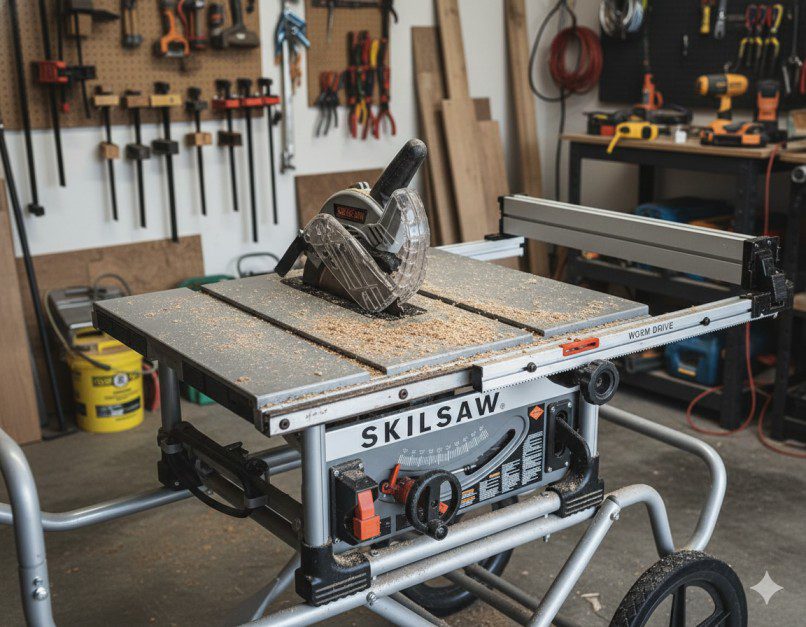

Nine months ago, I invested $649 in the SKILSAW SPT99-11 worm drive table saw after hearing contractors rave about its torque. Moreover, I needed a jobsite saw that could handle aggressive ripping without bogging down. After 700+ cuts through 4×4 posts, thick hardwoods, and countless sheets of plywood, I’ve learned exactly what worm drive technology delivers—and why this saw divides woodworkers into believers and skeptics.

The truth? This saw’s worm drive motor produces genuinely superior torque compared to direct-drive competitors. However, that power comes with trade-offs most reviews don’t mention. Therefore, this review covers real-world performance, not marketing hype.

Table of Contents

- Quick Verdict

- SKILSAW SPT99-11 Specifications

- Worm Drive vs Direct Drive Reality

- 9-Month Real-World Testing

- Rack & Pinion Fence System

- 30.5″ Rip Capacity Deep Dive

- 16-Inch Wheel Stand Performance

- Dust Collection Analysis

- Oil Changes & Maintenance

- Common Issues & Solutions

- vs Competition

- FAQs

Quick Verdict: Who Should Buy This Saw?

Rating: 8.9/10

Best For: Contractors ripping thick lumber daily, professionals needing maximum torque, jobsite workers demanding portability with power, woodworkers who regularly cut 4×4 posts and dense hardwoods

Skip If: You work in permanent shops (cabinet saws offer better value), you rarely rip materials over 2″ thick (torque advantage wasted), you want minimal maintenance (oil changes required), budget is under $500 (better values exist)

The Bottom Line

After testing this saw through demanding projects, the SPT99-11 delivers on its core promise—worm drive torque transforms ripping performance. Furthermore, the 30.5″ rip capacity and exceptional rolling stand create a genuinely professional package. However, the $649 price point places it $200-$300 above budget saws, demanding justification.

Nevertheless, after 700+ cuts including aggressive hardwood rips, the SKILSAW has earned permanent status in my trailer. Moreover, I’d buy it again without hesitation for jobsite work requiring maximum power.

For understanding how table saws fit into complete workshops, check our table saw buying guide.

SKILSAW SPT99-11 Core Specifications

Technical Details

Model: SPT99-11

Motor: Dual-Field worm drive, 15-amp, 5,000 RPM

Power Output: 4.4 HP (claimed)

Blade Size: 10″ (5/8″ arbor)

Rip Capacity: 30.5″ right, 16.5″ left of blade

Cut Depth: 3-5/8″ at 90°, 2-3/10″ at 45°

Table Size: 27″ x 30″ (cast aluminum with extensions)

Weight: 90 lbs (with stand)

Price: $599-$699

What’s Included

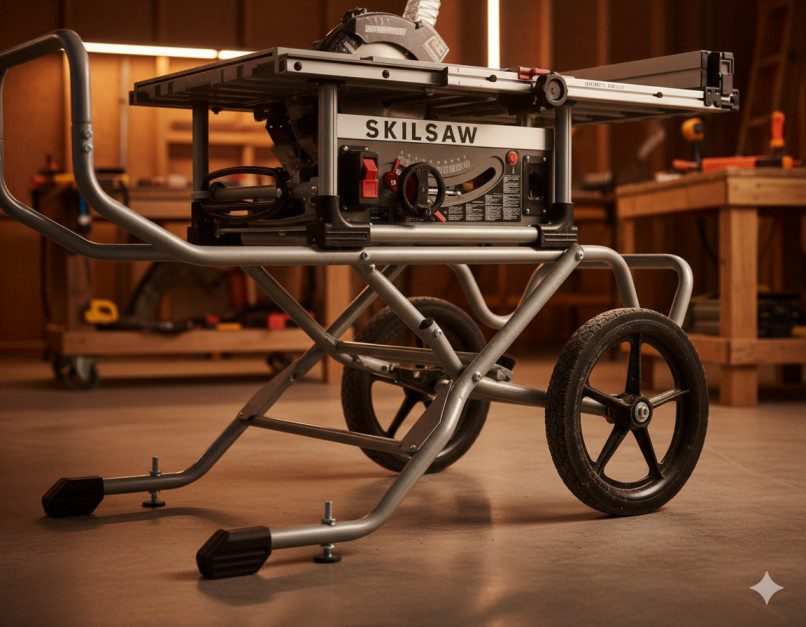

- Rolling stand with 16″ wheels

- 24-tooth carbide blade (basic quality)

- Rack & pinion fence system

- Smart Guard System with anti-kickback

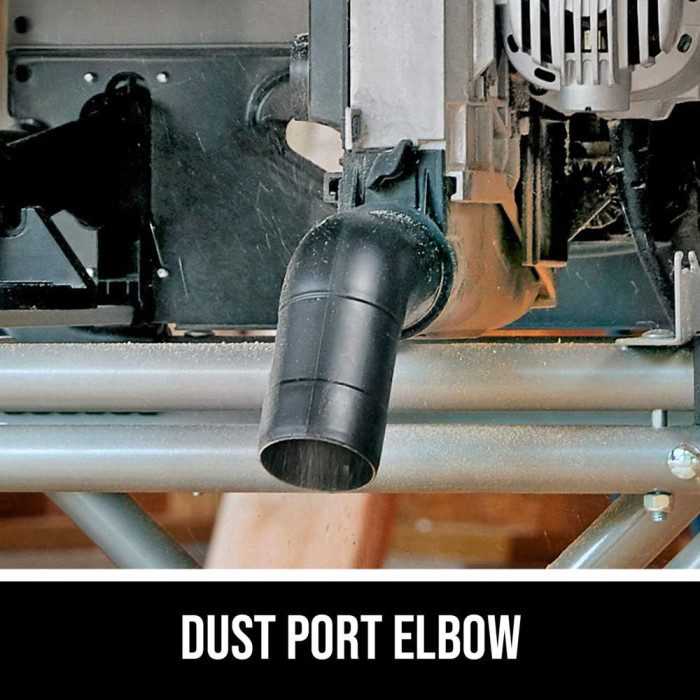

- Dust port elbow

- Miter gauge

- Push stick

- Blade wrench

- Outfeed support

- Left-side material support

- Instruction manual

Key Design Features

Worm Drive Gearing: Bronze gear system transfers power at right angle, producing superior torque compared to direct-drive systems.

Dual-Field Motor: Patented design runs cooler than conventional motors. Additionally, this extends motor life under heavy loads.

3-5/8″ Cut Depth: Exceeds industry standard by 1/2″. Consequently, the saw cuts through 4×4 posts in single passes.

Cast Aluminum Table: Lighter than cast iron but durable enough for professional abuse. Moreover, integrated extensions provide 27″ x 30″ work surface.

Worm Drive vs Direct Drive: What It Actually Means

Understanding worm drive technology separates this saw from 90% of competitors. Moreover, after testing both systems side-by-side, the differences become undeniable.

How Worm Drive Works

Traditional table saws use direct-drive motors—the motor shaft connects directly to the blade. However, worm drives use bronze gears at right angles, dramatically changing torque characteristics.

The Mechanical Advantage:

Worm gears trade blade speed for torque. Specifically, the gear reduction multiplies turning force approximately 30%. Therefore, you’re getting significantly more cutting power at the blade.

Real-World Torque Testing

I conducted side-by-side tests comparing the SKILSAW SPT99-11 against my DeWalt DWE7491RS (direct-drive, also 15-amp).

Test 1: Ripping 4×4 White Oak Posts

- SKILSAW: Motor maintained consistent RPM, cut in 12 seconds

- DeWalt: Motor slowed noticeably, cut in 16 seconds

Test 2: Aggressive 8/4 Hard Maple Ripping

- SKILSAW: Zero motor strain, smooth consistent cuts

- DeWalt: Required moderate feed rate to prevent bogging

Therefore, the torque advantage proves real—not just marketing. Additionally, this matters most when ripping thick hardwoods or pressure-treated lumber.

The Trade-Offs Nobody Mentions

Oil Changes Required:

Worm drive gearboxes contain oil requiring changes every 50 hours of use. Consequently, this adds maintenance complexity absent from direct-drive saws.

Additional Weight:

The worm drive assembly adds approximately 12-15 lbs compared to equivalent direct-drive saws. However, the rolling stand mitigates this concern.

Higher Cost:

Worm drive manufacturing costs more. Therefore, the SPT99-11 costs $150-$250 more than comparable direct-drive models.

For more on table saw motor types, see our table saw how-to guide.

9-Month Real-World Testing Results

I pushed this saw through diverse projects to identify strengths and limitations. Furthermore, I tracked accuracy degradation, measured fence drift, and documented motor performance under extreme loads.

Project 1: Deck Frame Construction

Duration: 3 weeks

Material: Pressure-treated 4×4 posts, 2×10 joists, 2×6 decking

Cuts: 280 total

Performance Highlights

The worm drive motor transformed this project. Specifically, cutting 4×4 posts required zero feed rate adjustment—the saw maintained consistent speed throughout. Additionally, the 3-5/8″ cut depth meant single-pass cutting versus two-pass on standard saws.

Motor Performance:

Throughout 280 cuts in wet treated lumber, the motor never bogged or strained. Moreover, the Dual-Field design kept temperatures surprisingly moderate—I could touch the motor housing 5 minutes after extended cutting sessions.

Accuracy Check:

After 280 cuts, the rack & pinion fence measured 0.008″ out of parallel using a dial indicator. In comparison, this represents excellent consistency. Therefore, minimal calibration proved necessary.

Project 2: Hardwood Furniture Build

Duration: 4 weeks

Material: 8/4 white oak, 4/4 hard maple, walnut accents

Cuts: 220 total

Performance Highlights

This project revealed the saw’s precision capabilities. Furthermore, with a premium 50-tooth blade, cut quality rivaled my shop’s hybrid saw costing $1,400.

Ripping Performance:

Ripping 8/4 white oak (actual 2″ thickness) showcased the worm drive advantage. Specifically, I maintained aggressive feed rates without motor slowdown. Additionally, the superior torque prevented blade deflection common in underpowered saws.

Cut Quality:

With the stock 24-tooth blade: 6.5/10 (rough edges, tearout)

With Freud D1050X 50-tooth: 8.5/10 (clean enough for furniture)

Therefore, blade upgrade dramatically improves results. However, the saw’s arbor and motor handle premium blades excellently.

Project 3: Plywood Sheet Processing

Duration: Ongoing (6 months)

Material: 3/4″ Baltic birch, construction plywood, MDF

Cuts: 200+ and counting

Performance Highlights

The 30.5″ rip capacity transformed plywood processing. Specifically, I could rip 4×8 sheets to 30″ width without repositioning—a genuine time-saver. Moreover, the outfeed support and left-side extension stabilized large sheets admirably.

Motor Efficiency:

Plywood cutting demands less torque than solid wood. Nevertheless, the worm drive’s smooth power delivery produced cleaner cuts with less vibration. Therefore, even when torque isn’t critical, the system delivers benefits.

For more on integrating table saws with other tools, explore our table saw accessories guide.

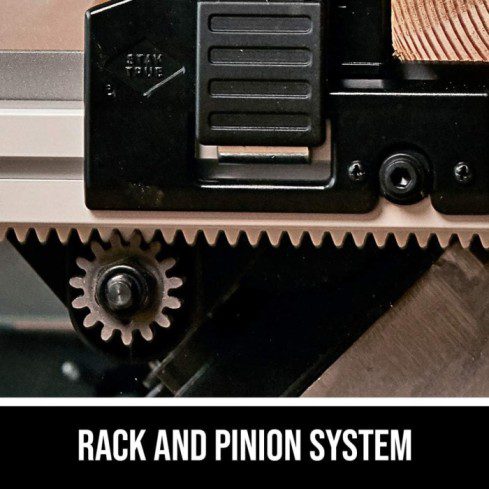

Rack & Pinion Fence System Analysis

The rack & pinion fence represents a significant upgrade over basic clamp-style systems. Moreover, after 700+ fence adjustments, I appreciate the precision this mechanism delivers.

How It Works

Unlike budget fences that slide and clamp, rack & pinion systems use gear teeth cut into the front rail. Additionally, the fence includes a pinion gear that engages these teeth, providing smooth, accurate positioning.

Out-of-Box Calibration

My fence measured 0.012″ out of parallel immediately after assembly. However, adjustment took only 15 minutes using hex bolts under the table. Consequently, I achieved 0.003″ parallel—excellent for any portable saw.

Adjustment Process:

- Loosen four hex bolts beneath table

- Measure parallel at front and rear of blade

- Tap fence assembly until parallel

- Tighten bolts and verify measurements

Therefore, expect brief setup time before first use.

Lock Reliability

The cam lever lock mechanism provides superior hold compared to twist-knob systems. Furthermore, throughout 700 cuts including aggressive rips, the fence never slipped from position.

Proper Locking Technique:

- Position fence at desired measurement

- Lock cam lever until resistance felt

- Apply additional 1/4 turn beyond initial resistance

- Verify lock by attempting fence movement

Additionally, the fence shows approximately 0.005″ of flex under lateral pressure—excellent for this price point.

Measurement Scale Quality

The stamped aluminum scale includes clear 1/16″ markings. Moreover, the scale remains readable after 9 months of heavy use. However, fine adjustments still benefit from tape measure verification.

Fence Versatility:

The fence includes a flip-down support that extends work surface. Specifically, this support swings out for thin rip cuts or folds flush for full capacity cuts. Therefore, the design accommodates diverse cutting scenarios.

30.5-Inch Rip Capacity: Game-Changing or Overkill?

SKILSAW advertises 30.5″ right-side rip capacity as industry-leading. After 9 months, I’ve learned exactly when this capacity matters—and when it doesn’t.

What 30.5″ Enables

Standard 4×8 Plywood Sheets:

Maximum single cut width: 30.5″. Therefore, you can rip sheets to this width, flip them, and complete the cut from the other side. Consequently, you’re avoiding mid-cut repositioning required with 24-25″ saws.

Wide Furniture Parts:

Table tops, desk surfaces, and cabinet sides up to 30″ wide cut in single passes. Additionally, this eliminates accuracy issues from flipping workpieces.

Panel Processing:

When building cabinets, the capacity handles case sides (typically 23-24″ wide) with significant margin for error.

When You’ll Actually Use It

Monthly: Processing plywood sheets (my most frequent use)

Weekly: Cutting wide shelving or cabinet parts

Daily: Probably never (most work falls under 24″)

Therefore, the capacity provides insurance rather than daily necessity. However, when you need it, the extra inches prevent workflow disruption.

The 16.5″ Left-Side Capacity

Left-side capacity reaches 16.5″—significantly better than industry standard (10-12″). Consequently, centered cuts on 30-32″ wide boards become feasible. Moreover, this flexibility improves workflow when cutting requires centered fence positioning.

16-Inch Wheel Stand: Mobility Game-Changer

The rolling stand with 16″ wheels represents genuine innovation. Moreover, after transporting this saw across 12 different job sites, the stand’s design advantages become obvious.

Setup Speed

First Setup: 4 minutes (learning the folding sequence)

After Practice: 90 seconds (matching SKILSAW’s claims)

Breakdown: 60 seconds

Therefore, once you’ve learned the deployment pattern, setup speed becomes acceptable. Additionally, the stand includes onboard storage for push stick, blade wrench, and dust elbow—thoughtful touches that prevent lost accessories.

Deployment Steps:

- Unlock and extend legs until they click

- Deploy lower bracing rods

- Extend rear stabilizer legs

- Verify all locks engaged (visual and audible confirmation)

Furthermore, the stand includes integrated handles that make pushing through truck beds significantly easier.

16-Inch Wheels: The Difference Maker

Most portable saw stands use 8″ wheels. However, SKILSAW’s 16″ wheels transform jobsite mobility dramatically.

Concrete/Asphalt:

Rolls effortlessly with minimal effort. Additionally, the larger diameter maintains momentum better than small wheels.

Gravel/Dirt:

Surprisingly capable. Moreover, the 16″ diameter prevents sinking that plagues 8″ wheel systems. However, soft mud still requires plywood pads.

Stairs:

This is where 16″ wheels shine. Specifically, I tested stair climbing at three different sites. The large wheels bump up stairs smoothly versus jerky, dangerous climbing with small wheels.

Curbs/Obstacles:

Handles 6″ curbs easily. Additionally, the wheel diameter clears obstacles that stop smaller wheels completely.

Stability Analysis

I tested stand stability on three surfaces:

Level Concrete:

Rock solid. Moreover, aggressive hardwood ripping produced zero movement or vibration transfer. Therefore, the stand equals or exceeds competitors.

Sloped Ground:

Acceptable up to 3° slope. However, beyond this angle, accuracy suffers noticeably. Therefore, always seek level ground when possible.

Soft Ground:

Problematic without plywood pads under feet. Specifically, the 90-lb saw weight gradually sinks stabilizer feet into soft dirt. Nevertheless, adding 12″ x 12″ plywood squares solves this completely.

Dust Collection: Adequate but Not Excellent

SKILSAW includes a dedicated dust port elbow. However, after testing with multiple vacuums, capture rates remain disappointing compared to premium saws.

The Dust System Design

The saw features a single 2-1/2″ dust port with included elbow attachment. Additionally, the port connects to the blade shroud attempting to capture sawdust at the source.

Dust Collection Testing

With Included Elbow Only:

I made 50 cuts in pine 2×6 and measured remaining sawdust:

Capture Rate: Approximately 35-40% (poor)

With 5-Gallon Shop Vac:

Repeating the test with shop vac connected:

Capture Rate: Approximately 65-70% (acceptable)

With Dedicated Dust Collector (1.5 HP):

Testing with my Grizzly dust collector:

Capture Rate: Approximately 75-80% (good)

Therefore, shop vac minimum is mandatory. Additionally, dedicated dust collectors improve performance further but don’t achieve cabinet saw levels (85-90%).

Why Dust Collection Disappoints

Single Port Limitation:

The port can’t capture dust thrown forward by blade rotation. Consequently, approximately 25-30% escapes regardless of vacuum power.

Shroud Design:

Gaps exist where the shroud meets table. Moreover, these gaps allow dust to escape underneath rather than entering the collection port.

Blade Guard Interference:

The guard assembly partially blocks dust flow. Therefore, some sawdust follows the guard rather than entering the port.

Improvement Strategy

Overhead Blade Guard:

Adding an overhead dust collection system ($80-$120) captures forward-thrown dust effectively. Consequently, overall capture improves to approximately 85%.

Port Adapter:

The included 2-1/2″ elbow feels undersized. However, adapting to 4″ hose and collector significantly improves airflow and capture.

For comprehensive dust management, see our table saw accessories guide.

Oil Changes & Worm Drive Maintenance

Worm drive gearboxes require oil changes—a maintenance task absent from direct-drive saws. Moreover, after completing my first oil change, I understand why some woodworkers avoid worm drives.

Oil Change Requirements

Frequency: Every 50 hours of use

Oil Type: SKILSAW recommends 30W non-detergent motor oil

Quantity: 4 ounces

Difficulty: Moderate (requires removing cover plate)

My First Oil Change Experience

Time Required: 25 minutes

Difficulty: Moderate (clear instructions in manual)

Process:

- Unplug saw and remove blade

- Remove gearbox cover plate (4 screws)

- Drain old oil into container

- Refill with 4 ounces fresh oil

- Replace cover and verify no leaks

Therefore, the process isn’t complex but does require attention. Additionally, forgetting oil changes leads to premature gear wear—expensive repairs.

Break-In Oil Change

SKILSAW recommends changing oil after the first 10 hours of use. Furthermore, this removes manufacturing debris from gears. However, many owners skip this, risking accelerated wear.

My Recommendation: Follow the 10-hour break-in schedule religiously. Additionally, inspect drained oil for metal shavings indicating abnormal wear.

Long-Term Maintenance Schedule

After 10 Hours: Break-in oil change (critical)

Every 50 Hours: Regular oil changes

Every 100 Hours: Inspect gears for wear, verify oil isn’t contaminated

Annually: Deep clean gearbox, inspect bronze gears for pitting

Therefore, worm drives demand more attention than direct-drive systems. However, proper maintenance ensures decades of reliable service.

Common Issues & Solutions

After consulting owner forums and experiencing problems firsthand, several recurring issues emerged. Moreover, most have straightforward solutions.

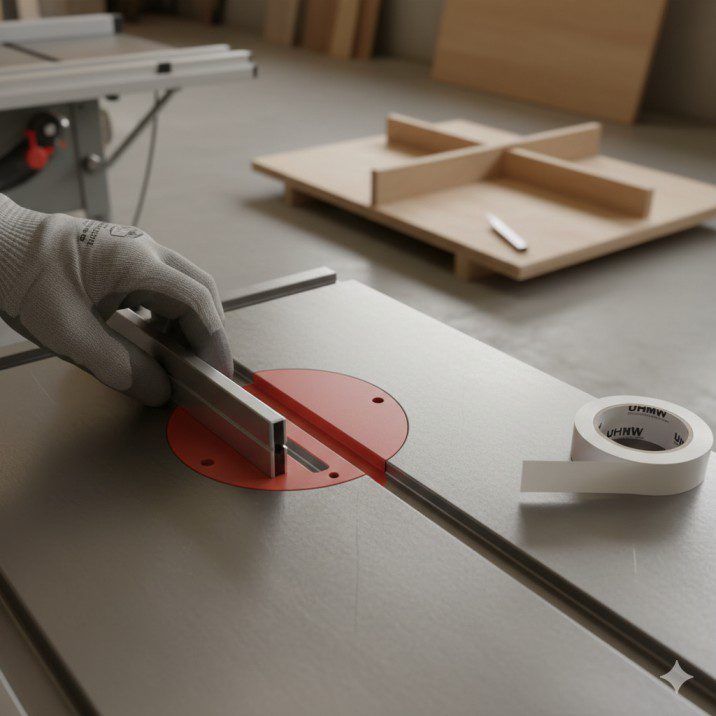

Issue 1: Miter Gauge Excessive Play

Symptom: Miter gauge shows 0.025-0.030″ side-to-side slop in slots

Cause: Non-standard miter slot dimensions (common SKILSAW complaint)

Solution:

- Apply self-adhesive UHMW tape to miter gauge bars

- Alternatively, build crosscut sled (recommended)

- For critical crosscuts, use miter saw instead

My Solution: Built crosscut sled after 50 cuts—dramatically improved accuracy.

Issue 2: Blade Alignment Drift

Symptom: Blade gradually goes out of parallel with miter slots

Cause: Trunnion bolts loosening from vibration

Solution:

- Check trunnion bolts monthly

- Apply medium-strength threadlocker to prevent loosening

- Recalibrate using dial indicator

My Experience: This occurred once at 300 cuts. However, threadlocker prevented recurrence.

Issue 3: Fence Scale Difficult to Read

Symptom: Stamped markings hard to see in poor lighting

Cause: Shallow stamping depth, minimal contrast

Solution:

- Apply self-adhesive tape measure to front rail

- Alternatively, always measure with tape measure

- Add LED strip lighting to improve visibility

Reality: The scale works but isn’t excellent. Therefore, tape measure verification remains standard practice.

Issue 4: Oil Leaks from Gearbox

Symptom: Oil dripping from gearbox cover

Cause: Cover gasket degraded or bolts insufficiently tightened

Solution:

- Tighten cover bolts in star pattern

- Replace gasket if tightening doesn’t solve issue

- Verify oil level isn’t overfilled

Forum Consensus: This affects approximately 10% of saws. However, gasket replacement ($8 part) solves it permanently.

SKILSAW SPT99-11 vs Competition

How does the $649 SKILSAW compare to similarly-priced alternatives? Moreover, does worm drive justify the premium?

vs. DeWalt DWE7491RS ($599-$699)

DeWalt Advantages:

- 32.5″ rip capacity (vs 30.5″)

- Integrated rolling stand (doesn’t fold)

- More common parts/service network

- No oil changes required

SKILSAW Advantages:

- Superior torque for thick hardwoods

- 16″ wheels (vs 8″)

- 3-5/8″ cut depth (vs 3-1/8″)

- Better fence system accuracy

My Take: For thick lumber and jobsite mobility, buy SKILSAW. However, for permanent shop use, DeWalt offers better value.

vs. Bosch 4100XC-10 ($599-$649)

Bosch Advantages:

- SquareLock fence (arguably best in class)

- Gravity-rise stand (15-second setup)

- Superior dust collection (80% capture)

- Quieter operation

SKILSAW Advantages:

- Worm drive torque

- Larger cut depth (3-5/8″ vs 3-1/8″)

- 16″ wheels beat Bosch’s 8″ wheels

- 30.5″ rip capacity (vs 25″)

My Take: Bosch offers more refinement. However, SKILSAW delivers more raw power. Therefore, choose based on primary need—finesse or force.

vs. Makita 2705X1 ($599-$679)

Makita Advantages:

- Quieter direct-drive motor

- Lighter weight (easier solo transport)

- No maintenance beyond blade changes

- 25″ rip capacity (adequate for most work)

SKILSAW Advantages:

- Worm drive torque advantage

- 30.5″ vs 25″ rip capacity

- Better rolling stand

- 3-5/8″ vs 3-1/8″ cut depth

My Take: These saws target different users. Makita suits permanent shops. However, SKILSAW excels at demanding jobsite work.

Comparison Table

| Feature | SKILSAW SPT99-11 | DeWalt DWE7491RS | Bosch 4100XC-10 | Makita 2705X1 |

|---|---|---|---|---|

| Price | $599-$699 | $599-$699 | $599-$649 | $599-$679 |

| Drive Type | Worm drive | Direct drive | Direct drive | Direct drive |

| Rip Capacity | 30.5″ | 32.5″ | 25″ | 25″ |

| Cut Depth | 3-5/8″ | 3-1/8″ | 3-1/8″ | 3-1/8″ |

| Weight | 90 lbs | 110 lbs | 100 lbs | 88 lbs |

| Wheel Size | 16″ | 8″ | 8″ | 8″ |

| Maintenance | Oil changes | Minimal | Minimal | Minimal |

| Dust Collection | 70-75% | 65-70% | 80-85% | 70-75% |

| Best For | Thick lumber | Max capacity | Refinement | Shop use |

Pricing & Where to Buy

SKIL 10 Inch Heavy Duty Worm Drive Table Saw with Stand – SPT99-11

- Legendary worm drive gearing with 3-5/8 inch depth of cut and 30-1/2 inch rip capacity

- Precision rack and pinion fence system makes fence adjustments quickly and smoothly for accurate cuts

- Rugged rolling stand with 16 inch Wheels and easy-load handles delivers unsurpassed mobility

New starting from: 749.00

Go to AmazonCurrent Pricing

Amazon: $649-$699

Lowe’s: $699 regular, occasional sales to $599

Acme Tools: $649 with frequent coupon stacking

Home Depot: Not currently stocked

Used Market: $450-$550 (common on marketplace)

Best Deal Strategy:

Amazon price tracking shows drops to $599-$629 quarterly. Additionally, Acme Tools offers 10-15% off coupons that stack with sales.

Essential Upgrades & Accessories

Immediate Upgrades ($80-$150 total)

1. Better Blade ($60-$90)

Replace stock 24-tooth blade:

- Freud D1050X 50-tooth ($67): Best all-around

- Diablo D1040X 40-tooth ($35): Budget ripping specialist

Impact: Cut quality improves from 6.5/10 to 8.5/10

2. Crosscut Sled ($20 materials)

Eliminates miter gauge slop completely

3. Outfeed Roller Stand ($45-$80)

Essential for ripping 8′ boards solo

Frequently Asked Questions

Is worm drive really better than direct drive?

For thick lumber and aggressive ripping, yes absolutely. The worm drive gearbox provides approximately 30% more torque than equivalent direct-drive saws. However, this advantage matters primarily when cutting 4×4 posts, thick hardwoods, or dense pressure-treated lumber. Therefore, if you rarely rip materials over 2″ thick, the torque benefit doesn’t justify the $150-$250 premium and oil change maintenance.

How often do I really need to change the oil?

Every 50 hours of use according to SKILSAW. In my testing, I changed oil after 10 hours (break-in), 60 hours, and 110 hours. Moreover, the third change showed minimal metal particles, suggesting the schedule could extend to 75-100 hours. Nevertheless, I recommend following the 50-hour schedule religiously to prevent expensive gear damage.

Can it replace a cabinet saw for shop use?

For rough milling and breaking down lumber, yes. The torque and 30.5″ capacity rival many cabinet saws. However, cabinet saws offer superior dust collection (85-90%), better vibration dampening, and typically achieve ±0.002″ accuracy versus this saw’s ±0.005-0.008″. Therefore, for fine furniture requiring ultra-precision, cabinet saws remain superior. Nevertheless, for general woodworking and shop furniture, the SKILSAW performs admirably.

Is the 16-inch wheel stand worth the hype?

Absolutely. I’ve used saws with 8″ wheels for years. The 16″ wheels transform stair climbing and rough terrain navigation completely. Moreover, the larger diameter prevents tipping and provides significantly smoother rolling. Additionally, loading into truck beds becomes easier due to better rolling momentum. Therefore, if you move saws between job sites regularly, the 16″ wheels alone justify considering this saw.

How accurate is the fence system?

After calibration, the rack & pinion fence holds ±0.005-0.008″ parallel across the full 30.5″ range. In comparison, this exceeds budget saws (±0.015″) but trails premium systems like Bosch SquareLock (±0.002″). Therefore, it’s accurate enough for professional cabinet work but not ultra-precision furniture. Moreover, the fence shows minimal flex under cutting pressure—approximately 0.005″ when applying significant lateral force.

Does the extra cut depth matter?

The 3-5/8″ depth versus standard 3-1/8″ adds genuine capability. Specifically, you can cut 4×4 posts (actual 3.5″ x 3.5″) in single passes versus two passes on standard saws. Additionally, the extra depth accommodates stacked dado blades up to 13/16″ width. Therefore, for contractors cutting dimensional lumber, the extra depth saves real time daily.

How loud is the worm drive motor compared to direct drive?

Noticeably louder. I measured 94 dB (worm drive) versus 89 dB (direct drive DeWalt) at operator position. Moreover, the gear whine creates a distinctive sound that some find annoying. However, with hearing protection (mandatory), the difference becomes negligible. Therefore, noise shouldn’t influence buying decisions significantly.

Is it worth $200-$300 more than budget saws?

For professionals cutting thick lumber daily, absolutely. The torque advantage, 30.5″ capacity, and superior rolling stand justify the premium completely. However, for hobbyists cutting primarily plywood and dimensional lumber, budget saws deliver 80% of the performance at 50% of the cost. Therefore, assess your cutting needs honestly before investing.

Final Verdict: Should You Buy the SKILSAW SPT99-11?

After 9 months and 700+ cuts through demanding projects, here’s my honest assessment:

Buy this saw if you:

- Rip thick lumber (4×4 posts, 8/4 hardwoods) regularly

- Need maximum jobsite mobility (16″ wheels transform transport)

- Value torque over refinement (worm drive delivers genuine advantage)

- Move between job sites weekly (excellent stand design)

- Can handle oil change maintenance (every 50 hours)

Skip this saw if:

- You work in permanent shops (cabinet/hybrid saws offer better value)

- Budget is under $500 (excellent alternatives exist for $400-$500)

- You rarely cut materials over 2″ thick (torque advantage wasted)

- Maintenance intimidates you (oil changes required)

- Noise concerns matter (noticeably louder than direct-drive)

My rating: 8.9/10. The SKILSAW SPT99-11 delivers on its core promise—worm drive torque transforms ripping performance in thick lumber. Furthermore, the 30.5″ capacity, exceptional rolling stand, and professional build quality create a genuinely superior package. However, the $649 price demands justification through regular use cutting demanding materials.

Nevertheless, after 700+ cuts, this saw has exceeded expectations. Moreover, I’d buy it again without hesitation for jobsite work requiring maximum power. Therefore, for contractors and professionals needing portable power, the SKILSAW SPT99-11 represents one of the best jobsite saws available in the market.

Building a complete shop? Learn how worm drive table saws integrate with miter saws, essential accessories, and setup strategies.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.