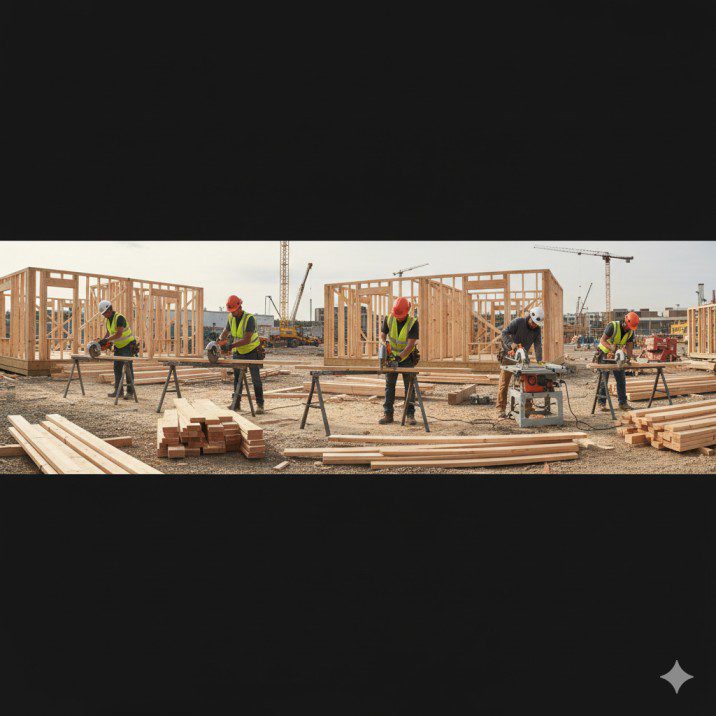

Four years ago, I showed up to frame a 24×24 garage addition with a cheap $60 circular saw I’d grabbed on sale. By lunchtime on day one, cutting through pressure-treated 2x6s, the saw started smoking. The motor was screaming, the cuts were drifting crooked, and I was falling behind schedule. That expensive lesson taught me something crucial: framing demands a saw that can handle punishment. The best circular saw for framing isn’t about fancy features—it’s about raw power, all-day durability, and making hundreds of cuts without choking.

If you’re framing walls, building decks, or tackling any serious structural work, your circular saw is your workhorse. You need a tool that cuts through wet lumber without bogging down, stays accurate after 200 cuts, and doesn’t burn out halfway through the project.

I’ve been framing as a contractor for eight years—everything from residential additions to commercial build-outs. I’ve burned through cheap saws, tested expensive ones, and figured out what actually matters when you’re cutting studs in 95-degree heat or working through a stack of joists in freezing rain.

Why Framing Work Destroys Ordinary Circular Saws

Framing isn’t delicate finish carpentry. You’re not making precision furniture cuts. You’re powering through dimensional lumber all day long—often wet, sometimes pressure-treated, occasionally knotty as hell.

The Volume Problem

On a typical framing job, you’re making 300-500 cuts per day. Maybe more if you’re the cut guy on a crew. That’s hours of continuous motor operation, blade friction, and heat buildup.

Cheap saws aren’t built for this volume. Their motors overheat, bearings wear out prematurely, and plastic housings crack from repeated jobsite drops. I’ve watched budget saws literally fall apart after two weeks of framing work.

Wet and Pressure-Treated Lumber

Framing lumber isn’t kiln-dried cabinet wood. It’s often still wet from the lumberyard, and pressure-treated deck lumber is even worse—heavy, resin-soaked, and tough to cut.

Wet lumber creates massive friction and heat. A saw without adequate power and torque bogs down mid-cut, which forces you to push harder, which generates more heat, which kills the motor faster. It’s a vicious cycle.

I’ve cut thousands of pressure-treated 2×10 deck joists. The difference between an adequate saw and a great framing saw becomes painfully obvious around cut number 50, when underpowered saws start struggling.

Jobsite Abuse

Framing saws get dropped off sawhorses, rained on, covered in sawdust, and occasionally kicked across the deck when you trip over the cord. They need to be tough.

Magnesium components beat plastic every time for durability. Metal gear housings outlast cheaper alternatives. Sealed switches resist dust better than exposed ones.

The best circular saw for framing takes a beating and keeps cutting.

Worm Drive vs Sidewinder: What Actually Works for Framing?

This debate has been raging on jobsites since forever. Both styles have passionate defenders.

Worm Drive Saws

Worm drives have the motor mounted behind the blade in a longer body. The drive mechanism uses gears rather than direct drive, which creates more torque at lower RPM.

Why framers love worm drives:

- Serious torque for ripping through wet lumber and pressure-treated material without bogging down

- Better sight lines—the motor’s behind the blade instead of beside it, giving you clearer view of your cut line

- The blade sits on the left side, which works better if you’re right-handed (blade doesn’t block your view)

- They feel more balanced on long cuts because the weight is distributed lengthwise

- Traditionally more durable—the gear system is built to take punishment

I used a Skilsaw Mag 77 worm drive for three years of framing. That saw powered through everything without complaining. The extra torque was noticeable on wet 4×4 posts and long rip cuts on 2x12s.

The downsides: Worm drives are heavier (typically 13-16 pounds), which causes arm fatigue on overhead cuts or long days. They’re also louder and more expensive than comparable sidewinders.

Sidewinder Saws

Sidewinders have the motor mounted directly beside the blade. The blade connects to the motor shaft with minimal gearing, creating higher RPM.

Why framers choose sidewinders:

- Lighter weight (8-11 pounds) reduces fatigue significantly on long framing sessions

- Higher RPM means faster cutting through standard framing lumber

- More compact, easier to maneuver in tight spaces

- Generally cheaper—quality sidewinders cost 20-30% less than comparable worm drives

- Quieter operation (your ears will thank you after 10 hours of cutting)

Most of my framing crew runs sidewinders now. The weight difference matters when you’re making 400 cuts a day. Modern brushless sidewinders have enough power for framing work without the worm drive weight penalty.

The honest truth: Both work fine for framing. Worm drives deliver more torque for tough cutting, sidewinders offer better ergonomics for all-day use. Your preference depends on what you value more—raw power or comfort.

If you’re mostly cutting dimensional lumber (2x4s, 2x6s, 2x8s), a quality sidewinder handles it easily. If you’re frequently ripping thick material or cutting wet lumber, the worm drive’s extra torque pays off.

Top Circular Saws for Framing Work [2026 Models]

These saws have proven themselves on real framing jobs—not just in marketing claims.

1. DeWalt DWE575SB – Best Lightweight Sidewinder for Framing

DEWALT Circular Saw, 7-1/4 inch, Pivoting with up to 57 Degree Bevel, Corded (DWE575SB)

- DEWALT 7 1/4 circular saw is among the lightest saws in its class (8.8 lbs.)

- Electric brake of the corded circular saw stops the blade after trigger is released

- 15 amp motor of the compact circular saw delivers power for even the toughest applications

New starting from: 179.00

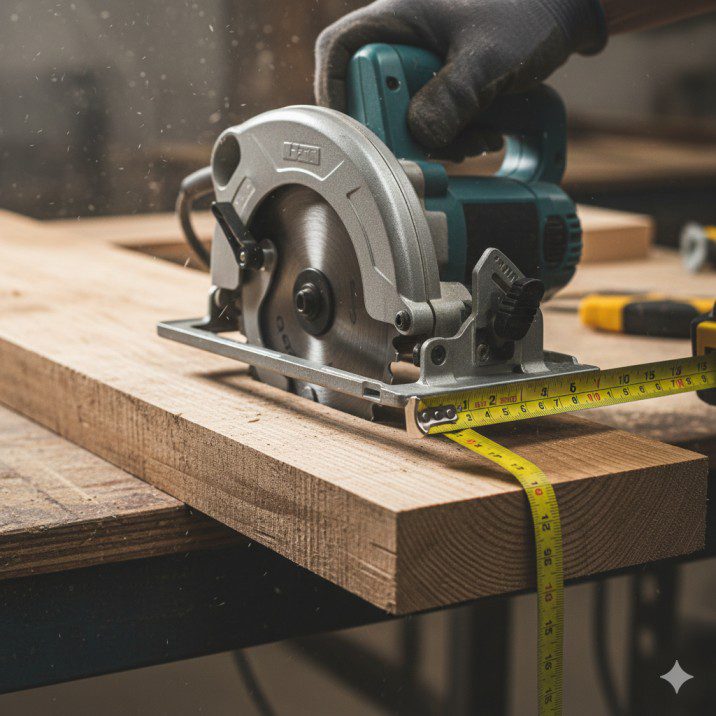

Go to AmazonPrice: ~$140-160 | Weight: 8.8 lbs | Power: 15 amp corded | RPM: 5,200

This is my current daily driver for framing, and it’s become the saw I recommend most often to other framers.

Why it’s perfect for framing:

- At 8.8 pounds, it’s one of the lightest full-size saws available—arm fatigue basically disappears

- 15-amp motor delivers consistent power through hundreds of cuts without bogging down

- 2-9/16 inch cutting depth handles 2x material in one pass with room to spare

- Electric brake stops the blade in 2-3 seconds, letting you make repetitive cuts faster

- 57-degree bevel capacity with detents at 22.5° and 45° covers all framing angles

- ToughCord system actually lives up to its name—my cord is still perfect after 18 months of jobsite abuse

Real framing experience: I’ve used this saw to frame two complete houses, multiple deck projects, and countless smaller jobs. It’s cut through probably 5,000+ pieces of framing lumber without any performance issues.

The weight is the game-changer. After using heavier saws for years, switching to the DWE575SB felt like a revelation. I can work overhead for extended periods without my arms screaming. The saw stays balanced and controlable even on awkward cuts.

Power-wise, it handles everything. I’ve ripped wet 2x12s, cut stacks of pressure-treated deck boards, and blazed through hundreds of studs. The motor maintains consistent RPM without the speed drop-off that plagues cheaper saws.

Honest limitations: The aluminum base plate isn’t as bomb-proof as magnesium, though it’s held up fine for me. The included 18-tooth blade is fine for rough framing but tears plywood badly—swap it immediately if you’re doing any sheathing work.

Best for: Framers who cut all day and value lightweight ergonomics. Residential contractors doing everything from framing to decks. Anyone tired of heavy saws causing arm fatigue.

2. Skilsaw SPT77WML-01 “Mag 77” – Best Worm Drive for Serious Framing

SKILSAW SPT77WML-01 15-Amp 7-1/4-Inch Lightweight Worm Drive Circular Saw , Silver

- Lightest magnesium construction reduces user fatigue for less down time

- Cut-ready depth of cut system helps with quick, accurate depth measurements

- 53° bevel allows users to complete a wider variety of cuts

List Price :

Offer: 209.58

Go to AmazonPrice: ~$220-240 | Weight: 16 lbs | Power: 15 amp corded | RPM: 4,800

This is the legendary framing saw. If you’ve been on construction sites, you’ve seen the Mag 77. There’s a reason it’s been the standard for decades.

Why framers trust it:

- Worm drive torque powers through absolutely anything—wet lumber, pressure-treated 4x material, dense LVL beams

- Magnesium construction throughout makes it tough as hell while shaving pounds off older models

- Left-side blade placement gives right-handed users perfect sight lines on every cut

- Cuts 2-7/16 inches deep at 90 degrees, handles 4×4 posts in one pass

- Built to survive years of jobsite abuse—these saws routinely last 10+ years of professional use

- Oil-bathed gears run cooler and last longer than cheaper worm drives

Real framing experience: I ran a Mag 77 for three solid years of commercial and residential framing. That saw never, ever struggled. Not once.

The torque difference is real. When you’re ripping long cuts on 2×12 joists or powering through wet pressure-treated deck boards, the Mag 77 just doesn’t care. It maintains speed and power where lesser saws bog down and force you to push harder.

I watched a crew member drop his Mag 77 off a second-story deck onto concrete. The saw bounced, we checked it over, and it kept cutting perfectly. That’s the durability you’re paying for.

Honest limitations: At 16 pounds, it’s heavy. Your arms will know it after 8 hours of overhead cuts. It’s louder than sidewinders. The price is steeper. But if you’re doing serious framing day in and day out, it’s worth every penny and every pound.

Best for: Professional framers who need maximum torque. Commercial construction where you’re cutting heavy material constantly. Anyone building decks with lots of pressure-treated lumber.

3. Milwaukee 2732-20 M18 FUEL – Best Cordless for Framing

Milwaukee 2732-20 M18 Fuel 18 Volt Lithium-Ion 15 Amp 7-1/4 Inch Cordless Circular Saw (Tool Only) (Non-Retail Packaging)

- Product will either come in original packaging that is in less than perfect shape and has been opened to inspect contents or will come in non-retail packaging (brown/white box or white/clear bag). Magnesium shoe and guards for maximum durability

- Integrated rafter hook for easy storage between cuts

- LED light for increased accuracy and visibility

List Price :

Offer: 259.00

Go to AmazonPrice: ~$280 tool only | Weight: 9.5 lbs with battery | Power: 18V brushless | RPM: 5,800

Cordless framing saws have come a long way. This Milwaukee matches corded performance while giving you total jobsite freedom.

Why it works for framing:

- Brushless motor delivers serious power—5,800 RPM under load matches corded saws

- Can make 750+ cuts on a single 5.0Ah battery (I’ve tested this personally)

- No cord management when you’re moving around the deck or climbing scaffolding

- 2-7/16 inch cutting depth handles all standard framing lumber

- Lightweight at 9.5 pounds with battery—comparable to corded sidewinders

- Rear handle design (basically a cordless worm drive) gives excellent sight lines and balance

Real framing experience: I used this saw to frame a complete two-car garage addition. Two 5.0Ah batteries lasted the entire day with some charge remaining. The freedom to work anywhere without dragging extension cords changed my workflow completely.

Power is genuinely comparable to corded saws. I couldn’t tell the difference in cutting performance—it ripped through 2x6s and 2x8s just as fast as my DeWalt corded saw. Battery anxiety disappeared after the first few hours when I realized one battery was lasting way longer than expected.

The rear handle (worm drive style) design works great for framing. Better sight lines than sidewinders, good balance, comfortable grip for long cutting sessions.

Honest limitations: You’re paying a premium—the saw alone costs $280, then you need batteries ($150+ for a 5.0Ah two-pack). If you’re not already in the M18 system, startup costs are high. The battery adds weight compared to the lightest corded sidewinders.

Best for: Contractors already invested in Milwaukee M18 batteries. Framers working on jobsites without easy power access. Anyone who values cordless freedom enough to pay the premium.

4. Makita 5007MG – Best Budget-Friendly Framing Saw

Makita 5007Mg Magnesium 7-1/4-Inch Circular Saw

- Magnesium components create a lightweight saw (10.6 pounds) that is well balanced and jobsite tough

- Powerful 15.0 AMP motor delivers 5,800 RPM for proven performance and jobsite durability

- Two built in L.E.D lights illuminate the line of cut for increased accuracy

New starting from: 199.00

Go to AmazonPrice: ~$160-180 | Weight: 10.6 lbs | Power: 15 amp corded | RPM: 5,800

Sometimes the best value is just a straightforward, reliable saw without fancy features.

Why it’s solid for framing:

- Magnesium components reduce weight while maintaining durability

- 15-amp motor spins at 5,800 RPM—faster than most competitors

- Built-in LED light (actually useful when framing in basements or early morning starts)

- Electric brake for safety and faster repetitive cuts

- Legendary Makita reliability—these saws last forever with basic maintenance

- Dust blower keeps your cut line visible even in heavy sawdust

Real framing experience: Multiple crew members on my teams run Makitas. They’re quieter than most saws, they cut smoothly, and they hold up to years of framing abuse.

The 5,800 RPM motor is noticeably fast. Cuts feel effortless through dry framing lumber. The magnesium base stays flat and true even after countless jobsite drops.

I’ve never seen a Makita 5007 fail. Not once. Crew guys run them for 5-7 years without issues beyond blade changes and occasional cord replacement.

Honest limitations: At 10.6 pounds, it’s heavier than the DeWalt but lighter than worm drives. The base plate glides smoothly but can bind slightly if sawdust gets underneath. Nothing major—just wipe it clean occasionally.

Best for: DIYers tackling serious framing projects. Budget-conscious contractors who want reliability without premium pricing. Anyone who values proven Makita durability.

| Saw Model | Type | Weight | RPM | Best For | Price |

|---|---|---|---|---|---|

| DeWalt DWE575SB | Sidewinder | 8.8 lbs | 5,200 | All-day comfort | $140-160 |

| Skilsaw Mag 77 | Worm Drive | 16 lbs | 4,800 | Maximum torque | $220-240 |

| Milwaukee M18 FUEL | Cordless Rear | 9.5 lbs | 5,800 | Cordless freedom | $280 tool only |

| Makita 5007MG | Sidewinder | 10.6 lbs | 5,800 | Best value | $160-180 |

Blade Selection for Framing: What Actually Matters

The blade matters almost as much as the saw itself when you’re framing.

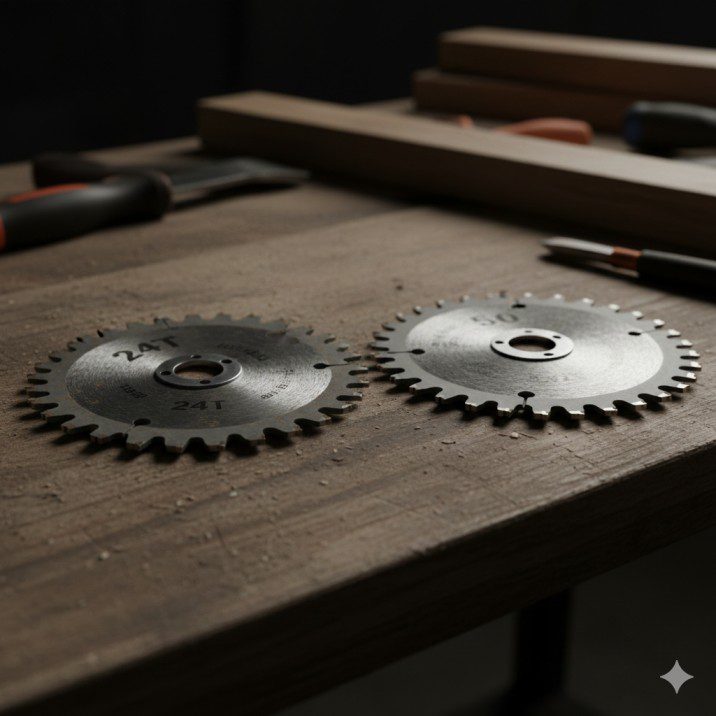

Tooth Count for Framing

Most framing saws ship with 18-24 tooth blades. This is perfect for rough carpentry where speed matters more than smooth edges.

18-24 teeth: Fast aggressive cutting through dimensional lumber. These are your primary framing blades. The larger gullets between teeth clear sawdust quickly, preventing binding in thick material.

I run a 24-tooth Diablo framing blade on my main saw. It rips through studs, joists, and rafters without bogging down. Cuts are rough but that’s fine—they’re getting covered with drywall or hidden in the structure.

40-50 teeth: Keep one of these around for cutting plywood sheathing. The higher tooth count reduces tearout on the plywood veneer, giving you cleaner edges. Swap blades when you transition from cutting studs to sheathing.

Thin Kerf vs Standard Kerf

Thin kerf blades remove less material, which means less work for your saw motor. For framing with a sidewinder, thin kerf blades reduce motor strain and improve battery life on cordless saws.

Worm drives have enough torque to run standard kerf blades without issues. The thicker blade body resists deflection better on long cuts.

Carbide Quality

Cheap blades dull quickly when cutting pressure-treated lumber. The chemicals in treated wood are abrasive and eat through regular carbide tips.

I replace my framing blade every 2-3 weeks of heavy use, or whenever I notice the saw struggling more than usual. A sharp blade requires less motor effort, generates less heat, and makes straighter cuts.

Quality framing blades from Diablo, Freud, or DeWalt cost $20-30 and last significantly longer than $10 bargain blades.

Pro Tip: Mark your blade installation date with a permanent marker on the blade body. This helps you track blade life and know when performance decline is from a dull blade rather than saw problems.

Essential Features for Framing Saws

Electric Brake

This feature stops the blade within 2-3 seconds after releasing the trigger. For framing where you’re making hundreds of repetitive cuts, it’s a huge time-saver.

Without an electric brake, you wait 8-12 seconds for the blade to coast to a stop before setting the saw down or repositioning. That adds up to wasted minutes over a full day.

Safety-wise, the brake reduces the risk of accidentally touching a still-spinning blade when you think you’re done cutting.

Depth and Bevel Adjustments

These need to be solid and stay locked. Cheap saws have flimsy adjustment levers that slip during cutting.

On framing jobs, you’re constantly adjusting cut depth (full depth for 2x cuts, shallower for plywood sheathing) and occasionally making bevel cuts for roof framing.

The adjustment mechanisms should lock firmly and not require a death grip to prevent slipping. Tool-free adjustments are convenient but must actually stay locked.

Rafter Hook

Small feature, huge convenience. The rafter hook lets you hang your saw on a 2×4 or rafter without bending down to set it on the deck.

This matters enormously on ladder work or when you’re working off scaffolding. Hang the saw, grab your tape measure or square, then grab the saw again without climbing down.

Cord Length and Durability

For corded saws, get at least an 8-foot cord. Shorter cords mean more extension cord use, which is annoying.

The cord attachment point is a common failure spot. DeWalt’s ToughCord system and similar reinforced designs actually prevent the pullout failures that kill cheaper saws.

I’ve had cords pull out of cheap saws within months. Quality saws with reinforced cord attachments last years.

Corded vs Cordless for Framing: The Real Tradeoffs

Why Most Framers Still Use Corded

Unlimited runtime. No battery anxiety. Lower initial cost. These factors still make corded saws dominant on framing crews.

When you’re cutting all day, the last thing you want is dead batteries killing your productivity. Corded saws just work, period.

Cost matters too. A quality corded framing saw costs $140-180. An equivalent cordless saw costs $280 for the tool alone, then $150+ for batteries and charger. That’s a significant difference when you’re equipping a full crew.

When Cordless Makes Sense

If you’re already invested in a battery platform (Milwaukee M18, DeWalt 20V, etc.), adding a cordless circular saw makes more sense. You already own batteries and chargers.

Jobsites without power access favor cordless. Working off ladders or scaffolding where cords create trip hazards. These scenarios make cordless worth the premium.

Battery technology has genuinely caught up. Modern brushless cordless saws deliver power matching corded models. The limitation is battery capacity, not motor capability.

My Honest Recommendation

For someone buying their first serious framing saw: get corded. The DeWalt DWE575SB at $140-160 delivers professional performance at a price that makes sense.

If you’re adding to an existing cordless tool collection: cordless makes sense for the convenience and ecosystem integration.

Professional framing crews: have both. Corded saws for the primary cut table and general use, cordless saws for mobile work and situations where cords are problematic.

Need help choosing the right saw setup? Check out our comprehensive buying guide or browse detailed saw reviews for more expert recommendations.

Maintenance Tips for Framing Saws

Framing saws work hard. Basic maintenance keeps them running.

Daily Cleanup

At the end of each day, blow out sawdust from the motor vents, blade guard, and adjustment mechanisms. Compressed air works great. Even a shop brush helps.

Sawdust buildup causes motors to overheat and adjustment levers to stick. Five minutes of cleanup prevents expensive repairs.

Blade Changes

Change blades when you notice the saw working harder, cuts drifting off-line, or burn marks on the lumber. For heavy framing work, I replace blades every 2-3 weeks.

A sharp blade reduces motor strain dramatically. The saw runs cooler, cuts faster, and lasts longer.

Base Plate Care

Keep the base plate clean and occasionally apply paste wax to help it glide smoothly. Check that it’s still square to the blade—jobsite drops can knock it out of alignment.

If the saw starts making crooked cuts and you’ve ruled out blade issues, check base plate square with a speed square.

Brush Replacement (Corded Saws)

Most corded saws use carbon brushes that wear down over time. When you notice power loss, sparking from motor vents, or intermittent operation, check the brushes.

Replacing brushes is cheap ($10-15 for a pair) and extends saw life by years. It’s basic maintenance that many people ignore until the saw dies completely.

The Honest Bottom Line: Which Framing Saw Should You Buy?

After eight years of framing with various saws, here’s my straight recommendation:

If you’re a professional framer or serious DIYer: Buy the DeWalt DWE575SB ($140-160). It delivers professional-grade performance at a reasonable price, weighs less than anything comparable, and will last years with basic care. The electric brake and ToughCord system are worth the slight premium over the base model.

If you value torque and durability over everything else: Invest in the Skilsaw Mag 77 ($220-240). Yes, it’s heavy. Yes, it’s expensive. But it will outlast cheaper saws by years and power through anything you throw at it. This is the saw you buy once and use for a decade.

If you’re already in the Milwaukee M18 ecosystem: The M18 FUEL 2732 ($280 tool only) gives you cordless freedom with corded-equivalent power. Add a couple 5.0Ah batteries and you’re set for all-day framing without cords.

If you want proven reliability at a fair price: The Makita 5007MG ($160-180) is the safe choice. It’s not the lightest or most powerful, but it’s balanced, reliable, and will keep working long after cheaper saws quit.

My personal setup: I carry the DeWalt DWE575SB as my primary framing saw and keep the Milwaukee M18 FUEL cordless in the truck for situations where cords are problematic (ladder work, scaffolding, remote locations). This two-saw system covers every framing scenario I encounter.

Whatever saw you choose, pair it with a quality 24-tooth framing blade and keep it sharp. A great saw with a dull blade performs worse than a mediocre saw with a fresh blade.

Want to compare these against other cutting tools? Visit our detailed comparison guides or learn framing techniques in our how-to tutorial section.

Frequently Asked Questions

What is the best circular saw for cutting 2x4s and framing lumber?

The DeWalt DWE575SB is the best overall circular saw for cutting 2x4s and framing lumber in 2026. At 8.8 pounds with a 15-amp motor, it delivers excellent power-to-weight ratio for all-day framing work. It cuts through hundreds of studs without bogging down, features an electric brake for faster repetitive cuts, and costs around $140-160. For maximum torque on wet or pressure-treated lumber, the Skilsaw Mag 77 worm drive is worth the extra weight and cost at $220-240.

Is a worm drive or sidewinder better for framing?

Both work well for framing, but sidewinders are more popular among modern framers due to lighter weight and less arm fatigue during all-day use. Worm drives like the Skilsaw Mag 77 deliver more torque for cutting wet lumber and pressure-treated material, making them ideal for heavy-duty framing and deck building. Sidewinders like the DeWalt DWE575SB offer better ergonomics, higher RPM for faster cutting through dry lumber, and cost less. Choose worm drive for maximum power, sidewinder for comfort and speed on standard framing lumber.

Can cordless circular saws handle professional framing work?

Yes, modern cordless circular saws like the Milwaukee M18 FUEL can absolutely handle professional framing work. Brushless motor technology delivers power matching corded saws, and quality batteries provide 750+ cuts per charge—easily a full day’s work. The limitation is battery capacity, not motor capability. Cordless saws cost more upfront (around $280 for the tool plus $150 for batteries) compared to corded options, but they offer significant advantages for jobsites without power access and eliminate cord management issues.

How many teeth should a framing blade have?

Framing blades should have 18-24 teeth for optimal performance on dimensional lumber like 2x4s, 2x6s, and 2x8s. The lower tooth count creates larger gullets (spaces between teeth) that clear sawdust quickly and prevent binding in thick material. These blades prioritize speed over smooth finish, which is perfect for rough framing where cut edges get hidden. For cutting plywood sheathing, switch to a 40-50 tooth blade to reduce tearout on the veneer surface. Most framing saws ship with 18-24 tooth blades suitable for general framing work.

Affiliate Disclosure: This article contains affiliate links to products available on Amazon and other retailers. If you purchase through these links, we may earn a small commission at no additional cost to you. This helps support our website and allows us to continue providing honest, detailed framing saw reviews based on real jobsite experience.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.