Last week, I was cutting through some oak boards for a bookshelf project. Halfway through the third cut, my cheap blade started burning the wood and leaving nasty tear-out on the edges. I had to sand for an hour just to fix the mess. Sound familiar?

Choosing the right circular saw blade isn’t just about saving money—it’s about getting clean cuts, staying safe, and not wasting your expensive lumber on second attempts.

After burning through (literally) dozens of blades over the past few years in my garage workshop, I’ve learned what actually works for everyday woodworking. This guide shares real experiences cutting plywood, hardwood, and softwood with different blades—so you don’t waste money on the wrong ones.

| Blade | Teeth | Best For | Cut Quality | Speed |

|---|---|---|---|---|

| Diablo D0724A | 24T | Ripping, framing | Rough | Very Fast |

| Freud D0760A | 60T | Plywood, crosscuts | Excellent | Slower |

| DEWALT Combo | 60T + 24T | Both needs | Good | Varies |

| Makita A-93681 | 40T | General use | Good | Medium |

| Diablo D0740A | 40T | General use | Good | Medium |

Why Your Circular Saw Blade Choice Actually Matters

Most DIYers grab whatever blade comes with their circular saw and wonder why their cuts look terrible. Here’s the truth: the stock blade that came with your saw is usually garbage.

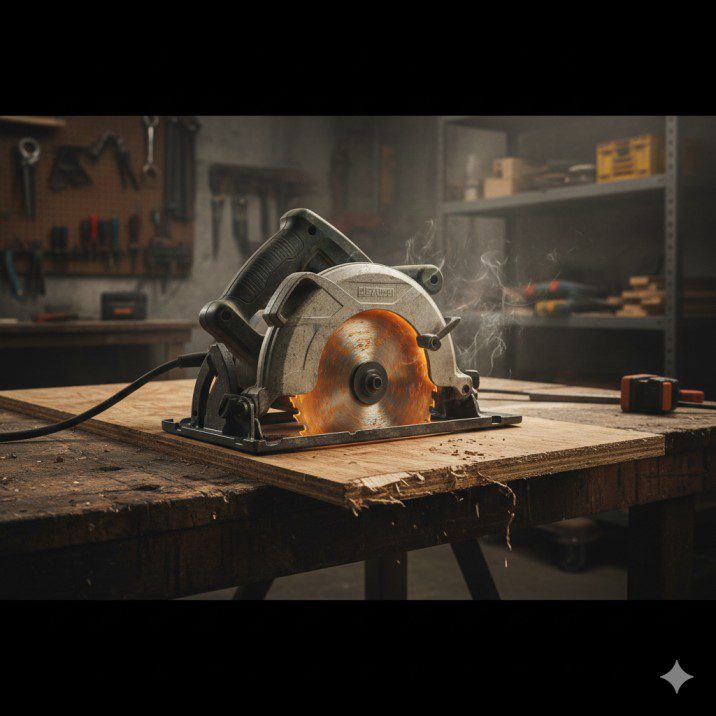

I learned this the hard way when I tried ripping a 4×8 sheet of plywood with my stock 24-tooth blade. The result? Splintered edges, a wandering cut line, and a blade that got so hot I couldn’t touch it for 10 minutes.

What happens with the wrong blade:

- Burn marks on your wood

- Rough, splintered edges that need heavy sanding

- The saw bogs down and struggles

- Dangerous kickback from binding

- Blade teeth break off (scary!)

What happens with the right blade:

- Smooth cuts that barely need sanding

- Clean edges on plywood without tear-out

- Your saw cuts faster with less effort

- Safer operation with less binding

- Blades last way longer

The difference between a $15 blade and a $40 blade might seem like a lot. But when you factor in wasted lumber, extra sanding time, and frustration, the better blade pays for itself fast.

Understanding Circular Saw Blade Basics (Simple Version)

Before we get to specific blades, let’s cover the basics without the confusing jargon.

Tooth Count: The Most Important Number

This is simple: more teeth = smoother cuts.

- 24-40 teeth: Fast ripping cuts through dimensional lumber (2x4s, framing). Rougher finish.

- 40-60 teeth: All-purpose woodworking. Good balance of speed and smoothness.

- 60-80 teeth: Fine crosscuts, plywood, finished work. Very smooth but slower.

I keep a 24-tooth blade for rough framing cuts and a 60-tooth blade for finish work. That covers 90% of my projects.

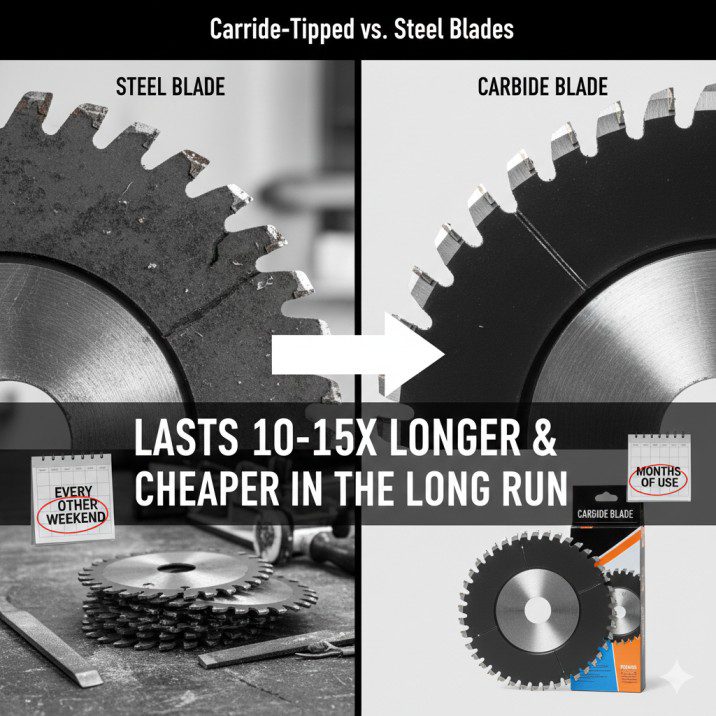

Carbide-Tipped vs. Steel Blades

Every blade I recommend has carbide-tipped teeth. Here’s why:

Steel blades dull after a few cuts and aren’t worth your time. Carbide tips stay sharp 10-15 times longer. Yes, they cost more upfront, but you’ll replace steel blades so often that carbide is actually cheaper in the long run.

I tried using cheap steel blades when I first started woodworking. I was sharpening or replacing them every other weekend. Now I use carbide blades and they last me months of regular use.

Kerf Width (Blade Thickness)

The kerf is how much material the blade removes when cutting.

- Thin kerf (around 0.059″): Easier on your saw’s motor, faster cuts, less waste

- Full kerf (around 0.098″): Stronger, less vibration, better for thick hardwood

For most DIY circular saws (especially cordless), thin kerf blades work better. They don’t bog down the motor as much.

Blade Diameter

Most circular saws use 7-1/4 inch blades. Some smaller saws use 6-1/2 inch. Always check your saw’s manual—using the wrong size is dangerous.

The arbor hole (center hole) is usually 5/8 inch, but again, check your saw to be sure.

Top Circular Saw Blades for Woodworking in 2026

I’m recommending blades I’ve actually used or that come highly rated from woodworkers I trust. These are all currently available and proven performers.

1. Diablo D0724A 7-1/4″ 24-Tooth Framing Blade

Best for: Fast ripping cuts, framing, rough carpentry

Diablo Framing Saw Blade for Wood – 7-1/4" x 24-Tooth, Thin Kerf, Anti-Vibration, Long Life for Framing & Pressure-Treated Wood, Tracking Point Tooth Design – D0724A

- Advanced Tracking Point Tooth Design – Provides unmatched cutting precision, delivering straight cuts while extending blade life up to 5X longer than standard framing blades.

- Enhanced Efficiency – Optimized for corded and cordless saws, offering up to 30% more cuts per battery charge in cordless models, reducing downtime on job sites.

- Anti-Vibration Technology – Laser-cut stabilizer vents minimize vibration and blade wobble, ensuring smooth, precise cuts with added durability and stability.

This is my go-to blade for ripping dimensional lumber and rough cuts. The 24 teeth tear through 2x4s and 2x6s like butter.

Real-world experience: I used this blade to rip down dozens of pine boards for a deck project. It never bogged down, stayed sharp through the whole job, and the cuts were straight. Yeah, the edges were a bit rough, but that’s expected with a ripping blade—and I wasn’t doing finish work anyway.

Pros:

- Cuts fast through softwood and framing lumber

- Stays sharp for a long time

- Great price for the quality

- Thin kerf doesn’t strain your saw motor

Cons:

- Rough finish (not for plywood or finish work)

- Can cause tear-out on crosscuts

Price range: $10-15

2. Freud D0760A 7-1/4″ 60-Tooth Fine Finish Blade

Best for: Plywood, crosscuts, finish carpentry

This is the blade I grab when I need clean cuts. The 60 carbide teeth leave edges so smooth you barely need to sand.

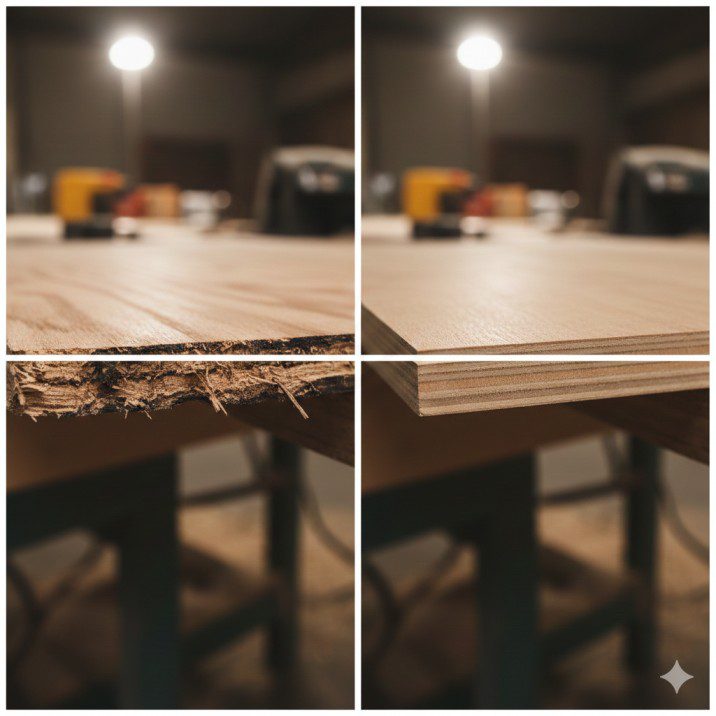

Real-world experience: I was cutting cabinet-grade plywood for some built-in shelves. With my old 40-tooth blade, I was getting splinters on the bottom side of every cut. I switched to this Freud 60-tooth blade and the difference was night and day. Clean cuts on both sides, minimal tear-out even without scoring first.

Pros:

- Super smooth cuts on plywood and hardwood

- Almost no tear-out if you cut with good side up

- Lasts a long time between sharpenings

- Works great for trim and finish work

Cons:

- Slower cutting than low-tooth blades

- Can bog down smaller saws in thick hardwood

- Costs more than basic blades

Price range: $35-45

3. DEWALT DW3106P5 7-1/4″ 60-Tooth Crosscutting & 24-Tooth Ripping Blade Combo Pack

DEWALT 10-Inch Miter Saw Blades/Table Saw Blades, 2-Blade Combo, 60-Tooth & 32-Tooth Pack (DW3106P5)

- Tougher tungsten carbide stays sharper longer

- Thin kerf for fast and smooth cutting action and The arbor size is 5/8”.

- Computer-balanced plate reduces vibration for improved accuracy and better finish

New starting from: 67.98

Go to AmazonBest for: DIYers who want versatility

If you don’t want to buy blades separately, this combo pack gives you both a ripping blade and a fine-cutting blade.

Real-world experience: I bought this set when I was building a workshop workbench. I used the 24-tooth blade for ripping plywood strips and the 60-tooth blade for the crosscuts. Having both blades meant I could switch based on the cut type and get better results than trying to use one blade for everything.

Pros:

- Two blades for different jobs

- Good value compared to buying separately

- Both blades perform well

- DEWALT quality and warranty

Cons:

- Not quite as refined as premium single blades

- The 60-tooth isn’t as smooth as the Freud

- You’re stuck with these tooth counts

Price range: $25-35 for the set

4. Makita A-93681 7-1/4″ 40-Tooth General Purpose Blade

Makita A-93681 10-Inch 80 Tooth Micro Polished Mitersaw Blade Silver

- PRECISION : ATAF (Alternate Top and Alternate Face) tooth design for ultra precision cutting

- EFFICIENCY : Japanese ultra-thin kerf carbide-tipped design provides smoother cuts with less drag on the motor

- ACCURACY : Fully hardened and expertly hand-tensioned steel saw plates for true cuts

Best for: All-purpose woodworking

The 40-tooth count is the sweet spot for general woodworking. This blade handles both ripping and crosscutting reasonably well.

Real-world experience: This was my only blade for the first year of woodworking, and it served me well. I used it for everything from breaking down plywood sheets to cutting 2x4s to length. The cuts weren’t as smooth as a 60-tooth blade, but they were good enough for most projects. And it cut way faster than high-tooth blades.

Pros:

- Good balance of speed and smoothness

- Handles both ripping and crosscutting

- Doesn’t bog down on most saws

- Affordable

Cons:

- Not the best at any one thing (jack of all trades)

- Still get some tear-out on fine plywood

- Not ideal for finish carpentry

Price range: $15-25

5. Diablo D0740A 7-1/4″ 40-Tooth General Purpose Blade

Best for: Budget-friendly all-around performance

Diablo 7-1/4-Inch x 40 Tooth Finish Saw Blade for Wood – Ideal for Smooth Crosscuts in Hardwood, Softwood & Plywood – Tico Hi-Density Carbide, Perma-Shield Coating – D0740A

- High-Performance TiCo Hi-Density Carbide Teeth – Designed for smooth crosscuts in hardwood, softwood, and plywood, delivering a perfect combination of cutting speed and long-lasting durability.

- Perma-SHIELD Non-Stick Coating – Protects the blade from heat, gumming, and corrosion, ensuring superior cutting performance and extended blade life.

- Super Thin Laser-Cut Kerf – Provides fast, clean cuts with minimal material loss, optimizing cutting efficiency and delivering a smoother finish.

List Price :

Offer: 16.93

Go to AmazonSimilar to the Makita, but Diablo’s anti-vibration design and heat-resistant coating make it stand out.

Real-world experience: I grabbed this blade when my Makita was out for sharpening. The Diablo cut noticeably smoother with less vibration. The red coating (Perma-SHIELD) actually seems to reduce friction—the blade runs cooler and doesn’t gum up as fast when cutting treated lumber.

Pros:

- Anti-vibration slots reduce wobble

- Heat-resistant coating keeps blade cooler

- Great all-purpose performance

- Thin kerf works on any circular saw

Cons:

- Still a compromise blade

- Won’t match a 60-tooth for smooth cuts

- Won’t rip as fast as a 24-tooth

Price range: $12-18

How to Choose the Right Blade for Your Project

Stop overthinking this. Here’s my simple decision tree:

Cutting plywood or doing finish work? → Get a 60-tooth fine-finish blade (Freud D0760A)

Ripping lumber or framing? → Get a 24-tooth ripping blade (Diablo D0724A)

Doing a bit of everything and don’t want multiple blades? → Get a 40-tooth general purpose blade (Diablo D0740A)

Just starting out and want flexibility? → Get the DEWALT combo pack with both 24 and 60-tooth blades

Material-Specific Tips

For hardwood (oak, maple, walnut): Use a 60-tooth blade and take your time. Let the saw do the work—don’t force it. I burned through an expensive piece of walnut by pushing too hard with a 40-tooth blade. Lesson learned.

For softwood (pine, cedar, fir): A 24-40 tooth blade works great. Softwood cuts easy, so you don’t need tons of teeth unless you’re doing finish work.

For plywood: Always use a 60+ tooth blade. Put the good side of the plywood facing UP when cutting to minimize tear-out on the visible side. The blade teeth exit on the bottom, which is where most splintering happens.

For MDF: Use a 60-tooth blade and wear a dust mask—MDF creates insane amounts of fine dust. The high tooth count gives you clean edges since MDF chips easily.

Making Your Blades Last Longer

Good blades aren’t cheap, so here’s how to get the most life out of them.

Clean Your Blades

Pitch and resin build up on blades, especially when cutting treated lumber or softwoods. This gunk makes the blade work harder and cut worse.

I clean my blades every few months with oven cleaner or a dedicated blade cleaner. Spray it on, let it sit for 10 minutes, scrub with an old toothbrush, and rinse. The blade cuts like new again.

Don’t Cut Nails or Screws

This sounds obvious, but it happens. I once hit a hidden nail in some reclaimed wood and chipped three carbide teeth. The blade was toast.

Check your wood carefully before cutting. A metal detector can help with reclaimed lumber.

Use the Right Blade for the Job

Don’t use your fine-finish 60-tooth blade for ripping treated 2x4s all day. You’ll dull it fast and the cuts will be slow anyway. Match the blade to the task.

Store Blades Properly

I used to toss my spare blades in a drawer where they banged against each other. Now I hang them on blade hooks or keep them in the cases they came in. Protecting those carbide tips makes them last way longer.

Know When to Sharpen or Replace

A dull blade is dangerous. It makes you push harder, which can cause kickback. Signs your blade needs attention:

- Burn marks on the wood

- The saw bogs down in cuts it used to handle easily

- Rough, torn edges

- You have to push hard to make the cut

Most carbide blades can be sharpened 2-3 times before the teeth get too short. Sharpening costs $10-20, which is way cheaper than a new blade.

Safety Tips for Changing and Using Circular Saw Blades

Circular saws are powerful and can be dangerous. Here’s how to stay safe:

Changing Blades Safely

- Unplug your saw (or remove the battery on cordless). I know this seems basic, but people skip this step and get hurt.

- Lock the blade using your saw’s spindle lock button. Press it while turning the blade until it clicks.

- Loosen the arbor bolt. It’s usually reverse-threaded on the right side of the blade (lefty-tighty, righty-loosey). Use the wrench that came with your saw.

- Note the blade direction. The teeth should point forward in the direction of the cut. Installing a blade backward is surprisingly common.

- Tighten firmly but don’t over-torque. Hand-tight plus a little extra is enough.

Using Your Blade Safely

Let the blade reach full speed before cutting. Plunging into wood while the blade is accelerating can cause kickback.

Don’t force the saw. If you’re pushing hard, your blade is probably dull or you’re using the wrong blade for the material.

Support your work properly. Make sure the cutoff piece won’t pinch the blade as it falls. This causes scary kickback.

Wear safety glasses. Wood chips fly everywhere. I’ve taken more chips to the face than I can count—glad I always wear protection.

Watch the cord. I’ve come close to cutting my power cord more times than I’d like to admit. Keep it clear of the blade path.

Common Mistakes to Avoid

Learn from my expensive mistakes:

Using one blade for everything: I did this for too long. You’ll get way better results having a ripping blade and a crosscut blade. The DEWALT combo pack is perfect for this.

Buying the cheapest blade: I bought a $7 blade from the hardware store once. It lasted three cuts before the teeth started breaking off. Scary and wasteful.

Not cleaning pitch buildup: A dirty blade cuts terribly and can overheat. Clean your blades regularly.

Cutting too fast: Especially with fine-finish blades, slow down. Let the blade do the work. I’ve burned plenty of wood by rushing.

Ignoring vibration: If your blade is wobbling or vibrating badly, stop. The blade might be damaged, installed wrong, or the arbor might be bent. Don’t keep cutting.

Final Recommendations

Here’s my honest take after years of woodworking:

If you’re on a tight budget: Get the Diablo D0740A 40-tooth blade. It’s cheap, versatile, and way better than whatever came with your saw. Use it for everything until you can afford specialized blades.

If you want the best value: Get the DEWALT combo pack with 24-tooth and 60-tooth blades. You’ll have the right blade for any job, and the price is fair.

If you want the best performance: Buy the Diablo D0724A for ripping and the Freud D0760A for finish cuts. This combo covers all your needs with top-quality blades.

If you only do finish work: Just get the Freud D0760A 60-tooth blade. You’ll love the smooth cuts.

The most important thing is to stop using those cheap stock blades. Even a mid-range carbide blade will transform how your circular saw performs. Your cuts will be cleaner, your work will be safer, and you’ll waste less lumber.

Looking for more guidance on getting the most from your woodworking tools? Check out our complete woodworking how-to guides for tips on technique, safety, and tool selection.

Remember: a sharp, quality blade is one of the best investments you can make in your workshop. It’s cheaper than wasting lumber and safer than fighting with dull blades.

Frequently Asked Questions

Q: How often should I replace my circular saw blade?

A: It depends on usage, but most carbide blades can be sharpened 2-3 times before replacement. Replace when you notice burn marks, excessive tear-out, or if the saw bogs down even after cleaning and sharpening. For casual DIY use, a good blade can last 1-2 years.

Q: Can I use the same blade for ripping and crosscutting?

A: Yes, a 40-tooth general purpose blade works for both, but it’s a compromise. You’ll get better results using a 24-tooth blade for ripping (faster, smoother in that direction) and a 60-tooth blade for crosscuts (cleaner edges). If you can only have one blade, go with 40 teeth.

Q: What’s the difference between thin kerf and full kerf blades?

A: Thin kerf blades (about 0.059″ thick) remove less material, which means less strain on your saw’s motor and faster cuts. Full kerf blades (about 0.098″ thick) are more stable and vibrate less, but require more power. For most DIY circular saws, especially cordless models, thin kerf works better.

Q: Why do my plywood cuts always splinter on the bottom?

A: Circular saw teeth exit on the bottom of the cut, which causes tear-out on that side. To fix this: (1) place the good side of plywood facing UP when cutting, (2) use a 60+ tooth blade, (3) support the wood properly so it doesn’t sag, and (4) you can score the cut line first with a utility knife for extra-clean results.

Q: Are expensive blades really worth it for weekend DIYers?

A: Yes, but you don’t need the most expensive. A mid-range carbide blade ($20-40) will dramatically outperform a cheap blade and last 10 times longer. The jump from cheap to mid-range is huge. The jump from mid-range to premium is smaller. For most DIYers, brands like Diablo, Freud, and DEWALT offer the best value.

Disclosure: This article contains affiliate links. If you purchase through these links, we may earn a commission at no extra cost to you. We only recommend products we’ve used or thoroughly researched.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.