I’ll never forget the day I walked into a woodworking store with $2,500 in my pocket, ready to buy my first “serious” table saw. The salesperson pointed me toward a beautiful cabinet saw, then casually mentioned a hybrid model at half the price. “It’s 80% of the cabinet saw at 50% of the cost,” he said. That moment sparked a six-month research obsession that completely changed how I understood table saw value propositions.

The cabinet saw vs hybrid saw decision represents one of the most critical crossroads for advancing woodworkers. You’re past the beginner stage, you know what quality feels like, but you’re also smart enough to question whether premium always means better. After owning both types of saws and talking with dozens of woodworkers about their experiences, I can tell you the “right” answer isn’t what most people expect.

Whether you’re upgrading from a contractor saw, setting up a new workshop, or simply trying to make the smartest investment for your woodworking future, this comprehensive comparison will give you the clarity you need to choose confidently.

What Makes Cabinet Saws and Hybrid Saws Unique?

Before diving into comparisons, let’s establish exactly what defines each saw type. The differences go far beyond just price points—they represent fundamentally different engineering approaches to solving woodworking challenges.

Cabinet Saw Design Philosophy

Cabinet saws embody the “no compromises” approach to stationary woodworking equipment. Every component is designed for maximum performance, longevity, and precision. The motor—typically 3-5 horsepower—hangs inside a fully enclosed cabinet, driving the blade through multiple belts. This configuration isolates vibration, contains dust, and provides the mass necessary for dead-stable operation.

When I first fired up my 5HP cabinet saw to rip 8/4 walnut, the experience felt almost anticlimactic. The motor hummed quietly, the blade didn’t slow down even a fraction, and the cut edge looked hand-planed. That’s when I understood what “industrial-grade” actually means—it’s not about brute force, it’s about effortless capability.

Hybrid Saw Design Philosophy

Hybrid saws represent intelligent engineering compromise. They take the best features of cabinet saws—enclosed cabinets, improved dust collection, cast iron construction—and implement them at a more accessible price point. The motor typically mounts on the cabinet rather than hanging inside it, using lighter-duty components that still deliver substantial performance.

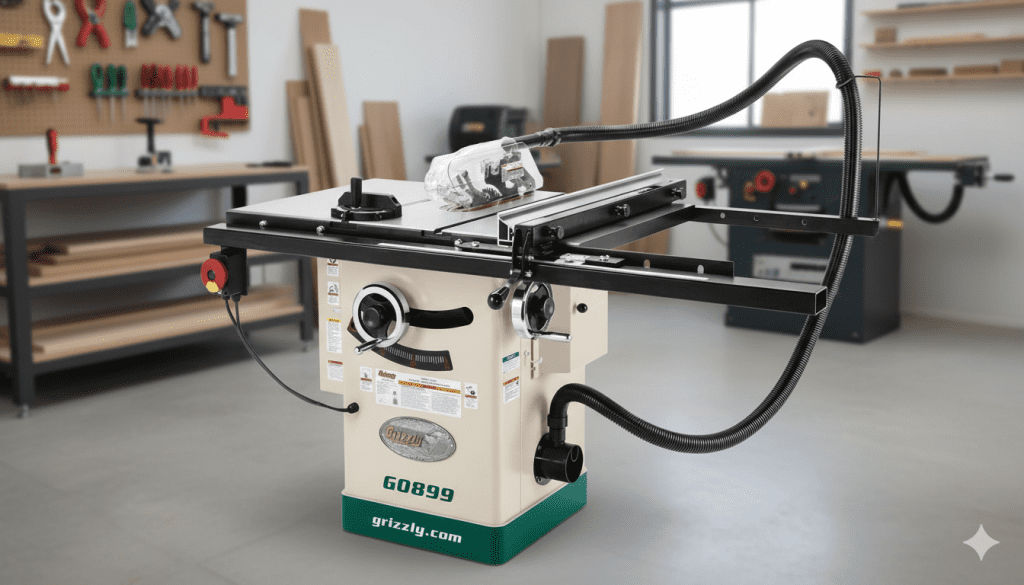

The genius of hybrid design lies in identifying which premium features matter most to non-production woodworkers and delivering those without unnecessary expense. My workshop partner runs a Grizzly hybrid saw, and for his furniture-making business focused on custom pieces rather than production runs, it delivers everything he needs at a fraction of cabinet saw ownership costs.

Head-to-Head Performance Comparison Table

Let’s examine the key differences between cabinet saws and hybrid saws across the metrics that matter most to woodworkers:

| Feature | Cabinet Saw | Hybrid Saw | Winner |

|---|---|---|---|

| Motor Power | 3-5 HP | 1.75-2 HP | Cabinet Saw |

| Electrical Requirements | 220V (typically) | 110V or 220V options | Hybrid Saw (flexibility) |

| Weight | 450-700 lbs | 300-450 lbs | Hybrid Saw (mobility) |

| Vibration Control | Excellent (minimal) | Very Good | Cabinet Saw |

| Dust Collection | 95%+ capture rate | 85-90% capture rate | Cabinet Saw |

| Price Range | $2,000-$5,000+ | $1,200-$2,200 | Hybrid Saw (value) |

| Rip Capacity | 30″-52″ (standard) | 30″-36″ (standard) | Cabinet Saw |

| Cut Quality | Exceptional | Excellent | Cabinet Saw (marginal) |

| Setup/Installation | Complex, professional recommended | Moderate, DIY-friendly | Hybrid Saw |

| Resale Value | Excellent (70-80% retention) | Good (50-60% retention) | Cabinet Saw |

| Maintenance Requirements | Low (annual tune-ups) | Low (annual tune-ups) | Tie |

| Noise Level | 90-95 dB | 92-97 dB | Cabinet Saw |

This table tells an interesting story. Cabinet saws win on pure performance metrics, but hybrid saws win on practical considerations like flexibility, value, and ease of integration into existing workshops.

Power and Motor Specifications Breakdown

The cabinet saw vs hybrid saw debate often starts and ends with power specifications, but raw horsepower numbers don’t tell the complete story. Let’s dig into what these motor differences actually mean for your woodworking.

Motor Configuration and Performance

Cabinet saws house their powerful motors completely within the enclosed cabinet, suspended to minimize vibration transfer. Most run 3-5HP induction motors on 220-volt circuits, delivering continuous power output that never wavers even under sustained heavy loads.

I’ve run production batches of 50+ cabinet doors on my 5HP cabinet saw, ripping oak and maple for hours without any performance degradation. The motor temperature barely rises, the blade speed remains constant, and the circuit breaker never even thinks about tripping.

Hybrid saws typically feature 1.75-2HP motors mounted on the cabinet exterior or partially enclosed. This represents the sweet spot for serious hobbyist and small professional work—enough power for hardwoods and demanding operations, but without requiring dedicated electrical infrastructure.

Real-World Cutting Capacity

Here’s a practical comparison table showing what each saw type handles comfortably:

| Material & Operation | Cabinet Saw (3-5HP) | Hybrid Saw (1.75-2HP) | Notes |

|---|---|---|---|

| 3/4″ Plywood Ripping | Effortless, full feed rate | Effortless, full feed rate | No meaningful difference |

| 2″ Hard Maple Ripping | No blade slowdown | Slight slowdown, maintain steady feed | Both complete the cut successfully |

| Full 3/4″ Dado Stack | Powers through without hesitation | Requires slower feed rate | Cabinet saw significantly faster |

| Bevel Cuts in Hardwood | Maintains full power | Noticeable motor strain | Cabinet saw more comfortable |

| Repeated Cuts (50+ pieces) | Consistent performance | May need cooldown breaks | Cabinet saw better for production |

| Exotic Hardwoods (Ebony, Purpleheart) | Handles easily | Possible, but challenging | Cabinet saw recommended |

The performance gap narrows considerably when working with softwoods, plywood, and moderately thick hardwoods—which represents 80% of most woodworkers’ projects. The cabinet saw’s power advantage becomes genuinely important primarily for production work or when regularly processing very thick or very dense materials.

Precision and Build Quality Analysis

Beyond raw power, the cabinet saw vs hybrid saw comparison reveals meaningful differences in construction quality that affect long-term accuracy and satisfaction.

Construction Materials and Stability

Cabinet saws are built on massive cast iron tables, trunnions, and cabinet structures. My SawStop cabinet saw weighs 650 pounds—that mass isn’t just for show, it’s functional engineering that dampens vibration and maintains alignment under stress.

Hybrid saws use cast iron where it matters most (tabletops and trunnions) while incorporating lighter materials elsewhere to control costs and weight. A typical hybrid saw weighs 350-400 pounds—still substantial, but manageable for repositioning if needed.

I’ve measured runout on both saw types with dial indicators. My cabinet saw consistently shows blade runout under 0.001 inches. My friend’s quality hybrid saw measures around 0.002-0.003 inches. In practical terms, both produce furniture-grade cuts, but the cabinet saw’s extra precision becomes noticeable in joinery work requiring absolute accuracy.

Fence Systems and Adjustment Precision

Here’s a detailed comparison of fence system capabilities:

| Fence Characteristic | Cabinet Saw | Hybrid Saw |

|---|---|---|

| Standard Fence Type | Premium (Biesemeyer-style) | Good quality T-square or similar |

| Repeatability Accuracy | ±0.001″ to ±0.005″ | ±0.005″ to ±0.010″ |

| Locking Mechanism | Heavy-duty cam lock | Standard lever lock |

| Rail Deflection Under Pressure | Virtually none | Minimal but measurable |

| Micro-Adjustment | Often included | Sometimes available |

| Aftermarket Upgrade Options | Limited (already premium) | Extensive upgrade path |

For context, a 0.005-inch variation equals about half the thickness of standard printer paper. For most woodworking operations—even fine furniture making—both saw types deliver acceptable precision. The cabinet saw’s tighter tolerances matter primarily for production work or extremely exacting joinery.

Our comprehensive table saw buying guide explores fence systems and accuracy considerations in greater depth.

Cost-Benefit Analysis with Real Numbers

Let’s address the elephant in the workshop—the substantial price difference between cabinet and hybrid saws demands careful justification. Here’s an honest breakdown of what you’re actually paying for.

Initial Investment Comparison

| Cost Factor | Cabinet Saw | Hybrid Saw | Difference |

|---|---|---|---|

| Base Saw Price | $2,000-$5,000 | $1,200-$2,000 | $800-$3,000 more |

| Electrical Upgrade (if needed) | $300-$800 (220V) | $0-$400 (often 110V compatible) | $0-$400 more |

| Delivery/Setup | $150-$400 | $0-$150 (often DIY-able) | $150-$250 more |

| Accessories Included | Premium fence, often mobile base | Standard fence, basic accessories | Variable |

| Total Initial Investment | $2,450-$6,200 | $1,200-$2,550 | $1,250-$3,650 more |

When I purchased my cabinet saw setup in 2022, the total cost including electrical work hit $3,800. My workshop partner’s hybrid saw cost $1,600 delivered to his garage, requiring no electrical modifications. That $2,200 difference funded his bandsaw and jointer purchases—arguably creating more woodworking capability than the cabinet saw upgrade alone would have provided.

Value Proposition Over Time

Here’s where the analysis gets interesting. Let’s project 10-year ownership costs and value:

| 10-Year Factor | Cabinet Saw | Hybrid Saw |

|---|---|---|

| Purchase Price | $3,500 (average) | $1,600 (average) |

| Maintenance Costs | $200 (belts, alignments) | $250 (belts, alignments, parts) |

| Energy Costs | $180 (higher power draw) | $120 (lower power draw) |

| Resale Value After 10 Years | $2,500 (70% retention) | $800 (50% retention) |

| Net 10-Year Cost | $1,380 | $1,070 |

| Annual Cost of Ownership | $138/year | $107/year |

This table reveals something surprising—while cabinet saws cost significantly more upfront, their superior resale value means the actual cost of ownership over a decade differs by only $31 per year. That’s assuming you eventually sell the saw, which many woodworkers never do.

For detailed reviews of specific models in both categories, check our best table saw reviews section.

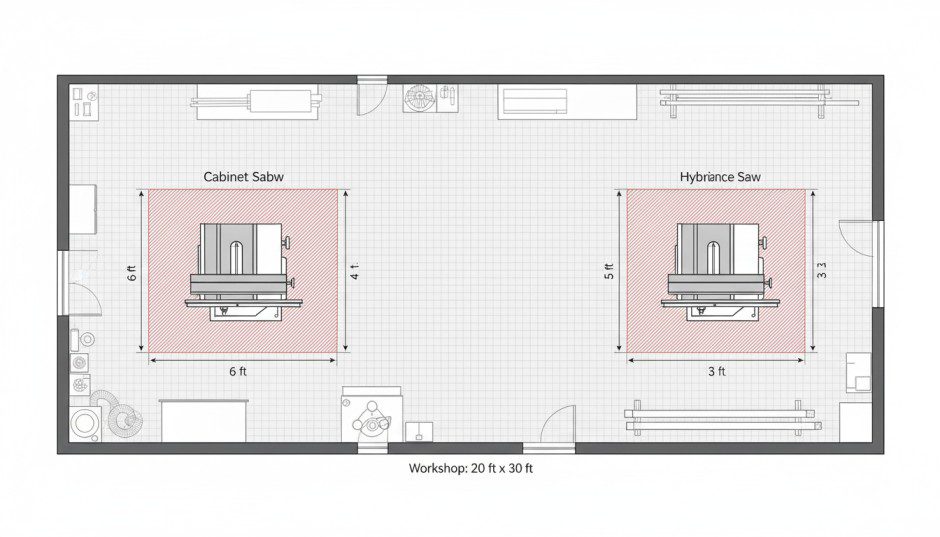

Space Requirements and Workshop Integration

The cabinet saw vs hybrid saw decision often comes down to practical workshop realities rather than performance preferences. Let’s examine the spatial footprint and integration requirements for each option.

Physical Footprint Comparison

| Dimension | Cabinet Saw | Hybrid Saw | Difference |

|---|---|---|---|

| Base Saw Footprint | 40″-60″ wide × 27″-36″ deep | 36″-48″ wide × 27″-30″ deep | Cabinet 10-20% larger |

| With Standard Extension | 60″-80″ wide × 27″-36″ deep | 50″-65″ wide × 27″-30″ deep | Cabinet 15-25% larger |

| Recommended Working Clearance | 8′ × 6′ minimum | 7′ × 5′ minimum | Cabinet needs more space |

| Height (with mobile base) | 36″-42″ to table surface | 34″-40″ to table surface | Minimal difference |

| Weight Distribution | Concentrated, requires strong floor | More distributed, less demanding | Cabinet needs better foundation |

My cabinet saw sits in the center of my 24′ × 20′ workshop, allowing workflow from all directions. This central placement works beautifully for my production-oriented work, but it’s only feasible because I have dedicated workshop space.

My friend’s hybrid saw occupies a corner of his two-car garage, mounted on a quality mobile base. When he needs full vehicle space, he can roll the saw against the wall—something completely impractical with a 650-pound cabinet saw.

Electrical and Infrastructure Requirements

Cabinet saws typically demand 220-volt circuits with dedicated 30-amp breakers. If your workshop doesn’t already have 220-volt service, expect to pay $400-800 for professional installation depending on distance from your electrical panel and local code requirements.

Hybrid saws offer flexibility—many models run on standard 110-volt circuits, though 220-volt options often provide better performance. This flexibility means you can set up a hybrid saw almost anywhere without infrastructure modifications.

When I moved workshops three years ago, relocating my cabinet saw required hiring professionals, renting equipment, and installing new 220-volt service. Total cost: $1,200. A hybrid saw owner could handle the same move with a trailer rental and a couple of friends.

Dust Collection Capabilities Compared

Effective dust collection significantly impacts shop air quality, equipment longevity, and cut visibility. The cabinet saw vs hybrid saw comparison reveals meaningful differences in this often-overlooked category.

Dust Collection System Effectiveness

| Collection Feature | Cabinet Saw | Hybrid Saw |

|---|---|---|

| Cabinet Enclosure | Fully sealed | Partially sealed |

| Dust Port Size | 4″ standard | 2.5″-4″ variable |

| Collection Efficiency | 90-95% capture | 80-90% capture |

| Required Collector CFM | 600-800 CFM minimum | 400-600 CFM minimum |

| Fine Dust Control | Excellent | Good to Very Good |

| Shroud Design | Integrated, optimized | Integrated, functional |

I run a 1.5HP dust collector with my cabinet saw’s 4-inch port, and after a full day of cutting, I find minimal sawdust inside the cabinet and virtually none in the shop air. The fully enclosed cabinet creates controlled airflow that directs debris toward the collection point.

Hybrid saws with partially enclosed cabinets and sometimes smaller dust ports capture less efficiently. My workshop partner empties his hybrid saw’s collection bag more frequently and finds more dust escaping into his shop environment. It’s not terrible—certainly better than contractor saws—but noticeably inferior to cabinet saw collection.

For maximizing dust collection performance on any saw type, explore our guide to table saw accessories, including aftermarket collection upgrades.

Who Should Buy Which Saw: Decision Framework

After comparing specifications and performance, let’s address the real question: which saw makes sense for your specific situation? Here’s an honest assessment based on different woodworker profiles.

Choose a Cabinet Saw If You:

Run a professional woodworking business. When your saw generates income, the reliability, performance, and efficiency of a cabinet saw pays dividends daily. The time saved on production runs and reduced material waste from superior cut quality quickly justifies the investment.

Focus on fine furniture and demanding joinery. If you’re building heirloom-quality pieces with hand-cut dovetails and precision joinery, the cabinet saw’s accuracy advantage becomes genuinely meaningful. That 0.001-inch difference in runout matters when fitting tenons.

Have a dedicated, permanent workshop. With space allocated specifically for woodworking and no need to share or relocate, the cabinet saw’s immobility becomes irrelevant. You’re building infrastructure, not buying portable equipment.

Regularly process thick hardwoods or exotic species. If your typical project involves 12/4 walnut, dense tropical hardwoods, or extended ripping sessions, the cabinet saw’s power advantage prevents frustration and potential safety issues from overloaded motors.

Value long-term investment over initial cost. Cabinet saws are genuinely buy-it-for-life tools. If you view woodworking as a decades-long pursuit and want equipment you’ll never outgrow, the higher upfront cost spreads across many years of reliable service.

Choose a Hybrid Saw If You:

Are a serious hobbyist advancing your skills. You’ve outgrown contractor saws and want better performance, but you’re not running a production shop. Hybrid saws deliver 80-90% of cabinet saw capability at 50-60% of the cost—ideal for advancing woodworkers.

Work primarily with common hardwoods and sheet goods. If your projects center on oak, maple, cherry, and plywood—materials that hybrid saws handle easily—you won’t encounter the limitations that justify cabinet saw power.

Need flexibility in workshop arrangement. Whether you’re in a shared garage, might relocate in coming years, or want the option to reconfigure your shop layout, the hybrid saw’s manageable weight and 110-volt options provide valuable flexibility.

Want to build a well-rounded tool collection. The $1,500-2,000 saved by choosing a hybrid over a cabinet saw can fund a quality bandsaw, jointer, or planer—potentially adding more capability to your shop than incremental table saw improvement would provide.

Prefer practical value over ultimate performance. If you appreciate quality tools but question whether premium pricing delivers proportional value, hybrid saws represent the sweet spot where performance meets pragmatic decision-making.

Detailed Specifications Comparison Table

For woodworkers who want to dive deep into technical specifications, here’s a comprehensive comparison of typical features across both saw categories:

| Specification | Entry Cabinet Saw | Premium Cabinet Saw | Entry Hybrid Saw | Premium Hybrid Saw |

|---|---|---|---|---|

| Price Range | $2,000-$2,800 | $3,500-$5,000+ | $1,200-$1,500 | $1,600-$2,200 |

| Motor Power | 3 HP | 5 HP | 1.75 HP | 2 HP |

| Voltage | 220V | 220V | 110V or 220V | 220V (typically) |

| Blade Diameter | 10″ | 10″ | 10″ | 10″ |

| Arbor Size | 5/8″ | 5/8″ | 5/8″ | 5/8″ |

| Maximum Rip Capacity | 30″-36″ | 50″-52″ | 30″ | 36″ |

| Table Surface Area | 27″ × 40″ | 27″ × 44″ | 27″ × 36″ | 27″ × 40″ |

| Table Material | Cast iron | Cast iron (ground) | Cast iron | Cast iron (ground) |

| Weight | 450-550 lbs | 600-700 lbs | 300-350 lbs | 400-450 lbs |

| Dust Port Size | 4″ | 4″ | 2.5″ | 4″ |

| Trunnion Type | Cabinet-mounted | Cabinet-mounted | Hybrid (semi-enclosed) | Cabinet-mounted |

| Fence Type | T-square | Premium (Biesemeyer) | T-square | T-square or Premium |

| Included Mobile Base | Rare | Sometimes | Sometimes | Often |

| Blade Tilt | Left (typically) | Left or Right options | Left (typically) | Left (typically) |

| Miter Slots | 3/4″ × 3/8″ | 3/4″ × 3/8″ | 3/4″ × 3/8″ | 3/4″ × 3/8″ |

| Maximum Dado Width | 13/16″ (full stack) | 13/16″ (full stack) | 13/16″ | 13/16″ (full stack) |

| Warranty | 2-5 years | 5-7 years | 1-2 years | 2-5 years |

This specification table reveals that entry-level cabinet saws and premium hybrid saws occupy overlapping territory in features and capabilities, despite their price differences stemming primarily from motor power and construction mass.

Making the Cabinet Saw vs Hybrid Saw Decision

After exploring every angle of the cabinet saw vs hybrid saw comparison, the “right” choice becomes surprisingly personal. Unlike many tool decisions where one option objectively outperforms another, these two saw categories excel in different ways for different woodworkers.

The Performance Perspective

If we’re being completely honest, cabinet saws deliver superior performance across almost every measurable metric. They’re more powerful, more precise, better at dust collection, and built to tighter tolerances. But here’s the critical question: do those performance advantages matter for your actual woodworking?

I can confidently say my cabinet saw has never limited my projects or frustrated me with insufficient power. But equally honestly, when I use my friend’s quality hybrid saw to help on his projects, I rarely find myself wishing for my cabinet saw’s extra capabilities. We’re both building furniture that sells, and customers can’t distinguish between pieces built on either saw.

The Value Perspective

The hybrid saw’s value proposition is genuinely compelling. For $1,500-1,800, you get a saw capable of handling virtually any woodworking project a non-production shop will encounter. That’s remarkable when you consider that cabinet saws delivering marginally better performance cost $2,000-3,500 more.

Think about what else $2,500 buys: a quality 14″ bandsaw, a 6″ jointer, a thickness planer, and a decent dust collector. That combination of tools expands your woodworking capabilities far more than incremental table saw improvements.

The Practical Perspective

Workshop reality often makes the decision for you. If you don’t have 220-volt power and can’t install it, cabinet saws become impractical regardless of their performance advantages. If you’re working in a shared or temporary space, the hybrid saw’s flexibility becomes essential rather than merely nice-to-have.

I’ve seen woodworkers agonize over this decision for months, build elaborate spreadsheets comparing specifications, and ultimately choose based on which saw their local dealer had in stock. Sometimes overthinking prevents doing, and either choice will serve you well if you commit to learning proper technique and maintaining your equipment.

For step-by-step guidance on setup, alignment, and maintenance for either saw type, visit our table saw how-to guide.

Frequently Asked Questions About Cabinet Saws vs Hybrid Saws

Can a hybrid saw really handle hardwoods like maple and oak?

Absolutely. Quality hybrid saws with 1.75-2HP motors cut hardwoods successfully—you just need to maintain reasonable feed rates. I’ve watched my friend rip 8/4 white oak on his hybrid saw dozens of times without issues. The cut takes slightly longer than on a cabinet saw, but the results are indistinguishable. Where hybrid saws struggle is with sustained production work or extremely dense exotics like ebony or lignum vitae.

Will I eventually regret not buying the cabinet saw?

Maybe, but probably not. Most woodworkers who choose hybrid saws report high satisfaction even years later. The regret typically comes not from the hybrid saw’s limitations, but from outgrowing any tool as skills and ambitions expand. If you start doing production work or processing large volumes of thick hardwoods, you might eventually want more power—but that’s true whether you start with a hybrid or contractor saw.

Can I upgrade a hybrid saw to cabinet saw performance?

Not really. The fundamental differences—motor power, cabinet construction, mass—can’t be retrofitted. However, you can upgrade hybrid saw components like fences, insert plates, and dust collection shrouds to improve performance within the saw’s design parameters. Many hybrid saw owners find that strategic accessory upgrades deliver the specific improvements they need without replacing the entire saw.

How much difference does the extra weight really make?

More than you might expect. The additional 200-300 pounds of cabinet saw mass translates directly to reduced vibration and increased stability during cuts. I can literally place a nickel on edge on my cabinet saw’s table while running, and it won’t fall over. Try that on a lighter saw and the vibration topples it immediately. For fine furniture work where clean cuts minimize sanding, this stability produces measurably better results.

Are there hybrid saws that perform nearly as well as cabinet saws?

Yes, particularly at the premium end of the hybrid category. Saws like the Grizzly G0833P and Shop Fox W1837 offer 2HP motors, cabinet-mounted trunnions, and quality fences that deliver performance approaching entry-level cabinet saws. The gap between a $2,000 premium hybrid and a $2,200 entry cabinet saw is smaller than the gap between a $1,200 basic hybrid and that same premium hybrid.

Do I need 220-volt power for a hybrid saw?

Not necessarily. Many hybrid saws offer both 110-volt and 220-volt motor options, giving you flexibility based on your electrical situation. However, the 220-volt versions typically deliver better performance—smoother startups, consistent power delivery, and less circuit breaker sensitivity. If you have or can easily add 220-volt service, choosing that option provides headroom for future needs.

Final Thoughts: Choosing Wisely in the Cabinet Saw vs Hybrid Saw Debate

The cabinet saw vs hybrid saw decision represents one of those rare situations where there’s genuinely no wrong answer—only different answers for different people. Both saw types deliver quality performance that will serve dedicated woodworkers for decades.

My recommendation? Start by honestly assessing your current needs, not your aspirational future. If you’re primarily building furniture for yourself and occasional clients, working with common hardwoods and sheet goods, and operating in a space with typical garage electrical service, a quality hybrid saw delivers everything you need at a price that leaves budget for other essential tools.

If you’re running a business, processing lumber regularly, or have a dedicated workshop with proper electrical infrastructure, the cabinet saw’s performance advantages justify the premium pricing. You’re buying capability you’ll use daily, and the improved efficiency translates to real time and material savings.

I’ve owned both saw types, and I genuinely appreciate the strengths of each. My cabinet saw is the right tool for my current situation—I run a small furniture business, have a dedicated workshop, and needed the power for production work. But five years ago when I was a serious hobbyist, my hybrid saw served me beautifully and never left me wanting.

The woodworking community sometimes creates artificial hierarchies around tools, suggesting that serious woodworkers “must” have cabinet saws. That’s nonsense. Serious woodworkers have tools appropriate to their work, and hybrid saws absolutely qualify for anything short of production shop environments.

Choose based on your workspace reality, budget comfort level, and actual project requirements. Master proper technique, maintain your equipment carefully, and focus on building skills rather than accumulating equipment. The saw is just a tool—your creativity, dedication, and craftsmanship determine what you build with it.

Whichever direction you choose in the cabinet saw vs hybrid saw comparison, you’re investing in equipment that will serve you well for years to come. Buy confidently, cut safely, and enjoy the process of transforming lumber into beautiful projects.

I

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.