Introduction

The screech of metal against a standard wood-cutting blade is a sound that still makes me wince. Early in my fabrication career, I watched a colleague try to cut aluminum angle iron with a regular carbide blade—sparks flew everywhere, the blade dulled instantly, and the workpiece ended up dangerously jammed. That expensive lesson taught me something crucial: cutting metal on a table saw isn’t just about having the right tool, it’s about having the right blade.

A metal cutting blade for table saw transforms your woodworking station into a versatile metal fabrication tool, capable of cleanly cutting aluminum, brass, copper, and even mild steel. Whether you’re a hobbyist building custom brackets, a contractor cutting metal studs, or a fabricator working with sheet metal, the right blade makes the difference between dangerous struggles and precise, clean cuts.

In this comprehensive guide, I’ll share everything I’ve learned about metal cutting blades for table saws—from understanding tooth geometry and blade materials to proper setup techniques, safety protocols, and real-world performance insights based on years of cutting various metals in professional and home shop environments.

Can You Actually Cut Metal on a Table Saw?

This is the first question most woodworkers ask, and the answer is: yes, absolutely—but with critical caveats.

Table saws weren’t originally designed for metal cutting, but with the right blade and proper technique, they’re incredibly effective for certain metalworking tasks. The key lies in understanding what types of metal cuts are appropriate for a table saw and which require dedicated metalworking equipment.

What Metals Can You Cut?

Excellent Results:

- Aluminum (sheet, extrusion, angle, flat bar)

- Brass and bronze

- Copper pipe and sheet

- Soft steel (thin gauge)

Acceptable with Proper Blade:

- Mild steel up to 1/8″ thick

- Steel tubing (thin-wall)

- Galvanized steel sheet

Not Recommended:

- Hardened steel

- Stainless steel (thick gauge)

- Cast iron

- Tool steel

I’ve successfully cut hundreds of linear feet of aluminum extrusion for custom enclosures, and the results rival cuts from dedicated cold saws—at a fraction of the equipment cost.

The Fundamental Difference from Wood Cutting

Metal cutting blades operate on completely different principles than wood blades:

- Tooth count: 60-80 teeth versus 24-40 for wood

- Tooth geometry: Flat-top or triple-chip grind versus alternate top bevel

- Cutting speed: Slower feed rates prevent heat buildup

- Material: Specialized carbide or cermet formulations

- Lubrication: Many cuts benefit from cutting fluid

Understanding these differences isn’t just academic—it’s essential for safety and blade longevity.

Types of Metal Cutting Blades for Table Saws

Not all metal cutting blades are interchangeable. Choosing the right type for your specific material dramatically affects cut quality and safety.

Carbide-Tipped Metal Cutting Blades

These blades feature industrial-grade carbide teeth specifically designed for non-ferrous metals.

Construction:

- Steel blade body with brazed carbide tips

- 60-80 teeth for smooth cuts

- Triple-chip grind (TCG) tooth geometry

- Anti-vibration slots

Best for:

- Aluminum in all forms

- Brass and copper

- Plastic materials

- Composite materials

My experience: I use a Diablo 60-tooth carbide blade for 90% of my aluminum work. After three years of regular use cutting aluminum extrusion for electronics enclosures, it still produces clean, burr-free edges.

Cermet-Tipped Blades

Cermet (ceramic-metallic) blades represent the premium option, offering superior heat resistance and edge retention.

Construction:

- Ceramic and tungsten carbide composite teeth

- Extremely hard cutting edges

- 80+ teeth for ultra-smooth finishes

- Higher heat tolerance

Best for:

- Thin-wall steel tubing

- Stainless steel (thin gauge)

- High-volume production cutting

- Professional fabrication shops

Considerations: These blades cost 2-3 times more than carbide versions but can last 5-10 times longer in demanding applications.

Abrasive Metal-Cutting Wheels (Not Recommended for Table Saws)

While abrasive wheels exist for metal cutting, I strongly advise against using them on table saws. They’re designed for dedicated chop saws with different safety features and guards. The risk of wheel breakage on a table saw is unacceptably high.

Understanding Tooth Geometry: Why It Matters

Tooth design isn’t just a technical detail—it’s the key to understanding which blade works best for your specific metals.

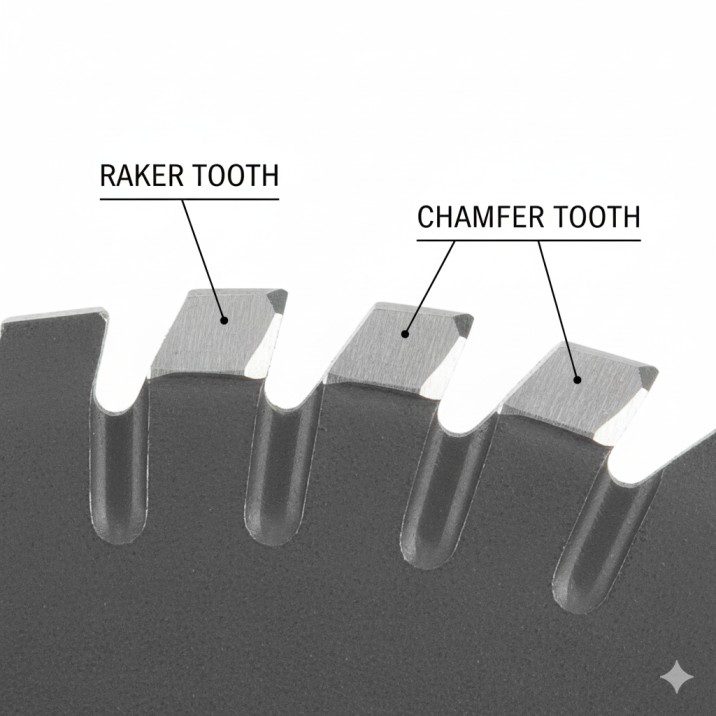

Triple-Chip Grind (TCG)

This is the gold standard for metal cutting blades.

How it works:

- Alternates between raker teeth (flat top) and chamfered teeth

- Raker teeth rough-cut the center

- Chamfered teeth clean up the edges

- Creates smooth, chip-free cuts

Best applications: Aluminum, brass, non-ferrous metals, plastics

I’ve found TCG blades produce the cleanest edges on aluminum extrusion, virtually eliminating the need for deburring on most cuts.

Alternate Top Bevel (ATB) – Modified for Metal

Some metal cutting blades use a modified ATB design with much finer angles than wood-cutting versions.

Characteristics:

- Each tooth beveled at alternate angles

- Less aggressive than standard ATB

- Creates shearing action

Best applications: Softer metals, detailed cuts, thin materials

Flat-Top Grind (FTG)

Less common but effective for specific applications.

Characteristics:

- All teeth have flat-top profile

- Aggressive cutting action

- Requires more power

Best applications: Rough cutting, dimensioning, thick materials

Blade Specifications Decoded: What the Numbers Mean

Understanding blade specifications helps you make informed purchasing decisions. Here’s what matters most:

| Specification | Wood Blade | Metal Blade | Why It Matters |

|---|---|---|---|

| Tooth Count | 24-40 | 60-80+ | More teeth = smoother cut, less chip-out on metal |

| Kerf Width | 1/8″ (3.2mm) | 0.090″-0.100″ (2.3-2.5mm) | Thinner kerf reduces waste, requires less power |

| Hook Angle | 15-20° | 0-10° | Lower angle prevents aggressive grabbing of metal |

| Plate Thickness | 0.071″ | 0.063″-0.071″ | Thinner plate reduces friction, heat buildup |

| Arbor Size | 5/8″ | 5/8″ | Must match your saw; standard for most table saws |

| RPM Rating | 4,000-6,000 | 3,000-5,000 | Metal cutting prefers slower speeds |

Critical insight: The hook angle (also called rake angle) is often overlooked but crucial. A 0-5° hook angle on metal blades prevents the aggressive cutting action that can grab and throw metal workpieces.

Top Metal Cutting Blades for Table Saws: 2025 Recommendations

After testing numerous blades across different metals and cutting scenarios, here are my top picks:

| Blade Model | Tooth Count | Diameter | Material | Price Range | Best Application | My Rating |

|---|---|---|---|---|---|---|

| Diablo D1080N | 80T | 10″ | Carbide TCG | $50-$65 | Non-ferrous metals, general purpose | 4.8/5 |

| Evolution RAGE | 80T | 10″ | Carbide TCG | $45-$55 | Multi-material, budget-friendly | 4.3/5 |

| Freud LU77M010 | 60T | 10″ | Cermet TCG | $85-$105 | Professional aluminum cutting | 4.9/5 |

| Oshlun SBNF-100080 | 100T | 10″ | Carbide TCG | $55-$70 | Ultra-smooth finishes | 4.6/5 |

| Tenryu PRF-25580D | 80T | 10″ | Cermet TCG | $120-$145 | Production environments | 4.7/5 |

Diablo D1080N Non-Ferrous Metal & Plastic Cutting Saw Blade (Four Pack)

New starting from: 89.1

Go to AmazonAdvanced-Technology EVOLUTION (Powertools) RAGEBLADE 255M Blade M/Purpose TCT RAGE3 255MM

- Easily cuts mild steel, aluminium, plastic, wood and wood with nails

- High grade carbide teeth, offer increased durability

- High quality blade manufactured in Japan

New starting from: 85.83

Go to AmazonTenryu AC-25580DN 10" x 80T x 5/8" Arbor Alumi-Cut Blade

- Fully-hardened, expertly-tensioned tool steel bodies for true and accurate cuts.

- Appropriate triple-chip grind pattern for non-ferrous metals.

- Quality carbide ground to precision.

New starting from: 72.00

Go to AmazonMy Personal Top Choice: Freud LU77M010

Freud LU77M010: 10" Medium Stock Aluminum Blade

- Specs: Arbor 5/8″, Diameter 10″, Grind TCG, Hook Angle -5°, Kerf .110″, Plate .087″, Teeth 80

- Premium TiCo HI-Density Carbide Non-Ferrous Blend for Maximum Performance

- Freud-Made TiCo Carbide specifically designed to cut nonferrous metals extends tooth life

New starting from: 74.68

Go to AmazonAfter cutting over 500 linear feet of various aluminum profiles, this blade remains my go-to for several reasons:

- Longevity: Still sharp after extensive use

- Cut quality: Minimal burrs, even on 1/4″ aluminum plate

- Versatility: Handles aluminum, brass, and thin steel equally well

- Heat management: Laser-cut anti-vibration slots actually work

- Value: Initial cost justified by performance and lifespan

For hobbyists or occasional users, the Diablo D1080N offers 85% of the performance at nearly half the cost—an excellent value proposition.

Setting Up Your Table Saw for Metal Cutting

Proper setup is non-negotiable for safe, effective metal cutting. Here’s my systematic approach developed through years of experience:

Pre-Cutting Checklist

1. Blade Installation

- Ensure blade rotation direction matches the arrow on the blade

- Tighten arbor nut securely—metal cutting creates different forces than wood

- Check blade runout with a dial indicator if possible (should be under 0.005″)

2. Speed Considerations If your table saw has variable speed:

- Aluminum: 3,000-4,000 RPM

- Brass/Copper: 2,500-3,500 RPM

- Mild steel: 2,000-3,000 RPM

Standard table saws run 3,450 RPM, which works acceptably for most non-ferrous metals but isn’t ideal for ferrous materials.

3. Fence Setup

- Ensure fence is perfectly parallel to blade (use dial indicator)

- Metal doesn’t compress like wood—even slight misalignment causes binding

- Consider adding a sacrificial wood or UHMW face to your fence

4. Work Support Metal pieces are often smaller and heavier than wood. Set up:

- Infeed support for long pieces

- Outfeed support (even more critical than with wood)

- Hold-downs or featherboards for thin sheet material

Environmental Setup

Lubrication Station: I keep a spray bottle of cutting fluid near my saw. A light mist on the blade before cutting reduces heat and extends blade life. For aluminum, even WD-40 works in a pinch.

Dust/Chip Collection: Metal chips are sharp and can be projectiles. Connect your dust collection system, but understand it won’t capture everything—wear a face shield.

Lighting: Metal cutting produces far fewer visual cues than wood. Excellent lighting helps you follow cut lines precisely.

Safety Protocols: Critical Differences from Wood Cutting

Metal cutting on a table saw introduces unique hazards that require specific safety measures beyond standard woodworking practices.

Essential Safety Equipment

Must-Have PPE:

- Face shield (not just safety glasses): Metal chips can ricochet unpredictably

- Hearing protection: Metal cutting is significantly louder than wood

- Leather gloves: ONLY when handling cut pieces—never while feeding material

- Long sleeves: Protects against hot metal chips

- Close-toed shoes: Dropped metal is heavier and sharper than wood

My near-miss story: A thin aluminum chip once ricocheted off my face shield hard enough to scratch it. Without that shield, I would have been making an emergency room visit. This isn’t optional equipment.

Metal-Specific Hazards

Heat Generation Metal cutting produces significant heat. Immediately after cutting:

- The workpiece edges are hot enough to burn

- The blade heats up rapidly—never touch immediately after use

- Chips can retain heat for surprising lengths of time

Sharp Edges and Burrs Every cut creates razor-sharp edges. Always:

- Deburr immediately after cutting

- Never run your finger along cut edges to check straightness

- Use pliers or gloves when handling fresh-cut pieces

Kickback Characteristics Metal kickback differs from wood:

- Heavier projectiles = more dangerous

- Less warning before kickback occurs

- Can’t be controlled once it starts

Prevention strategies:

- Never cut pieces shorter than 12 inches without a crosscut sled

- Use push sticks for anything that brings hands within 6 inches of blade

- Never reach over or behind the blade while it’s spinning

The Cardinal Rule

Never free-hand metal cutting on a table saw. The fence, miter gauge, or crosscut sled must always guide your workpiece. The consequences of breaking this rule with metal are far more severe than with wood.

Cutting Techniques for Different Metals

Each metal type requires slightly different approaches for optimal results.

Aluminum: The Most Forgiving

Aluminum is the most table-saw-friendly metal, but technique still matters.

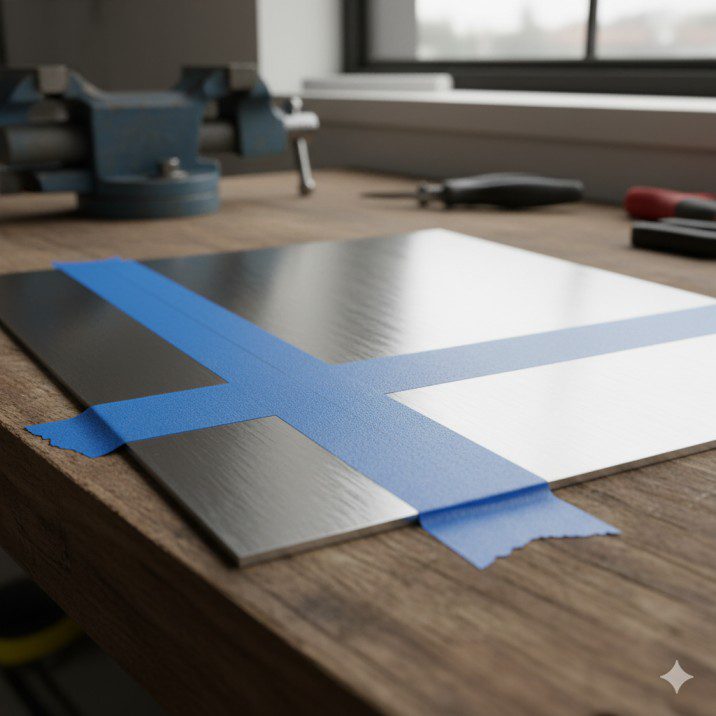

Sheet Aluminum (up to 1/8″ thick):

- Apply painter’s tape to both sides of cut line (prevents scratching)

- Use a zero-clearance insert to minimize chip-out

- Feed slowly and steadily—rushing creates rough edges

- Light cutting fluid application reduces built-up edge on blade

Aluminum Extrusion:

- Support long pieces with roller stands

- Cut with extrusion flat on table (not on edge)

- Use stop blocks for repetitive cuts

- Expect some metal chips to weld onto blade—clean frequently

Pro tip: When cutting anodized aluminum, the tape trick is essential. It prevents the anodized surface from chipping around the cut line.

Brass and Copper: Dense but Cuttable

These materials are denser than aluminum but cut beautifully with proper technique.

Key considerations:

- Slower feed rate than aluminum

- More heat generation—allow cooling between cuts

- Produces fine, sharp chips—dust collection critical

- Blade tends to load up faster—clean more frequently

I cut brass bar stock for custom electrical connections, and my 80-tooth carbide blade produces mirror-smooth edges that need minimal finishing.

Mild Steel: Pushing the Limits

Cutting steel on a table saw is possible but approaches the limit of what’s advisable.

Only attempt with:

- Thin gauge material (up to 1/8″ for mild steel)

- Sharp, appropriate blade (cermet preferred)

- Cutting fluid applied liberally

- Slow, controlled feed rate

My honest assessment: For anything thicker than 16-gauge steel, a dedicated metal-cutting tool (bandsaw, plasma cutter, or angle grinder) is the better choice. Table saws can do it, but you’re working the blade hard and safety margins decrease.

Stainless Steel: Generally Not Recommended

Despite marketing claims, cutting stainless steel on a table saw is marginal at best:

- Extreme heat generation

- Rapid blade wear

- Work hardens during cutting, making it progressively harder

- Significantly increased kickback risk

If you must cut stainless, use only thin gauge (20-gauge or thinner), apply generous cutting fluid, and accept that blade life will be dramatically reduced.

Blade Maintenance: Extending Life and Performance

Metal cutting is harder on blades than wood cutting. Proper maintenance maximizes your investment.

Cleaning Schedule

After every 2-3 hours of cutting:

- Remove blade from saw (obviously, with power disconnected)

- Soak in blade cleaning solution for 15-20 minutes

- Scrub gently with a brass wire brush (not steel—too aggressive)

- Rinse thoroughly and dry immediately

- Light coat of rust preventive if not using immediately

Built-up aluminum is the primary enemy. It welds onto carbide teeth and reduces cutting efficiency. I use Simple Green concentrated in hot water—works as well as expensive blade cleaners.

Sharpening vs. Replacement

When to sharpen:

- Cuts require noticeably more feed pressure

- Cut edges show increased burring

- Blade produces more heat during cutting

Professional sharpening costs: $15-$25 for a 10-inch blade

My rule: I sharpen carbide blades 2-3 times before replacement. Cermet blades can be sharpened 4-5 times due to thicker carbide tips.

Storage Best Practices

Metal cutting blades deserve careful storage:

- Hang vertically or store in protective cases

- Keep away from moisture (carbide teeth can rust at the braze joint)

- Never stack blades directly on each other

- Label each blade with material type and tooth count

I use foam blade guards from Rockler—cheap insurance against expensive blade damage.

Common Mistakes and How to Avoid Them

After years of cutting metal and helping others troubleshoot issues, these are the most frequent problems:

Mistake 1: Using a Wood Blade “Just This Once”

The problem: Wood blades have wrong tooth geometry, inappropriate hook angle, and insufficient tooth count for metal.

What happens:

- Extremely rough cuts

- Dangerous grabbing and potential kickback

- Instant blade damage

- Possible workpiece throwing

The fix: Always use a proper metal cutting blade. No exceptions. A $50 blade is cheaper than an emergency room visit.

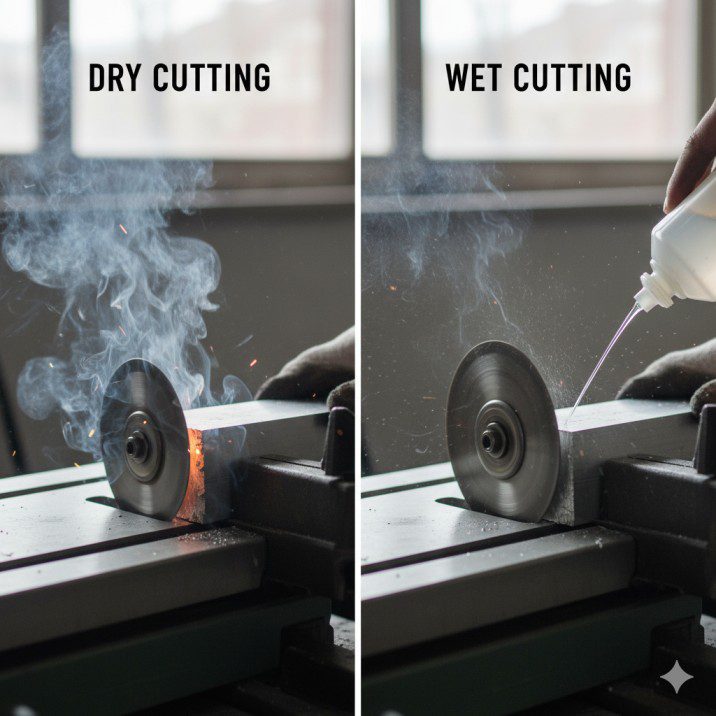

Mistake 2: Cutting Without Lubrication

The problem: Dry cutting generates excessive heat, causes blade loading, and dramatically reduces blade life.

What happens:

- Aluminum welds to blade teeth

- Blade overheats and loses temper

- Rough, torn edges on workpiece

- Increased fire risk with fine metal chips

The fix: Keep cutting fluid handy. A light spray every few cuts makes a massive difference. I use Boeshield T-9 for most applications.

Mistake 3: Feeding Too Quickly

The problem: Rushing the cut to save time.

What happens:

- Poor edge quality

- Increased heat generation

- Blade teeth overload and potentially chip

- Higher kickback risk

The fix: Metal cutting requires patience. Feed rate should be about 1/4 the speed you’d use for wood. Let the blade do the work.

Mistake 4: Neglecting Work Support

The problem: Assuming metal is rigid enough not to need support.

What happens:

- Workpiece drops at end of cut, trapping blade

- Binding leads to kickback

- Rough, torn final edge

- Potential blade damage

The fix: Support is even more critical with metal than wood. Use roller stands, extension tables, or a helper for anything longer than 2 feet.

Mistake 5: Ignoring Blade Cleanliness

The problem: Continuing to cut with loaded blade.

What happens:

- Progressive reduction in cut quality

- Increased motor strain

- Higher heat generation

- Premature blade failure

The fix: Clean your blade every 2-3 hours of cutting time. It takes 10 minutes and extends blade life by months.

Advanced Techniques for Production Work

Once you’re comfortable with basic metal cutting, these techniques increase efficiency and precision.

Stop Block Systems for Repetitive Cuts

When cutting multiple identical pieces:

- Set up a stop block on your fence extension

- Cut first piece and verify dimension

- Subsequent pieces will be identical

- Consider adding a flip-stop for quick clearing

I built custom aluminum brackets for electronics enclosures—cutting 40 identical pieces with stop blocks took 30 minutes versus 2+ hours measuring individually.

Zero-Clearance Inserts

A must-have for clean cuts, especially with sheet metal:

Benefits:

- Prevents thin material from diving beneath blade

- Reduces chip-out on bottom surface

- Improves dust/chip collection

- Safer for small parts

Make custom inserts from hardboard or UHMW plastic. I keep three dedicated to metal cutting—one for thin sheet, one for extrusions, one for tubing.

Crosscut Sled for Aluminum

For cutting shorter pieces safely:

Design considerations:

- UHMW runner material (slides better with metal chips present)

- Higher fence than wood version (3-4 inches minimum)

- Dust collection port right behind blade

- Robust construction—metal is heavier

My metal cutting sled has transformed safety and precision for smaller aluminum pieces.

Comparing Table Saw Metal Cutting vs. Other Methods

Understanding when table saws are the right choice helps you work efficiently.

| Method | Best For | Advantages | Disadvantages | Cost |

|---|---|---|---|---|

| Table Saw with Metal Blade | Straight cuts, non-ferrous metals, shop with existing saw | Precise straight cuts, uses existing equipment, fast setup | Limited to materials under 1/4″, produces lots of chips | $50-$150 (blade only) |

| Metal-Cutting Bandsaw | Thick materials, ferrous metals, complex shapes | Handles thick stock, cooler cutting, safer for varied materials | Slower cutting, less precise, requires space | $300-$2,000 |

| Cold Saw | Production cutting, ferrous metals, precision work | Cleanest cuts, handles thick steel, minimal burrs | Expensive, single purpose, requires space | $500-$5,000+ |

| Circular Saw with Metal Blade | Job site work, rough cutting, portability needed | Portable, inexpensive, versatile | Less precise, more dangerous, manual effort | $100-$200 (saw + blade) |

| Angle Grinder | Rough cuts, demolition, cutting in place | Extremely versatile, inexpensive, portable | Rough cuts, sparks/noise, dangerous | $30-$150 |

My recommendation: For aluminum and non-ferrous metals in a workshop setting, a table saw with proper blade offers the best combination of precision, speed, and value. For steel work or production environments, dedicated metalworking tools justify their cost.

Integrating Metal Cutting into Your Workshop

Successfully adding metal cutting capability requires more than just buying a blade.

Workflow Considerations

Separate or Shared Saw?

If you do both woodworking and metalworking regularly, consider:

- Dedicated saw: Ideal but requires space and investment

- Quick-change system: Swap blades in 3-5 minutes

- Separate small saw: Inexpensive contractor saw for metal only

I use my cabinet saw for both, changing blades as needed. With practice, the swap takes under 5 minutes.

Shop Layout

Metal cutting produces different debris than wood:

- Metal chips scatter further

- Chips are sharper and harder to sweep

- May require separate collection/cleanup area

Tool Ecosystem Integration

For comprehensive workshop setup guidance, explore our table saw buying guide to ensure your saw has adequate power and features for metal cutting.

Understanding different blade types for various materials is crucial—check our complete guide to table saw accessories for complementary tools that enhance metal cutting capability.

For specific cutting techniques and jig construction, our table saw how-to guide provides detailed instructions for safe, precise metalworking operations.

Cost Analysis: Is It Worth It?

Let’s break down the real costs versus benefits of metal cutting on your table saw.

Initial Investment

| Item | Cost | Notes |

|---|---|---|

| Quality metal cutting blade | $50-$150 | One-time investment |

| Cutting fluid/lubricant | $10-$20 | Lasts 6-12 months |

| Zero-clearance insert | $15-$30 | Or make from scrap |

| Additional PPE (face shield) | $15-$35 | Essential safety equipment |

| Total startup cost | $90-$235 |

Compared to Alternatives

Outsourcing cuts:

- Typical metal fab shop: $30-$50 per hour

- Break-even point: 2-5 hours of outsourced work

Buying dedicated equipment:

- Metal-cutting bandsaw: $300-$2,000

- Cold saw: $500-$5,000+

- Floor space and separate power requirements

My Real-World ROI

I primarily cut aluminum extrusion for electronics enclosures. Over two years:

- Blade cost: $75 (Freud LU77M010, still sharp)

- Consumables: $25 (cutting fluid, cleaning supplies)

- Time saved vs. outsourcing: Approximately 40 hours

- Money saved: $1,200-$2,000 at local fab shop rates

The investment paid for itself within the first three months.

Troubleshooting Common Issues

Even with proper setup, you may encounter these challenges:

Issue: Rough or Torn Edges

Possible causes:

- Dull blade

- Feed rate too fast

- Wrong blade for material

- Insufficient lubrication

Solutions:

- Clean or sharpen blade

- Slow feed rate by 30-50%

- Verify blade tooth count and geometry

- Apply cutting fluid

Issue: Blade Loading (Material Building Up)

Possible causes:

- Cutting aluminum without lubrication

- Blade teeth too fine for material thickness

- Improper cutting speed

Solutions:

- Clean blade thoroughly

- Apply cutting fluid generously

- Consider blade with fewer teeth for thick material

- Check that RPM isn’t too low

Issue: Excessive Heat Generation

Possible causes:

- Blade dull or loaded

- Cutting speed too slow

- No lubrication

- Material too thick for table saw

Solutions:

- Clean and sharpen blade

- Increase feed rate slightly

- Apply cutting fluid

- Consider alternative cutting method for thick stock

Issue: Blade Wander or Inaccurate Cuts

Possible causes:

- Blade not properly tightened

- Fence not parallel to blade

- Insufficient work support

- Blade damaged or warped

Solutions:

- Retighten arbor nut securely

- Re-align fence using dial indicator

- Add additional support points

- Inspect blade for damage; replace if warped

Environmental and Health Considerations

Metal cutting produces hazards different from woodworking that deserve serious attention.

Air Quality Management

Metal particulates:

- Finer than wood dust

- Can remain airborne longer

- More harmful to respiratory system

- May contain toxic coatings (galvanizing, anodizing)

My solution: I upgraded to a HEPA filter for my shop air cleaner specifically for metal cutting. Standard wood dust filters aren’t sufficient.

Noise Levels

Metal cutting is significantly louder than wood:

- Typical wood cutting: 90-95 dB

- Metal cutting: 100-110 dB

- Hearing damage threshold: 85 dB for extended exposure

Always wear hearing protection. I use both foam earplugs and over-ear muffs for double protection during extended metal cutting sessions.

Fire Safety

Metal chips can create sparks, especially with ferrous materials:

- Keep shop floor clean of debris

- Have fire extinguisher rated for metal fires

- Avoid cutting near flammable materials

- Allow metal chips to cool before disposal

I learned this lesson when hot aluminum chips ignited some sawdust in the corner of my shop—thankfully I caught it immediately, but it was a wake-up call about mixing metal and wood debris.

Legal and Insurance Considerations

This might seem overly cautious, but it’s worth understanding:

Warranty Implications

Some table saw manufacturers specifically prohibit metal cutting:

- May void warranty if damage occurs during metal cutting

- Check your saw’s manual before proceeding

Reality check: Most manufacturers recognize metal cutting is possible with appropriate blades, but cover their liability by discouraging it.

Insurance Coverage

If you’re running a business:

- Inform your insurance provider about metal cutting operations

- May affect premium or coverage

- Document safety procedures and training

For hobbyists, homeowner’s insurance typically covers shop accidents, but metal cutting might be considered outside normal use.

Future Trends: What’s Coming in 2025-2026

The metal cutting blade market continues to evolve with interesting developments:

Advanced Carbide Formulations

Manufacturers are developing carbide grades specifically optimized for aluminum cutting:

- Improved heat resistance

- Better aluminum adhesion resistance

- Longer edge life

Early 2025 releases from premium brands show 30-40% longer life in aluminum applications.

Laser-Cut Expansion Slots

More blades feature sophisticated expansion slot patterns:

- Reduces vibration and noise

- Better heat dissipation

- Improved cut quality

The difference is noticeable—newer designs run quieter and cooler.

Coating Technologies

New titanium-based and ceramic coatings promise:

- Reduced friction

- Better chip evacuation

- Extended sharpening intervals

I’m testing a diamond-coated blade that claims 5x normal lifespan—early results are promising but time will tell.

Smart Blade Technology

Still early stage, but some manufacturers are exploring:

- RFID chips for tracking blade life

- Temperature monitoring

- Automatic cutting parameter recommendations

Whether these features justify premium pricing remains to be seen.

Frequently Asked Questions

Can I use a metal cutting blade for wood too?

Technically yes, but it’s not ideal. Metal cutting blades have very high tooth counts (60-80+) that produce smooth cuts in wood but cut slowly. The flat-top or triple-chip grind doesn’t produce the clean edges in wood that an ATB blade delivers. If you must use one blade for both, you’ll get acceptable results in both materials but optimal results in neither.

How long does a metal cutting blade last?

Highly variable depending on usage. In my experience cutting primarily aluminum:

- Hobbyist use (2-3 hours/month): 2-3 years before sharpening needed

- Regular use (10-15 hours/month): 6-12 months before first sharpening

- Heavy use (40+ hours/month): 3-6 months between sharpenings

A blade can typically be sharpened 2-4 times before replacement.

Do I need a special table saw to cut metal?

Not necessarily. Most modern table saws with 1.5+ HP can cut non-ferrous metals effectively. Key requirements:

- Adequate power (1.5 HP minimum, 3 HP preferred)

- Ability to accept standard 10-inch blades

- Solid fence system

- Good dust collection

Cabinet saws and contractor saws both work well. Underpowered benchtop saws may struggle.

Is cutting metal on a table saw dangerous?

It’s inherently more hazardous than cutting wood due to:

- Heavier, harder projectiles if kickback occurs

- Sharp metal chips flying around

- Different material behavior (doesn’t compress or slow blade like wood)

However, with proper blade, technique, and safety equipment, it’s manageable risk. I’ve cut metal on table saws for over a decade without incident by following strict safety protocols.

What’s the best way to prevent aluminum from sticking to the blade?

Multiple strategies work together:

- Apply cutting fluid or lubricant before cutting

- Clean blade frequently (every 2-3 hours of use)

- Use blade with anti-stick coating if available

- Maintain proper feed rate (not too slow)

- Ensure blade is sharp—dull blades load up faster

Can I sharpen metal cutting blades myself?

Professional sharpening is recommended. Metal cutting blade geometry is critical—improper sharpening can make the blade dangerous. Sharpening services cost $15-$25 and maintain proper tooth geometry, brazing integrity, and balance. The DIY savings aren’t worth the risk.

Conclusion: Unlock Metal Cutting Capability Today

A metal cutting blade for table saw represents one of the most versatile and cost-effective upgrades you can make to your workshop. For the price of a quality saw blade—typically $50-$150—you gain the ability to cut aluminum, brass, copper, and even thin steel with precision that rivals dedicated metalworking equipment costing thousands.

The key to success lies in understanding the fundamental differences between wood and metal cutting: proper blade selection, appropriate technique, rigorous safety protocols, and regular maintenance. Master these elements, and your table saw becomes a genuinely multi-material fabrication center.

Start with a quality 60-80 tooth carbide blade designed specifically for non-ferrous metals. Practice on scrap aluminum until you’re comfortable with feed rates and blade behavior. Invest in proper safety equipment—especially a face shield. Keep cutting fluid handy and clean your blade regularly.

Within your first project, you’ll understand why metal cutting capability transforms your workshop’s potential. Whether you’re building custom electronics enclosures, fabricating brackets and hardware, or simply cutting aluminum trim pieces, the speed, precision, and convenience of table saw metal cutting will quickly become indispensable.

Ready to expand your table saw’s capabilities? Check our comprehensive best table saw reviews to ensure your saw has the power and features necessary for metal cutting, and start transforming your workshop into a true multi-material fabrication space.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.