Last spring, I stood in my garage staring at a pile of 2x4s for a deck project. I had my trusty circular saw ready to go, but after three crooked cuts and a near-miss kickback, I realized I was using the wrong tool for the job. That frustrating afternoon cost me two boards and taught me an expensive lesson: choosing between a miter saw vs circular saw isn’t about which one is “better”—it’s about matching the right saw to your actual cutting needs.

If you’re building a workshop or adding your second power saw, this choice matters more than most tool decisions you’ll make. Both saws cut wood, sure, but they excel at completely different tasks. Buy the wrong one first, and you’ll fight your tools on every project.

I’ve spent the past eight years using both saws across dozens of projects—from framing walls to building furniture. This comparison breaks down the miter saw vs circular saw decision with real workshop experience, not just manufacturer specs rewritten for SEO.

What’s the Fundamental Difference Between Miter Saws and Circular Saws?

Before diving into capabilities, let’s clear up what these saws actually do.

A miter saw is a stationary tool with a circular blade mounted on a pivoting arm. You bring the wood to the saw, position it against the fence, and pull the blade down through the material. The saw stays put while you move the workpiece.

A circular saw is a handheld power tool you carry to the work. The blade spins on a motorized base you guide along your cut line. You move the saw while the material stays stationary.

This fundamental setup difference—stationary versus portable—shapes everything else about how these tools perform.

The Precision vs Versatility Trade-Off

Miter saws win on accuracy for crosscuts and angled cuts. The fence and preset angle stops make repeatable, clean cuts almost foolproof. Once you dial in your settings, you can make fifty identical cuts without measuring twice.

Circular saws win on versatility. They’ll rip plywood, cut bevels, trim door jambs flat on the floor, or break down full sheets at the lumberyard. If you can clamp a straightedge, you can make nearly any cut.

Neither saw does everything, which is why most serious woodworkers eventually own both.

Cutting Capabilities: What Each Saw Actually Does Best

Miter Saw Strengths

Miter saws dominate three specific cutting tasks:

- Crosscutting boards to length – Cutting across the grain with dead-accurate 90-degree cuts. Building a deck? You’ll crosscut dozens of joists and decking boards. A miter saw makes this fast and consistent.

- Mitered angle cuts – Picture frame corners, crown molding, baseboard trim. The saw rotates to preset angles (typically 0° to 45° left and right) with positive stops that click into place.

- Bevel cuts – The blade tilts for compound angles. Essential for crown molding and certain furniture joints.

I’ve used my 10-inch sliding miter saw for trim work on three room remodels. The time savings versus marking and cutting each piece individually is massive. More importantly, the accuracy is consistent—my first cut matches my hundredth cut.

Where miter saws struggle: They can’t rip boards lengthwise, can’t cut large sheet goods, and they’re terrible for anything that doesn’t fit on the saw table. Try cutting a 4×8 sheet of plywood on a miter saw and you’ll understand why you need a different tool.

Circular Saw Strengths

Circular saws handle the cuts miter saws can’t touch:

- Ripping plywood and boards – Cutting with the grain to reduce width. Ripping a 2×10 down to 2×6 width? Circular saw with a straightedge guide.

- Breaking down sheet goods – A 4×8 sheet of plywood is too large for a miter saw. With a circular saw and a straightedge clamp, you can cross-cut that sheet into manageable pieces right on your sawhorses.

- Cutting installed materials – Trimming door jambs for flooring, cutting deck boards in place, notching studs for plumbing. The saw goes to the work.

- Portable jobsite cuts – Contractors love circular saws because you can toss one in a truck and cut anywhere.

Last month I built storage shelves in my garage using 3/4-inch plywood. Every single rip cut—breaking down the 4×8 sheets into shelf widths—required my circular saw. I couldn’t have completed that project with just a miter saw.

Where circular saws struggle: Freehand accuracy. Without a guide, it’s tough to make perfectly straight cuts. Angled cuts require setup time and a speed square. Repetitive crosscuts take longer because you measure each one individually.

Accuracy and Repeatability: Which Delivers Cleaner Cuts?

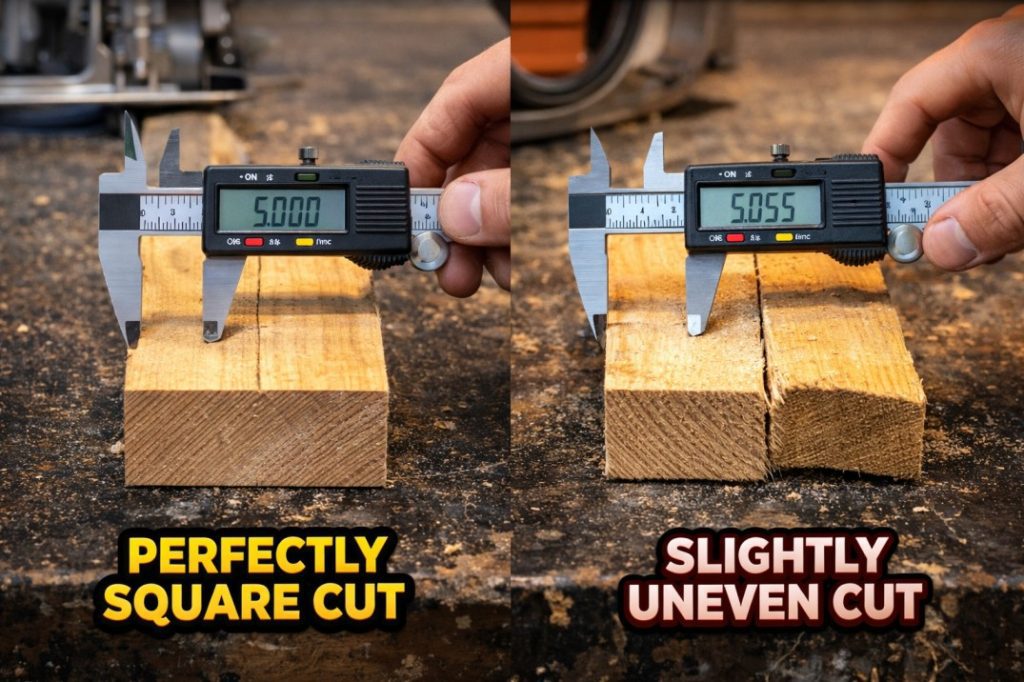

For crosscuts and miters, the miter saw wins hands-down. The fence keeps your board square, the blade path is fixed, and the angle stops are precise. I can cut twenty 16-inch pieces from a 2×4 and they’ll all measure within 1/32 inch of each other.

The laser guides and LED shadows on newer 2026 models (like the DeWalt DWS780 or Bosch GCM12SD) make placement even easier. You see exactly where the blade will cut before pulling the trigger.

For straight rip cuts, a circular saw with a quality straightedge guide approaches miter saw accuracy. I use a Kreg Rip-Cut on my circular saw for plywood, and the cuts are clean enough for visible furniture edges. But you’re adding setup time for each cut.

Freehand circular saw cuts—following a pencil line without a guide—rarely match miter saw precision. They’re good enough for framing lumber and rough carpentry, but not for finish work where gaps show.

Real-World Accuracy Test

I tested both saws cutting 2x4s to identical 24-inch lengths. After ten cuts with each saw:

- Miter saw: All ten pieces measured 24 inches ± 1/64 inch. Cuts were square and clean.

- Circular saw (with speed square guide): Pieces ranged from 23-15/16 to 24-1/16 inches. Cuts were mostly square but required more sanding.

- Circular saw (freehand): Pieces ranged from 23-7/8 to 24-1/8 inches. Several cuts were noticeably out of square.

For finish carpentry and visible joints, this accuracy difference matters. For structural framing, freehand circular saw cuts are usually fine.

Safety Considerations: Injury Risks and Protection Features

Both saws demand respect, but they present different risks.

Miter Saw Safety

The primary danger is the blade descending toward your hands. Keep fingers away from the cut line and use the saw’s clamp for small pieces. Never reach under the blade guard or remove safety features.

Modern miter saws include:

- Blade guards that automatically cover the blade when raised

- Electric brakes that stop the blade in 2-3 seconds after release (older saws coast for 10+ seconds)

- Dust collection ports that improve visibility and reduce airborne sawdust

The stationary setup reduces kickback risk compared to handheld tools. Once you learn proper hand placement, miter saws feel very controlled.

Honest assessment: I’ve had one close call with a miter saw when a small cutoff piece kicked back. Since then, I never hold pieces smaller than 6 inches without the clamp engaged. That scared me enough to change my habits permanently.

Circular Saw Safety

Kickback is the biggest circular saw danger. If the blade binds in the cut, the saw can violently jump backward toward you. This happens when:

- The kerf closes on the blade during a rip cut

- You’re cutting warped lumber that pinches

- The blade guard catches on the workpiece

Better circular saws (2026 models from Milwaukee, Makita, DeWalt) include electric brakes and anti-kickback clutches that help, but they can’t eliminate the risk entirely.

Other circular saw risks:

- Blade exposure – More of the blade is exposed during cutting compared to a miter saw

- One-handed operation temptation – Always use both hands, no exceptions

- Workpiece movement – If the material shifts mid-cut, you can lose control

I wear safety glasses and hearing protection with both saws, but I’m significantly more cautious with the circular saw. The handheld nature means you’re in closer contact with the blade throughout the entire cut.

| Safety Factor | Miter Saw | Circular Saw |

|---|---|---|

| Kickback Risk | Low | Moderate to High |

| Blade Guard | Automatic, enclosed | Spring-loaded, can catch |

| Hand Proximity to Blade | Moderate | Close |

| Beginner Friendliness | Higher | Moderate |

| Injury Severity if Accident Occurs | Severe | Severe |

Bottom line: Both saws can cause serious injuries. Miter saws feel more controlled, but complacency is dangerous with either tool. The miter saw vs circular saw safety debate doesn’t have a clear winner—you need proper training and respect for both.

Portability and Workshop Space: Setup and Storage Reality

Workshop Footprint

Miter saws need dedicated space. A 10-inch miter saw requires roughly 4-5 feet of table length (saw plus extension supports for long boards). A 12-inch sliding compound miter saw might need 6 feet. You’ll also need clearance behind the saw for the sliding rail movement.

Many woodworkers mount miter saws on mobile stands with folding wings. This works great until you’re cutting 8-foot boards alone—you need those support wings extended, which takes up serious garage real estate.

Circular saws store in a small case or hang on a pegboard. When I’m not using mine, it takes up maybe 12×12 inches of shelf space. For small garage workshops or apartment DIYers, this matters enormously.

Jobsite Portability

Contractors doing trim work often bring miter saws to jobsites on mobile stands. A 10-inch miter saw plus stand weighs 40-55 pounds total—manageable for one person but awkward up stairs.

A corded circular saw weighs 8-10 pounds. A cordless model with battery might hit 11 pounds. You can carry it in one hand with your tool bag in the other. For remodeling work where you’re moving between rooms or floors, this portability difference is massive.

I’ve done finish carpentry in occupied homes where I couldn’t set up a miter saw without moving furniture. In those situations, I cut everything with a circular saw and speed square in the garage, then brought the pieces inside. It added time, but it was the only practical option.

Cost Comparison: Initial Investment and Long-Term Value

Entry-Level Options (2026 Prices)

- Basic miter saw: $120-$180 (7.5-inch or basic 10-inch non-sliding models)

- Basic circular saw: $50-$80 (corded sidewinder models)

Circular saws have a lower barrier to entry, which is why they’re often a beginner’s first power saw purchase.

Mid-Range Quality (Recommended for Serious DIY)

DEWALT 12-Inch Miter Saw, 15-Amp, Single Bevel, Compound (DWS715)

- Stainless-steel miter detent plate of 12-inch miter saw blade comes with 14 positive stops

- The mitre saw features the precise miter system and machined base fence support

- Tall sliding fence of DEWALT miter saw supports 5-1/2-inch base vertically

List Price :

Offer: 248.98

Go to Amazon- 10-inch sliding compound miter saw: $300-$450 (DeWalt DWS779, Metabo HPT C10FSHC, Bosch GCM10SD)

- Quality circular saw: $120-$180 corded, $180-$250 cordless with battery (Makita 5007MG, DeWalt DWE575, Milwaukee M18 Fuel)

DEWALT 20V MAX Circular Saw, Cordless Sidewinder Style Portable, 6-1/2-Inch Blade, 5150 RPM, 0-50 Degree Bevel Capability, Battery Not Included (DCS391B)

- 5150 RPM motor delivers power and speed to make the most demanding cuts with ease

- High strength and lightweight magnesium shoe provides jobsite durability for long-term cut accuracy

- Optimized rubber over molded comfort grip delivers optimal balance and control of electric saw for wood cutting

List Price :

Offer: 129.00

Go to AmazonAt this price point, you’re getting accuracy, durability, and features that matter—electric brakes, better dust collection, more power.

Professional Grade

- 12-inch dual-bevel sliding miter saw: $500-$700+ (DeWalt DWS780, Bosch GCM12SD, Festool Kapex)

- Track saw system: $400-$600+ (basically a premium circular saw with precision track)

For someone choosing their first power saw with a $200 budget, a quality circular saw plus a speed square gives you more versatility than a budget miter saw. You can make most of the same cuts with more setup time, but you gain the ability to rip plywood and work on large materials.

If you’re doing extensive trim work or building furniture, the miter saw becomes worth the investment and space. I bought my sliding miter saw after completing two rooms of baseboards with a circular saw—the frustration convinced me the upgrade was justified.

Still unsure which saw fits your projects? Check out our comprehensive buying guide for detailed selection criteria based on your specific workshop needs and budget.

Which Projects Actually Need Which Saw?

Miter Saw Projects

- Crown molding installation

- Baseboard and door trim

- Deck building (crosscutting deck boards and joists)

- Picture frames

- Furniture with multiple pieces cut to identical lengths

- Door and window casing

Circular Saw Projects

- Breaking down plywood sheets

- Framing walls and structures

- Ripping boards to width

- Cutting hardwood flooring

- Outdoor construction (building sheds, fences)

- Any project requiring the saw to come to the workpiece

Projects Where Either Works (But One Is Easier)

Simple crosscuts on 2x4s or 2x6s can be done with either saw. The miter saw is faster and more accurate. The circular saw is more versatile if you need to work on-site or don’t have workshop space.

For my garage shelf project, I needed both saws: circular saw to rip plywood shelves to width, miter saw to crosscut the shelf supports to identical lengths. Neither saw alone would’ve completed that project efficiently.

Blade Options and Material Capabilities

Blade Compatibility

Both saws use circular blades, but the sizing differs. Miter saws typically use 10-inch or 12-inch blades. Circular saws use 7-1/4-inch blades (most common) or 6-1/2-inch blades (compact models).

The smaller circular saw blades mean shallower maximum cutting depth:

- 7-1/4-inch circular saw: ~2-3/8 inches at 90°, ~1-11/16 inches at 45°

- 10-inch miter saw: ~5-1/2 inches wide at 90° (crosscut capacity), ~3-1/2 inches thick

For cutting 4×4 posts, a miter saw handles them in one pass. A circular saw requires cutting from both sides, which is doable but less convenient.

Material Versatility

With the right blade, both saws cut:

- Softwood and hardwood lumber

- Plywood and MDF

- Composite decking

- Plastic and PVC trim

- Aluminum (with non-ferrous metal blade)

I’ve used my circular saw with a diamond blade to cut concrete backer board for tile work. You can swap miter saw blades for specific materials, but circular saws see more blade changes in my workshop because they handle such varied tasks.

Specialty blades make a huge difference. A quality 80-tooth crosscut blade on a miter saw produces glass-smooth cuts in oak and maple. The cheap 24-tooth blade that came with your saw will tear out grain and require heavy sanding.

Maintenance and Durability: Long-Term Ownership Reality

Miter Saw Maintenance

Keep the sliding rails clean and lightly lubricated. Dust and sawdust buildup causes binding and reduces accuracy. I wipe down my saw rails every few months and add a thin layer of dry lubricant.

The fence and angle indicators need occasional checks. After a year of heavy use, my miter saw’s 90-degree stop was off by about 1/16 inch. A five-minute adjustment with an Allen wrench fixed it.

The biggest wear item is the blade. A good carbide blade lasts 50-100 hours of cutting before it needs sharpening. Budget $15-20 for resharpening or $40-80 for replacement depending on tooth count and quality.

Circular Saw Maintenance

Circular saws take more abuse because they’re portable and work in harsher conditions. Check the blade guard operation before each use—sawdust can jam it open, which is dangerous.

Corded models are nearly maintenance-free beyond blade changes and occasional brush replacement (every few years for DIY use).

Cordless models add battery care to the equation. Lithium-ion batteries lose capacity over time regardless of use. A battery that’s 4-5 years old might only hold 60-70% of its original charge.

I burned out a cheap circular saw after 18 months of heavy use. The bearings started screaming and the motor struggled in hardwood. Quality models (Makita, Milwaukee, DeWalt) routinely last 5-10 years of regular DIY use.

Durability Comparison

Miter saws have fewer moving parts exposed to debris, so they generally last longer when properly maintained. My 8-year-old DeWalt miter saw still cuts as accurately as day one.

Circular saws endure more physical stress—drops, jobsite conditions, cuts through debris-laden lumber. If you’re rough on tools, expect to replace circular saws more frequently than miter saws.

The Honest Recommendation: Which Should You Buy First?

After using both saws across hundreds of projects, here’s my straight answer to the miter saw vs circular saw question:

Buy a circular saw first if:

- You have limited workshop space (small garage, apartment)

- Your projects involve plywood, sheet goods, or long rip cuts

- You need portability for jobsite work

- Your budget is under $150-200

- You’re doing rough carpentry, framing, or outdoor construction

Buy a miter saw first if:

- You have dedicated workshop space

- You’re doing trim work, molding, or finish carpentry

- Your projects require many identical crosscuts (deck boards, fence pickets)

- Accuracy matters more than versatility for your typical work

- You rarely need to rip boards lengthwise

Both When Bought:

- You’re serious about woodworking and have the space

- Your projects mix rough carpentry with finish work

- You’re building furniture or doing complex projects

- You value efficiency and using the right tool for each cut

For most DIY homeowners tackling varied projects, I recommend starting with a quality circular saw ($120-180) and a reliable speed square ($15-25). This combination handles 80% of home improvement cutting tasks. Add a straightedge clamp guide ($30-50) and you can rip plywood with near-miter-saw accuracy.

Once you’ve completed a few projects and identified your most common cuts, you’ll know whether a miter saw is worth the investment and space. If you find yourself making dozens of repetitive crosscuts or fighting for accuracy with angled trim work, that’s when the miter saw upgrade makes sense.

I ran my DIY hobby for three years with just a circular saw before buying a miter saw. Looking back, that was the right sequence. The circular saw taught me fundamental cutting skills and handled everything I threw at it. When I finally added the miter saw, I knew exactly how I’d use it because I’d been making those cuts the hard way.

Ready to dive deeper? Compare specific models, read detailed reviews, and find the perfect saw for your workshop at our saw comparison hub.

Frequently Asked Questions

Can a circular saw do everything a miter saw can do?

Technically yes, but not practically. A circular saw with guides can make crosscuts and angled cuts, but it requires more setup time, delivers less accuracy, and can’t match the repeatability of a miter saw for tasks like cutting trim or making dozens of identical pieces. For occasional crosscuts, a circular saw works fine. For finish carpentry or projects with many repetitive cuts, a miter saw is significantly more efficient and accurate.

Which saw is better for cutting 2x4s?

For crosscutting 2x4s to length, a miter saw is faster and more accurate. For ripping 2x4s lengthwise (reducing width), you need a circular saw—miter saws can’t rip. If you’re building something like a deck frame with many studs cut to identical lengths, the miter saw will save hours compared to measuring and cutting each 2×4 individually with a circular saw.

Is a miter saw safer than a circular saw for beginners?

Generally yes. Miter saws have a more controlled cutting action with less kickback risk, automatic blade guards, and your hands stay further from the blade during operation. Circular saws require more technique to use safely and have higher kickback potential. However, both tools demand respect and proper safety practices—complacency with any power saw can lead to serious injury regardless of experience level.

Can I cut plywood with a miter saw?

You can crosscut plywood strips that fit on your miter saw table (usually up to 12 inches wide depending on your saw’s capacity), but you cannot break down full 4×8 sheets or make long rip cuts. For cutting plywood shelves to width or breaking down sheet goods, you need a circular saw with a straightedge guide or a table saw.

What’s the best budget option for someone buying their first saw?

A quality corded circular saw in the $120-180 range (like the Makita 5007MG or DeWalt DWE575) plus a speed square and straightedge clamp gives you the most versatility for around $175 total. This setup handles everything from breaking down plywood to crosscutting framing lumber to making angled cuts. You can add a miter saw later when specific projects justify the investment, but a circular saw is the most practical first power saw for general DIY work.

Affiliate Disclosure: This article contains affiliate links to products. If you purchase through these links, we may earn a small commission at no additional cost to you. This helps support our website and allows us to continue providing honest, detailed tool reviews and comparisons.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.