When buying new table saws, the age-old Harvey machinery name holds revered status. Meanwhile, SawStop dominates in discussions around high-tech safety advancements. So how do these brands and their offerings truly compare?

This comprehensive Harvey vs SawStop table saw comparison explains key differences in safety systems, build quality, dust collection, accessories, and other table saw traits to consider. Understanding the pros and cons of pricing helps identify the best value and type of table saw for your woodshop needs.

Brief Brand Backgrounds

First, let’s explore where Harvey and SawStop brands come from before pitting models head to head:

Harvey History

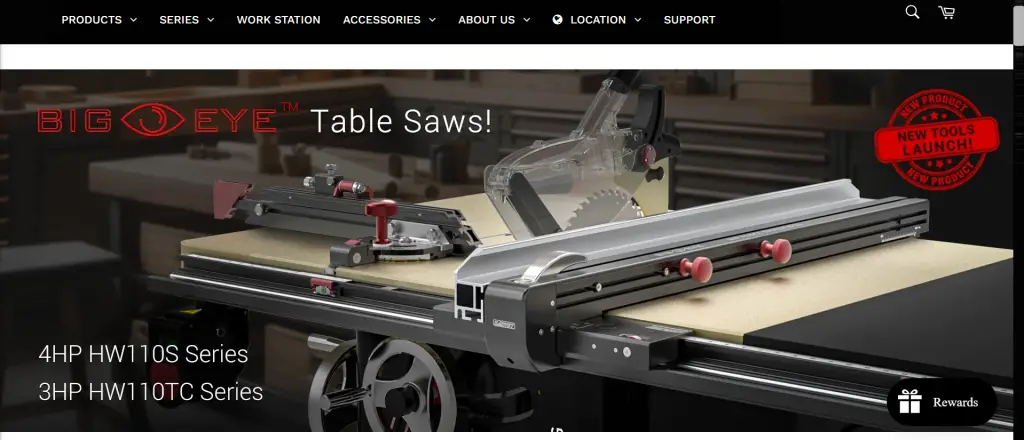

- Harvey, a Canadian family business since 1895, specializes in high-end woodworking/forestry machinery

- Harvey is renowned for manufacturing premium hand-hydraulic panel saws since the 1960s used at Smithsonian restoration

- Harvey introduced advanced unified frame table saws and jointers in 2003 before shuttering in 2016 for bankruptcy

- Harvey Industries brands back in 2018 and now produces table saws/jointers again with past Harvey heritage

SawStop Origins

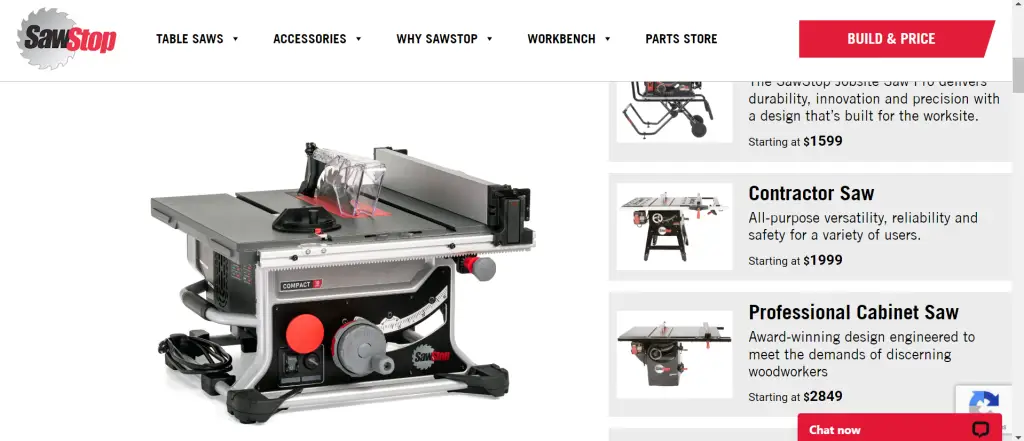

- Roy Strato invented ‘SawStop’ table braking system in 2001 after an engineer lost fingers in a sawing accident

- Founded SawStop corporation in 2003 when major saw-makers initially declined licensing tech

- Global expansion after Gass-authored jobsite braking saw standard in 2021

- Now produces the widest range of brake saws including jobsite, pro cabinet & contractor

So big-picture here are a smaller resurgent Canadian manufacturer known for premium classic machinery vs American inventors and pioneers in safety braking.

Harvey vs SawStop Safety Systems

Safety braking is likely the hottest table saw talking point these days. So let’s dig deeper into how these brands handle safety first:

Harvey Safety Features

Technology: Modern electronics during standard magnet safety switch operations

Response Time: Instant power shutdown within 7 milliseconds

Detection: Switch disruption if blade touched

Appendix A Compliant: Yes, comes with compliant clear base guard, riving knife, and anti-kickback pawls

Safety and Certification: Harvey provides full 1 year warranty covering parts and labor, plus detailed documentation

User Actions: Fast reaction needed to pull hands away

While Harvey table saws don’t claim innovative safety tech, they meet or exceed compliance guidelines through magnet switch systems and safety features common on cabinet grade contractor saws.

SawStop Safety Systems

Technology: Digital sensors and onboard computers tripping brake cartridges

Response Time: 12 milliseconds, plus override preventing blade restart

Detection: Contact with blade triggers – so no reaction needed. More dependable for injury avoidance.

Appendix A Compliant: Yes, compliant with latest anti-kickback and riving knife standards

Safety and Certification: Certified UL safe by OSHA. Also protected by 200+ approved global patents.

User Actions: None, since cartridges fire independent of human reaction speed

SawStop saws feel unmatched when weighing braking systems and complete injury prevention safeguards, but at higher costs for premium capability.

Unlike full Murphy switch resettings, the smart electronic SawStop safety systems can also restart almost instantly after false alarms from wood moisture.

Harvey vs SawStop – Build Quality

Another key shopping criterion involves overall fit and finish. These brands again differ:

Harvey Build and Component Quality

- Professional-grade 5HP+ motors, heavy cast-iron top and wings, steel infrastructure, belt-driven efficiency

- High-caliber trunnions with premium micro-ground cast-iron table mounted using doweling for accurate alignment

- High-quality rip fences – some types fully chrome-plated on sides, anodized aluminum guide tubes

- Heavy cast-iron handwheels control blade height and bevel movement via engineered worm gears

- Lasting reputation built upon high-end commercial saws inspiring craftsmen for generations

SawStop Professional Build Quality

- Cabinets contain heavy-gauge steel interior structures, cast-iron top and wings, though lighter than vintage Harvey saws

- Top notch trunnions quality – comparable to Harvey but less total mass and steel percentage

- Industry-acclaimed T-Glide fence systems renowned for stable length adjustments with locking positive stops and secure angles

- Blade height controls feature large front mounted handwheel with accurate worm gear adjustment

- Overall supreme fit and finish; more precision and tech vs nostalgia and brute strength in designs

Clearly Harvey does edge SawStop when weighing sheer mass and raw industrial toughness. But SawStop matches or exceeds most Harvey traits related to reliability and accuracy through advanced techniques and smarter materials.

Dust Extraction and Collection

Fine dust handling merits considerations too. Here’s how these brands address keeping shops tidy:

Harvey Dust Control

Collection Rating: Standard dust ports capture around 80% dust particles

Dust Port: Single 4” port

Capabilities: Can integrate straightforward duct tubing into various dust collector brands or shop vac systems

Quietness: Generates average 80 db shop noise levels on par with cabinet saws when idling or running

SawStop Dust Collection

Collection Rating: Precision shrouding and twin vents capture over 95% particle dust

Dust Ports: Dual integrated 2.5” dust ports

Capabilities: Easily adapts flexible dust collection tubing into DIY or commercial dust management systems

Quietness: Quietest on market, even under load

For simplified portable dust collection, SawStop packs a performance edge thanks to dual dedicated vents and engineered airflow shrouding – though premium bags/filters come recommended.

Accessories and Expandability

The ability to accessorize tools expands functionality over time. Harvey vs SawStop again shows divergence here:

Harvey Saw Accessories

Inserts: Various replaceable zero-clearance and dado inserts

Outfeed: some models include pivoting aluminium outfeed work extensions for long Stock and thin panels

Fences: Harvey saws feature beefy T-square style fences by default. Can add upgraded aftermarket fences.

Mobility: Optional wheeled bases for certain floorstanding models

SawStop Accessories

Inserts: Supports their own patent-pending zero-clearance inserts and dado cartridges

Outfeed: Built-in or optional stable work support table extensions

Fences: Native high standard T-Glide fences. Third party fences not recommended.

Mobility: Optional contractor saw wheeled bases or shop mobility packages

Harvey holds the edge for third-party fence upgrades meeting craftsmen needs. But SawStop supports hobbyists better out-the-box then protects proprietary inserts/cartridges for liability reasons, forcing reliance on their first-party ecosystem.

Pricing Comparison

MSRP pricing also shows meaningful separation as expected given market positions:

| Model Class | Harvey Price | SawStop Price |

|---|---|---|

| Contractor/Hybrid | $2,500+ | $1,700+ |

| Cabinet | $3,500+ | $3,000+ |

In part due to smaller production runs and veteran workforce expenses, Harvey prices trend higher across model tiers – but build quality also shows in materials and workmanship. Value depends on budgets and seeing beyond spec sheets.

SawStop commands premiums for high-tech safety systems which skew costs upwards too. But other model elements seem aligned with contractor and prosumer cabinet saws when removing patented tech fees.

Harvey and SawStop Reliability Reputations

Both Harvey and SawStop enjoy esteemed reputations for reliability despite contrasting approaches:

Harvey cabinet saws built tank-tough aim to run reliably for decades, valuing strength, mass and craftsmanship paying dividends over generations of ownership.

SawStop utilizes tighter manufacturing tolerances and integrated mechanical/digital engineering for consistent safety and precision daily operation out the factory for less maintenance.

So while Harvey echoes the reliability mantra of old-school woodworking purists, SawStop speaks to modern hobbyists and professionals valuing accuracy, safety, and tech optimization as shop tools adapted tighter homes and small businesses in 2023.

Conclusion

In closing, choosing between Harvey table saws versus popular SawStop models depends greatly on work style preferences, budgets, volatility attitudes, accessory needs, and shop space limitations.

Harvey suits traditional power users focused purely on building stamina and brute cutting force. SawStop answers smart shop budgeting wanting the latest safety innovations reasonably attainable for prosumers.

Neither choice remains foolproof nor risk-free when operating heavy cutting machinery daily amid pressures. So mindset matters as much as features when committing significant investments in 2023 table saws from these industry frontrunners.

Choose wisely by reflecting honestly on habits, objectives and shop conditions before pulling the trigger. And never underestimate the importance of always practicing safety protocols, wearing protective gear, and maintaining respectful fear regardless of brand claims.