Three years ago, I showed up to frame a deck addition with my brand-new cordless circular saw, fully charged batteries, and total confidence. By 2 PM, I was dead in the water—both batteries drained, no charger on site, and 150 more cuts to make. I borrowed a crew member’s beat-up corded saw and finished the job. That embarrassing afternoon taught me something crucial: the corded vs cordless circular saw decision isn’t about which technology is “better”—it’s about matching the tool to how you actually work.

If you’re standing in the tool aisle right now trying to decide between a corded or cordless circular saw, you’re facing one of the most important tool choices you’ll make. Get it wrong, and you’ll either be tangled in extension cords all day or constantly hunting for charged batteries.

I’ve been a carpenter for nine years, and I’ve used both corded and cordless saws across hundreds of projects. I currently own three circular saws—two cordless and one corded—because each serves different purposes. This comparison breaks down the real differences based on actual job experience, not marketing hype.

The Fundamental Difference: Power Delivery and What It Means

Before diving into pros and cons, you need to understand how power delivery shapes everything about using these tools.

Corded Circular Saws: Unlimited Power, Limited Mobility

Corded saws plug into standard 120V outlets and draw 13-15 amps continuously. That electrical connection delivers consistent power as long as you keep your finger on the trigger.

When I’m ripping through 100 studs for wall framing or breaking down a stack of plywood sheets, my corded saw maintains identical cutting speed on cut #1 and cut #100. The motor doesn’t care how long I’ve been working—it just keeps spinning at full RPM.

The tradeoff is obvious: you’re tethered to an outlet. I’ve been that guy dragging 100 feet of extension cord around a jobsite, constantly managing cord position to avoid trip hazards and cutting through my own power supply (yes, I’ve done that twice).

Cordless Circular Saws: Total Freedom, Battery Constraints

Cordless saws run on rechargeable lithium-ion batteries, typically 18V or 20V systems (some brands offer 60V high-capacity options). Modern brushless motors extract maximum power from those batteries efficiently.

The freedom is incredible. No cord management. extension cords. And no, searching for outlets. I can work on a roof, in a basement under construction, or in my backyard cutting deck boards without any infrastructure.

But batteries run down. Even the best cordless saw with a fully charged 5.0Ah battery will eventually quit mid-cut if you’re doing serious volume work. I’ve learned to always have a spare battery charging, but that requires planning and discipline.

Power and Performance: The Honest Reality in 2026

The gap between corded and cordless performance has narrowed dramatically, but it hasn’t closed completely.

Raw Cutting Power

For light to moderate cutting tasks—crosscutting 2x4s, cutting plywood, general DIY work—modern cordless saws match corded performance. My Milwaukee M18 FUEL cuts dimensional lumber just as fast as my corded DeWalt on the first 50-75 cuts.

Where you notice the difference: extended heavy cutting and demanding materials. When I’m ripping long cuts through 2×12 joists or cutting wet pressure-treated deck boards all day, the corded saw maintains power indefinitely while the cordless saw’s performance gradually drops as battery voltage declines.

It’s not that cordless saws suddenly die. They slow down subtly. That aggressive initial cutting speed softens after 20-30 minutes of continuous use. The saw still cuts, just not quite as aggressively.

Motor Technology: Brushless Changes Everything

Older cordless saws with brushed motors were genuinely underpowered compared to corded options. Modern brushless motors are game-changers.

Brushless motors are more efficient (longer battery life), deliver more torque, and require less maintenance. Every quality cordless saw in 2026 uses brushless technology. If you’re looking at a cordless saw with a brushed motor, skip it—the performance gap isn’t worth it.

My 2019 cordless saw (brushed motor) couldn’t keep up with basic framing work. My 2024 Milwaukee M18 FUEL (brushless) powers through the same tasks without complaint. The technology advancement in five years is massive.

Sustained Performance

Here’s where corded saws still dominate: hour three of continuous cutting.

Last month I built a 16×20 deck. Cut all the joists, decking boards, and rim boards with my corded saw. Never slowed down, never stopped, just hundreds of consistent cuts over two full days. A cordless saw would’ve required battery swaps every 45-60 minutes, breaking workflow rhythm.

If you’re making 20-30 cuts and putting the saw away, cordless performance is fine. If you’re making 300 cuts, corded reliability eliminates anxiety.

Runtime and Battery Life: The Real-World Numbers

How Long Do Batteries Actually Last?

Manufacturer claims are optimistic. They test under ideal conditions—fresh batteries, new blades, easy material.

Real-world runtime depends on:

- Battery capacity: 2.0Ah batteries last maybe 100-150 cuts. 5.0Ah batteries get you 300-400 cuts. 6.0Ah or larger can approach 500+ cuts.

- Material hardness: Cutting softwood pine uses less battery than cutting hardwood oak or pressure-treated lumber.

- Blade sharpness: A dull blade forces the motor to work harder, draining batteries faster.

- Cut type: Quick crosscuts use less power than long rip cuts.

- Temperature: Cold weather reduces battery capacity significantly.

My typical experience with a 5.0Ah battery on my Milwaukee: about 250-300 cuts through standard 2x framing lumber before the battery dies. That’s roughly 2-3 hours of intermittent cutting.

For a DIY project where I’m measuring, cutting, installing, repeat—one battery usually lasts the entire work session. For production cutting where I’m just blasting through material, I swap batteries 3-4 times per day.

Battery Management on Jobsites

Cordless saws require thinking ahead. You need:

- At least two batteries (while one’s in the saw, one’s charging)

- A charger on site with power access

- A system to track which batteries are charged

I keep my spare batteries in a small cooler to protect them from heat in summer and extreme cold in winter. Battery performance drops noticeably in temperature extremes—something you never worry about with corded saws.

The Corded Advantage: Infinite Runtime

Plug in a corded saw and it runs literally forever. I’ve had 8-hour days where my corded saw was cutting almost continuously. Never slowed down. Never needed recharging. Just consistent performance.

The only limitation is the cord itself—you need outlet access and enough extension cord to reach your work area. But for shop work or construction sites with power, that’s rarely an issue.

Portability and Convenience: Where Cordless Dominates

Jobsite Mobility

Cordless saws win this category decisively. The freedom to cut anywhere without cord management is transformative.

Working on a roof? Grab your cordless saw and go. No extension cord to drag up a ladder. No cord snagging on roofing nails or falling off the edge.

Cutting in a basement under construction? No hunting for the one working outlet. No tripping over cords in dim light.

I’ve done bathroom remodels in occupied homes where running extension cords through living spaces wasn’t acceptable. The cordless saw meant I could cut material in the garage or outside, then bring cut pieces inside without disturbing the homeowners.

Cord Management Frustration

Let’s be honest: extension cords are annoying. They tangle, get run over by tool carts. And they also create trip hazards. You accidentally cut through them (I’ve ruined three cords this way).

On large jobsites, managing 50-100 feet of extension cord adds measurable time to every task. You can’t just grab the saw and go—you need to find an outlet, run the cord, avoid creating hazards, and then reverse the process when done.

Cordless saws eliminate all of that. Grab saw, insert battery, cut. It’s legitimately faster.

Setup and Cleanup Time

For quick cuts—one or two pieces that need trimming—cordless saws save significant time. No cord setup, no outlet hunting, just grab and go.

I timed myself: Setting up my corded saw (find outlet, run extension cord, plug in) takes about 90 seconds. Grabbing my cordless saw with a battery takes 10 seconds. If I’m making three quick cuts throughout the day, that time difference adds up.

But for a dedicated cutting session where the saw stays set up for hours, setup time becomes irrelevant. The corded saw sits on the sawhorse, plugged in, ready whenever I need it.

Cost Comparison: Initial Investment and Long-Term Value

Purchase Price Reality

Corded circular saws cost significantly less than equivalent cordless models:

- Quality corded saw: $130-180 (DeWalt DWE575SB, Makita 5007MG, Skil SPT67WM)

- Quality cordless saw (tool only): $180-280 (Milwaukee M18 FUEL, DeWalt DCS573B, Makita XSH06)

- Batteries and charger: Add $120-200 for two batteries and a charger if you’re not already in that battery platform

DEWALT Circular Saw, 7-1/4 inch, Pivoting with up to 57 Degree Bevel, Corded (DWE575SB)

- DEWALT 7 1/4 circular saw is among the lightest saws in its class (8.8 lbs.)

- Electric brake of the corded circular saw stops the blade after trigger is released

- 15 amp motor of the compact circular saw delivers power for even the toughest applications

New starting from: 179.00

Go to AmazonA complete cordless setup costs $300-480 total. A corded saw is ready to use at $130-180.

M18 Cordless Circular Saws – milwaukee m18 cordless circular saw

List Price :

Offer: 100.00

Go to AmazonThat price difference matters enormously if you’re a beginner building your tool collection. Spending an extra $200 on batteries could instead buy you a quality miter saw or other essential tool.

Battery Platform Lock-In

Once you buy into a battery platform (Milwaukee M18, DeWalt 20V, Makita 18V LXT, etc.), you’re incentivized to stay with that brand for future cordless tool purchases.

I’m deep in the Milwaukee M18 ecosystem—circular saw, drill, impact driver, oscillating multi-tool, all sharing batteries. Buying a DeWalt cordless circular saw would require investing in a completely new battery platform.

This isn’t necessarily bad (battery sharing across tools is convenient), but it creates brand loyalty that limits your options.

Corded tools have no such lock-in. I own corded saws from DeWalt, Makita, and Skil. They all plug into the same outlets. I can choose the best tool for each job without worrying about battery compatibility.

Long-Term Battery Costs

Batteries degrade over time. Even if you never use them, lithium-ion batteries lose capacity as they age. After 3-5 years, batteries hold maybe 60-70% of their original charge.

I replace batteries every 4-5 years of regular use. At $60-100 per battery, that’s an ongoing cost corded tools never have.

Corded saws just need occasional cord replacement if you damage the cord (I’ve replaced cords twice in nine years, $15-20 each time). Way cheaper than battery replacement.

Resale Value

Corded saws hold value better because they don’t have aging batteries. A 5-year-old corded saw with a good motor is still fully functional. A 5-year-old cordless saw with original batteries has degraded capacity.

When selling used tools, cordless saws sell for less because buyers assume they’ll need new batteries soon.

Weight and Ergonomics: The Fatigue Factor

Weight Comparison

Corded saws are generally lighter than cordless equivalents:

- Corded 7-1/4″ saw: 8-11 pounds typically

- Cordless 7-1/4″ saw with battery: 10-13 pounds typically

The battery adds 1-3 pounds depending on capacity. A 2.0Ah battery might add a pound. A 6.0Ah high-capacity battery adds 2-3 pounds.

This matters during extended use. After 4 hours of cutting, that extra 2 pounds causes noticeable arm fatigue. My shoulders feel it at the end of a long framing day with my cordless saw versus my corded saw.

Balance and Handling

Battery placement affects balance. Most cordless saws position the battery behind the handle, which can make the tool feel rear-heavy.

Corded saws balance differently. The motor and blade carry most of the weight, with the lightweight cord trailing behind. This forward balance feels more natural to me for sustained cutting.

That said, you adapt quickly. After using my cordless saw for a week, the balance feels normal and I stop noticing the difference.

One-Handed vs Two-Handed Use

Neither saw should be used one-handed (unsafe), but cordless saws are easier to maneuver into position one-handed before engaging the trigger.

With corded saws, you’re managing both the saw and the cord. Sometimes the cord catches on materials or pulls the saw slightly off-line. Small annoyance, but it happens.

Still deciding which saw type fits your needs? Check out our comprehensive buying guide for detailed selection criteria, or browse our expert saw reviews for hands-on testing results.

Maintenance and Longevity: What Actually Breaks

Corded Saw Maintenance

Corded saws are mechanically simpler and typically last longer with basic care:

- Carbon brush replacement: Every 2-5 years depending on use ($10-20 for parts)

- Cord damage: Replace if you cut through it or it gets damaged ($15-25 for replacement cord)

- Standard wear items: Blade changes, occasional cleaning, bearing replacement (rare)

My oldest corded saw is 11 years old. I’ve replaced brushes once and the cord twice. It still cuts like new.

Cordless Saw Maintenance

Cordless saws have similar mechanical maintenance but add battery care:

- Battery replacement: Every 3-5 years ($60-100 per battery)

- Battery storage: Store at 40-50% charge for longevity, avoid temperature extremes

- Brushless motors: No brush replacement needed (major advantage)

- Electronics: More complex electronics can fail (less common but more expensive to fix)

The brushless motor advantage is real—that’s one major maintenance item eliminated compared to older cordless or current corded saws.

Lifespan Expectations

With reasonable care:

- Quality corded saw: 10-15+ years of regular DIY use, 5-10 years of professional use

- Quality cordless saw: 8-12 years (limited by battery technology advancement, not motor failure)

The limiting factor for cordless isn’t usually the saw itself—it’s that batteries become obsolete. Your 10-year-old cordless saw might work fine, but finding replacement batteries becomes difficult as manufacturers discontinue older battery platforms.

Best Use Cases: When Each Type Excels

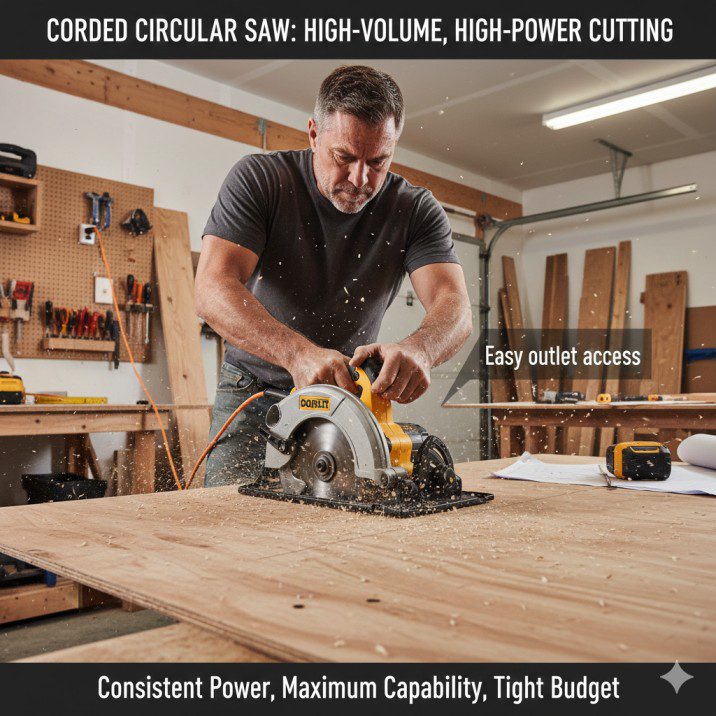

Choose Corded Circular Saw When:

- You’re doing high-volume cutting (framing walls, building decks, cutting lots of plywood)

- You work primarily in a shop or garage with easy outlet access

- Budget is tight and you need maximum capability for minimum cost

- You value consistent power and don’t mind cord management

- Projects last multiple hours or full days of continuous cutting

- You’re cutting particularly demanding materials (thick hardwood, wet lumber, etc.)

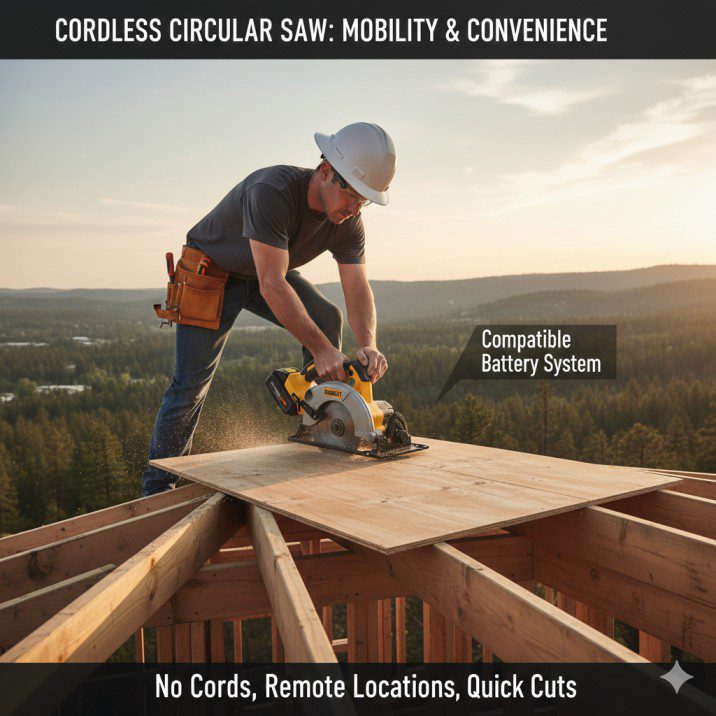

Choose Cordless Circular Saw When:

- You work on sites without reliable power access (roofing, remote locations, unfinished spaces)

- Mobility and convenience matter more than maximum power

- You already own compatible batteries from other cordless tools

- You make short bursts of cuts throughout the day rather than extended sessions

- Cord management frustrates you or creates safety hazards in your work environment

- You work in occupied spaces where running extension cords isn’t practical

Real Project Examples

Deck building: I use my corded saw. Hundreds of cuts over multiple days, outlet available on the house exterior. The unlimited runtime eliminates battery anxiety.

Kitchen remodel in occupied home: Cordless saw every time. No cords through the living space, cut materials outside or in garage, bring cut pieces in.

Workshop furniture building: Corded saw. I’m working in one location with outlet right there. Why deal with batteries?

Roof work: Cordless saw exclusively. Carrying an extension cord up a ladder is dangerous and annoying.

The Honest Recommendation: Which Should You Buy?

After nine years using both types across hundreds of projects, here’s my straight answer to the corded vs cordless circular saw question:

Buy a corded circular saw first if:

- You’re building your first tool collection on a budget

- You work primarily in a shop or garage

- Your projects involve lots of cutting (framing, decks, large furniture builds)

- You value consistent power and don’t have other cordless tools creating battery platform investment

Recommended corded saw: DeWalt DWE575SB ($140-160) for best lightweight performance, or Makita 5007MG ($160-180) for legendary reliability.

A cordless circular saw first if:

- You already own batteries from a major platform (Milwaukee M18, DeWalt 20V, Makita 18V)

- Your work takes you to locations without power access

- Convenience and mobility matter more than maximum power

- You make shorter cutting sessions rather than extended marathon sessions

Recommended cordless saw: Milwaukee M18 FUEL 2732 ($280 tool-only) for best overall cordless performance matching corded power.

Buy both when:

- You’re a professional contractor or serious DIYer tackling varied projects

- You’ve identified specific needs for both unlimited runtime (corded) and portable convenience (cordless)

- Your budget allows building a complete tool arsenal

My personal setup: I own a corded DeWalt for shop work and high-volume cutting, plus two Milwaukee M18 cordless saws (one for me, one for my helper) for jobsite mobility. The corded saw gets used on probably 60% of projects, but that 40% where cordless convenience matters is worth having both.

If you can only afford one saw right now and work in varied locations, get cordless—the versatility is worth the extra cost. If you work primarily in one location with power access, save money and get corded—you won’t miss the mobility.

Ready to compare specific models? Visit our detailed saw comparison guides or learn essential cutting techniques in our how-to tutorial section.

Frequently Asked Questions

Are cordless circular saws as powerful as corded?

Modern brushless cordless circular saws nearly match corded saw power for most cutting tasks in 2026. For light to moderate work—cutting dimensional lumber, plywood, and general DIY projects—quality cordless saws like the Milwaukee M18 FUEL deliver comparable performance. However, corded saws still maintain an advantage during extended heavy-duty cutting sessions, as battery voltage gradually declines during use while corded saws deliver consistent power indefinitely. For occasional use, cordless performance is excellent; for all-day professional use, corded reliability still wins.

How long do cordless circular saw batteries last per charge?

Battery runtime varies significantly based on capacity and usage. A quality 5.0Ah battery typically provides 250-350 cuts through standard 2×4 framing lumber—roughly 2-3 hours of intermittent cutting. Larger 6.0Ah or 9.0Ah batteries can deliver 400-600 cuts. Runtime decreases when cutting harder materials, making long rip cuts, using dull blades, or working in cold weather. For production cutting, plan on having at least two batteries so one charges while the other is in use. Budget cordless saws with smaller 2.0-3.0Ah batteries may only last 100-150 cuts.

Which is cheaper: corded or cordless circular saw?

Corded circular saws cost significantly less. Quality corded models range from $130-180 and are ready to use immediately. Cordless saws cost $180-280 for the tool alone, then require $120-200 additional investment in batteries and charger if you’re not already in that battery platform—total cost $300-480. Long-term, cordless saws also require periodic battery replacement every 3-5 years ($60-100 per battery), while corded saws only need occasional cord replacement. For budget-conscious buyers or those building their first tool collection, corded delivers more capability per dollar.

Can I use my cordless drill batteries in a cordless circular saw?

Only if the circular saw and drill are from the same manufacturer’s battery platform. For example, Milwaukee M18 batteries work in all Milwaukee M18 tools, DeWalt 20V MAX batteries work across DeWalt’s 20V system, and Makita 18V LXT batteries are interchangeable within that platform. However, you cannot mix brands—Milwaukee batteries won’t fit DeWalt tools and vice versa. This battery compatibility within platforms is a major advantage of cordless tools, allowing you to share batteries across multiple tools, but it also creates brand lock-in that limits future purchasing flexibility.

Do cordless circular saws work for framing and heavy-duty cutting?

Yes, modern cordless circular saws handle framing work effectively, though with some limitations. Brushless cordless saws like the Milwaukee M18 FUEL or DeWalt FLEXVOLT models deliver sufficient power for cutting studs, joists, and dimensional lumber all day. The main limitation is battery runtime—you’ll need multiple high-capacity batteries (5.0Ah or larger) and must manage charging schedules. For professionals doing extreme-volume framing (500+ cuts per day), corded saws still offer better sustained performance. For typical framing projects, quality cordless saws work great with proper battery planning.

Affiliate Disclosure: This article contains affiliate links to products. If you purchase through these links, we may earn a small commission at no additional cost to you. This helps support our website and allows us to continue providing honest, detailed tool comparisons based on real jobsite experience.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.