workshop Requirements

My cabinet saw occupies roughly 6 feet by 4 feet of floor space when you account for the table extension and adequate working clearance. It weighs around 650 pounds—once you position it, that’s where it lives. You’ll also need 220-volt electrical service, which requires professional installation if you don’t already have it.

Standard table saws offer much more flexibility. A contractor saw might weigh 200-300 pounds and run on standard 110-volt outlets. While still substantial, you could theoretically relocate them with a helper or move them on a mobile base. If you’re working in a single-car garage or shared space, this mobility matters immensely.

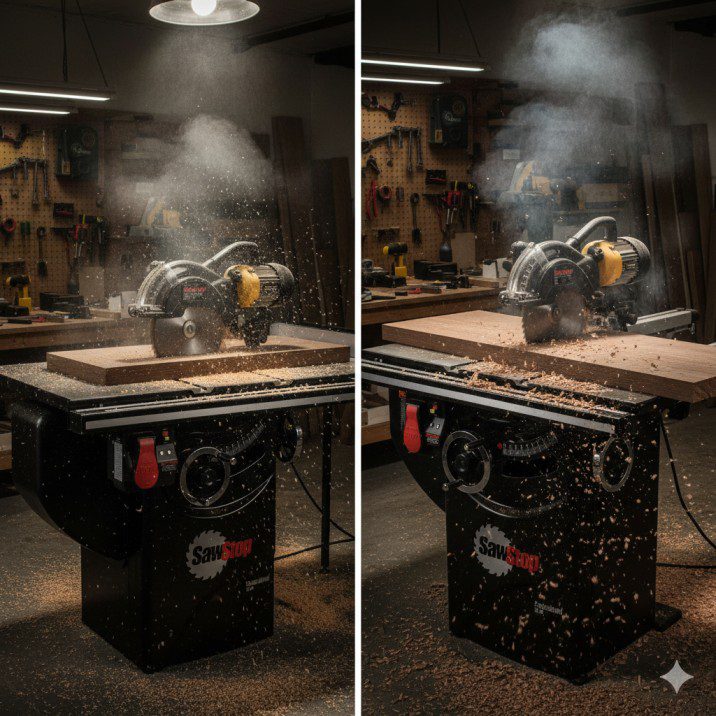

Dust Collection Efficiency

Here’s an unexpected advantage of cabinet saws—superior dust collection. The enclosed cabinet design allows you to connect a 4-inch dust collector directly to the cabinet, and the internal design efficiently captures sawdust before it escapes into your shop.

I connect my 1.5HP dust collector to my cabinet saw’s 4-inch port, and it captures approximately 95% of the sawdust produced. My old contractor saw, even with a dust collection shroud, probably captured 60-70% at best. After a full day in the shop, the difference in airborne dust is remarkable.

Cost Analysis: Initial Investment vs Long-Term Value

Let’s talk money, because the price difference in the cabinet saw vs table saw equation is substantial and deserves honest analysis.

Upfront Investment Breakdown

As of 2025, quality cabinet saws start around $2,000 for entry-level models like the Grizzly G0691 and can exceed $5,000 for premium options like the SawStop Professional Cabinet Saw or Powermatic PM2000. You’ll also need to budget for electrical work (potentially $300-800) and delivery/setup costs.

Standard table saws present a much friendlier entry point. Decent contractor saws range from $500-1,200, while hybrid models sit in the $1,200-2,000 range. They plug into standard outlets and can often be transported in a pickup truck.

When I made the leap to a cabinet saw, the total investment including electrical upgrades hit $3,200. That was a significant commitment that required serious consideration of whether my woodworking justified the expense.

Long-Term Value and Durability

Here’s where cabinet saws start justifying their premium. These machines are genuinely buy-it-for-life tools. My 12-year-old cabinet saw works exactly like it did when new—same precision, same power, same reliability. The heavy-duty components simply don’t wear out with normal use.

I’ve replaced two contractor saws over 15 years of woodworking before investing in a cabinet saw. When you factor in those replacement costs plus the frustration of dealing with equipment limitations, the cabinet saw’s higher upfront cost becomes more reasonable.

For detailed guidance on evaluating different saw options, our table saw buying guide covers everything from budget considerations to feature priorities.

Safety Features and Considerations in 2025

Safety technology has advanced significantly, and understanding the options available in both categories matters for protecting yourself in the workshop.

Modern Safety Systems

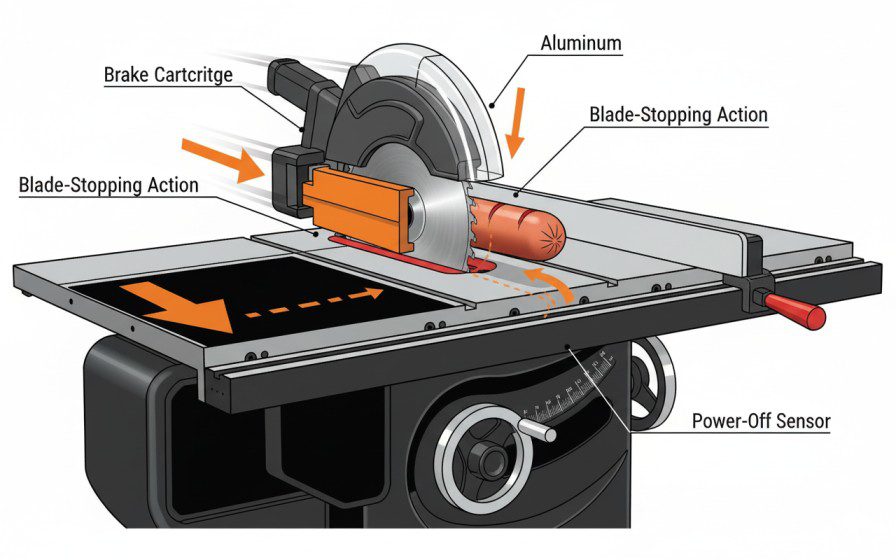

SawStop technology has revolutionized table saw safety, and it’s now available in both cabinet and contractor formats. The flesh-detecting brake system stops the blade in milliseconds upon contact with skin, preventing catastrophic injuries.

I’ve never triggered my SawStop’s brake (thankfully), but knowing it’s there changes how confidently I approach complex cuts. As of 2025, SawStop holds patents that are beginning to expire, and we’re seeing other manufacturers introduce similar safety systems at more competitive price points.

Inherent Safety Advantages

Cabinet saws offer some inherent safety benefits beyond electronic systems. The powerful motors are less likely to bog down and cause kickback. The heavier construction makes the saw more stable and less prone to walking during operation. The superior dust collection reduces airborne particles that can affect visibility and respiratory health.

However, the weight and power of cabinet saws also demand respect. These machines will cut through your hand as easily as they cut through oak—there’s no forgiveness for inattention. Proper technique and safety practices remain essential regardless of which saw you choose.

For comprehensive safety practices and proper setup procedures, explore our table saw how-to guide with step-by-step instructions.

Which Saw is Right for Your Needs? Making the Decision

After exploring the cabinet saw vs table saw differences in detail, let’s discuss who should choose which option based on real-world scenarios.

Choose a Cabinet Saw If You:

Are a serious hobbyist or professional woodworker. If you’re making furniture for sale, doing extensive hardwood projects, or simply committed to woodworking as a primary hobby, the performance and precision justify the investment.

Have a dedicated workshop space. You need room for the saw’s footprint and the ability to install 220-volt service. If you’re setting up a permanent shop, the immobility becomes irrelevant.

Value cut quality and precision. When the difference between furniture-grade work and amateur-looking projects matters to you, the superior accuracy of cabinet saws delivers measurable results.

Process hardwoods regularly. If you’re frequently working with oak, maple, cherry, walnut, or exotic hardwoods, the power advantage prevents frustration and potential safety issues from bogged-down cuts.

Plan to keep the saw long-term. Cabinet saws represent a decades-long investment. If you view woodworking as a lifelong pursuit, the higher upfront cost spreads across many years of reliable service.

Choose a Standard Table Saw If You:

Are beginning your woodworking journey. Starting with a quality contractor or hybrid saw lets you develop skills and determine if you’ll stick with the hobby before making a major investment.

Work primarily with sheet goods and softwoods. If your projects focus on plywood cabinetry, pine furniture, or general construction, a 1.5-2HP saw handles these materials efficiently.

Need portability or flexibility. Whether you’re a contractor moving between job sites or a hobbyist sharing garage space, the ability to relocate your saw matters.

Have budget constraints. The $1,500-2,500 you save by choosing a contractor or hybrid saw can go toward other essential tools like a quality bandsaw, jointer, or planer—building a more well-rounded shop.

Lack 220-volt electrical service. If running 220-volt power isn’t feasible due to rental restrictions or electrical panel limitations, contractor saws running on standard outlets remain the practical choice.

Frequently Asked Questions

Can I upgrade a contractor saw to cabinet saw performance?

Not really. While you can add better fences, mobile bases, and improved dust collection to contractor saws, you can’t overcome the fundamental differences in motor power, construction mass, and vibration control. These characteristics are built into the saw’s design from the ground up.

Are hybrid table saws a good compromise?

Hybrid saws represent a genuine middle ground, offering partially enclosed cabinets, improved dust collection, and usually 1.75-2HP motors. They’re excellent choices for serious hobbyists who want better performance than contractor saws but can’t justify or accommodate full cabinet saws. Models from brands like Grizzly and Shop Fox deliver impressive value in this category.

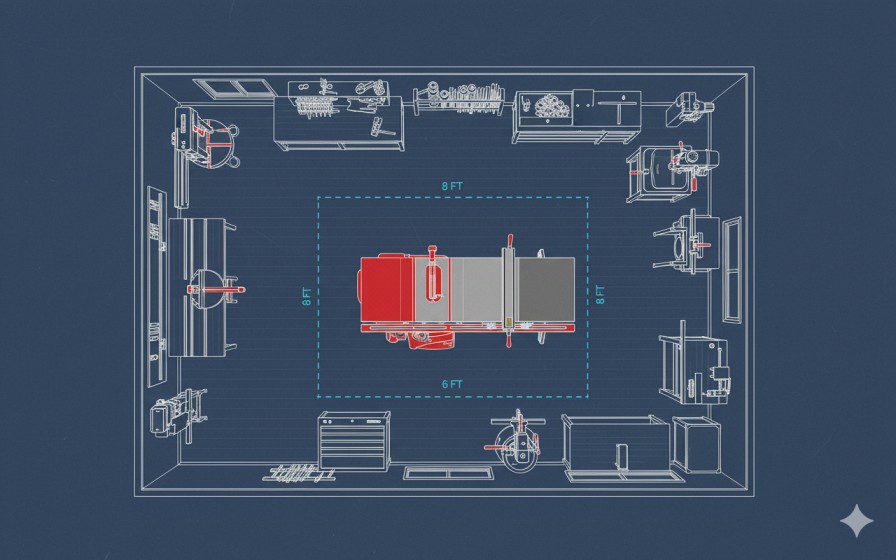

How much space do I really need for a cabinet saw?

Plan for at least 8 feet by 6 feet of floor space to accommodate the saw and provide adequate working clearance on all sides. You’ll need additional space for infeed and outfeed support when processing long stock. Many woodworkers position cabinet saws centrally in their shops to allow workflow from all directions.

Do all cabinet saws require 220-volt power?

Most cabinet saws require 220-volt service due to their powerful motors, though a few entry-level models offer 110-volt options with reduced motor sizes. If you’re considering a cabinet saw, factor in electrical requirements during your planning—retrofitting 220-volt service typically costs $300-800 depending on your panel location and local code requirements.

Will a cabinet saw make me a better woodworker?

Not directly. Skills come from practice, learning, and experience—not from equipment alone. However, cabinet saws remove certain frustrations and limitations that can hold back your progress. When your saw delivers consistent accuracy and has power to spare, you can focus on technique rather than fighting with your equipment. The saw won’t make you skilled, but it won’t limit your potential either.

Final Thoughts: Making Your Cabinet Saw vs Table Saw Decision

The cabinet saw vs table saw choice ultimately depends on where you are in your woodworking journey and what you realistically need from your primary cutting tool.

I don’t regret spending three years with contractor saws before upgrading to a cabinet saw. Those years taught me proper technique, helped me understand what features I actually valued, and ensured I was committed enough to woodworking to justify the investment. When I finally bought my cabinet saw, I appreciated every aspect of its performance because I had direct experience with the limitations I was overcoming.

For beginners and budget-conscious woodworkers, quality contractor or hybrid saws deliver excellent value and capability. Focus on developing skills with the tools you can afford, and upgrade when your projects and commitment justify the expense. Check out our best table saw reviews to find the right option for your current needs.

For established woodworkers ready to invest in premium equipment, cabinet saws represent one of the smartest tool purchases you can make. They’ll serve you reliably for decades, deliver precision that elevates your work quality, and provide the power to tackle any project without compromise.

The right saw isn’t about what’s “best” in absolute terms—it’s about what’s best for your specific situation right now. Assess your workspace honestly, consider your budget realistically, and choose based on the projects you’re actually building rather than aspirational work you might do someday.

Whichever direction you choose in the cabinet saw vs table saw decision, commit to learning proper technique, maintaining your equipment carefully, and always prioritizing safety. The saw is just a tool—your skills, creativity, and dedication determine the quality of what you build.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.