When Harbor Freight launched their Hercules line of power tools, I’ll admit I was skeptical. Harbor Freight has built their reputation on ultra-cheap tools that work okay for occasional use but often can’t handle serious workloads. Could their premium-ish Hercules brand really compete with established table saw manufacturers?

I’ve now spent four months using the Hercules 10-inch portable table saw in my workshop, supplemented by conversations with other woodworkers who’ve taken the plunge on this budget option. The results surprised me—though not always in the ways you might expect.

The Hercules table saw sits in an interesting market position. At roughly $300-$350, it costs significantly more than Harbor Freight’s bottom-tier Chicago Electric saws but substantially less than name-brand contractor saws from DeWalt, Bosch, or Makita. The question every budget-conscious woodworker asks: does it deliver enough performance to justify the purchase, or should you save longer for a premium option?

In this honest review, I’ll share exactly what the Hercules table saw does well, where it falls short, and who should seriously consider buying one versus investing elsewhere. No marketing hype—just real-world experience from someone who actually uses this saw for projects, not just test cuts.

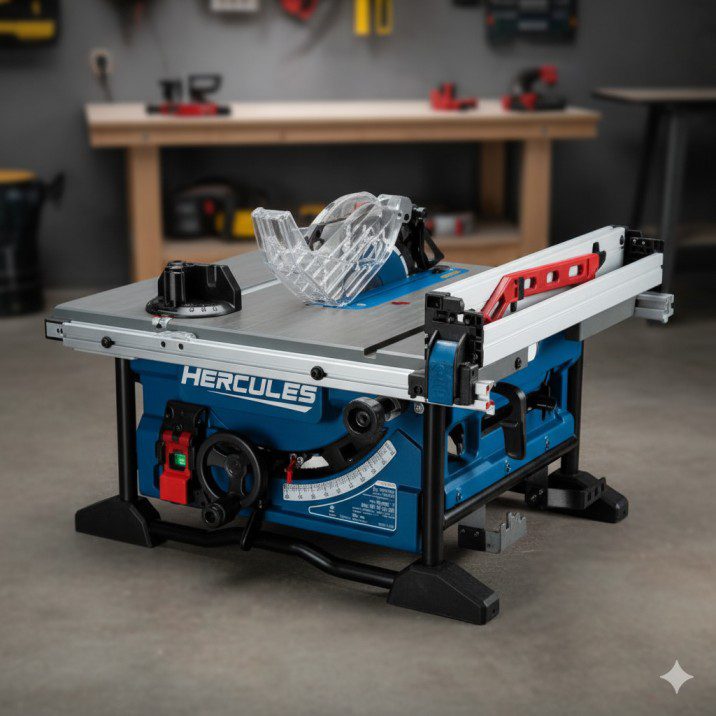

Hercules Table Saw: What You’re Actually Getting

Harbor Freight currently offers one main Hercules table saw model, though specifications and features have evolved slightly since the line’s introduction.

Current Specifications (2025 Model)

Motor and Power:

- 15-amp motor

- 120V standard household power

- No-load speed: 5,000 RPM

- Adequate power for 10-inch blade cutting

Cutting Capacity:

- 10-inch blade diameter

- Maximum rip capacity: 32 inches to right of blade

- Maximum depth of cut at 90°: 3-1/8 inches

- Maximum depth of cut at 45°: 2-1/4 inches

Table and Build:

- Cast aluminum table surface (not cast iron)

- Table dimensions: approximately 26″ x 22″

- Portable design with folding stand

- Rolling wheels for mobility

- Weight: approximately 90 pounds with stand

Fence System:

- Rack-and-pinion fence adjustment

- T-square style fence design

- Measurement scale on front rail

- Right-side extension support

Price Point:

- Typical retail: $299-$349

- Frequent sales drop to $250-$280

- Harbor Freight coupons often available

Warranty:

- 90-day money-back guarantee

- 2-year warranty coverage (tools purchased after certain date)

What’s In the Box

The saw arrives mostly assembled but requires setup:

- Main saw unit with motor

- Folding stand with wheels

- T-square fence and rail system

- Miter gauge

- Blade guard assembly

- Push stick

- Basic wrenches for blade changes

Assembly takes 30-60 minutes for most people. Instructions are adequate though not as detailed as premium brands provide.

Build Quality: Where Hercules Makes Compromises

Understanding the Hercules build quality requires appreciating what Harbor Freight prioritized and where they cut costs to hit their target price point.

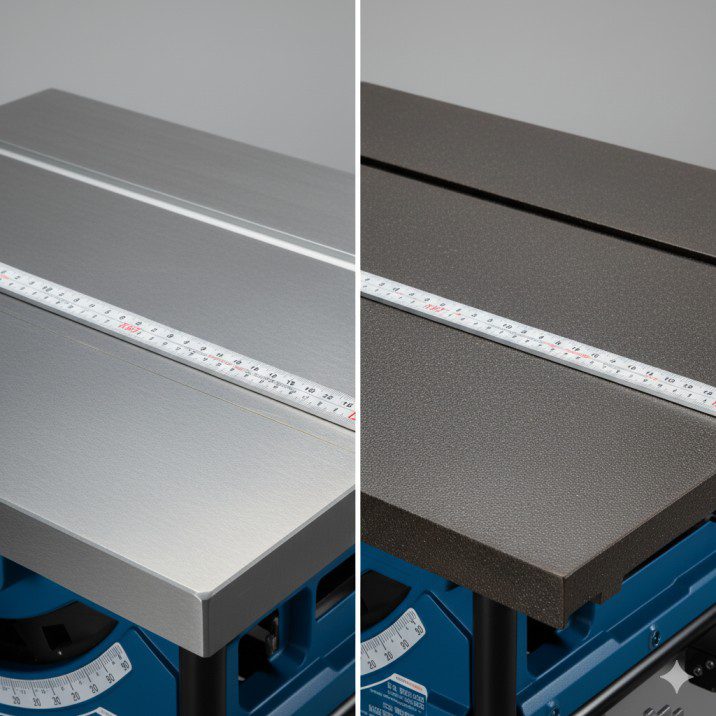

The Aluminum Table Trade-off

The most significant compromise: the Hercules uses a cast aluminum table instead of cast iron. This decision saves weight (important for portability) and manufacturing cost, but introduces real performance limitations.

What I’ve observed: The aluminum table is reasonably flat out of the box—I measured variations of about 0.015 inches across the surface using a straightedge. That’s acceptable for general woodworking but not precision furniture making. Cast iron tables on premium saws typically hold tolerances under 0.010 inches.

More importantly, aluminum flexes more than cast iron under load. When pushing heavy hardwood through the saw, I can feel slight deflection in the table. It’s not dramatic, but it’s noticeable compared to my old cast iron contractor saw. For plywood and softwoods, this rarely matters. For precision hardwood work, it occasionally shows up as slight variations in cut consistency.

The aluminum surface is smooth enough that material slides reasonably well after waxing, but it doesn’t have the same glass-like feel of machined cast iron. I apply paste wax every 2-3 weeks to maintain good sliding properties.

Motor Performance and Limitations

The 15-amp motor provides adequate power for most tasks a portable saw encounters. I’ve successfully ripped:

- 2x material in pine, fir, and other softwoods: no issues

- 3/4-inch hardwood plywood: handles easily

- 8/4 hard maple and oak: completes cuts but bogs down with aggressive feed rates

- Multiple crosscuts in 2×12 lumber: works fine with reasonable feed pressure

Motor limitations become apparent with:

- Very dense hardwoods (hard maple, white oak) at full depth

- Dull blades—the motor doesn’t have excess power to compensate

- Dado blade stacks wider than 1/2 inch

- Continuous production-style cutting without rest periods

The motor runs noticeably louder than premium saws, operating around 95 decibels versus 85-90 for higher-end models. Hearing protection is non-negotiable with this saw.

After four months of regular use, the motor shows no signs of deterioration or problems. It runs hot during extended use but hasn’t triggered thermal protection even during demanding sessions.

Fence System: Functional But Not Refined

The rack-and-pinion fence uses a T-square design that locks at the front rail. In theory, this provides square, parallel cuts. In practice, results vary.

Fence positives:

- Locks reasonably firmly with minimal deflection

- Slides smoothly across the full range of travel

- Measurement scale is legible and fairly accurate

- Extension support provides adequate outboard stability

Fence limitations:

- Initial setup required 45 minutes of adjustment to achieve parallel alignment

- Fine micro-adjustments aren’t possible—the fence moves in roughly 1/32-inch increments

- The locking mechanism occasionally allows 0.010-0.015 inch of play after locking

- Scale accuracy degrades toward the far right of travel

I spent an entire evening with a dial indicator getting the fence properly aligned when I first set up the saw. Once dialed in, it stayed reasonably true, but I verify parallelism every few weeks because it can drift slightly. Premium saws maintain alignment more reliably.

For cabinet-making where tolerances matter, I’ve learned to measure and verify each setup rather than trusting the fence scale. For general construction or shop projects, the fence works adequately.

Stand and Portability

The folding stand represents one of Hercules’ better features. It’s sturdy when deployed, folds reasonably compact for storage or transport, and the wheels make moving the saw manageable for one person.

Stand strengths:

- Quick setup and takedown (under 2 minutes once familiar)

- Good stability on level surfaces

- Wheels make repositioning easy

- Reasonable weight for portability (90 lbs total)

Stand weaknesses:

- Slight wobble on uneven surfaces

- Wheels are small and struggle with rough terrain

- Not as rock-solid as stationary saw stands

- Height isn’t adjustable

I use this saw both in my shop and occasionally at job sites. The portability proves genuinely useful—I wouldn’t want to regularly move a 250-pound contractor saw, but the Hercules handles transportation reasonably well.

For more on different saw types and their applications, see our table saw buying guide.

Real-World Performance Testing

Specifications and build analysis only tell part of the story. Here’s how the Hercules performs with actual woodworking tasks.

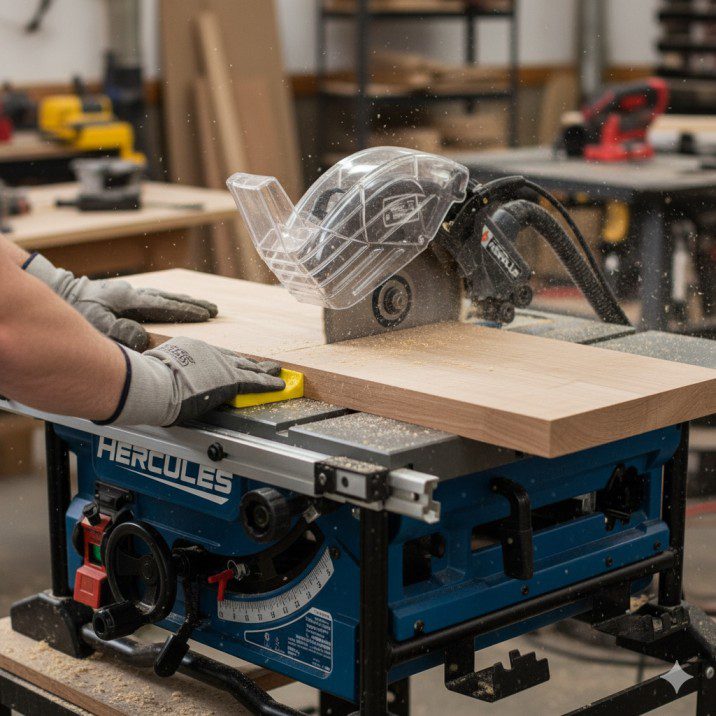

Ripping Performance

Dimensional lumber (2×4, 2×6, etc.): The Hercules handles softwood dimensional lumber easily. I’ve ripped dozens of 2x4s and 2x6s for various projects without the motor straining or bogging down. Feed rates can be aggressive without problems.

Hardwood boards: This is where motor limitations appear. Ripping 8/4 hard maple requires slower, more deliberate feed rates. The saw completes the cuts, but you can hear the motor working hard. I’ve never had it stop mid-cut, but I’ve definitely slowed my feed to avoid overloading the motor.

With 4/4 hardwood, performance is better—still not effortless like a 2 HP contractor saw, but adequate for hobbyist work. I wouldn’t want to rip hundreds of board feet of hardwood on this saw, but for occasional furniture projects, it manages.

Sheet goods (plywood, MDF): The Hercules handles 3/4-inch plywood and MDF well, which is fortunate since these materials are common in many projects. The motor maintains speed through cuts, and the fence (when properly set) keeps cuts straight and accurate.

The 32-inch rip capacity accommodates breaking down full sheets, though you’ll need adequate outfeed and side support like any portable saw.

Crosscutting Accuracy

The included miter gauge is basic—it slides in the milled slots with minimal play, but the angle adjustment and locking aren’t particularly refined.

Miter gauge issues:

- Angle indicator scale isn’t highly accurate

- Locking lever requires significant force

- Face is small, providing limited workpiece support

- No built-in stop system or measurement scale

For occasional crosscuts, the miter gauge works. For serious crosscut work, I immediately upgraded to an aftermarket miter gauge ($40) and built a crosscut sled. The saw itself can make accurate crosscuts; the factory miter gauge just doesn’t facilitate precision work easily.

With a good sled, I’ve made hundreds of accurate crosscuts. The saw holds angles well once set, and the blade runs true enough for quality results.

Bevel Cutting

Blade tilt adjustment uses a wheel at the front of the saw. The mechanism operates smoothly enough, though it feels less refined than premium saws.

Bevel capabilities:

- Tilts left 0-45 degrees (standard)

- Built-in stops at 0° and 45°

- Angle indicator scale (accuracy varies)

- Adequate locking mechanism

The 0° and 45° stops get you close but require verification with a square. I’ve had to adjust the 90° stop by about 0.5 degrees to achieve truly square cuts. This is disappointing but not uncommon on budget saws—just expect to spend time setting stops accurately.

Bevel cuts in hardwood push the motor harder than 90° cuts since you’re engaging more blade in the material. The saw manages but requires slower feed rates.

Dust Collection Reality

The Hercules includes a 2.5-inch dust port below the table. In practice, dust collection is mediocre at best.

Dust collection performance: With a shop vacuum connected, I estimate 40-50% of dust gets captured. The rest escapes into the air, accumulates on the motor housing, and settles on the floor. This is typical for portable saws but still disappointing.

The internal blade shroud doesn’t direct dust effectively toward the port. Much of the dust bounces around inside the saw housing before finding its way out through various gaps.

I’ve improved collection somewhat by sealing gaps around the blade insert with tape and upgrading my dust collection setup, but this remains a weakness. If dust management is critical, budget additional money for a good dust extractor.

Learn more about improving collection on our dust collection system guide.

Safety Features and Concerns

The Hercules includes basic safety features but lacks advanced protection technology.

Standard safety equipment:

- Blade guard with anti-kickback pawls

- Riving knife (essential for preventing kickback)

- Push stick

- Paddle-style power switch

- Thermal overload protection on motor

What’s missing:

- No SawStop-style flesh detection technology

- No electric brake (blade coasts for 8-10 seconds after shutdown)

- Blade guard is cumbersome to remove/reinstall

- No integrated riving knife quick-release

The riving knife is non-removable, which is good for safety but limits certain cuts (dado operations, non-through cuts). The guard, however, comes off easily—too easily, which tempts users to remove it and not reinstall it.

My safety concerns: The aluminum table can flex under heavy pressure, potentially causing binding. I’ve had material pinch once when making an aggressive rip cut through twisted 2×6 lumber. The riving knife prevented kickback, but the experience reminded me that this isn’t a heavy, stable saw that forgives poor technique.

The blade takes noticeably longer to stop compared to premium saws with brake systems. Always wait for complete blade stoppage before reaching near the blade area.

Overall safety is adequate with proper technique and respect for the saw’s limitations, but this isn’t a saw that compensates for operator errors with advanced safety technology.

For comprehensive safety practices, visit our table saw how-to guide.

Assembly, Setup, and Adjustment

The Hercules arrives partially assembled, requiring 30-90 minutes of setup depending on your mechanical experience and how precisely you want everything dialed in.

Initial Assembly Process

What’s required:

- Attach the folding stand to the saw base

- Install the front and rear fence rails

- Mount the fence and extension wing

- Install blade guard assembly

- Adjust fence parallelism

- Verify blade alignment to miter slots

Steps 1-4 are straightforward and well-explained in the instructions. Steps 5-6 require patience and aren’t detailed adequately in the manual.

The Critical Fence Alignment

This is where you’ll spend most of your setup time. Out of the box, my fence wasn’t parallel to the blade—it was approximately 0.020 inches closer at the back than the front. This small variation causes binding and poor cut quality.

Adjustment process: The fence rail has adjustment slots that allow repositioning. Using a dial indicator or careful measurement, I adjusted the rear rail position until the fence ran parallel to within 0.005 inches across its full length.

This took 45 minutes of measuring, adjusting, and re-measuring. Harbor Freight’s instructions don’t adequately explain this critical setup step. YouTube videos proved more helpful than the included manual.

Blade Alignment

Verify that the blade runs parallel to the miter slots. My saw was reasonably close out of the box (within 0.010 inches), but I’ve heard from other owners who needed to adjust the blade alignment by shimming the trunnion.

Blade alignment adjustment on the Hercules is possible but not easy—it requires partial disassembly and shimming. If your saw needs significant adjustment here, consider returning it for a better unit rather than struggling with a fundamentally misaligned saw.

Ongoing Maintenance Adjustments

Every few weeks, I verify fence parallelism because it can drift slightly. The fence rail mounting hardware can work loose from vibration, allowing the rail to shift. I now apply thread-locking compound to the mounting bolts, which has improved consistency.

The blade height and angle adjustment mechanisms require occasional tightening of the locking components. These aren’t set-and-forget systems like premium saws—expect periodic maintenance to keep everything functioning properly.

Value Analysis: Is Hercules Worth the Money?

The critical question for any budget tool: does it deliver enough performance to justify its cost, or should you save longer for something better?

What You Get for $300-$350

Reasonable capabilities:

- Adequate motor power for hobbyist woodworking

- Portable design with decent stand

- Enough cutting capacity for most projects

- Basic safety features including riving knife

- T-square fence that works when properly set up

What you’re sacrificing:

- Cast iron table precision and stability

- Refined fence with micro-adjustability

- Powerful motor that doesn’t strain with hardwoods

- Premium fit and finish

- Extensive customer support network

- Long-term durability (unclear—saw is relatively new to market)

Comparison to Alternatives

Versus premium portable saws ($500-$700): DeWalt, Bosch, and Makita portable saws cost $400-$550. They offer cast iron or higher-quality aluminum tables, more powerful motors, better fence systems, and proven reliability. The extra $200-$300 buys significantly better performance and longevity.

I tested a DeWalt DWE7491RS alongside the Hercules. The DeWalt felt noticeably more refined—smoother adjustments, more stable table, better dust collection, quieter operation. Was it worth $250 more? For professional use, absolutely. For a hobbyist making occasional cuts, the gap narrows considerably.

Versus other budget saws ($200-$300): Harbor Freight’s lower-tier Chicago Electric saws and similarly priced models from Skil or Craftsman offer comparable performance to Hercules but often with less portability or slightly lower build quality. The Hercules represents the best option in this price tier based on my research and testing.

Versus used contractor saws ($300-$500): This is interesting territory. A used contractor saw from Delta, Craftsman, or Ridgid offers cast iron tables, more powerful motors, and proven durability. However, you’re buying used equipment with unknown history, no warranty, and no portability.

I’d choose a good used contractor saw over the Hercules for a permanent shop location, but the Hercules wins if portability matters or if you can’t find quality used equipment in your area.

Who Gets Good Value from Hercules

This saw makes sense for:

- Weekend hobbyists working on occasional projects

- DIYers doing home renovation work

- Beginning woodworkers building skill before investing heavily

- Contractors needing portable capability for job sites

- Woodworkers with limited budgets who need table saw capability now

- Second saw for portable use while owning a stationary primary saw

Consider alternatives if you:

- Work daily or run production operations

- Primarily work with hardwoods requiring powerful motor

- Demand precision for high-end furniture making

- Want refined user experience and premium features

- Have budget for $500+ and don’t need portability

Compare with other options on our best table saw reviews.

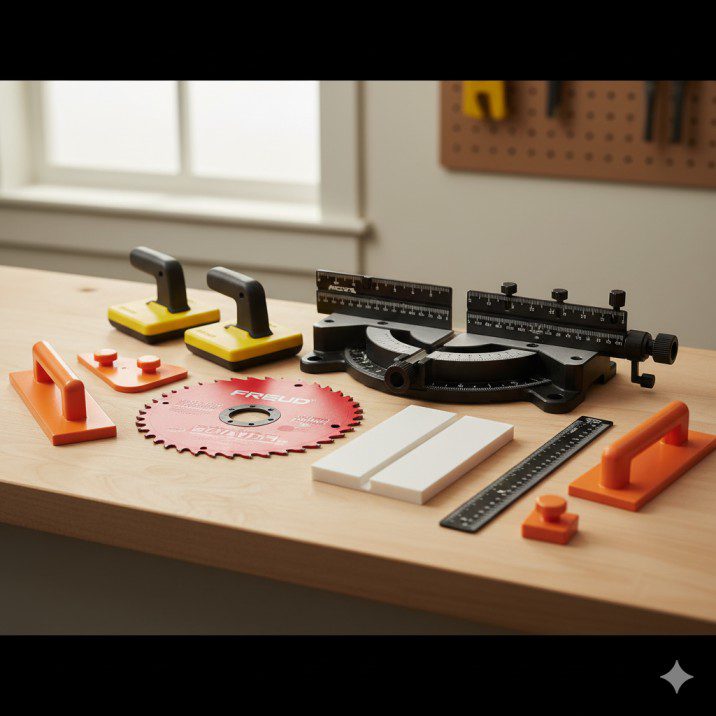

Recommended Upgrades and Accessories

Maximize Hercules performance with these strategic additions:

Essential Upgrades

Quality blade ($40-$60): The factory blade is adequate for construction work but not furniture making. Upgrade to a Freud, Forrest, or similar premium 40-50 tooth combination blade. This single upgrade improves cut quality dramatically.

Aftermarket miter gauge ($40-$80): The factory miter gauge is the saw’s weakest component. An Incra, Kreg, or similar aftermarket gauge transforms crosscutting accuracy.

Zero-clearance insert ($10-$15 or DIY): Make custom inserts from hardboard or MDF to reduce tearout on crosscuts and prevent small pieces from falling into the blade opening.

Mobile base upgrade (optional, $60-$100): If the factory stand doesn’t suit your needs, aftermarket mobile bases offer more stability and better mobility.

Recommended Accessories

Outfeed support: Build or buy an outfeed table or roller stand. The Hercules provides no rear support, making large sheet goods and long boards difficult to handle safely.

Blade stabilizers ($30-$50): These reduce vibration and improve cut quality, particularly helpful on portable saws with lighter construction.

Featherboards and push blocks: Beyond the basic push stick included, invest in proper push blocks and featherboards for safer, more controlled cuts.

Explore more options on our table saw accessories page.

Long-Term Durability Questions

The Hercules line is relatively new (introduced around 2018-2019), so long-term durability remains somewhat uncertain. My four-month testing period and conversations with owners who’ve had their saws 1-2 years suggest:

Holding up reasonably well:

- Motor continues running without issues

- Fence maintains alignment (with occasional checks)

- Stand remains functional and stable

- No catastrophic failures reported commonly

Showing wear:

- Aluminum table surface scratches more easily than cast iron

- Fence locking mechanism feels looser after extensive use

- Some users report bearing noise developing after 12-18 months

- Adjustment mechanisms can develop play requiring periodic tightening

Unknown: Will this saw last 10+ years like quality contractor saws often do? Probably not with heavy use. For occasional hobbyist use, it might serve adequately for 5-8 years. For daily professional use, I’d expect issues within 2-3 years.

Harbor Freight’s 2-year warranty provides some protection during the early ownership period, though warranty service requires returning to a Harbor Freight store, which may be inconvenient depending on your location.

Frequently Asked Questions

Is the Hercules table saw better than Chicago Electric? Yes, noticeably. The Hercules has better build quality, more powerful motor, and superior fence system compared to Harbor Freight’s budget Chicago Electric saws. The price difference ($150-200) is justified by improved performance.

Can the Hercules handle hardwood? Yes, but with limitations. It cuts hardwoods like oak, maple, and walnut but requires slower feed rates than premium saws. For occasional hardwood projects, it’s adequate. For extensive hardwood work, consider more powerful options.

Does it accept dado blades? Yes, the Hercules accommodates dado blade sets up to approximately 13/16 inches wide. The arbor length and motor power support basic dado operations, though performance isn’t as strong as with dedicated contractor saws.

How does Hercules compare to DeWalt or Bosch portable saws? DeWalt and Bosch offer better build quality, more refined features, and proven long-term reliability at $200-$300 higher prices. Hercules delivers 70-75% of their performance at 50-60% of their cost—good value but noticeable compromises.

Is the aluminum table a deal-breaker? It depends on your needs. For precision furniture making, yes—the flex and lower precision matter. For general woodworking, home projects, and construction work, aluminum is acceptable. Cast iron would be better but increases cost and weight substantially.

What’s the warranty and return policy? Harbor Freight offers 90-day money-back guarantee and 2-year warranty coverage. This provides reasonable protection, though customer service experiences vary by location.

Final Verdict: Should You Buy the Hercules?

After four months of real-world use, I’ve reached a nuanced conclusion about the Hercules table saw. It’s neither the budget miracle some hoped for nor the disappointing disaster skeptics predicted. It’s a capable, if compromised, tool that serves specific users well while frustrating others.

The honest truth: This saw punches above its price point in many ways while revealing its budget origins in others. For $300-$350, you’re getting legitimate table saw capability with real portability—something previous budget saws struggled to deliver. But you’re also getting aluminum instead of cast iron, adequate power instead of abundant, and functional rather than refined adjustments.

Who should seriously consider buying:

If you’re a weekend hobbyist who makes 20-30 cuts per month, primarily in softwoods and plywood, and needs portability or has budget constraints, the Hercules delivers solid value. It’s a capable saw that can produce quality results with proper technique and realistic expectations.

If you’re a beginning woodworker who isn’t sure how committed you’ll be to the hobby, the Hercules provides a reasonable entry point without massive financial commitment. If woodworking sticks, you can upgrade in a few years. If it doesn’t, you haven’t blown $800 discovering it wasn’t your thing.

If you need a second saw for portable use while owning a stationary primary saw, the Hercules fills that role adequately at reasonable cost.

Who should look elsewhere:

If you’re building a long-term workshop and this will be your primary saw for years, spend more on a premium portable saw or quality contractor saw. The compromises in the Hercules will frustrate you over time, and the durability questions make it risky as a primary long-term tool.

If you primarily work with hardwoods and demand precision for furniture making, the motor limitations and aluminum table flexibility will constantly remind you that you’re working with a budget tool. Invest in something better.

If you’re a professional relying on your saw for income, the Hercules isn’t built for daily production use. Spend the money on professional-grade equipment that won’t let you down.

My personal take:

I bought the Hercules as a portable second saw while keeping my older contractor saw as my shop primary. In that role, it serves me well—I can take it to job sites, use it for rough work, and not worry about damaging or moving my heavy primary saw. Would I want it as my only saw? Probably not. But as a budget portable option, it’s proven more capable than I expected.

The Hercules represents Harbor Freight’s genuine attempt to compete in the “good enough” power tool market—above their bottom-tier offerings but below premium brands. If your needs and budget align with what this saw delivers, you’ll likely be satisfied. If you’re hoping it performs like a $600 saw despite its $300 price, you’ll be disappointed.

Bottom line recommendation: The Hercules table saw earns a cautious recommendation for budget-conscious woodworkers with appropriate expectations. It’s a capable tool that delivers decent value, but know the compromises you’re making and decide whether those compromises fit your specific needs.

Rating by user type:

- Hobbyist woodworkers (occasional use): 7.5/10 – Good value

- Beginning woodworkers: 8/10 – Solid entry point

- Professional contractors: 6/10 – Acceptable for portable backup, not primary

- Serious furniture makers: 5/10 – Too many compromises for precision work

- Budget-constrained buyers: 8.5/10 – Best capability at this price point

Your woodworking journey deserves quality tools, but quality doesn’t always require maximum investment. The Hercules proves that budget tools can be legitimately useful when matched to appropriate applications and realistic expectations.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.