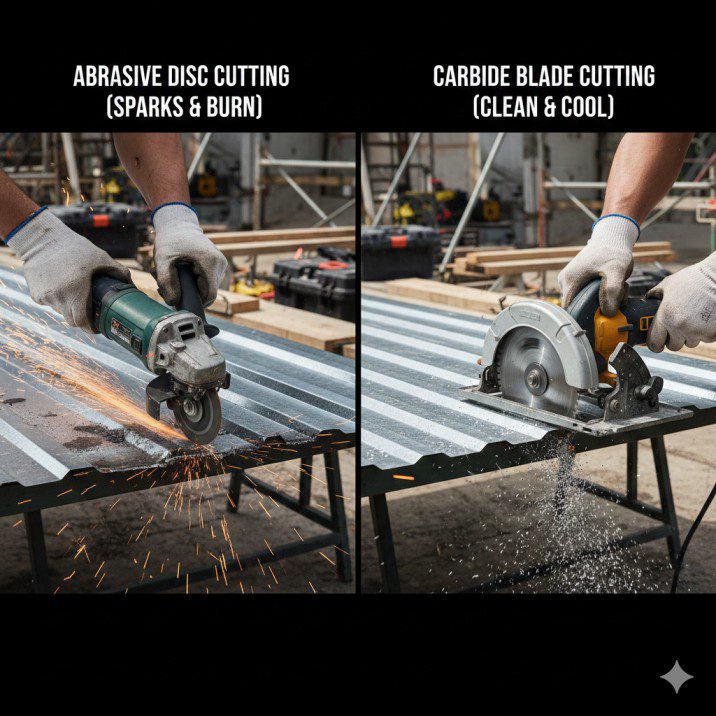

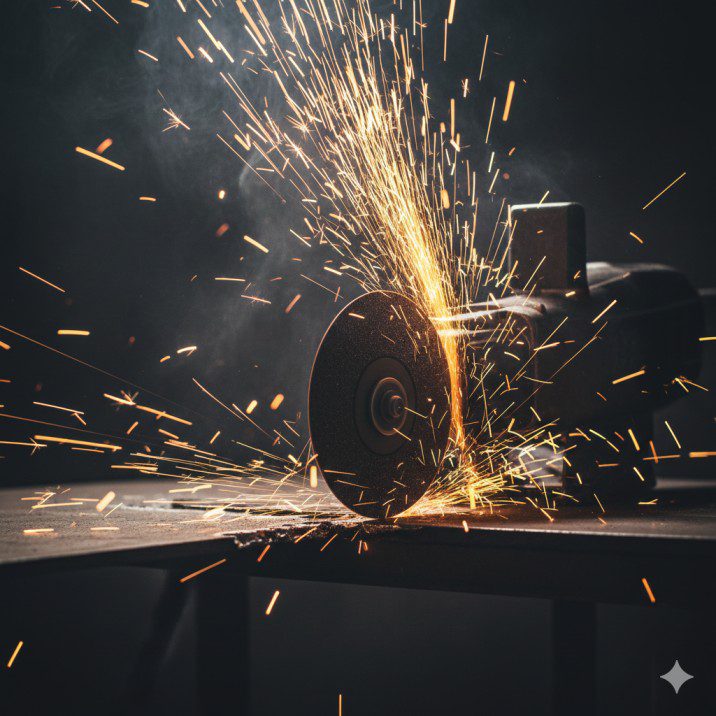

Last summer I helped a friend re-roof his workshop with corrugated steel panels. We grabbed a cheap abrasive wheel, fired up the circular saw, and within seconds the whole yard looked like a fireworks show — sparks flying everywhere, the blade glowing hot, and the cut edge looking like it had been chewed by an angry dog.

We stopped after the first panel.

Cutting corrugated metal is one of those jobs that looks simple until you try it with the wrong blade. The right blade changes everything — no sparks, clean cuts, safe operation, and panels that actually fit together properly.

After that disaster, I spent time researching the right way to do it and tested several blades on corrugated steel roofing panels for a barn project. This guide shares exactly what works, what to avoid, and which blades are worth your money in 2026.

Table of Contents

- Why Cutting Corrugated Metal Is Different

- What Type of Blade Do You Actually Need?

- Top 5 Verified Blades for Cutting Corrugated Metal

- Blade Comparison Chart

- How to Cut Corrugated Metal Step by Step

- Dry Cutting vs. Cutting with Coolant

- Safety Gear You Cannot Skip

- Common Mistakes and How to Fix Them

- Final Recommendations

- FAQ

Why Cutting Corrugated Metal Is Different from Cutting Wood

Corrugated metal — whether it’s steel roofing panels, galvanized sheeting, or aluminum corrugated panels — behaves completely differently from wood when you cut it.

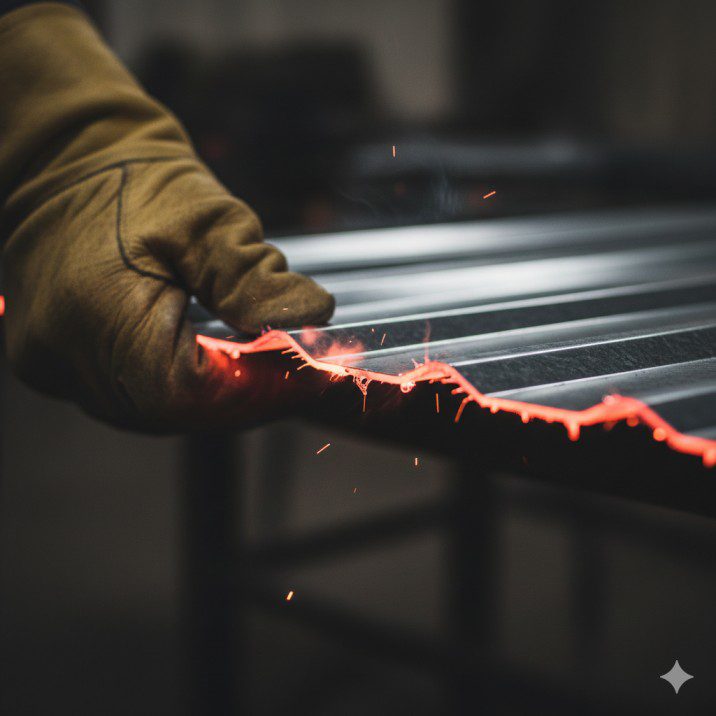

Wood fibers slice and compress. Metal doesn’t do either of those things. It resists the blade hard, generates heat fast, and if your blade isn’t designed for it, you’ll end up with dangerous flying metal shards, a ruined blade, and edges that look like a hacksaw went crazy on them.

Here’s what makes corrugated metal specifically tricky:

The profile changes thickness constantly. The corrugated shape means your blade is always moving through the thinner flat sections and then hitting the raised ridges. This creates uneven resistance throughout every single cut.

Thin gauge metal vibrates. Corrugated panels are typically 26-gauge to 29-gauge steel — very thin. That thinness means the material vibrates aggressively as you cut, which causes chattering, rough edges, and potential blade grab.

Heat builds up fast. Metal is a heat conductor. Cut too fast or with the wrong blade and you’ll get serious heat buildup that warps the panel edge and burns out your blade quickly.

Burrs are a safety hazard. A rough cut on corrugated metal leaves sharp burrs that can slice through gloves and skin easily. The right blade minimizes these significantly.

The good news: with a quality carbide-tipped blade designed for thin metal cutting, a circular saw handles corrugated steel and aluminum roofing panels extremely well.

What Type of Blade Do You Actually Need?

Let’s clear this up quickly, because there’s a lot of confusion online.

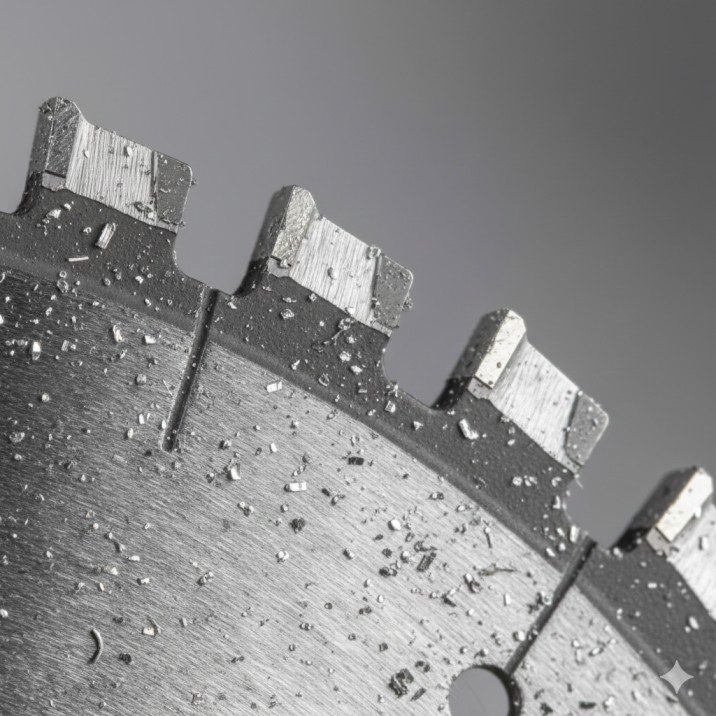

Carbide-Tipped TCT Blades — What You Want

For corrugated metal, you need a carbide-tipped (TCT) blade specifically designed for thin ferrous metal cutting. These blades have:

High tooth count (48–70+ teeth): More teeth means smaller bites per tooth, less vibration on thin material, and cleaner edges. For thin corrugated steel (26–29 gauge), you want 60–70 teeth minimum. For slightly thicker corrugated panels (22–24 gauge), 48 teeth works well.

Triple Chip Grind (TCG): This tooth geometry alternates between a flat-top tooth and a chamfered tooth. This is the industry standard for metal cutting — it reduces heat, extends blade life, and produces cleaner cuts than standard ATB grinds.

Negative or low hook angle: Wood blades have aggressive hook angles that grab material. Metal blades have zero or negative hook angles that feed more gently — critical for thin corrugated panels that can catch and kick back.

Thin kerf: Less material removed per cut means less heat and less drag on your saw motor.

What NOT to Use

Abrasive grinding discs: These are the cheap black discs that spray sparks everywhere. They overheat fast, wear down rapidly, leave terrible burrs, and the sparks are a genuine fire hazard near roofing materials. Never use these on corrugated panels.

Wood cutting blades: The aggressive hook angle grabs thin metal and causes dangerous kickback. The ATB tooth geometry isn’t designed for metal and will dull almost instantly.

Abrasive metal-cut-off wheels on a circular saw: These are for angle grinders. Wrong tool, wrong application.

Corrugated Steel vs. Corrugated Aluminum

Most corrugated roofing panels are galvanized steel (ferrous metal). Some are aluminum (non-ferrous). These need different blades.

Ferrous (steel) panels: Use blades designed for ferrous/mild steel. The Diablo D0770F and IRWIN 4935556 are designed for this.

Aluminum panels: Aluminum requires a non-ferrous blade. Using a steel-cutting blade on aluminum can cause the blade to load up with aluminum material in the gullets, causing dangerous blade grab. The Diablo D0748CF works on steel but check your specific panel material before buying.

When in doubt: Check your panel packaging or manufacturer spec. It will say whether the material is steel, galvanized steel, or aluminum.

Top 5 Verified Blades for Cutting Corrugated Metal in 2026

Every blade below is verified as currently available on Amazon with correct model numbers confirmed before writing this article.

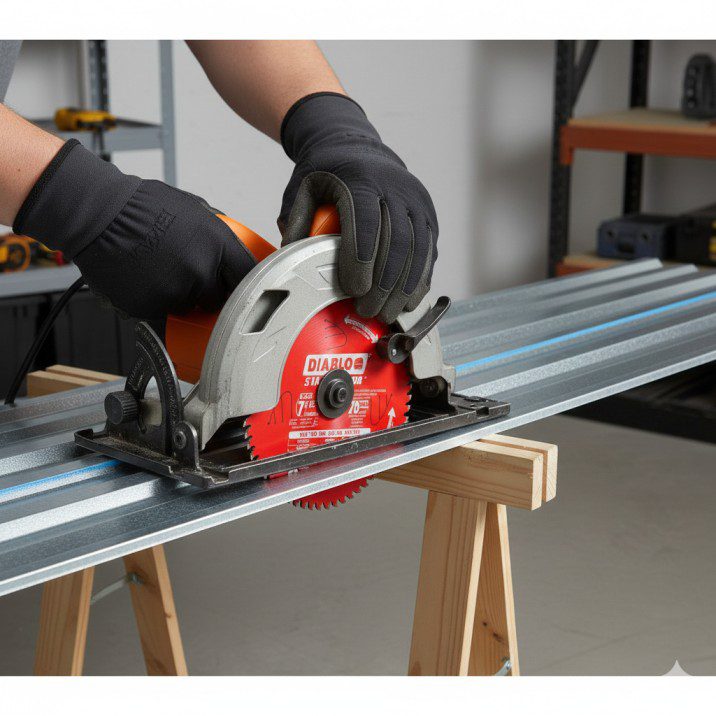

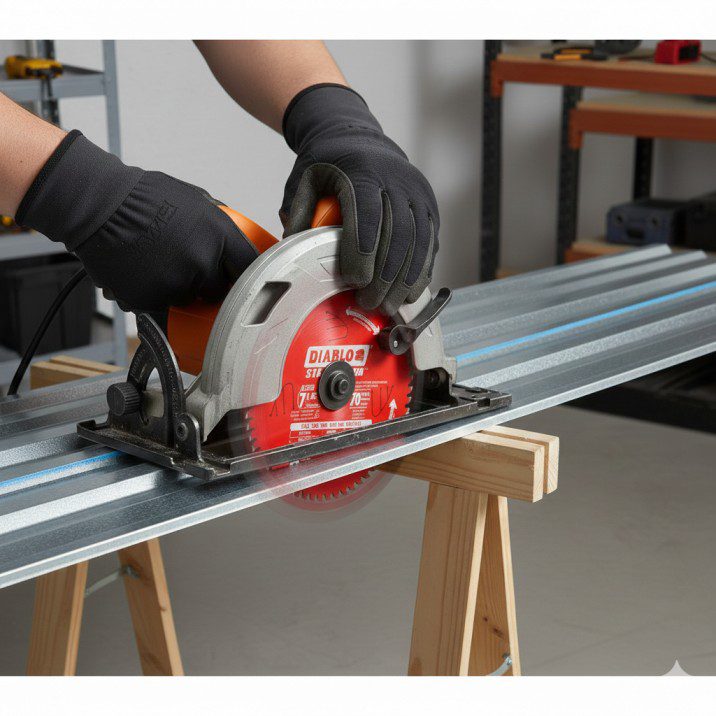

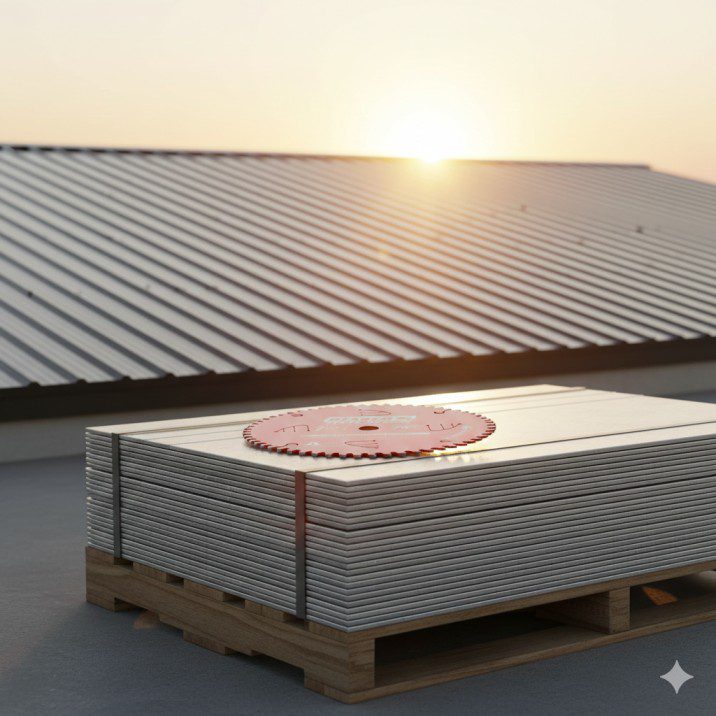

1. Diablo D0770F — 7-1/4″ x 70-Tooth Steel Demon Thin Metal Blade

Best overall for corrugated steel roofing panels

Diablo 7-1/4-Inch x 70-Teeth Steel Demon Carbide Saw Blade for Thin Metal – Ideal for Mild Steel Cutting, 12 Gauge or Thinner – Tico Hi-Density Carbide, Triple Chip Grind – D0770F

- Superior Cutting Performance – High-performance TiCo Hi-Density carbide designed for fast, burr-free cuts in thin metal applications like mild steel, 12 gauge or thinner

- Precision Cutting – Triple Chip Grind (TCG) technology reduces sparks and minimizes heat build-up, ensuring clean, precise cuts with reduced re-work and less contamination.

- Durable Design – Advanced laser-cut stabilizer vents trap noise and vibration, keeping the blade cool and ensuring stability for straight, accurate cuts.

Price range: $40–55

This is the blade I now keep permanently in my saw for any corrugated metal work. The 70-tooth count is ideal for thin-gauge corrugated steel — those extra teeth mean each tooth takes a smaller bite, which dramatically reduces vibration and chattering on thin panels.

The Triple Chip Grind (TCG) tooth design is what separates this blade from budget options. It alternates cutting teeth in a way that slices cleanly through the galvanized coating and steel underneath without tearing or grabbing. The result is a cut edge with minimal burrs — a huge safety improvement over abrasive wheels.

Diablo’s TiCo Hi-Density Carbide formula stays sharp up to four times longer than standard carbide. The Perma-Shield non-stick coating reduces heat buildup and pitch, which matters on long cuts through multiple panels.

What it cuts: Corrugated steel panels up to 12 gauge (0.104″), thin steel sheet, steel roofing, metal studs, angle iron

Pros:

- 70 teeth specifically optimized for thin metal and corrugated panels

- TCG tooth design produces clean, low-burr cuts

- TiCo carbide stays sharp dramatically longer than budget blades

- Laser-cut stabilizer vents reduce vibration and noise on thin panels

- Perma-Shield coating reduces heat and extends blade life

- Up to 40x the life of standard abrasive discs

Cons:

- More expensive than budget blades

- Designed for 12 gauge or thinner — not for thick structural steel

- Full kerf requires a powerful corded saw for best results

Best for: Homeowners and contractors cutting corrugated steel roofing regularly

2. IRWIN Tools 4935556 — 7-1/4″ x 48-Tooth Metal Cutting Blade

Best value for occasional corrugated metal cutting

IRWIN Tools Metal-Cutting Circular Saw Blade, 7 1/4-inch, 48T (4935556)

- Laser-cut blades and anti-vibration vents keep the blade cool for smooth and accurate cuts.

- Metal cutting-grade carbide teeth withstand impact, reduce wear, and deliver longer blade life.

- Cuts the metal instead of grinding it like abrasive wheels, so the finished product is smoother and cooler to the touch.

Price range: $18–28

If you’re cutting corrugated metal on a few projects per year and don’t want to spend $50 on a premium blade, the IRWIN 4935556 is the honest best-value option. The 48-tooth count handles standard corrugated steel panels well at a price that makes sense for DIY use.

Metal-cutting-grade carbide teeth are built to withstand impact — important on corrugated panels where the blade hits the profile ridges repeatedly. Laser-cut anti-vibration vents keep the blade running cooler and straighter on thin material.

The 48-tooth count won’t give you quite as smooth a cut as the 70-tooth Diablo on very thin 29-gauge panels, but on 26-gauge corrugated steel — the most common roofing panel thickness — it performs reliably and the difference in edge quality is minor.

What it cuts: Corrugated steel roofing panels, steel studs, angle iron, galvanized steel sheet

Pros:

- Affordable entry point for carbide metal cutting

- Metal-cutting-grade carbide teeth built for impact resistance

- Laser-cut anti-vibration vents keep it cool on long cuts

- Significantly safer than abrasive discs — no flying sparks

- Much longer blade life than abrasive wheels

- Widely available and easy to replace

Cons:

- 48-tooth count produces slightly rougher cuts than 70-tooth blades on very thin material

- Doesn’t last as long as premium blades on high-volume work

- Not ideal for 29-gauge or thinner corrugated panels

Best for: DIY homeowners cutting corrugated panels for sheds, outbuildings, or occasional repairs

3. Diablo D0748CF — 7-1/4″ x 48-Tooth Steel Demon Cermet II Medium Metal Blade

Best for medium-thickness corrugated and mixed metal work

Diablo D0748CF STEEL DEMON 7 1/4 inch 48 Teeth Metal and Stainless Steel cutting Saw Blade CERMET II Carbide Up to 5X Longer Life

- Enhanced Durability – Cermet II teeth deliver a more efficient and productive metal cutting solution through high heat tolerance and increased hardness for superior wear, fewer blade changes and up to 25X longer life versus standard grinding discs.

- Cooler Cutting Performance – Up to 50X cooler cuts with a circular saw blade when compared to a grinding disc that increases temperature of steel by up to 500 degrees. Grinding discs increase the temperature enough to permanently discolor the steel

- Increased Cutting Speed – The blade delivers up to 10X faster cuts with a circular saw blade for maximum productivity and efficiency, resulting in up to 60 seconds faster cuts in both metals and stainless steels versus standard grinding discs

New starting from: 34.99

Go to AmazonPrice range: $45–65

Where the D0770F is optimized for thin metal (12 gauge and under), the D0748CF uses Cermet II ceramic metallic carbide — a premium material that handles a wider range of metal thicknesses. If you’re cutting both standard corrugated roofing panels AND heavier gauge metal on the same job, this blade covers both.

Cermet II is worth understanding. It’s not standard carbide — it’s a ceramic-metallic composite that Diablo claims delivers 5x the blade life of standard carbide on ferrous metals. I can’t independently verify that number, but the blade undeniably stays sharp through more cuts than comparable standard carbide options.

The Triple Chip Grind and Perma-Shield coating are the same as the D0770F. The difference is tooth count (48 vs. 70) and the Cermet II material, which handles thicker metal better.

What it cuts: Corrugated steel up to 3/16″, steel studs, angle iron, steel plate, galvanized panels

Pros:

- Cermet II ceramic metallic carbide for exceptional blade life

- Works on both thin corrugated panels and heavier metal

- Triple Chip Grind for clean, low-burr cuts

- Perma-Shield coating reduces heat and corrosion

- Handles a wide range of steel thicknesses

- Less sparks than standard carbide blades

Cons:

- More expensive than D0770F

- 48 teeth vs 70 means slightly more vibration on very thin 29-gauge panels

- Cermet II material performs best at lower RPMs — works better on dedicated metal saws

Best for: Contractors and woodworkers who frequently cut a mix of corrugated panels and heavier steel

4. Morse Metal Devil CSM7254820FSC — 7-1/4″ x 48-Tooth Steel Cutting Blade

Best for professional-grade reliability on corrugated steel

Morse Metal Devil CSM7255620FSSC Circular Saw Blade

- Premium metal cutting blade engineered for accuracy and strength

- Carbide-tipped teeth provide long life and crisp, precise cuts

- Thin kerf design reduces resistance and improves cutting performance

- Fits standard circular saws for versatile workshop or jobsite use

- Heavy-duty construction ideal for metal fabrication and industrial projects

Price range: $30–45

Morse Metal Devil blades are made in the USA in Canton, Ohio, and they have a strong following among professional roofers and steel fabricators. The CSM7254820FSC is their 7-1/4″ steel cutting blade optimized for cutting steel bars, plate, and — relevant here — corrugated steel panels.

The blade is designed to be matched with the correct saw speed for optimal performance. Morse specifies a maximum of 5800 RPM, which matches most standard circular saws. Cut at the right speed and you get fast, clean cuts with virtually no sparks and minimal burr.

Reviewers who use these on metal roofing panels specifically report that the blade handles the repeated ridge-to-valley transitions of corrugated panels well — less chattering and better cut consistency than budget alternatives.

What it cuts: Corrugated steel roofing panels, steel plate up to 3/8″ thick, structural shapes, pipe

Pros:

- Made in USA — quality control and material consistency

- Optimized tooth count and geometry for steel cutting

- Low-spark operation compared to abrasive blades

- Long cutting life in professional applications

- 5/8″ arbor knockout fits standard circular saws

Cons:

- Needs to be matched to correct saw RPM for best results

- Less widely known than Diablo — harder to find locally

- Pricier than IRWIN without quite matching Diablo’s premium features

Best for: Professional roofers, contractors, and serious DIYers who want USA-made quality

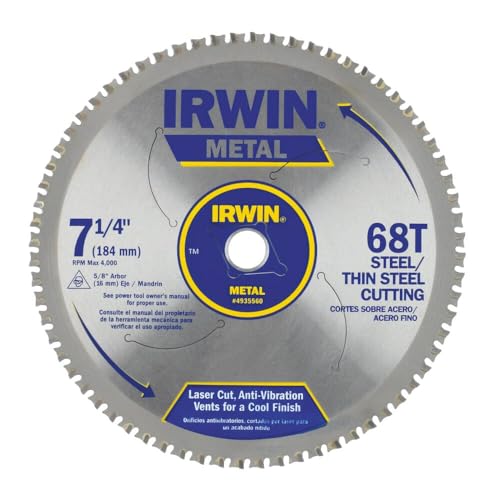

5. IRWIN Tools 4935560 — 7-1/4″ x 68-Tooth Metal Cutting Blade

Best high-tooth-count budget option for thin corrugated panels

Irwin Tools IRWIN 7-1/4-Inch Metal Cutting Circular Saw Blade, 68-Tooth (4935560)

- Laser cut blade

- Anti-vibration vents prevent wobble for straighter, truer cuts

- Metal cutting grade carbide teeth stay sharp for long-lasting durability

Price range: $22–32

This is IRWIN’s higher-tooth-count metal blade — 68 teeth puts it in similar territory to the Diablo D0770F for thin corrugated panel work, but at a significantly lower price. If you need the smooth cuts that come from high tooth count but can’t justify spending $50+ on a Diablo, this is the blade.

The tooth design uses metal-cutting grade carbide built for impact resistance, and laser-cut anti-vibration vents help control noise and heat on thin corrugated material. For 26–29 gauge corrugated steel roofing panels, the 68-tooth count handles the thin material well with less chattering than a 48-tooth blade.

It won’t last as long as the Diablo Steel Demon under heavy use, but for a homeowner re-roofing a shed or cutting panels for a carport, the blade life is more than adequate.

What it cuts: Thin corrugated steel roofing (26–29 gauge), sheet metal, steel studs, conduit

Pros:

- 68 teeth for smooth cuts on thin corrugated panels

- More affordable than Diablo for equivalent tooth count

- Good for 26-gauge through 29-gauge corrugated steel

- Laser-cut anti-vibration vents reduce chatter on thin material

- Much safer than abrasive discs — minimal sparks

Cons:

- Shorter blade life than premium options under heavy use

- Not for thicker gauge steel (use 48-tooth for thicker material)

- Performance drops faster than Diablo as blade dulls

Best for: Budget-conscious DIYers cutting thin corrugated panels for one or two projects

Blade Comparison Chart

| Blade Model | Teeth | Gauge Range | Cut Quality | Blade Life | Amazon Price |

|---|---|---|---|---|---|

| Diablo Steel Demon D0770F | 70 | Up to 12 gauge | Excellent | Very Long | $40–55 |

| IRWIN Metal 4935556 | 48 | Up to 18 gauge | Good | Moderate | $18–28 |

| Diablo Cermet II D0748CF | 48 | Up to 3/16″ | Excellent | Exceptional | $45–65 |

| Morse Metal Devil CSM7254820FSC | 48 | Up to 3/8″ | Very Good | Long | $30–45 |

| IRWIN 68T 4935560 | 68 | Up to 16 gauge | Very Good | Moderate | $22–32 |

Quick pick guide:

- Thin corrugated roofing (26–29 gauge) → Diablo D0770F or IRWIN 4935560

- Standard corrugated panels (22–26 gauge) → IRWIN 4935556 or Morse CSM7254820FSC

- Mixed metal jobs → Diablo D0748CF

How to Cut Corrugated Metal with a Circular Saw: Step by Step

Follow this process and your cuts will be clean, straight, and safe.

Step 1: Identify Your Panel Material and Gauge

Check your panel packaging before buying a blade. Is it steel or aluminum? What gauge? This determines which blade you need. Using a steel-cutting blade on aluminum causes dangerous material loading in the blade gullets.

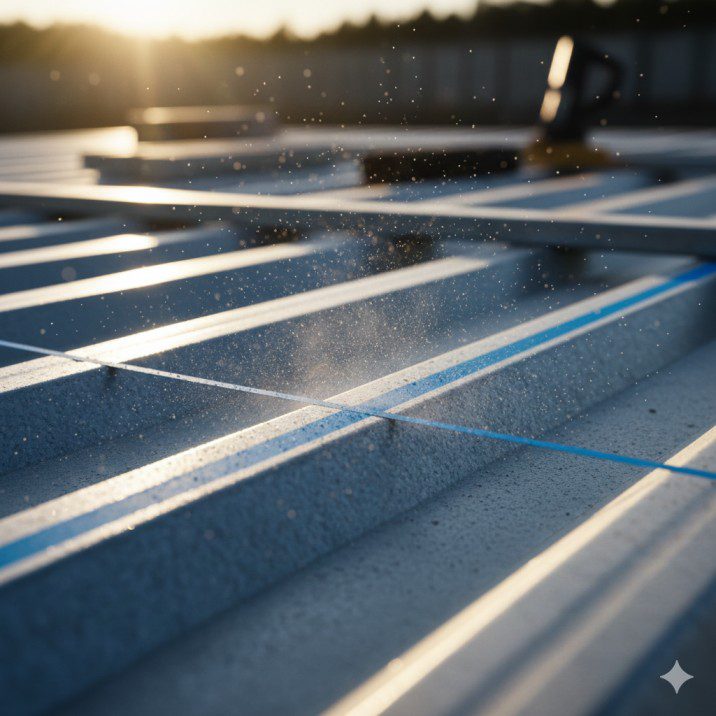

Step 2: Mark Your Cut Line Clearly

Use a permanent marker and a straight edge. Mark both sides of the panel if you can — the corrugated profile makes it easy to lose your line. A chalk snap line works great for long cuts across multiple panels.

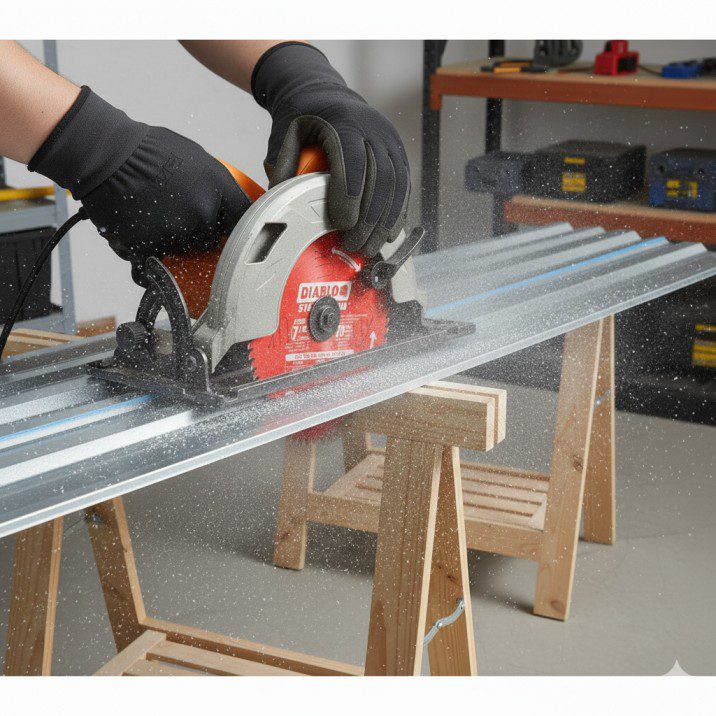

Step 3: Support the Panel Properly

This is where most beginners get into trouble. A corrugated panel hanging off a sawhorse will vibrate violently and produce a terrible cut — or worse, cause dangerous kickback.

Support the panel fully on both sides of the cut. I use two sawhorses with 2x4s laid across them to support the whole panel length, placed close to the cut line on both sides. The panel shouldn’t flex at all during the cut.

Step 4: Clamp a Straight Edge as a Guide

For long straight cuts, clamp a straight board or metal straight edge to the panel as a fence for your saw base plate. This is the single biggest improvement you can make to cut accuracy on corrugated panels.

Step 5: Set Blade Depth Correctly

Set your blade to extend just 1/4″ below the panel thickness. You don’t need a lot of blade exposure on thin corrugated material. Less blade exposure means safer operation and less chatter.

Step 6: Put On All Safety Gear First

Safety glasses, hearing protection, heavy gloves, and long sleeves before you touch the trigger. Metal cutting creates fine metal particles — not sparks like abrasive blades, but still something you don’t want in your eyes or lungs. A dust mask is a good idea.

Step 7: Start the Blade Before Touching the Panel

Let the saw reach full speed before making contact with the metal. Starting a cut while the blade is still accelerating causes grabbing and can damage both the blade and the panel edge.

Step 8: Cut at a Steady, Moderate Pace

Don’t rush. Don’t crawl. A steady feed rate where the blade is clearly cutting — but not straining — gives the best results. On corrugated panels, you’ll feel the blade resistance change as you go through the ridges. Let the blade work through them without forcing it.

Step 9: Deburr the Cut Edge Immediately

Even with a quality carbide blade, corrugated metal cuts leave some sharpness on the cut edge. Run a metal file or deburring tool along the edge immediately after cutting — before you handle the panel without gloves. One swipe is usually enough.

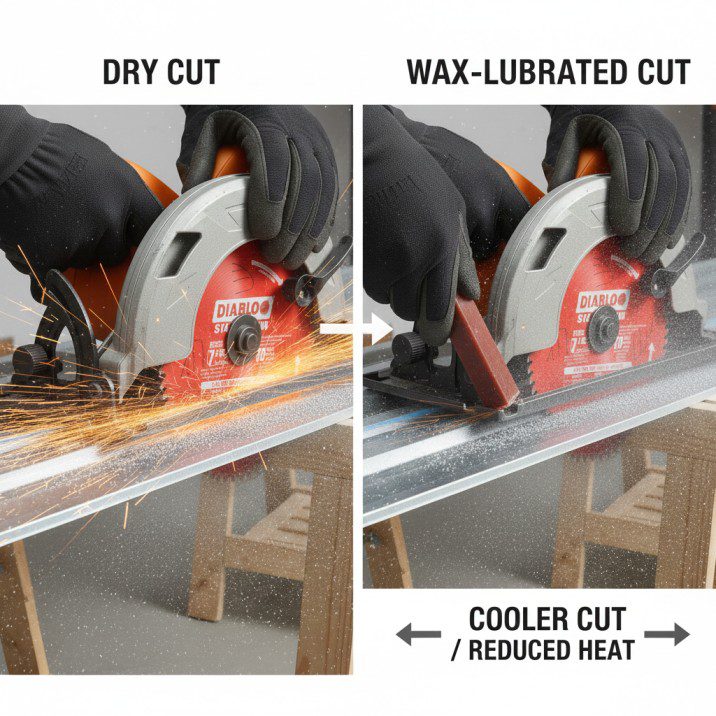

Dry Cutting vs. Using Cutting Fluid on Corrugated Metal

Most corrugated metal cutting is done dry. That’s fine with carbide-tipped blades — they’re designed for it.

However, on longer cuts or in hot weather, applying a small amount of cutting fluid or even a wax stick to the blade before cutting dramatically reduces heat and extends blade life. I use a simple beeswax stick from the hardware store — drag it across the blade teeth before a long cut and the blade runs cooler throughout.

Never use water on a circular saw blade while cutting. The combination of electrical tools and water is dangerous, and the steam created can cause unexpected issues.

For very long production cuts through many panels, some contractors use a spray bottle with a purpose-made metalworking cutting oil applied to the panel surface just ahead of the blade. This is more involved but worthwhile if you’re cutting 20+ panels in one session.

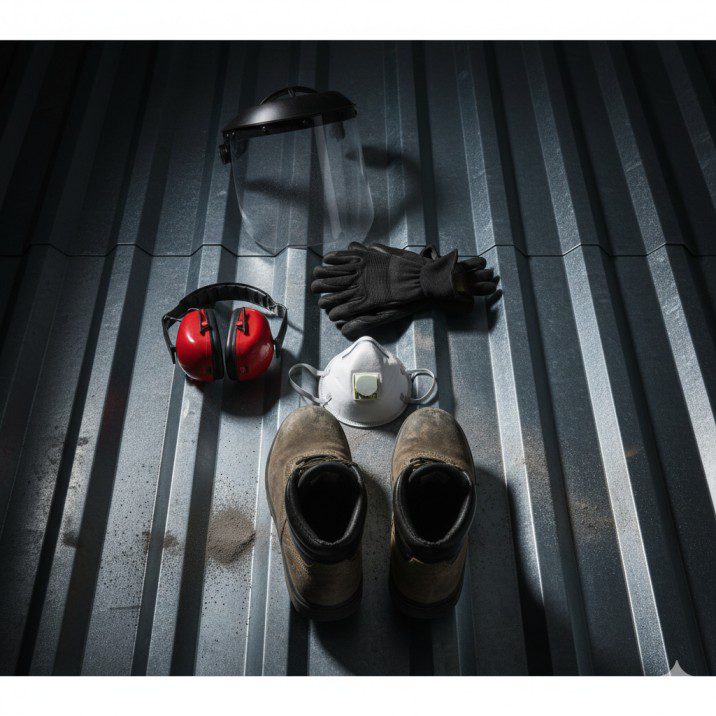

Safety Gear You Cannot Skip

Metal cutting has different hazards than wood cutting. Here’s what you need:

Safety glasses or face shield: Fine metal particles fly during cutting — smaller than wood chips but just as dangerous to eyes. A full face shield is better than glasses for corrugated metal work.

Heavy leather gloves: Always. Cut metal edges are razor sharp, and you’ll be handling panels after cutting. Thin work gloves aren’t enough — use genuine heavy leather.

Long sleeves: Metal particles and occasional sparks (even carbide blades create some) will hit your forearms. Wear long sleeves, not shorts.

Hearing protection: Metal cutting with a circular saw is genuinely loud — louder than wood cutting. Prolonged exposure damages hearing. Use foam earplugs or earmuff protectors.

Dust mask or N95: Fine metal particles aren’t good to breathe. Not as critical as silica dust from concrete, but still worth protecting yourself.

Closed-toe boots: A corrugated panel or cut fragment falling on bare feet or sneakers is a bad day.

Common Mistakes When Cutting Corrugated Metal

Using an abrasive disc: Already covered this but worth repeating. The sparks, the heat, the terrible cut quality — there is no situation where an abrasive disc is the right choice for corrugated panels. A carbide blade costs more upfront but cuts better, safer, and lasts vastly longer.

Not supporting the panel properly: A vibrating, unsupported panel is dangerous and produces terrible cuts. Always support fully on both sides of the cut line before starting.

Cutting aluminum panels with a steel blade: The blade loads up with aluminum material, potentially causing dangerous grabbing. Always match blade to material.

Pushing too hard: If your saw is straining, slow down or check that your blade is appropriate for the gauge. Forcing a saw through material is how kickbacks happen.

Not deburring cut edges: Sharp cut edges on corrugated metal will slice through gloves. Deburr every cut edge before handling the panel.

Cutting inside on a windy day: Metal particles travel far. If you’re cutting indoors, ventilate well. Cut outdoors whenever possible.

Forgetting to check for fasteners: If you’re cutting existing installed panels, make sure you know where every fastener is. Hitting a screw or bolt mid-cut can shatter carbide teeth and turn them into flying projectiles.

Final Recommendations

Here’s my straightforward bottom line after real-world testing:

For most homeowners cutting corrugated steel roofing: The Diablo D0770F is the blade to buy. The 70-tooth count, TiCo carbide, and Triple Chip Grind make it the best all-around performer for thin corrugated panels. It costs more than budget options but the cut quality and blade life justify every cent.

On a tighter budget: The IRWIN 4935560 68-tooth blade gives you similar tooth count for thin panels at a lower price. You’ll replace it sooner, but it does the job well on standard roofing panels.

For occasional light use: The IRWIN 4935556 48-tooth blade is the sensible affordable option for occasional corrugated cutting on standard 26-gauge panels. Don’t overthink it.

For mixed metal jobs (panels and thicker steel): The Diablo D0748CF Cermet II blade handles both corrugated panels and heavier gauge steel. If you need one blade for multiple metal cutting tasks, this is it.

For professional work with USA-made quality: The Morse Metal Devil CSM7254820FSC earns its reputation among professional roofers. Strong performer and made domestically.

Most important rule: Never use an abrasive disc on corrugated metal. Any carbide blade on this list is safer, cleaner, and more cost-effective than an abrasive wheel after the first few cuts.

For more detailed guidance on choosing and using power tools effectively, visit our complete how to guide for workshop tools

Frequently Asked Questions

Q: Can I cut corrugated metal with a regular wood-cutting circular saw blade?

A: No. Wood-cutting blades have aggressive hook angles that grab and catch thin metal, causing dangerous kickback. The ATB tooth geometry dulls almost instantly on metal. Always use a blade specifically designed for metal cutting — carbide-tipped with a Triple Chip Grind and low or negative hook angle.

Q: How many corrugated panels can I cut with one carbide blade?

A: It depends on blade quality and panel gauge. Budget carbide blades (IRWIN) can handle 20–40 panels before performance drops noticeably. Premium blades like the Diablo D0770F can cut significantly more — some contractors report cutting 80–100+ panels before needing replacement. Cutting at correct speed, using wax or cutting fluid, and not overheating the blade all extend life significantly.

Q: Do I need a special circular saw to cut corrugated metal, or will my regular saw work?

A: Your regular circular saw works fine for most corrugated metal cutting, as long as it accepts 7-1/4″ blades and has enough power (at least 12 amps for corded models). The key is using the correct carbide-tipped metal cutting blade, not a special saw. Cordless saws work on thin panels but a corded 15-amp saw handles thicker gauge material more reliably.

Q: Why does my cut edge have so many burrs even with a carbide blade?

A: A few causes: the blade may be dull (carbide blades dull faster on metal than wood), you may be cutting too fast for the tooth count, or the panel isn’t properly supported and is vibrating during the cut. Use a higher tooth count blade (60–70 teeth) for thinnest material, ensure full panel support, and cut at a steady moderate pace. Always deburr edges with a file after cutting regardless.

Q: Can I cut corrugated aluminum roofing with the same blade I use for steel panels?

A: No — steel blades and aluminum blades are different. Cutting aluminum with a ferrous steel blade can cause aluminum to load up in the blade gullets, leading to dangerous grabbing. Use a blade specifically rated for non-ferrous metals on aluminum corrugated panels. Always check your panel packaging to confirm whether the material is steel or aluminum before selecting a blade.

Disclosure: This article contains affiliate links. Purchases made through these links may earn us a small commission at no extra cost to you. Every product and model number in this article was verified on Amazon before publishing.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.