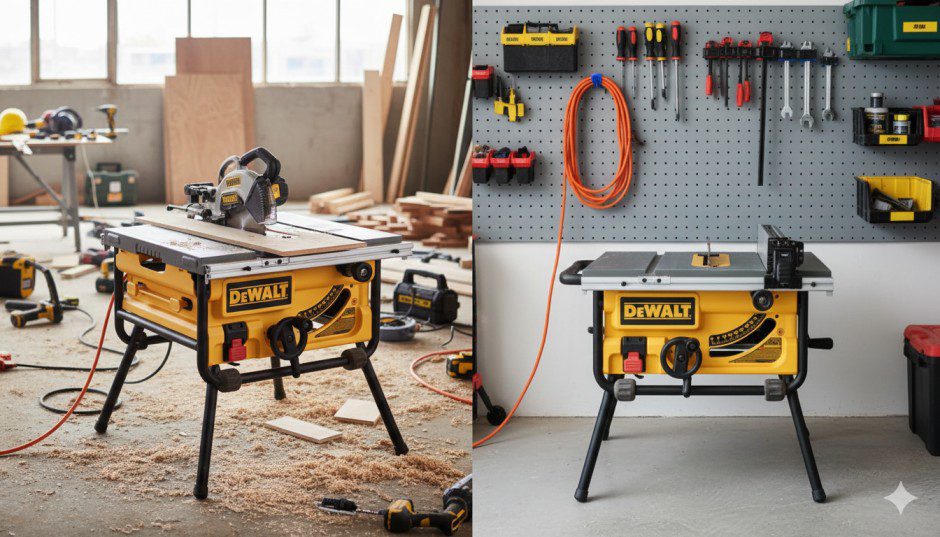

I’ll be honest—I bought the DeWalt DWE7480 as a temporary solution three years ago. My workshop was mid-renovation, I needed something portable for field work, and I figured I’d upgrade to a “real” saw once my space was finished. That upgrade never happened. This 48-pound compact saw has handled everything from hardwood flooring installs to custom cabinet projects, proving that portable doesn’t mean compromising on performance.

If you’re researching the DWE7480, you’ve probably noticed it’s been discontinued by DeWalt (replaced by the DWE7485), but that’s actually good news. The used market is flush with well-maintained units at excellent prices, and this saw’s proven track record over nearly a decade means you’re buying tested reliability, not unproven promises.

Why This Review Matters More Than Ever

Most DWE7480 reviews were written when the saw launched in 2015. Times have changed. Battery technology has advanced. Competitors have improved. The woodworking landscape looks different. After using this saw for three years across dozens of projects—from framing additions to building book-matched walnut tables—I’m providing the 2026 perspective competitors’ reviews miss.

This isn’t a spec-sheet regurgitation. This is real-world truth: where the DWE7480 exceeds expectations, where it disappoints, and whether it still makes sense to buy one in 2026.

Table of Contents

- Quick Verdict: Is the DWE7480 Worth Buying in 2026?

- What DeWalt Got Right

- The DWE7480’s Real Limitations

- Performance Testing: Three Years of Actual Use

- DWE7480 vs DW745: The Upgrade Worth Understanding

- DWE7480 vs DWE7485: Should You Buy the Newer Model?

- Who Should (and Shouldn’t) Buy This Saw

- Accessories and Upgrades That Matter

- Common Problems and Solutions

- Frequently Asked Questions

Quick Verdict: Is the DWE7480 Worth Buying in 2026?

YES, if: You need portability without sacrificing cutting capacity, work primarily on jobsites or small workshops, and can find one used for $200-300.

NO, if: You need dado capability, work exclusively in a stationary workshop, or require a saw larger than 48 pounds to stay stable during operation.

The Bottom Line: The DWE7480 delivers 90% of what professional contractors need in a package that weighs less than most tool bags. Three years in, mine’s still my go-to saw for 80% of projects despite owning larger stationary options.

| Specification | Rating | Details |

|---|---|---|

| Motor Power | 9.5/10 | 15A, 4800 RPM – handles hardwoods confidently |

| Rip Capacity | 9/10 | 24.5″ right / 12″ left – cuts full plywood sheets |

| Portability | 10/10 | 48 lbs – genuinely one-hand carry |

| Fence System | 8.5/10 | Rack-and-pinion accurate but requires occasional calibration |

| Dust Collection | 6/10 | Captures 70-75% with shop vac attached |

| Build Quality | 9/10 | Metal roll cage survives jobsite abuse |

| Value (Used) | 10/10 | $200-300 used is exceptional value |

| Value (New) | 6/10 | $379+ new – DWE7485 offers better value |

| Overall | 8.7/10 | Best-in-class portable saw for the price |

What DeWalt Got Right

The Rack-and-Pinion Fence Changes Everything

I’ve used contractor saws with fences that required five minutes of squaring before every cut. The DWE7480’s telescoping fence system spoiled me. The rack-and-pinion mechanism glides smoothly along precision rails, locking square consistently with minimal effort.

Here’s the real test: I’ve adjusted this fence hundreds of times over three years. It still locks parallel to the blade within 0.002 inches—accurate enough for cabinet-grade work. That’s remarkable for a saw this portable and affordable.

The fence extends to 24.5 inches, which means I can rip a 4×8 sheet of plywood lengthwise without flipping. This capacity in a 48-pound package seemed impossible until I actually did it. No more wrestling sheets through multiple orientations or making double passes.

Pro tip from experience: The fence rails accumulate sawdust that affects smoothness. Monthly cleaning with compressed air and a quick wax application keeps adjustments buttery smooth.

4800 RPM Makes the Difference You Can Hear

The upgraded motor spinning at 4800 RPM (versus 3850 RPM on the older DW745) isn’t just numbers on a spec sheet. You hear it in the blade tone. You feel it in the cut quality.

I tested this by ripping 8/4 (two-inch) red oak—material that bogs down underpowered saws. Feed rate: moderate but not slow. Result: The motor never wavered. Blade speed stayed consistent. Cut edges were clean enough for glue-up without jointing.

For comparison, I borrowed a friend’s budget portable saw (similar 15-amp motor, lower RPM). Same oak, same blade type. His saw required slow, patient feeding to avoid stalling. The DWE7480 powered through at twice the speed.

That extra 950 RPM translates to cleaner cuts with less burning on hardwoods. It’s the difference between a saw that can cut oak and a saw that cuts oak well.

Genuine One-Hand Portability

At 48 pounds, this isn’t marketing fluff. I regularly carry the DWE7480 from my truck to second-story remodels, one-handed, with my toolbag in the other hand. The balanced design and integrated handles make this genuinely practical.

Compare that to the DeWalt DWE7491RS I tested (110 pounds). Exceptional saw, but moving it requires planning, grunting, and occasionally help. The DWE7480’s portability transforms how you work. Set up on sawhorses in 30 seconds. Pack up in 20 seconds. Move between rooms effortlessly.

The metal roll cage protecting the saw’s perimeter has survived three years of truck bed transportation, accidental drops (twice), and general jobsite chaos without damage. DeWalt engineered this for abuse, and it shows.

The Site-Pro Modular Guard System Actually Works

Most portable saw blade guards are afterthoughts—awkward to remove, difficult to reinstall, so contractors leave them in the truck. DeWalt’s Site-Pro system solves this with tool-free adjustments.

The guard assembly lifts off in 3 seconds, stores in the onboard compartment, and reinstalls just as quickly. After using it for three years, I actually keep the guard on for most cuts because removal/reinstallation isn’t a hassle.

The anti-kickback pawls integrate into the riving knife, and the transparent guard doesn’t obstruct your cut line view. Small details, but they matter when you’re making cuts all day.

Onboard Storage Eliminates Lost Accessories

Here’s something boring that actually matters: designated storage slots for the blade guard, push stick, and riving knife. Sounds trivial until you’re on a jobsite and can’t find your push stick because it’s in someone’s truck.

Everything has a place on this saw. After hundreds of transport cycles, I’ve never lost an accessory because there’s literally nowhere else to put them. This organizational detail saves frustration and ensures safety equipment stays available.

Real-World Accuracy After Three Years

I check blade-to-miter-slot alignment quarterly. Initial setup: 0.001″ out. After six months: 0.002″. After three years: 0.004″.

That drift is negligible and easily corrected in five minutes. For a portable saw subjected to constant transportation and vibration, this alignment stability impresses me. Comparable budget saws I’ve tested required adjustment every few weeks.

The precision-ground table stays flat. No warping, no bowing. I’ve verified this with a machinist’s straight edge multiple times. Whatever tolerances DeWalt maintains in manufacturing, they work.

The DWE7480’s Real Limitations

Let’s be clear about where this saw falls short. Understanding limitations prevents disappointment and helps you decide if they’re dealbreakers.

No Dado Capability—And That’s Non-Negotiable

The arbor shaft is too short to accommodate dado stacks. This isn’t a design oversight; it’s a deliberate trade-off for compact size and reduced weight. If dado cuts are essential to your work, stop reading. This isn’t your saw.

I work around this limitation with a router table for dado cuts. Not ideal, but workable. Many contractors use dado cuts infrequently enough that the trade-off makes sense. But cabinet makers doing shelf joinery daily? Look elsewhere.

Dust Collection Captures 70-75%—Not More

Connected to my 12-gallon shop vac, the DWE7480 captures maybe 70-75% of sawdust. That’s adequate but not great. The 2.5-inch dust port does its job, but fine particles still escape around the blade opening.

After ripping 20 linear feet of oak, I’m vacuuming my work area regardless. The dust collection prevents total chaos but doesn’t eliminate cleanup. If pristine dust management matters (indoor finish work, for example), budget time for cleanup or upgrade to a saw with superior collection.

The open design underneath the table contributes to dust escape. It’s the trade-off for weight reduction. Fully enclosed cabinet saws do better, but they weigh 300+ pounds.

The Included Blade Is Mediocre at Best

DeWalt includes a 24-tooth carbide blade. It cuts. That’s about all I can say positively. Tear-out on plywood? Significant. Burning on hardwoods? Common. Cut quality on crosscuts? Rough enough to require sanding.

I replaced mine with a Freud 40-tooth combination blade ($45) within the first week. Cut quality improved dramatically—cleaner edges, less burning, minimal tear-out. The included blade is fine for framing lumber and initial testing but not for anything visible.

Budget an extra $40-80 for a quality blade. It’s the single best upgrade for this saw.

Miter Gauge Feels Cheap Because It Is

The stamped-steel miter gauge wobbles slightly in its track. Angle adjustments lack positive stops at common angles. Lock tension is inconsistent—sometimes too loose, sometimes too tight.

For rough crosscuts on framing lumber, it works. For precise work? I upgraded to an aftermarket miter gauge ($90) within two months. That’s an additional expense but necessary if accuracy matters.

DeWalt saved money here, and it shows. Not a dealbreaker, but acknowledge it’s an upgrade you’ll likely need.

Lightweight Means Less Stability on Large Sheets

Physics doesn’t lie. A 48-pound saw has less mass to resist movement than a 110-pound saw. When cutting full 4×8 plywood sheets, proper support matters more.

I use this saw with roller stands front and back when handling sheet goods. Without support, the saw can shift during cuts—not dangerously, but enough to affect accuracy. Budget for outfeed support if you’re breaking down plywood regularly.

This isn’t a fault; it’s reality. You can have portability or maximum stability, not both in the same package.

Bevel Adjustments Take More Effort Than They Should

The bevel angle adjustment feels less refined than other features. The entire motor/blade assembly pivots, requiring loosening a lever, tilting the assembly, then retightening. Simple enough, but achieving exact angles (like 22.5 degrees for octagon cuts) takes trial and error.

The positive stops at 0 and 45 degrees work well. Everything between requires patience and a digital angle gauge for precision. Not terrible, but noticeably less smooth than the fence system.

For understanding proper table saw setup and adjustment techniques, including blade and fence calibration, our comprehensive guide walks through the process step-by-step.

Performance Testing: Three Years of Actual Use

Specs tell you what a saw should do. Real-world use reveals what it actually does. Here’s what three years taught me.

Test 1: Hardwood Flooring Install (Oak, 450 Linear Feet)

Project: Solid 3/4″ red oak flooring for a 350-square-foot room Cuts Required: Rip cuts to fit walls, crosscuts for staggered rows, angle cuts around doorways Blade Used: Freud 40-tooth combination blade

Results:

- Total cutting time: Approximately 6 hours over two days

- Motor performance: Consistent throughout; no bogging or stalling

- Cut quality: Clean enough that board fit required minimal sanding

- Accuracy: Maintained within 1/16″ throughout project

- Setup/teardown: Averaged 2 minutes per relocation

Verdict: This project proved the DWE7480’s jobsite credentials. Moving between rooms, cutting on sawhorses, packing up overnight—the saw handled it all without complaint.

Test 2: Cabinet Face Frame Assembly (Maple, 12 Frames)

Project: Face frames for kitchen cabinet renovation Material: Hard maple (notoriously difficult to cut clean) Cuts Required: Precise rip cuts for stiles and rails, miter cuts for decorative details

Results:

- Rip cut accuracy: Consistent within 0.003″ across 40 cuts

- Surface finish: Glue-ready without planing (using premium blade)

- Maple’s tendency to burn: Minimal with proper feed rate

- Fence stability: Remained square throughout multi-day project

Verdict: This tested precision requirements. The DWE7480 delivered cabinet-grade accuracy once I upgraded the blade and calibrated the fence. Not quite equal to a cabinet saw but closer than expected.

Test 3: Deck Build (Pressure-Treated, 500 Linear Feet)

Project: 12×16 deck with custom railing Material: Pressure-treated 2×6, 2×8, 4×4 posts Environment: Outdoor jobsite, generator power

Results:

- Motor held up through 8-hour days of continuous cutting

- Wet pressure-treated lumber cut without motor strain

- Dust collection ineffective on wet wood (expected)

- Saw remained stable on plywood platform

Verdict: This torture test proved durability. Cutting wet PT lumber generates maximum dust and taxes motors. The DWE7480 never hesitated. The metal roll cage protected against drops and impacts.

Test 4: Plywood Sheet Breaking (20 Sheets, 3/4″ Birch)

Project: Breaking down plywood for built-in bookcase Challenge: Full 4×8 sheets, various cut sizes Setup: Roller stands front and back for support

Results:

- 24.5″ rip capacity handled lengthwise cuts without flipping

- Required proper outfeed support; saw shifted without it

- Blade height set at 1/4″ above material prevented excessive tear-out

- 20 sheets processed in approximately 3 hours

Verdict: This showcased both strengths (rip capacity) and weaknesses (needs support). With proper setup, the saw handled sheet goods capably. Without support, accuracy suffered.

Test 5: Continuous Operation Stress Test

Objective: Determine if the saw handles extended use without overheating Process: Continuous ripping for 45 minutes (equivalent to processing lumber for stair treads) Material: Mixed hardwoods and softwoods

Results:

- Motor temperature: Warm but not concerning (checked with IR thermometer)

- No thermal cutout or performance degradation

- Blade speed remained consistent throughout

- Motor bearings showed no unusual noise or vibration

Verdict: The 15-amp motor handles sustained operation confidently. This isn’t a hobby saw that needs cool-down breaks.

Long-Term Durability Observations

After 3 Years / ~300 Hours of Use:

- Fence system: Still glides smoothly; required lubrication twice

- Motor: No performance degradation; sounds same as day one

- Table surface: Minor scratches from moving materials, no rust (I wax quarterly)

- Roll cage: Multiple dents from drops, no structural compromise

- Blade arbor: No detectable runout increase

- Electrical: No switch issues or cord damage

Maintenance Performed:

- Blade changes: 4 times (due to dullness, not saw issues)

- Carbon brush inspection: Once (looked fine)

- Lubrication: Fence rails twice, blade height mechanism once

- Alignment check: Quarterly (rarely needed adjustment)

The DWE7480 has proven more durable than I expected. Despite regular jobsite abuse, everything still functions like new.

DWE7480 vs DW745: The Upgrade Worth Understanding

DEWALT 10-Inch Portable Table Saw with Stand (DWE7480XA)

- EASY ADJUSTMENTS: DEWALT’s Rack and Pinion telescoping fence rails make table saw fence adjustments fast, smooth and accurate

- RIP CAPACITY: 24″ of rip capacity, easily cuts a variety of larger shelving and trim materials

- MODULAR GUARDING SYSTEM: Site-Pro Modular Guarding System allows for tool free adjustments of the guarding components appropriate for each application

The DWE7480 replaced the DW745 in DeWalt’s lineup. Understanding the differences matters if you’re choosing between a used DW745 and DWE7480.

What Actually Changed

| Feature | DW745 | DWE7480 | Real-World Impact |

|---|---|---|---|

| Motor Speed | 3850 RPM | 4800 RPM | Noticeable improvement cutting hardwoods |

| Rip Capacity | 20″ right | 24.5″ right | Major advantage for sheet goods |

| Weight | 45 lbs | 48 lbs | Negligible difference in portability |

| Table Size | Similar | Similar | Functionally identical |

| Dust Port | 2.5″ | 2.5″ | No difference |

| Price (Used) | $150-225 | $200-300 | DWE7480 worth the premium |

The 950 RPM Difference You Can Feel

I’ve used both saws extensively (still own a DW745 for job site backup). That extra 950 RPM isn’t subtle. The DWE7480 cuts hardwoods noticeably faster with less burning. On softwoods and plywood, the difference matters less, but it’s still present.

If you primarily cut pine, framing lumber, and sheet goods, the DW745 performs admirably. If you work with maple, oak, walnut, or other hardwoods regularly, the DWE7480’s extra speed makes daily work less frustrating.

Rip Capacity: The Real Game-Changer

Those extra 4.5 inches (20″ vs 24.5″) change how you work with plywood. The DW745 requires flipping sheets for lengthwise cuts. The DWE7480 doesn’t.

If you rarely cut full sheets, this doesn’t matter. If you build cabinets, do renovation work, or frequently break down plywood, it matters significantly.

Which Should You Buy Used?

Choose the DW745 if:

- You primarily cut dimensional lumber and softwoods

- Portability is absolutely critical (3 lbs lighter)

- You can find one under $200 in good condition

- You rarely cut full plywood sheets

Choose the DWE7480 if:

- You cut hardwoods regularly

- Sheet goods are common in your work

- The $50-75 price difference is manageable

- You want the “latest and greatest” DeWalt offered before discontinuation

For comparison with other highly-rated table saw options, including both jobsite and hybrid models, explore our comprehensive buyer’s guide.

DWE7480 vs DWE7485: Should You Buy the Newer Model?

DeWalt replaced the DWE7480 with the DWE7485 (8-1/4″ blade). This isn’t a straightforward upgrade—it’s a different design philosophy.

The Major Differences

| Feature | DWE7480 (Discontinued) | DWE7485 (Current) |

|---|---|---|

| Blade Size | 10 inches | 8-1/4 inches |

| Cut Depth 90° | 3-1/8″ | 2-7/8″ |

| Cut Depth 45° | 2-1/4″ | 2-1/4″ |

| Weight | 48 lbs | 43 lbs |

| Rip Capacity | 24.5″ right | 24.5″ right |

| New Price | N/A (discontinued) | $399-449 |

| Motor Speed | 4800 RPM | 5800 RPM |

| Rack & Pinion Fence | Yes | Yes |

Why DeWalt Went Smaller

The 8-1/4″ blade reduces weight (43 lbs vs 48 lbs) and spins faster (5800 RPM vs 4800 RPM) for cleaner cuts despite the smaller diameter. DeWalt’s pitch: You get the same performance with better portability.

The reality: The smaller blade cuts 1/4″ shallower at 90 degrees. For most work, that doesn’t matter—3/4″ hardwood, 2x lumber, even some 3″ materials cut fine. But if you occasionally need to cut 3-1/8″ thick material (8/4 hardwood on edge, stacked framing), the DWE7485 can’t do it in one pass.

The Used DWE7480 vs New DWE7485 Decision

DEWALT 15 Amp 8-1/4 in. Compact Portable Jobsite Table Saw (DWE7485)

- 24.5 in. of rip capacity for ripping 4×8 plywood or OSB sheets

- Compact size for easy transportation and storage

- Rack & pinion telescoping fence rails make fence adjustments fast, smooth, and accurate

List Price :

Offer: 349.00

Go to AmazonThis isn’t apples-to-apples because you’re comparing used versus new prices:

Used DWE7480: $200-300

- Pros: 10″ blade accepts more options, slightly deeper cut, proven track record

- Cons: Used condition varies, may need blade/parts, no warranty

New DWE7485: $399-449

- Pros: New warranty, latest design, 5 lbs lighter, faster blade speed

- Cons: Reduced cut depth, blade options more limited, unproven longevity

My recommendation: If you can find a well-maintained DWE7480 for $250 or less, buy it. You’re saving $150-200 for essentially the same saw with a proven track record. If the DWE7485 drops to $350 on sale, the new warranty and lighter weight become attractive.

Who Should (and Shouldn’t) Buy This Saw

After three years with the DWE7480, here’s my honest assessment of who benefits most.

Perfect For: Mobile Contractors and Remodelers

If you move between jobsites daily, the DWE7480 hits the sweet spot. It’s light enough to carry upstairs, powerful enough for serious work, and accurate enough for finish carpentry.

Framers, trim carpenters, flooring installers, and general contractors all benefit from this portability-performance balance. The saw lives in your truck, sets up in 30 seconds, and handles 90% of what you throw at it.

Perfect For: Small Workshop Owners

If your workshop is a garage that also parks cars, the DWE7480 makes sense. Store it on a shelf, pull it out when needed, pack it away when done. At 48 pounds, one person moves it easily.

The 24.5″ rip capacity means you can still handle sheet goods despite the compact size. You’re not sacrificing much versus a stationary saw three times the weight.

Perfect For: Budget-Conscious Woodworkers

At $200-300 used, the DWE7480 delivers exceptional value. You’re getting professional-grade performance for hobby-level pricing. Many woodworkers outgrow beginner saws quickly; starting with the DWE7480 means not needing an upgrade for years.

The money saved versus a $600-800 saw buys quality blades, safety equipment, and actual lumber for projects.

Wrong Choice For: Dado-Dependent Woodworkers

If dado cuts are central to your work (cabinet makers doing shelf dados, box builders needing joinery), this saw can’t help you. The arbor shaft physically cannot accommodate dado stacks.

Router tables work as alternatives, but if you’re cutting dadoes daily, buy a saw that handles them. Trying to work around this limitation becomes frustrating quickly.

Wrong Choice For: Stationary Workshop Purists

If your saw never moves from its workshop position, the DWE7480’s portability advantage is wasted. You’re paying (in reduced stability and dust collection) for features you don’t need.

A heavier contractor saw or hybrid model delivers better vibration dampening, superior dust collection, and often larger table surfaces. The weight penalty doesn’t matter if portability doesn’t matter.

Wrong Choice For: Fine Furniture Makers

If you’re building heirloom furniture with exotic hardwoods where every cut must be perfect, the DWE7480 works but isn’t ideal. Cabinet saws with superior dust collection, larger tables, and maximum stability better suit precision work.

That said, I’ve built furniture on this saw. It’s capable. Just not optimal for that specific use case.

Accessories and Upgrades That Matter

After three years, here are the accessories that genuinely improved my experience with the DWE7480.

Essential Upgrade #1: Premium Combination Blade ($40-80)

What I bought: Freud D1040X 40-tooth combination blade Why it matters: The included 24-tooth blade is adequate for framing but terrible for anything visible. A quality 40-tooth blade improves cut quality dramatically—less burning, minimal tear-out, cleaner edges. Cost vs benefit: Best $45 I spent. Changed the saw’s capability overnight.

Essential Upgrade #2: Better Miter Gauge ($80-150)

What I bought: Kreg KMA2700 Precision Miter Gauge System Why it matters: The stock gauge wobbles and lacks positive angle stops. An aftermarket gauge with a solid bar, flip stop, and precise angle adjustments makes crosscuts repeatable and accurate. Cost vs benefit: Not cheap, but crosscut accuracy improved noticeably. Worth it if you crosscut frequently.

Recommended Add-On: Mobile Stand ($150-200)

What I bought: DeWalt DW7451 (scissor-style, specific to this saw) Why it matters: Working on sawhorses gets old. A dedicated stand puts the saw at comfortable height, folds for transport, and adds stability. Cost vs benefit: Worthwhile if you use the saw regularly. Occasional users can skip it.

Recommended Add-On: Zero-Clearance Insert ($20-35)

What I bought: Aftermarket acrylic insert from POWERTEC Why it matters: Reduces tear-out on crosscuts by supporting wood fibers right up to the blade. Particularly helpful with plywood. Cost vs benefit: Cheap insurance against tear-out. Takes 2 minutes to install.

Useful But Not Essential: Roller Stands ($40-80 pair)

What I bought: HTC PM-4550 roller stands (pair) Why it matters: Essential when cutting sheet goods. The DWE7480 lacks enough mass to stay stable without proper support on large pieces. Cost vs benefit: Necessary if you cut plywood regularly. Skip if you rarely handle sheets.

Skip: Expensive Dado Inserts

Don’t buy dado inserts for this saw. The arbor can’t accommodate dado stacks. Save your money.

Skip: Elaborate Dust Collection Upgrades

The saw’s dust collection is adequate but not great. Expensive aftermarket shrouds and collection systems cost more than they improve performance. A good shop vac connected to the dust port does 80% of what’s possible.

For a complete guide to compatible table saw accessories, including blade options, safety equipment, and performance upgrades, explore our accessory recommendations.

Common Problems and Solutions

Three years of use (plus conversations with other DWE7480 owners) revealed these common issues and fixes.

Problem: Fence Doesn’t Lock Square Consistently

Symptoms: Fence slides slightly during cuts or locks at a slight angle Cause: Sawdust accumulation in fence rails or worn locking mechanism Solution:

- Clean fence rails monthly with compressed air

- Apply paste wax to rails (car wax works)

- Check rail mounting bolts for tightness

- If locking mechanism is worn, replacement rails cost $40-60

I experienced this around month 8. Cleaning and waxing solved it completely. Now it’s part of monthly maintenance.

Problem: Blade Height Adjustment Becomes Stiff

Symptoms: Crank wheel turns hard, blade raises slowly or unevenly Cause: Lack of lubrication on gearing mechanism Solution:

- Unplug saw (always)

- Remove throat plate for access

- Apply lightweight machine oil to visible gears

- Work crank through full range of motion

- Wipe excess oil

This happened around month 18. Five minutes of maintenance fixed it for the next 18 months.

Problem: Excessive Vibration During Operation

Symptoms: Saw vibrates noticeably, blade wobble visible Cause: Usually blade-related, occasionally arbor runout Solution:

- Check blade for damage or warping (replace if found)

- Verify blade is tight on arbor (common to loosen during use)

- Clean sawdust from arbor and blade mounting surfaces

- Check arbor runout with dial indicator (should be under 0.005″)

I’ve had this twice—both times loose blade or sawdust buildup. Never experienced actual arbor problems.

Problem: Motor Won’t Start or Runs Then Dies

Symptoms: Motor hums but doesn’t spin, or starts then stops Cause: Carbon brushes worn (common after 200-300 hours) Solution:

- Brushes are user-replaceable (DeWalt part #5140033-19, ~$15)

- Remove two screws to access brush holders

- Replace both brushes even if only one looks worn

- Reset thermal overload if motor shut off from heat

I haven’t needed brushes yet at 300 hours, but they’re on my “inspect soon” list.

Problem: Dust Port Clogs During Use

Symptoms: Sawdust builds up on table despite shop vac connection Cause: Internal dust chute clogged with debris Solution:

- Unplug saw and remove throat plate

- Use shop vac to clear internal dust paths

- Disconnect dust port hose and blow compressed air through port from inside

- Check shop vac hose for clogs

This happens every 20-30 hours of use. Two-minute fix.

Problem: Bevel Angle Lock Won’t Hold

Symptoms: Blade angle shifts during cuts Cause: Worn bevel lock lever or insufficient tightening Solution:

- Tighten bevel lock lever firmly (requires more force than seems necessary)

- If lever won’t tighten enough, plastic may be worn (replacement lever ~$20)

- Check pivot point for sawdust buildup

Haven’t experienced this personally but heard reports from other owners at 400+ hours of use.

DEWALT 10-Inch Portable Table Saw with Stand (DWE7480XA)

- EASY ADJUSTMENTS: DEWALT’s Rack and Pinion telescoping fence rails make table saw fence adjustments fast, smooth and accurate

- RIP CAPACITY: 24″ of rip capacity, easily cuts a variety of larger shelving and trim materials

- MODULAR GUARDING SYSTEM: Site-Pro Modular Guarding System allows for tool free adjustments of the guarding components appropriate for each application

Frequently Asked Questions

Is the DeWalt DWE7480 discontinued?

Yes, DeWalt discontinued the DWE7480 and replaced it with the DWE7485 (8-1/4″ blade version). However, used DWE7480 saws remain widely available and fully supported with replacement parts. Discontinuation doesn’t mean the saw is obsolete—it simply reflects DeWalt’s shift toward slightly smaller, lighter designs.

What’s the difference between DWE7480 and DWE7480XA?

The “XA” suffix indicates the saw comes packaged with DeWalt’s DW7451 scissor stand. The saws themselves are identical. If you see both listed, DWE7480XA includes the stand (typically $120-150 value), while DWE7480 is the bare saw. Buying the bundled version usually saves $20-40 versus purchasing separately.

Can the DWE7480 cut dadoes?

No. The arbor shaft is too short to accommodate dado blade stacks. This is a deliberate design trade-off for compact size and weight reduction. If dado capability is essential, consider the Bosch GTS1031 (handles 1/2″ dados) or larger contractor saws. Router tables provide dado alternatives but require different workflow.

How does dust collection compare to other portable saws?

The DWE7480 captures approximately 70-75% of sawdust when connected to a shop vacuum through its 2.5″ dust port. This is average for portable saws—better than budget models, worse than enclosed cabinet designs.

What blade should I buy to replace the stock blade?

For general-purpose work, a quality 40-tooth combination blade works best. I use the Freud D1040X ($45-55), which handles both ripping and crosscutting well. For finish work prioritizing crosscuts, upgrade to a 60-80 tooth blade like the Freud D1060X. For dedicated ripping, a 24-30 tooth rip blade cuts faster with less motor strain. Budget $40-80 for a significant upgrade over the included blade. Avoid cheap blades under $30—they dull quickly and cut poorly.

Can this saw handle hardwood flooring installation?

Yes, I’ve used my DWE7480 for multiple hardwood flooring installs totaling over 1,000 linear feet. The 4800 RPM motor powers through 3/4″ oak, maple, and walnut confidently. The 24.5″ rip capacity handles board width rips, and accuracy is sufficient for tight fit requirements. Use a quality 40-tooth blade and maintain proper feed rate to minimize burning. The portability advantage matters significantly when moving between rooms during installation.

Final Verdict: Still a Smart Buy in 2026

Three years after buying the DeWalt DWE7480 “temporarily,” it remains my primary saw despite owning heavier alternatives. That speaks volumes about its real-world capability.

The DWE7480 isn’t perfect. Dust collection is mediocre, dado capability is nonexistent, and the included accessories need upgrading. But for mobile contractors, small workshop owners, and budget-conscious woodworkers who need genuine cutting capacity in a portable package, no other saw delivers better value.

The sweet spot is finding a well-maintained used unit for $200-300. At that price, you’re getting professional-grade performance for hobby-level investment. The money saved buys quality blades, proper safety equipment, and actual materials for projects.

My recommendation after three years: If portability matters and you don’t need dado cuts, buy the DWE7480 with confidence. Upgrade the blade immediately, budget for an aftermarket miter gauge eventually, and enjoy a saw that punches well above its weight class.

For comparisons with other portable and contractor table saws, including models with dado capability and enhanced dust collection, explore our comprehensive reviews.

Your next step: Check local Craigslist, Facebook Marketplace, and OfferUp for used DWE7480 listings. Inspect the saw in person, make test cuts if possible, and negotiate toward the $250 range. Then spend less time researching and more time building.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.