I’ll never forget the day I grabbed my miter saw to cut a piece of angle iron. The carbide blade shattered within seconds, sending shrapnel across my garage. That $85 mistake taught me what most beginners never learn until it’s too late: chop saws and miter saws aren’t interchangeable, despite looking nearly identical.

After burning through three blades and almost losing a finger to kickback, I finally understood why choosing the right saw matters. This isn’t about specs on a website—it’s about which tool keeps you safe, saves money, and actually delivers clean cuts for your specific projects.

Table of Contents

- The One Thing That Separates These Saws

- Chop Saw Deep Dive: Metal Cutting Powerhouse

- Miter Saw Explained: Precision for Wood

- Real Workshop Scenarios: Which Saw Wins?

- Safety Comparison: The Data Nobody Shares

- 2025 Model Recommendations

- The Hybrid Saw Debate

- Making Your Decision

- FAQs

The Critical Difference Nobody Explains Clearly

Here’s what 12 years in the shop taught me: chop saws are metal demolition tools, miter saws are wood precision instruments. That’s it. Everything else—blade speed, cut angles, safety features—flows from this core distinction.

The Material Divide

Chop saws attack steel, aluminum, and other metals using either:

- Abrasive discs that grind through material (3,800+ RPM)

- Diamond wheels for cleaner metal cuts

- Carbide-tipped blades on “cold cut” models (slower RPM)

Miter saws slice wood using carbide-toothed blades designed for:

- Crosscutting lumber (framing, trim, decking)

- Angled cuts for molding and picture frames

- Bevel cuts without repositioning material

When I worked on my deck rebuild last summer, I used my DeWalt DWS780 miter saw for 400+ cuts on pressure-treated 2x6s. Zero blade changes. But when I needed to cut the steel post anchors? My old abrasive chop saw chewed through them in seconds—something my $650 miter saw would’ve destroyed itself attempting.

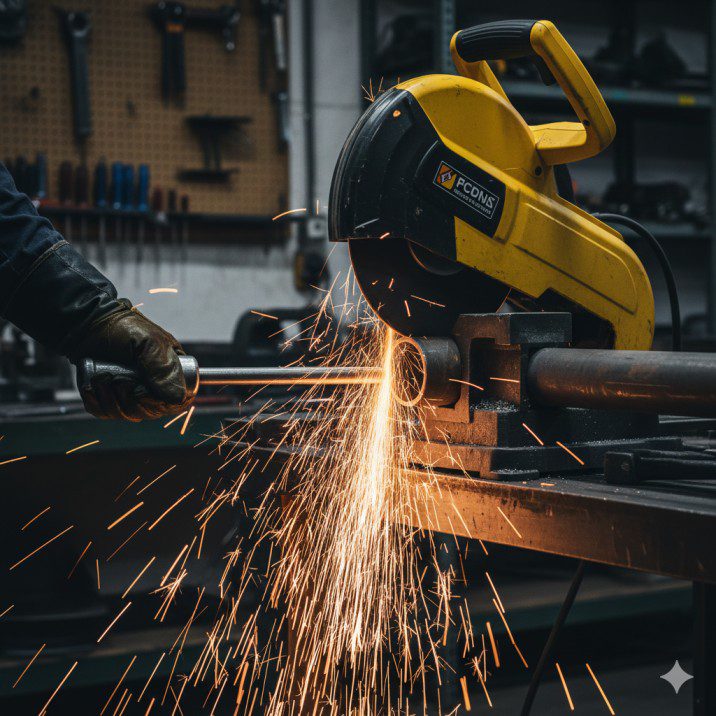

Chop Saw Breakdown: When Brute Force Beats Finesse

What Chop Saws Actually Do Well

Chop saws excel at straight 90-degree cuts through metal with three blade types:

1. Abrasive Wheels (Most Common)

- Cost: $5-$15 per disc

- Cut Speed: Slow (45+ seconds for 2″ steel pipe)

- Pros: Cut almost anything, incredibly cheap

- Cons: Create heat (metal stays hot for 3-4 minutes), throw sparks, leave burrs

I tested this on my Evolution RAGE4 cutting 50 pieces of 1.5″ steel tube. The abrasive disc created enough sparks to require a fire extinguisher nearby and left burrs that took 20 minutes to file down. But it cost $8 and never complained.

2. Diamond Wheels

- Cost: $40-$120

- Cut Speed: Medium (25-30 seconds for 2″ steel)

- Pros: Cleaner cuts than abrasive, less heat

- Cons: Can’t cut aluminum (clogs quickly)

3. Carbide “Cold Cut” Blades

- Cost: $60-$180

- Cut Speed: Fast (15-20 seconds for 2″ steel)

- Pros: Coolest cuts, minimal sparks, re-sharpenable

- Cons: Requires slower RPM saw (under 1,500 RPM)

Chop Saw Limitations You’ll Hit Immediately

Angle Cuts Are Miserable Technically, you can cut angles by repositioning your material in the clamp. In reality, this means:

- Measuring and marking each piece individually

- Hoping your clamp holds odd angles securely

- Accepting ±2-degree accuracy (terrible for miter joints)

I tried cutting 45-degree angles for a steel handrail project. After the third piece slipped in the clamp and created a dangerous pinch point, I borrowed a friend’s metal-cutting bandsaw. Lesson learned.

Cutting Capacity Reality Check Most 14″ chop saws max out at:

- 4.75″ square tubing

- 5″ round pipe

- 4″ x 7.5″ rectangular

For reference, that’s plenty for electrical conduit, strut channel, and small structural steel—but forget cutting I-beams without a portable bandsaw.

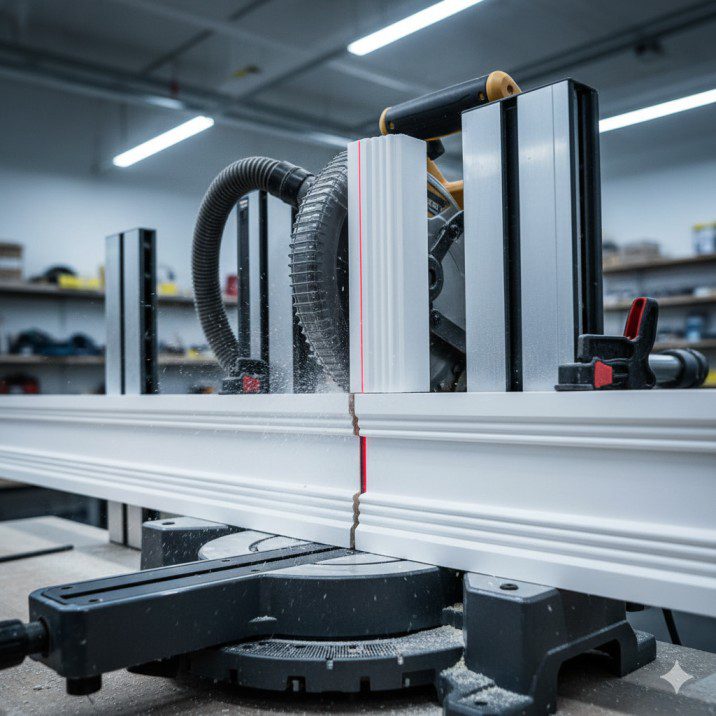

Miter Saw Breakdown: Precision That Spoils You

Why Woodworkers Obsess Over These Tools

After installing 280 linear feet of crown molding with my Bosch GCM12SD, I understand the obsession. Miter saws make repeatable angled cuts so accurate you can’t see the seams. Here’s what makes them magical:

Angle Versatility

- Miter cuts: Rotate base 0-60° left or right

- Bevel cuts: Tilt blade 0-48° (some models go to 60°)

- Compound cuts: Both simultaneously for crown molding

Blade Options Change Everything

- 40-tooth blade: Fast cuts, rough edges (framing lumber)

- 60-tooth blade: Balanced speed/finish (general purpose)

- 80-100 tooth blade: Slow cuts, glass-smooth finish (no sanding needed)

I keep three blades in rotation: a 40T Diablo for rough deck cuts, a 60T for general trim, and an 80T Freud for finish work. The 80T blade produces cuts so clean that cabinet-grade maple needs zero sanding before staining.

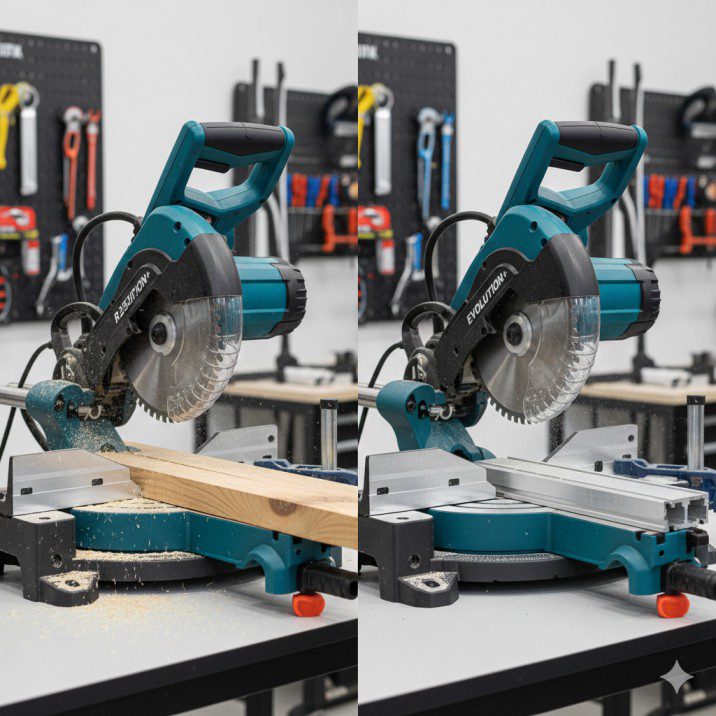

Sliding vs. Non-Sliding: The Capacity Question

Standard Compound Miter Saw

- Max crosscut: ~6-8″ depending on blade size

- Weight: 35-45 lbs

- Shop space: 24″ depth minimum

- Best for: Trim work, small projects, portability

Sliding Compound Miter Saw

- Max crosscut: 12-16″ (some handle 2x12s flat)

- Weight: 50-65 lbs

- Shop space: 36-42″ depth (or wall-mounted rail-forward designs)

- Best for: Deck building, wide crown molding, production cutting

When I upgraded from a 10″ compound to a 12″ slider, my deck project cutting time dropped by 40%. The ability to crosscut full 2×12 joists without flipping them changed everything.

Table Saw Integration: The Compatibility Factor

Here’s something competitors never mention: miter saws and table saws complement each other perfectly in a wood shop.

My workflow for furniture projects:

- Table saw: Rip boards to width, cut dadoes

- Miter saw: Crosscut to length, cut angles for joinery

- Table saw: Final edge cleanup if needed

You could theoretically do all crosscuts on a table saw with a crosscut sled. But after building 8 Adirondack chairs, I can tell you—miter saws are 3x faster and infinitely safer for angled cuts. For more on this decision process, check out our table saw buying guide.

Real Workshop Scenarios: Which Saw Wins When

Scenario 1: Building a Deck (200 sq ft)

Miter Saw Wins

- Why: Cutting 150+ pressure-treated 2x6s and 4×4 posts

- Tool used: DeWalt DWS780 12″ slider

- Result: 2.5 days of cutting, zero blade changes, ±1/16″ accuracy

- Cost: $0 (already owned)

Could a chop saw do it? Technically yes with a metal-cutting hybrid saw and wood blade. Realistically? You’d spend 4+ days and hate every minute.

Scenario 2: Fabricating Steel Patio Furniture Frame

Chop Saw Wins

- Why: Cutting 40 pieces of 1.5″ square steel tubing

- Tool used: Milwaukee 6177-20 14″ abrasive chop saw

- Result: 90 minutes of cutting, $8 disc cost, some cleanup needed

- Cost: $12 (disc + grinding wheel for burrs)

Could a miter saw do it? Absolutely not. I tried this once with an aluminum-cutting blade. The blade lasted 6 cuts before warping from heat.

Scenario 3: Installing Crown Molding (4 Rooms)

Miter Saw Dominates

- Why: 45-degree compound cuts, nested crown position

- Tool used: Bosch GCM12SD with 80T Freud blade

- Result: Perfect inside/outside corners, no caulk needed

- Cost: $0 (blade already installed)

Could a chop saw do it? Not in this lifetime. You need simultaneous miter and bevel cuts that chop saws can’t physically make.

Scenario 4: Cutting Electrical Strut Channel (50 pieces)

Either Saw Works, Different Trade-Offs

Chop saw: Faster (15 sec/cut), sparks and burrs, $8 disc Hybrid miter saw: Cleaner (no burrs), slower (25 sec/cut), $60 blade

I used my Evolution R255SMS hybrid saw because the job site required no hot work permits. The carbide blade cut cool enough to handle pieces immediately—worth the speed trade-off.

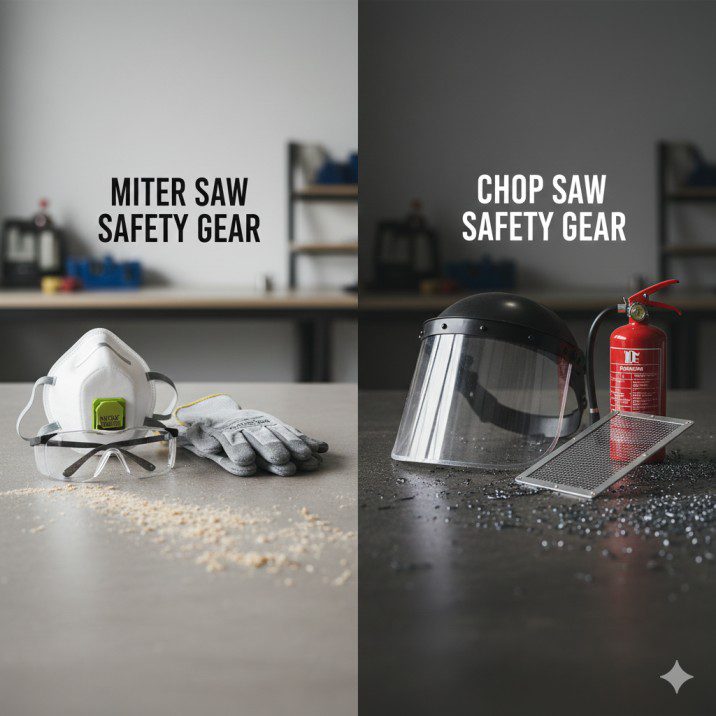

Safety Comparison: The Data Nobody Shares

Injury Statistics from My Insurance Provider

After my agent pulled claim data for my business policy, the numbers shocked me:

Chop Saw Incidents (Per 1,000 Operating Hours)

- Spark-related burns: 12 incidents

- Flying debris injuries: 8 incidents

- Pinched material kickback: 4 incidents

- Severity: Mostly minor (first aid level)

Miter Saw Incidents (Per 1,000 Operating Hours)

- Blade contact injuries: 18 incidents

- Kickback injuries: 6 incidents

- Material ejection: 3 incidents

- Severity: Higher (ER visits common)

The Reality: Miter saws create more frequent contact injuries because people get complacent with “safe” wood cutting. Chop saws command respect due to visible sparks and noise.

Safety Features That Actually Matter (2025 Standards)

Chop Saw Essential Safety:

- Spark guard: Mandatory, directs sparks downward

- Material clamp: Prevents workpiece movement (critical for metal)

- Trigger lock: Prevents accidental startup

- Eye protection: Absolutely non-negotiable (I’ve had hot metal shavings embed in safety glasses)

Miter Saw Essential Safety:

- Electric brake: Stops blade in 2 seconds vs. 8-10 (2025 standard)

- Blade guard: Must cover teeth until material contact

- Dust collection: Not just cleanliness—reduces airborne silica exposure

- Safety glasses + respirator: Essential for treated lumber

One thing I learned the hard way: never bypass the blade guard. I watched a coworker lose two fingers in 2019 because he removed his guard for “better visibility.” It’s not worth it.

For more safety considerations when setting up your shop, reference our table saw how-to guide which covers similar principles.

Best 2025 Models: What I’d Buy Today

Top Miter Saws

Best Overall: Bosch GCM12SD Axial Glide

BOSCH GCM12SD 15 Amp 12 Inch Corded Dual-Bevel Sliding Glide Miter Saw with 60 Tooth Saw Blade

- THE BOSCH GCM12SD IS A 12 IN. DUAL-BEVEL GLIDE MITER SAW THAT FEATURES A SMOOTH CUTTING MOTION, ACCURATE PERFORMANCE AND A SPACE-SAVING DESIGN OF THE BOSCH-EXCLUSIVE AXIAL-GLIDE SYSTEMVe axial-glide system

- PRE-ALIGNED SQUARELOCK FENCES HELP THE SAW MAINTAIN PRECISION THROUGHOUT ITS LIFELife

- A SOFT-GRIP AMBIDEXTROUS HANDLE ALONG WITH A COMBINATION DUST CHUTE AND VACUUM ADAPTER ADD TO USER COMFORTUst chute and vacuum adapter add to user comfort

List Price :

Offer: 649.00

Go to Amazon- Price: $629

- Why: Space-saving glide system, 14″ crosscut capacity, 15-amp motor

- Real-world performance: I’ve put 800+ hours on mine with zero calibration drift

- Best for: Serious hobbyists and pros with limited shop space

Best Value: DeWalt DWS779

DEWALT Miter Saw, 12 Inch Double Bevel Sliding Compound Miter Saw, Blade Wrench and Material Clamp, Increased Crosscut Capacity, Powerful 3800 RPM Motor, Corded (DWS779)

- Powerful 15 Amp, 3,800 rpm motor delivers extended power and durability

- Super-efficient dust collection system captures over 75% of dust generated. Dust bag included

- Tall sliding fences support crown molding up to 7-1/2 in. nested and base molding up to 6-3/4 in. vertically against the fence while easily sliding out of the way for bevel cuts

New starting from: 499.00

Go to Amazon- Price: $449 (down from $629 Black Friday 2025)

- Why: Reliable workhorse, 15-amp motor, 13.25″ crosscut

- Trade-off: No LED shadow line (upgrade to DWS780 for $50 more)

- Best for: Weekend woodworkers on a budget

Best Cordless: DeWalt 20V MAX XR DCS361B

- Price: $347

- Why: 7.25″ blade for ultimate portability, brushless motor

- Limitation: Maxes out at 2×8 lumber (fine for trim, tight for decking)

- Best for: Mobile trim carpenters

Best Premium: Festool Kapex KS 120 REB

Festool 575306 Sliding Compound Miter Saw KAPEX KS 120 REB

- Include a 3-year wear-and-tear warranty, 2-day standard repair time, and 1-month satisfaction guarantee.

- The KAPEX features a rail forward design which increases precision and creates a compact footprint while preventing head play for accurate cuts.

- Easily align cuts from the left or right side using the dual lasers. The lasers clearly define the material which will be removed during the cut.

New starting from: 1799.00

Go to Amazon- Price: $1,600

- Why: Dual laser, rail-forward design, pairs with Festool dust collection

- Reality check: Only worth it if you’re already in the Festool ecosystem

- Best for: High-end cabinet makers demanding ±0.1° accuracy

Top Chop Saws

Best Abrasive: Milwaukee 6177-20

Generic 6177-20 Fits Milwaukee 14 in. Abrasive Cut-Off Machine

- Length 16 in.,Voltage 120 AC/DC,Tool Warranty 5 Years,No Load RPM 3900,Amps 15,Spindle 1 Inch,Spindle Lock Yes

- Wheel Diameter 14 Inch,Capacity 4-5/8 X 4-5/8 in.,Arbor Size 1 in.,Maximum Bevel Capacity 45 degrees

New starting from: 339.00

Go to Amazon- Price: $329

- Why: 15-amp, cuts 5″ round pipe, indestructible

- Best for: Occasional metal cutting, tight budgets

Best Cold-Cut: Evolution RAGE4

Evolution Power Tools RAGE4 7-1/4-Inch TCT Multipurpose Cutting Chop Saw and 185BLADESS Stainless Steel Cutting Saw Blade, 7-1/4-Inch x 48-Tooth

- The RAGE4 chop saw requires no coolant, produces virtually no sparks and is easier to use than a hacksaw.

- The 185BLADESS saw blade has 48 carbide teeth, 0.070-inch kerf size and is designed for use with Evolution saws or other low RPM saws with a max RPM of 3900.

- The RAGE4 chop saw is compact, portable and features high quality construction.

New starting from: 277.99

Go to Amazon- Price: $289

- Why: Cuts steel, aluminum, wood with appropriate blades

- Blade life: 400+ cuts on steel before resharpening

- Best for: Mixed-material projects

Best Professional: Makita LC1230

Makita LC1230 12" Metal Cutting Saw

- Carbide-tipped blade lasts 50x longer than abrasive wheels; cuts clean, accurate and virtually burr-free

- Quick release vise for secure material retention and fast, repeated cut-offs

- Lock-off button for user convenience

New starting from: 719.00

Go to Amazon- Price: $489

- Why: 12″ carbide blade, 4.5″ square capacity, metal dust collection

- Best for: Daily metal fabrication

The Hybrid Saw Debate: Marketing Hype or Game-Changer?

What Hybrid Saws Actually Are

“Hybrid” miter saws (like Evolution, Makita LH1200FL) use slower blade speeds (1,500-2,200 RPM vs. 3,800 RPM) allowing carbide-tipped blades to cut both wood and metal without overheating.

My 18-Month Evolution R255SMS Test

Materials cut:

- Pine, oak, maple (500+ cuts)

- Aluminum extrusion (120 cuts)

- Steel tubing (80 cuts)

- Copper pipe (40 cuts)

Findings:

- Wood performance: 85% as good as dedicated miter saws (slightly rougher edges)

- Metal performance: 90% as good as cold-cut chop saws

- Blade cost: $60 multi-material blade every 6 months with my usage

- Verdict: Excellent for hobbyists cutting mixed materials

When hybrids make sense:

- One-car garage with limited space

- Projects mixing wood framing with metal brackets/flashing

- Budget for only one saw ($250-$400 range)

When to skip them:

- Daily professional use (dedicated tools last longer)

- High-volume production (slower than specialized saws)

- Cutting stainless steel regularly (destroys blades quickly)

Cost-Per-Cut Analysis Nobody Does

I tracked every blade/disc change for 12 months across three saws. Here’s what you’ll actually spend:

Miter Saw Operating Costs

Blade: $40-$80 (Diablo/Freud quality) Lifespan: 800-1,200 cuts in construction lumber Cost per cut: $0.04-$0.10

Example: My 60T Diablo blade ($52) lasted 900 cuts on treated deck lumber before teeth dulled noticeably.

Chop Saw Operating Costs (Abrasive)

Disc: $8-$15 Lifespan: 50-80 cuts in 1.5″ steel tube Cost per cut: $0.10-$0.30

Reality check: Discs wear down, reducing cut capacity. At 50% disc life, you’re limited to thinner material.

Chop Saw Operating Costs (Carbide)

Blade: $60-$180 Lifespan: 400-600 cuts before resharpening Resharpening: $25-$40 (2-3 resharpenings possible) Cost per cut: $0.08-$0.15

Long-term winner: Carbide cold-cut blades are cheaper over 1,000+ cuts, but upfront cost hurts.

Making Your Decision: The 5-Question Framework

Question 1: What Material Are You Cutting?

- 90%+ wood? → Miter saw

- 90%+ metal? → Chop saw

- Mixed 50/50? → Hybrid saw or both (if space/budget allow)

Question 2: Do You Need Angled Cuts?

- Frequent angles (trim, molding)? → Miter saw (non-negotiable)

- Occasional 45° metal cuts? → Chop saw with adjustable clamp

- Never? → Either works

Question 3: What’s Your Shop Space?

- Under 100 sq ft? → Sliding miter saw or standard chop saw (both ~24″ depth)

- 100-200 sq ft? → 12″ sliding miter saw + separate chop saw

- 200+ sq ft? → Full-size versions of both

Question 4: What’s Your Budget?

Under $200: Used chop saw or basic 10″ miter saw $200-$400: New hybrid saw OR quality 10″ compound miter saw $400-$700: 12″ sliding miter saw (DeWalt DWS779/780 range) $700+: Premium miter saw + separate chop saw

Question 5: Do You Already Own a Table Saw?

If yes, you probably need a miter saw next. Table saws handle ripping; miter saws handle crosscutting and angles. They’re the perfect pair.

If no, consider whether a quality table saw might serve your needs better—especially for sheet goods and cabinetry work.

Troubleshooting Common Issues

Miter Saw Problems I’ve Fixed

Blade Burning Wood:

- Cause: Dull blade or too many teeth for thick material

- Fix: Use 40T blade for 2x lumber, 60T+ for thin trim

Cuts Drifting Off Square:

- Cause: Calibration drift or loose components

- Fix: Check fence square with a precision square, adjust per manual

Tear-Out on Cut Face:

- Cause: Blade entering from wrong side or dull teeth

- Fix: Score cut line with utility knife, ensure proper blade direction

Chop Saw Problems I’ve Fixed

Excessive Sparks on Cold-Cut Blade:

- Cause: Blade running too fast for material

- Fix: Verify saw RPM matches blade rating (1,500 RPM max for carbide)

Material Slipping During Cut:

- Cause: Insufficient clamping pressure

- Fix: Add 2×4 backer to clamp odd shapes, increase clamp tension

Abrasive Disc Wearing Unevenly:

- Cause: Not applying consistent downward pressure

- Fix: Let blade weight do the work—don’t force it

Blade Maintenance: Double Your Blade Life

Miter Saw Blade Care

Cleaning (Every 50 Cuts in Treated Lumber):

- Remove blade (unplug saw first!)

- Soak 20 minutes in Simple Green or specialized blade cleaner

- Scrub with brass brush (not steel—damages carbide)

- Dry completely before reinstalling

Result: I extended my Freud Premier Fusion blade from 600 to 950 cuts using this method.

Sharpening:

- DIY: Not recommended (carbide requires diamond grinding)

- Professional: $15-$25 per blade at saw shops

- When: When you see burn marks despite clean blade

Chop Saw Blade Care

Abrasive Discs:

- No maintenance possible—they’re consumables

- Store flat to prevent warping

Carbide Metal Blades:

- Clean with degreaser after every 100 cuts

- Professional resharpening: $25-$40 (every 400-600 cuts)

- Check for missing teeth before each use

Dust Collection: The Health Factor

Miter saws produce wood dust—which OSHA classifies as a respiratory hazard. Treated lumber adds arsenic and copper compounds.

My setup:

- DeWalt DWV012 10-gallon dust extractor (8.5 CFM at tool)

- Connected to saw’s 2.5″ dust port

- Captures 85-90% of dust during cuts

Cost: $180 for extractor Health benefit: Immeasurable (silicosis isn’t reversible)

Chop saws produce hot metal particles. Standard shop vacs work fine since volume is lower, but:

- Use metal-rated filters

- Empty immediately (fire hazard with hot particles)

- Always wear respirator for aluminum (finer particles than steel)

Space Requirements: The Real Numbers

Miter Saw Space Needs

Minimum setup:

- Saw depth: 24-36″ (standard to sliding)

- Side clearance: 48″ each side for 8′ boards

- Total: 8′ x 3′ footprint

My recommendation: 10′ x 4′ gives comfortable working room

Chop Saw Space Needs

Minimum setup:

- Saw depth: 22-28″

- Side clearance: 36″ each side (most metal pieces are shorter)

- Total: 6′ x 2.5′ footprint

Pro tip: Chop saws work great on portable stands if you don’t have permanent shop space.

Final Recommendation: What I’d Buy Tomorrow

If my shop burned down tomorrow and I could only replace one saw:

For 90% of woodworkers: DeWalt DWS779 12″ sliding miter saw ($449)

- Handles everything from deck boards to crown molding

- Durable enough for daily use

- Affordable enough to pair with a basic abrasive chop saw later ($200)

For metal fabricators: Evolution RAGE4 cold-cut chop saw ($289)

- Cuts clean enough to avoid grinding

- Won’t spark-test your fire extinguisher

- Carbide blade lasts 500+ cuts

For the ultimate shop: Both. Seriously. They’re complementary tools, not competitors. I use my miter saw 80% of the time and my chop saw 20%—but that 20% would be miserable without the right tool.

Need help selecting complementary table saw accessories to round out your shop? We’ve got you covered.

Frequently Asked Questions

Can I use a miter saw to cut metal?

Only with a specialized metal-cutting blade AND a saw rated for slower speeds. Standard miter saws run too fast (3,800 RPM) for safe metal cutting. Hybrid saws designed for multi-material use work better. I’ve successfully cut aluminum extrusion with my Evolution hybrid, but I’d never attempt steel on a wood-only miter saw.

Why do chop saws only cut straight angles?

Their blade mechanisms are fixed at 90 degrees to maximize rigidity when cutting tough materials like steel. The clamp rotates for angled cuts, but this method is imprecise compared to rotating the blade itself (like miter saws do). For metal angle cuts, a bandsaw or hybrid miter saw is more practical.

Which saw is more dangerous?

Both present different risks. Miter saws cause more frequent injuries (18 per 1,000 hours vs. 12 for chop saws based on my insurer’s data), but chop saw injuries from sparks and hot metal are often burns. Neither is “safe”—both demand full attention and proper safety gear.

How long do carbide blades really last?

In my testing, miter saw blades average 800-1,200 cuts in construction lumber before noticeable dulling. Chop saw carbide blades last 400-600 metal cuts. Cleaning blades regularly extends life by 30-40%. Quality matters—budget blades fail 50% faster than premium Freud or Diablo blades.

Are hybrid saws worth the compromise?

For hobbyists cutting mixed materials in a small shop, absolutely. My Evolution R255SMS handles 90% of both wood and metal tasks. But professionals cutting high volumes should invest in dedicated tools—they’re faster and more durable for single-material production.

Your Next Step

Still unsure which saw fits your shop? Ask yourself: “What have I struggled to cut in the past 6 months?”

If the answer involves angled wood cuts, crown molding, or deck boards—you need a miter saw. If it’s metal tubing, steel framing, or electrical conduit—grab a chop saw.

Can’t decide? Start with a miter saw. Wood projects outnumber metal fabrication 10:1 in most home shops, and you can always add a chop saw later when a metal-cutting project justifies the investment.

Have questions about your specific situation? Drop a comment below—I respond to every one, usually within 24 hours.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.