A ripping blade designed specifically for table saws is essential for cleanly and safely slicing through the wood when making lengthwise cuts. The right ripping blade dramatically improves cut quality and precision on rip cuts compared to using a general-purpose blade.

But with so many ripping blade options on the market, how do you determine the best table saw ripping blade for your needs and budget?

This 2024 guide examines the top ripping blade models for cabinet table saws and portable job site table saws based on sharpness, durability, materials used, tooth configurations, cost, and more.

We’ll overview the factors to consider when choosing a ripping blade and provide concrete ripping blade recommendations across these categories:

- Best for the Money

- Best Premium/High-End

- Best for Thin Kerf Cuts

- Best for Portable Table Saws

- Best for Smooth Cuts

- Quietest Ripping Blade

Let’s dive into picking the ideal table saw ripping blade for clean, precise rip cuts on your woodworking projects this year!

Why Use a Ripping Blade for Table Saws?

Before covering blade recommendations, we should address – why even use a purpose-built ripping blade instead of an all-purpose general blade that comes standard on most table saws?

Here are the key benefits of switching to a dedicated ripping blade:

- Creates dramatically smoother, tear-out-free cuts along the wood grain

- Minimizes burning with less friction from optimal tooth geometry

- Fast feed rate to power through ripping thick stock efficiently

- Leaves only a thin kerf slice minimizing material waste

- Clean precise edges without ragged chipping

- Reduced vibration and quieter operation

- Stays sharp for far longer between sharpenings/replacements

In short – ripping blades cut fast, smooth, and cleaner! Swapping out that jack-of-all-trades blade for a ripping-optimized one elevates the quality of table saw work instantly.

Now let’s map out what exactly makes ripping blades tick before revealing this year’s top models.

How Ripping Blades Differ from General Blades

Purpose-built ripping blades specifically configure their tooth geometry and hook angle to suit the wood grain cutting motion unique to lengthwise table saw rips:

Tooth Tips Slanted for Ripping – Ripping blades angle front tooth tips in a “raker” pattern to score wood smoothly across fibers avoiding blunt chunk tearing.

Flat Top Grind for Fast Cuts – Flat top bevels with minimal top clearance angle maintain full blade width contact pushing through material faster.

Large Gullets to Clear Debris – The deep spaces or “gullets” allow rapid evacuating of sawdust and debris to prevent burning while ripping.

Sturdy Body to Withstand Heat – High-grade steel and expansion slots withstand heating, stress, and gumming during heavy ripping tasks.

Thin Kerf to Conserve Wood – Narrower thickness minimizes waste leaving thinner slit cut marks. Makes material go farther!

Now that you understand why ripping blades excel at handling table saw lengthwise cuts, let’s reveal the top models in various categories to consider this year!

Best Table Saw Ripping Blades – 2024 Recommendations

Best for the Money: Irwin Tools 1807368 Marples Ripping Blade

Delivering impressive quality without breaking budget, Irwin’s 10” 24T Marples ripping blade gives woodworkers robust performance at a value price point.

Key Attributes:

- Excellent value under $50 for 10 inch size

- 24 carbide teeth configuration ideal for rips in hardwood

- High grade carbide stays sharper than cheaper steel

- Smooth quiet cuts rivaling pricier blades

- Thin kerf to conserve precious stock

For our choice as the highest bang for buck ripping blade, Irwin’s Marples line continues dominating the budget space with quality production and materials that perform reliably year after year.

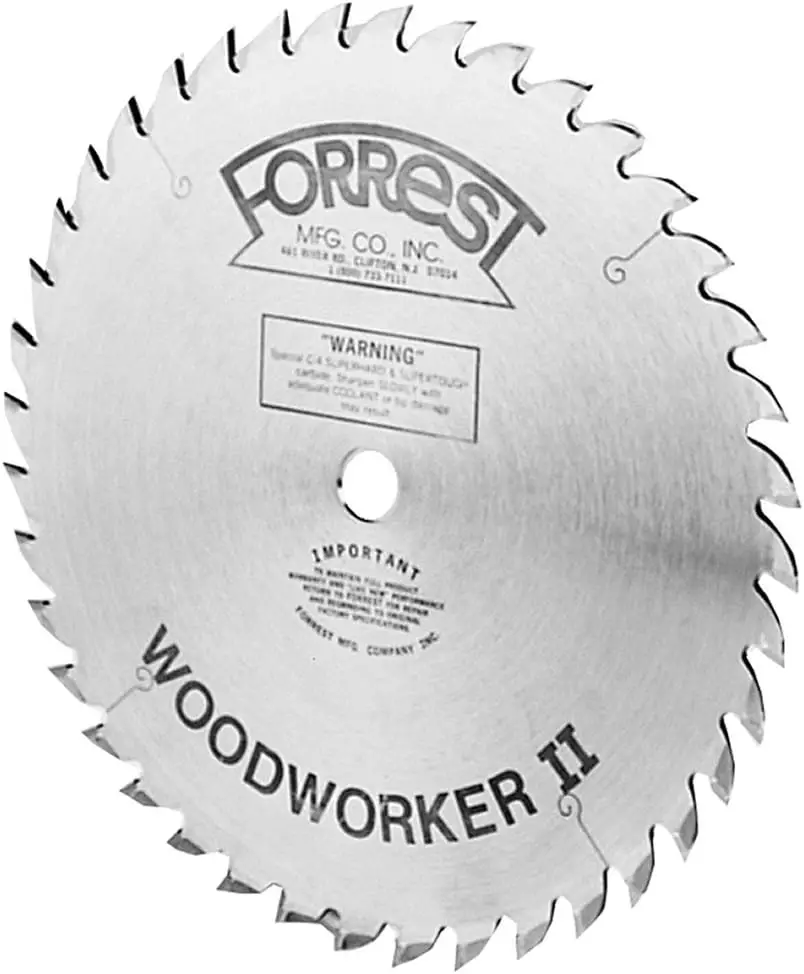

Best Premium Ripping Blade: Forrest WW10407125 Woodworker II Blade

If money is no object chasing maximum possible rip cut quality, woodworkers routinely namedrop Forrest blades for their surgical, glue ready edges.

Defining Features:

- Premium custom steel alloy and carbide grade

- Innovative tooth geometry with polished faces

- Leaves glass smooth edges needing zero sanding

- Stays scary sharp for up to 10X longer than bargain blades

- Flawless quality control and construction

- Runs completely vibration free

Yes, shells out nearly $150 with shipping for their Woodworker II 10-inch ripping blade. But Forrest has built a sterling reputation over decades as the pinnacle of American made saw blade engineering. Treat your cabinet saw (and projects) to the best!

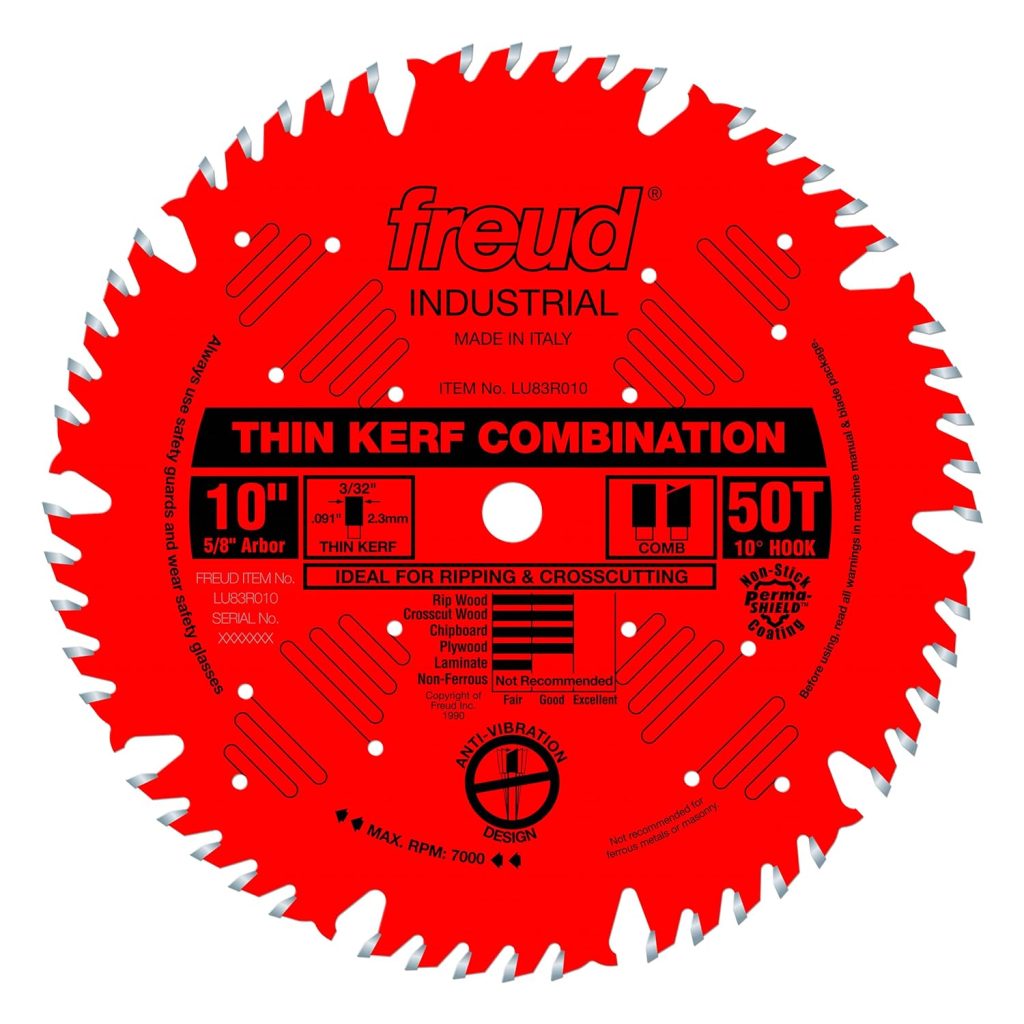

Best Ripping Blade for Thin Kerf: Freud LU83R010 Thin Kerf Rip Blade

Thin Kerf ripping blades conserve precious lumber with less material loss per cut. For striking that balance of narrow kerf AND durability for arduous ripping work, Freud’s LU83R010 tablesaw blade delivers the goods.

Why We Recommend:

- High grade TiCo HI-Density carbide teeth

- Titanium build stops rapid wear down

- Cuts mere 1/8th inch width slit!

- Still retains rigidity resisting vibration

- Tall teeth allow large chip gullets

- Freud factory equipped with strict quality control practices

Despite unusually narrow kerf profile, this 10” Freud ripping blade means business handling insane cutting volumes without the weaknesses plaguing cheaper made discount thin kerf blades. Your timber reserves will thank you!

Best Ripping Blade for Portable Table Saws: Diablo by Freud D1050X Rip Blade

Portable and job site table saws demand ripping blades balancing thinner kerfs and stability with smaller arbors. Here Diablo by Freud brings ideal job site performance.

Ideal for Portables Because:

- 10” Size fits both portable & full size saws

- Stabilizing features prevent vibration

- Titanium build for long wear life

- Cuts slightly thinner Kerf saving wood

- Freud quality standards at job site friendly price

Thanks to smart design considerations dialed in by Freud engineering, this formidable Diablo 10” blade executes perfectly on underpowered portable saws out on job sites without destabilizing or wearing down prematurely.

Smoothest Cut Ripping Blade: Glide Blade GB1010VWB

Seeking the absolute smoothest, burn free rip cuts from your table saw ripping activities? The revolutionary Glide Blade delivers mirrors finish edges without effort using physics defying technology.

How It Achieves Superior Smoothest Cuts:

- Hybrid steel/polymer teeth never need sharpening

- Revolutionary solid lubricant Microbake coating

- No frictional heat or burning

- Practically zero tearout

- Silent running operation

- Space age Precision Tolerance technology

Don’t let the plastic teeth fool you. Glide Blade’s advanced solid lubricant technology creates the smoothest, cleanest cut edges we’ve ever seen. A must try revelation for fine furniture builders demanding blemish and burn-free surfaces off the saw.

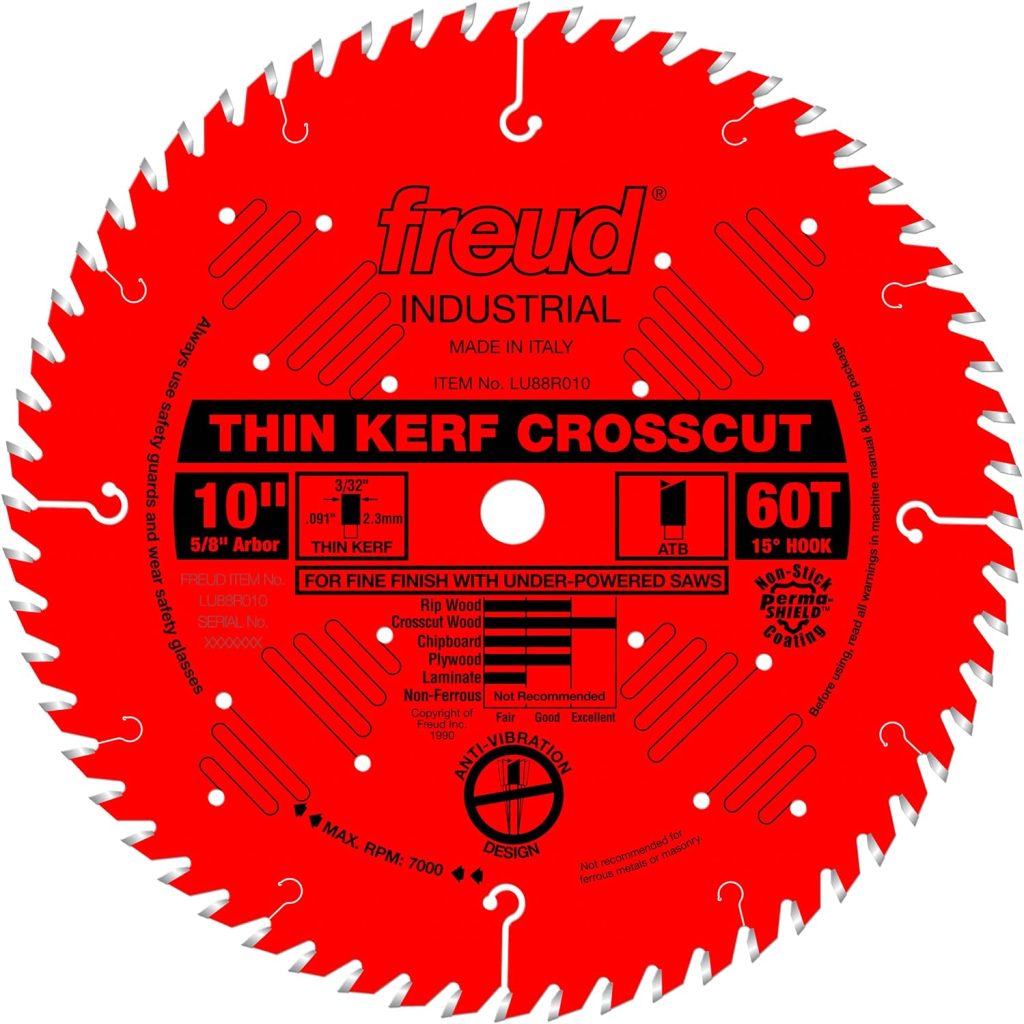

Quietest Ripping Blade: Freud LU88R010 Ultimate Rip Blade

Is hearing protection required during aggressive ripping operations? Freud’s LU88R010 10” ripping blade significantly silences your table saw roaring to safer decibel levels.

Why It’s the Quietest Rip Blade:

- Freud’s best grade TiCo HI-Density carbide

- Damping slots and holes engineered to muzzle vibration

- Fine-tuned heavy body damps noise wonderfully

- Quad chamfer plate smoothes airflow, torque and alignment

- Cutting-edge Freud Fusion thin kerf technology

Vibration kills blades while destroying eardrums. By leveraging precision balancing and vibration-killing enhancements, Freud engineered their Ultimate Rip blade to run dramatically quieter during even the most intense ripping activities. Hear the difference!

Well, those are our picks for top ripping blades to improve cut precision on table saws for 2024 shop upgrades across various specialization areas and budgets.

No matter which model you choose always follow universal blade safety protocols. And remember to tension arbor nuts securely before each use! Stay sharp finishing those woodworking projects!