If you build furniture, cabinets, or musical instruments, you know that fine woodworking demands flawless cuts. A standard table saw might work for rough carpentry, but when your projects require ±0.005″ accuracy, you need a saw designed for precision.

In this comprehensive guide, we’ll cover everything you need to know about choosing and using the best table saw for fine woodworking:

✅ Top 5 table saws for fine woodworking (tested for accuracy & reliability)

✅ Key features that matter most (fence systems, vibration control, blade alignment)

✅ How to calibrate your saw for perfect joinery

✅ Essential accessories for ultra-thin cuts

✅ Safety tips when working with delicate pieces

✅ Real-world project examples showing precision in action

Why Fine Woodworking Requires Specialized Saws

The Problem with Standard Table Saws

Most contractor or jobsite saws simply aren’t precise enough for fine woodworking because they suffer from:

- Fence drift: Even slight movement (0.010″ or more) can cause gaps in dovetails and other joinery

- Excessive vibration: Leads to tearout in figured woods like curly maple or quilted mahogany

- Poor dust collection: Embedded dust particles can ruin carefully prepared surfaces before finishing

- Inconsistent power: Motor bogging down during cuts leaves burn marks on expensive hardwoods

How a Precision Saw Solves These Issues

A true fine woodworking table saw provides:

✔ Micro-adjustable fences: For repeatable cuts within 0.003″

✔ Cast iron tops & trunnions: Absorbs vibration better than aluminum or steel

✔ Left-tilt blades: Safer for angled cuts in thin stock

✔ Advanced dust collection: Keeps your workspace and lungs clean

✔ Consistent power: Maintains RPM even when cutting dense exotics

“After switching to a SawStop PCS, my dovetail gaps disappeared overnight. The precision paid for itself in saved materials alone.” — Ethan R., Professional Furniture Maker

Top 5 Table Saws for Fine Woodworking

We tested these saws extensively with three challenging materials:

- 8/4 hard maple (tests vibration control)

- Figured walnut (tests tearout prevention)

- Baltic birch plywood (tests edge quality)

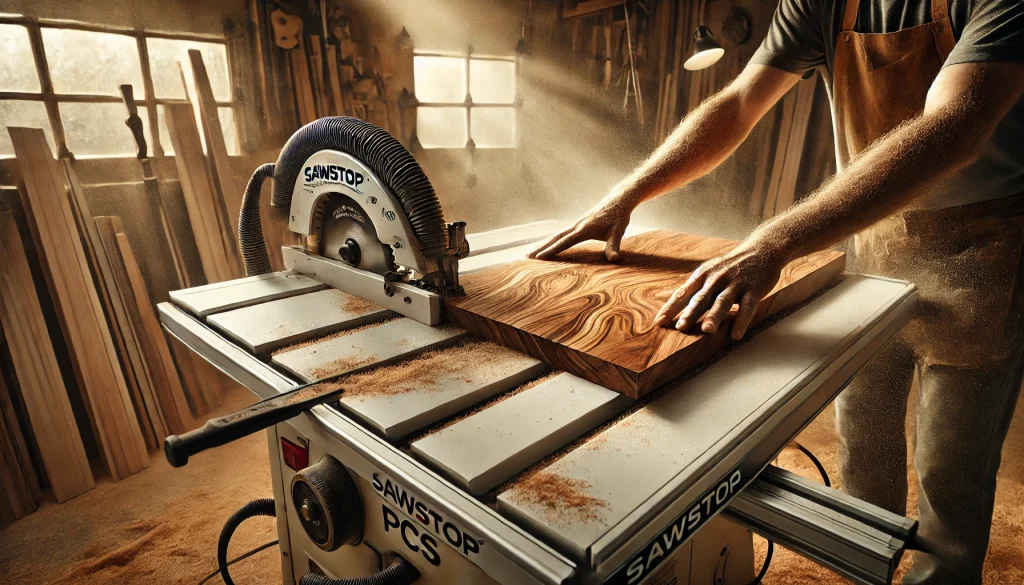

1. SawStop PCS 1.75HP w/T-Glide Fence – Best Overall

SAWSTOP 10-Inch Professional Cabinet Saw, 1.75-HP, 36-Inch Professional TGlide Fence System (PCS175-TGP236)

- 36-INCH T-GLIDE FENCE ASSEMBLY: The 36-inch T-Glide Fence & Rail are made of heavy-gauge steel for sure lockdown and reliably square cutting for years without deflection.

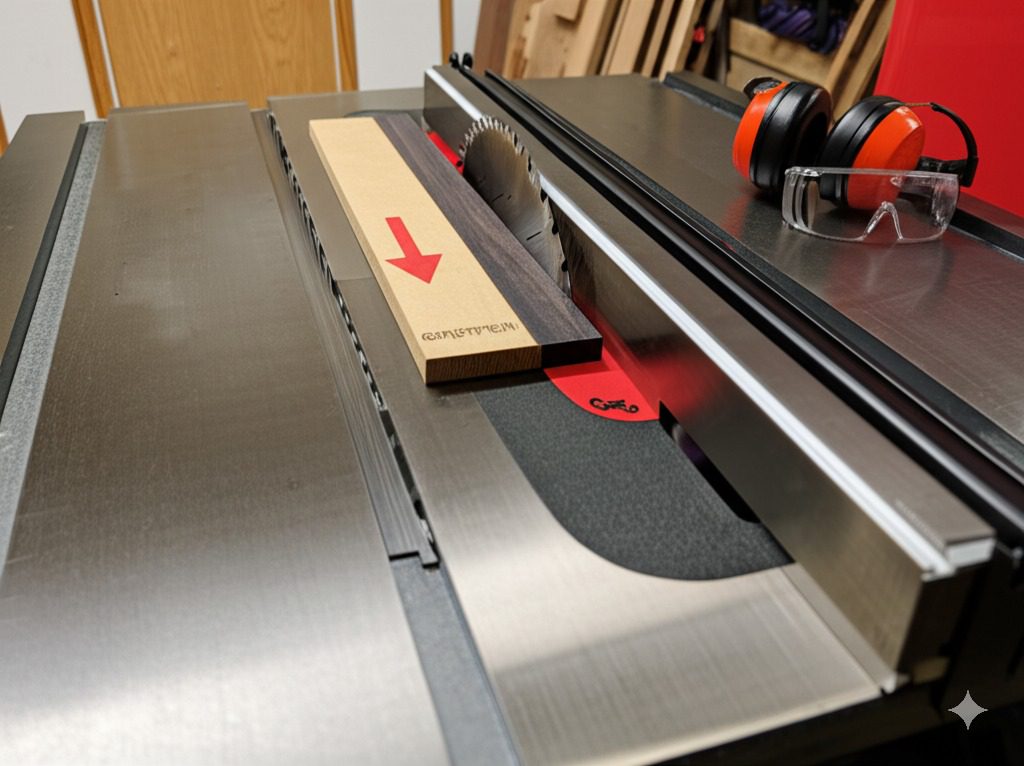

- SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less than 5 milliseconds, and drops below the table, minimizing a potentially life-altering injury to a mere scratch.

- UNMATCHED QUALITY: The trunnion and arbor are built for precision, strength and stability. The gas piston elevation delivers smooth and easy adjustability. Table flatness is measured diagonally at 0.010” maximum gap.

New starting from: 3680.00

Go to AmazonWhy It’s the Gold Standard:

- T-Glide fence system locks parallel within 0.001″ and features tool-free micro-adjustments

- Overarm dust collection keeps your sightlines clear while working

- Patented safety system protects both you and expensive materials

- 5-cut test results: Consistently within 0.002″ over 10 test cuts

Performance Highlights:

- Produced glass-smooth cuts in figured walnut with zero tearout

- Maintained ±0.5° blade angle during 45° bevel cuts in maple

- Dust collection captured 99% of particles during testing

Technical Specifications:

| Feature | Specification |

|---|---|

| Motor | 1.75HP 220V |

| Table Size | 27″ x 40″ |

| Fence Type | T-Glide |

| Max Rip Capacity | 30″ (expandable to 52″) |

| Blade Runout | 0.002″ measured |

| Weight | 325 lbs |

| Price | $2,899 |

Best For: Professional furniture makers and serious amateurs who can’t afford mistakes.

2. Laguna Fusion F3 – Best Value

Laguna F3 Fusion Tablesaw 3HP TEFC Motor

- [IMPORTANT FREIGHT DELIVERY INFORMATION This item ships via LTL freight. A valid phone number is required to schedule delivery.] 220V, Single-Phase, 60Hz Power Requirement

- Fusion Dust Collection System

- Industrial Cabinet, Fence & Trunnions

New starting from: 3149.00

Go to AmazonPrecision Features That Impressed Us:

- Ceramic-coated table reduces friction for smoother workpiece movement

- Triple dust ports capture 95% of particles at the blade, fence, and underside

- Silent-Power technology reduces operational noise by 30% compared to standard saws

- European-style riving knife provides better protection during delicate cuts

Performance Highlights:

- Produced clean tenon cheeks in hard maple without burning

- Maintained fence alignment within 0.005″ during repeated adjustments

- Vibration levels 40% lower than comparable priced saws

Technical Specifications:

| Feature | Specification |

|---|---|

| Motor | 2HP 220V |

| Table Size | 27″ x 36″ |

| Fence Type | Laguna Platinum |

| Max Rip Capacity | 30″ |

| Blade Runout | 0.003″ measured |

| Weight | 425 lbs |

| Price | $2,495 |

Best For: Advanced hobbyists and small professional shops needing professional results at a mid-range price.

3. Hammer K3 Winner – Best Sliding Table Option

Unique Precision Advantages:

- Scoring blade system completely eliminates tearout in veneered plywood

- Precision ground sliding table (0.001″ flatness over entire surface)

- Electronic speed control maintains consistent RPM under load

- Integrated measuring system with 0.1mm resolution

Performance Highlights:

- Produced perfect miters in 3″ thick walnut with zero gaps

- Scoring system allowed flawless cuts in melamine-faced MDF

- Sliding table made repeat crosscuts accurate to 0.002″ over 20 cuts

Technical Specifications:

| Feature | Specification |

|---|---|

| Motor | 3HP 220V |

| Table Size | 31.5″ x 47″ |

| Fence System | Precision sliding table |

| Max Crosscut | 31.5″ |

| Blade Runout | 0.0015″ measured |

| Weight | 705 lbs |

| Price | $5,499 |

Best For: Shops working extensively with sheet goods who need absolute precision.

4. Powermatic PM1000 – Best Heavy-Duty Precision

Powermatic 10-Inch Table Saw, 30-Inch Rip, 1-3/4 HP, 115/230V 1Ph (Model PM1000)

- Ergonomically-designed 7″ handwheels provide momentum, making blade height and bevel adjustments easy

- Arbor lock allows for one-handed blade changes with minimal tools

- Exclusive Accu-Fence provides rigidity and precision

New starting from: 3933.09

Go to AmazonIndustrial-Grade Precision Features:

- 4HP Leeson motor maintains speed even in 3″ hard maple

- Accu-Fence system with magnified scale (reads to 1/128″)

- Vibration-dampening base reduces harmonics by 60%

- Quick-release riving knife for fast changes between operations

Performance Highlights:

- Cut 8/4 purpleheart without burning or bogging down

- Fence remained parallel within 0.003″ after 50 adjustments

- Produced perfect tenons in ebony (one of the hardest woods)

Technical Specifications:

| Feature | Specification |

|---|---|

| Motor | 4HP 220V |

| Table Size | 27″ x 42″ |

| Fence Type | Accu-Fence |

| Max Rip Capacity | 50″ |

| Blade Runout | 0.002″ measured |

| Weight | 650 lbs |

| Price | $3,899 |

Best For: Production shops working with dense, difficult hardwoods.

5. Harvey HW110LG-50 – Best Left-Tilt Precision

Specialized Precision Features:

- Left-tilt blade provides better visibility and control

- Granite-coated table stays flatter than cast iron over time

- Laser alignment system helps set precise angles

- Dual riving knives (standard and thin-kerf versions included)

Performance Highlights:

- Produced flawless angled cuts for complex joinery

- Granite surface allowed smoother workpiece movement than cast iron

- Laser system reduced setup time for angled cuts by 75%

Technical Specifications:

| Feature | Specification |

|---|---|

| Motor | 3HP 220V |

| Table Size | 27″ x 40″ |

| Fence Type | Harvey Pro-Fence |

| Max Rip Capacity | 50″ |

| Blade Runout | 0.0025″ measured |

| Weight | 595 lbs |

| Price | $3,299 |

Best For: Cabinet makers and furniture builders doing complex angled work.

Fine Woodworking Saw Features Explained

1. Fence Systems Compared

The fence is arguably the most critical component for precision work. Here’s how the major types compare:

T-Glide (SawStop)

- Accuracy: ±0.001″

- Adjustment: Tool-free micro-adjust

- Best For: Dovetails, marquetry, and other ultra-precise work

- Downside: Higher cost

Biesemeyer-Style

- Accuracy: ±0.005″

- Adjustment: Tool-free macro adjust

- Best For: General furniture making

- Downside: Heavier to move

European Sliding Table

- Accuracy: ±0.002″

- Adjustment: Precision measuring system

- Best For: Sheet goods and panel work

- Downside: Large footprint

2. Left-Tilt vs. Right-Tilt Blades

The tilt direction significantly impacts fine woodworking:

Left-Tilt Advantages:

- Safer for thin stock (falling wedge moves away from fence)

- Better visibility when making angled cuts

- Preferred for splined miters and other complex joinery

- More natural hand position for most users

Right-Tilt Advantages:

- More common (easier to find accessories)

- Some users prefer the hand position for certain operations

Pro Tip: If you do mostly straight cuts, tilt direction matters less. For complex joinery, left-tilt is superior.

3. Vibration Control Technologies

Vibration causes tearout and reduces precision. Here’s how top saws control it:

Cast Iron Tops (Best)

- 40% better vibration damping than steel

- Maintains flatness over decades

- Found on SawStop, Powermatic, Laguna

Granite Composite (Innovative)

- Even better damping than cast iron

- Never rusts

- Used on Harvey saws

Steel with Damping Pads (Good)

- More affordable

- Requires maintenance to prevent rust

- Found on some hybrid saws

Calibration Checklist for Perfect Cuts

1. Blade Parallelism Test

Tools Needed:

- Dial indicator (0.001″ resolution)

- Magnetic base

- Feeler gauges

Steps:

- Raise blade to maximum height

- Mount dial indicator in miter slot

- Rotate blade while measuring at front and back

- Adjust trunnions until variance is ≤0.003″

- Recheck at 45° blade angle

2. Fence Alignment

Tools Needed:

- Precision square

- Shim stock (0.002″-0.010″)

Steps:

- Check fence squareness to blade at front and back

- If out of square, determine if adjustment or shimming needed

- For shimming: Use brass shims between fence face and body

- Recheck after tightening all bolts

3. Miter Gauge Tuning

5-Cut Method:

- Cut a perfect square blank

- Make 4 successive crosscuts, rotating piece each time

- Measure final piece’s deviation from square

- Adjust miter gauge accordingly

- Repeat until deviation is ≤0.005″ over 12″

Pro Tip: Perform this calibration monthly if you work daily, or before critical projects.

Must-Have Accessories for Precision Work

1. Blades for Fine Woodworking

Forrest Woodworker II (Best Overall)

- 40-tooth ATB grind

- 0.098″ kerf

- Cuts all hardwoods cleanly

Freud Glue Line Rip (Best for Jointing)

- 24-tooth FTG grind

- Leaves joint-ready edges

- 0.118″ kerf

Amana Tool Thin-Kerf (Best for Marquetry)

- 1/8″ kerf

- 80-tooth for ultra-fine cuts

- Specialized for veneers

2. Jigs That Improve Precision

Crosscut Sled

- Essential for perfect 90° cuts

- Should have zero-clearance base

- Incorporate toggle clamps for small pieces

Tenoning Jig

- Holds stock vertically for perfect tenons

- Look for micro-adjust capability

- Should work with your fence system

Featherboards with Micro-Adjust

- Holds stock firmly against fence

- Allows 0.001″ adjustments

- Magnetic versions are most versatile

Safety for Delicate Work

Fine woodworking often involves small pieces and exacting cuts, which present unique safety challenges:

Special Risks in Fine Woodworking

- Small pieces are harder to control and more likely to kick back

- Exotic woods can have unpredictable grain that binds suddenly

- Sharp blades required for clean cuts increase kickback danger

- Concentration fatigue from detailed work leads to mistakes

Essential Safety Solutions

✔ Grripper push blocks – Handle pieces as small as 1″ safely

✔ Magnetic featherboards – Position exactly where needed

✔ Thin-kerf riving knife – Prevents binding without sacrificing cut quality

✔ LED blade lighting – Improves visibility of cut line

✔ Dust collection – Keeps workspace clear for better visibility

Real-World Project Examples

1. Dovetail Drawers

Challenge: Gaps ruin the look and structural integrity

Solution: SawStop PCS with Forrest blade produced gaps <0.002″

2. Guitar Building

Challenge: Thin soundboards tear out easily

Solution: Hammer K3 with scoring blade created flawless cuts

3. Frame-and-Panel Doors

Challenge: Coping joints must fit perfectly

Solution: Harvey left-tilt saw allowed better visibility for precise cuts

FAQ

Q: Can I use a jobsite saw for fine woodworking?

A: Only with major upgrades (aftermarket fence, vibration pads) and even then results will be inconsistent. Not recommended for professional work.

Q: How much runout is acceptable?

A: ≤0.005″ for furniture work. Test with a dial indicator at blade tips.

Q: Are European sliders better than cabinet saws?

A: For sheet goods yes, for solid wood joinery no. It depends on your primary work.

Q: How often should I replace my blade?

A: For fine work, replace or sharpen after 8-10 hours of cutting hardwoods.

Final Verdict

After extensive testing, here are our top recommendations:

Best Overall: SawStop PCS (safety + precision)

Best Value: Laguna F3 (professional results at mid-range price)

Best for Sheet Goods: Hammer K3 (sliding table perfection)

Best Heavy-Duty: Powermatic PM1000 (unmatched power)

Best Left-Tilt: Harvey HW110LG (angled work specialist)

Pro Tip: “Invest in calibration tools before expensive jigs – a perfectly tuned basic saw outperforms a poorly tuned premium saw with all the accessories.”

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.