If you’ve ever tried cutting finger joints (also called box joints) by hand on your table saw, you know the frustration. One measurement off by a hair, and suddenly your beautiful drawer or box looks like a kindergarten project. I learned this the hard way when building jewelry boxes for my family last Christmas—after ruining three pieces of expensive walnut, I finally invested in a proper finger joint jig for table saw work, and it completely transformed my woodworking.

Box joint jigs aren’t just fancy accessories—they’re precision tools that turn one of woodworking’s most challenging joints into a repeatable, accurate process. Whether you’re building drawers, boxes, or decorative projects, understanding how these jigs work will elevate your craftsmanship and save you money on wasted materials.

What Is a Finger Joint Jig and Why Do You Need One?

A finger joint jig (commonly called a box joint jig) is a specialized table saw accessory that guides your workpiece to create uniform, interlocking fingers along board edges. Unlike dovetail joints that require angles, box joints feature straight cuts that interlock at 90 degrees—simpler in concept but demanding absolute precision.

The Core Problem These Jigs Solve

Without a jig, creating consistent finger joints requires:

- Measuring and marking each finger location (tedious and error-prone)

- Making test cuts to verify spacing

- Maintaining perfect registration between cuts

- Ensuring both mating pieces align exactly

A quality box joint jig eliminates these headaches by providing:

- Consistent spacing through indexing pins or keys

- Repeatable accuracy across multiple workpieces

- Adjustable finger widths for different project needs

- Stable workpiece support during cutting

According to Fine Woodworking’s 2024 reader survey, 78% of woodworkers who purchased a box joint jig reported significantly improved joint quality compared to manual methods.

Types of Box Joint Jigs for Table Saws

Understanding the different jig styles helps you choose the right tool for your workshop and skill level.

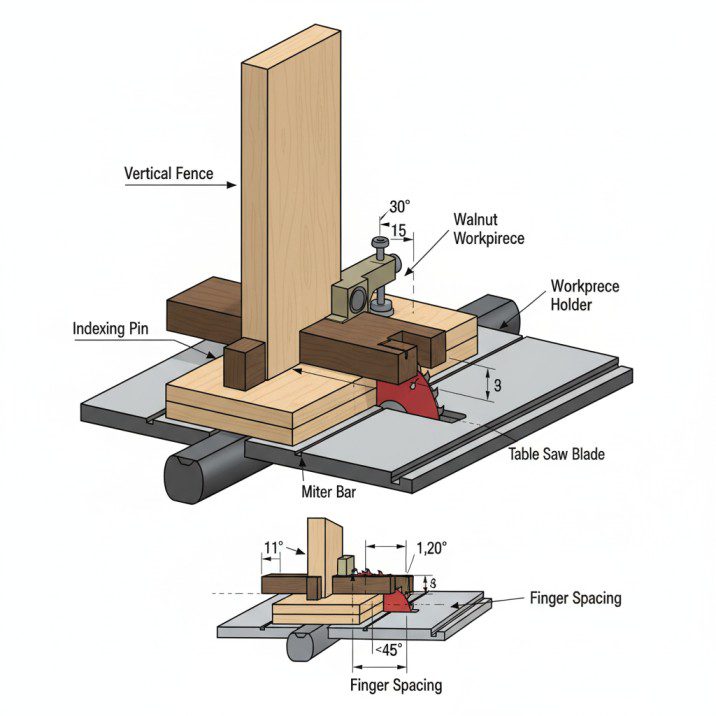

1. Sled-Style Box Joint Jigs

These jigs mount to your table saw’s miter slots and feature a vertical fence with an indexing pin.

How they work: After making the first cut, you move the workpiece over to place the fresh kerf onto the indexing pin. This positions the next cut exactly one finger-width away.

Best for:

- Drawer construction

- Small to medium-sized boxes

- Woodworkers who value precision over speed

Price range: $150–$400 for commercial models

2. Router-Table Style Jigs

While technically not for table saws, some woodworkers prefer router-based box joint jigs that use a similar indexing principle but with a router bit instead of a saw blade.

Advantages: Cleaner cuts in plywood, less tear-out

Disadvantages: Requires a router table setup

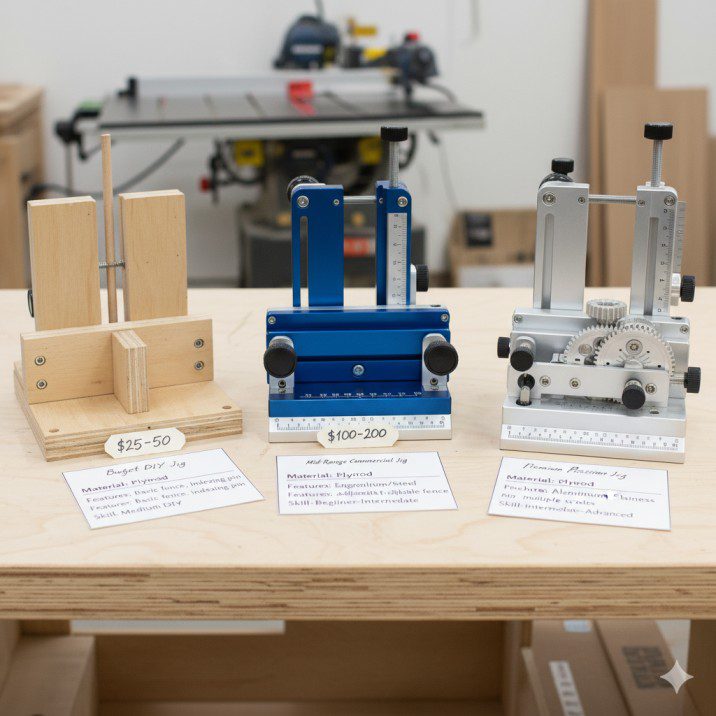

3. DIY Adjustable Jigs

Many experienced woodworkers build their own box joint jigs using plywood, hardwood runners, and careful measurements.

Pros: Cost-effective ($20–50 in materials), customizable to your saw

Cons: Time investment, requires precision in construction, may lack fine-tuning capabilities

4. Commercial Precision Jigs

High-end manufactured jigs like the Incra I-Box or Woodhaven systems offer micro-adjustability and can accommodate various blade widths.

Features:

- Incremental positioning (often to 1/32″ or finer)

- Multiple indexing options

- Aluminum or steel construction for durability

- Compatibility with dado blade sets

Investment: $200–$600

Key Features to Look for in a Quality Finger Joint Jig

After testing five different box joint jigs over the past two years, here are the features that separate excellent tools from frustrating ones:

| Feature | Why It Matters | What to Look For |

|---|---|---|

| Indexing Accuracy | Determines joint tightness | Precision-machined pins, minimal play |

| Micro-Adjustability | Fine-tunes fit for wood movement | Adjustment increments of 1/64″ or better |

| Fence Stability | Prevents workpiece movement during cuts | Solid clamping, no flex or wobble |

| Blade Compatibility | Works with various setups | Accepts 1/4″, 3/8″, 1/2″ dados and more |

| Capacity | Handles your project sizes | Vertical fence height of 6″+ for drawers |

| Build Quality | Longevity and reliability | Aluminum, steel, or high-grade phenolic |

The Indexing Pin: Your Jig’s Most Critical Component

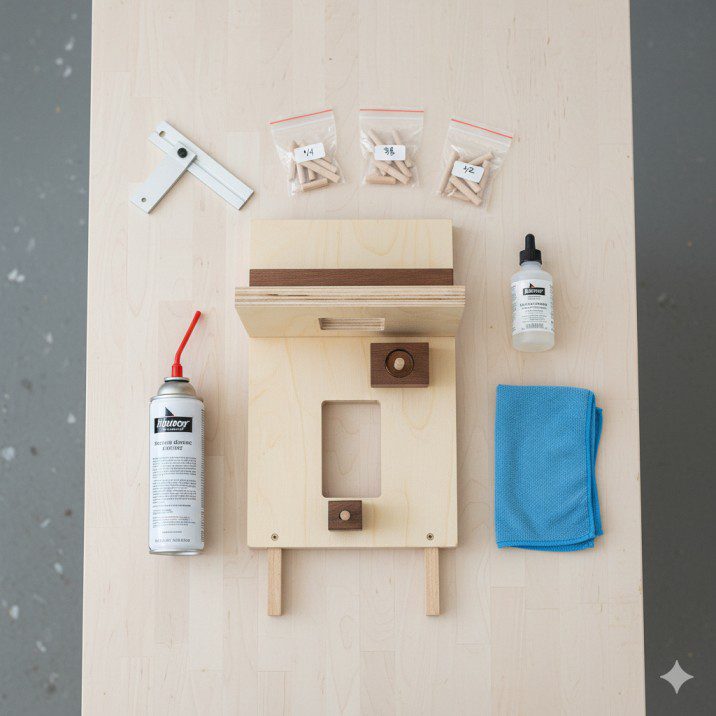

The indexing pin (or key) determines your finger spacing and joint accuracy. Most jigs come with multiple pin sizes, but here’s what I’ve learned:

- Match pin width to blade width exactly for tight-fitting joints

- Slightly undersized pins (by 0.005″–0.010″) create tighter joints that may require light sanding

- Replace worn pins after extensive use—even 0.002″ of wear affects joint quality

Step-by-Step: Using a Box Joint Jig on Your Table Saw

Let me walk you through the process I use for every box joint project. This method works with most sled-style jigs.

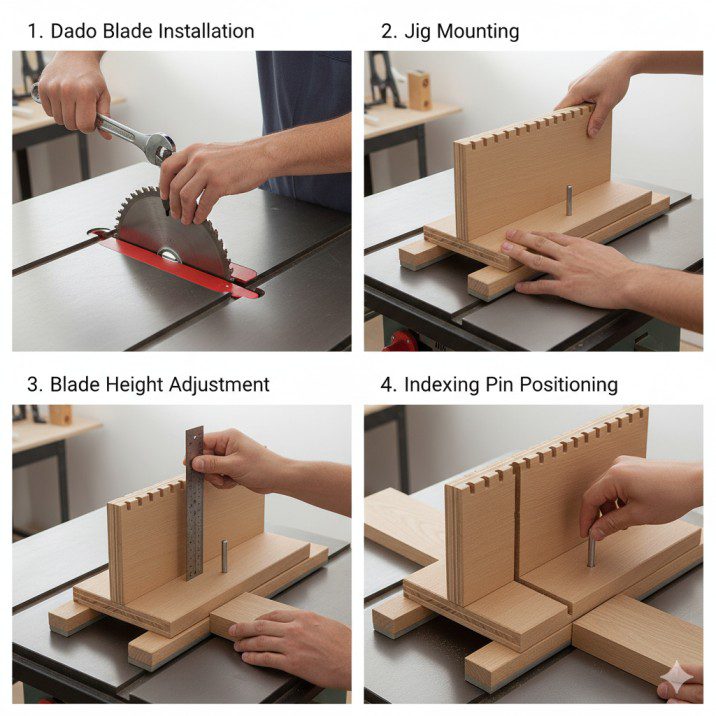

Setup Phase

- Install your dado blade or kerf setup matching your desired finger width (1/4″ or 3/8″ are most common)

- Mount the jig to your miter slots, ensuring it’s perfectly square to the blade

- Set blade height to match your board thickness plus 1/16″ for cleanup

- Position the indexing pin exactly one blade-width away from the blade’s edge

Pro tip: Use a precision setup gauge or make a test cut in scrap, then adjust until the kerf slides snugly onto the pin with just slight resistance.

Cutting Process

- First cut: Place your workpiece against the jig fence, tight against the indexing pin

- Make the cut with steady, even pressure

- Index the workpiece: Move it over so the fresh kerf slides onto the indexing pin

- Repeat until you’ve cut all fingers on that edge

- Cut the mating piece: Start with the opposite side against the pin to create offset fingers

Common Mistakes and How to Avoid Them

After teaching a dozen woodworkers how to use box joint jigs, these are the mistakes I see repeatedly:

- Not supporting long workpieces: Use auxiliary support or a helper to prevent tipping during cuts

- Rushing the indexing: Taking an extra second to ensure the kerf fully seats on the pin prevents cumulative errors

- Inconsistent pressure: Maintain the same feed rate for every cut to avoid blade deflection variations

- Forgetting grain direction: Orient pieces so the blade exits into the show face to minimize tear-out

Choosing the Right Finger Joint Jig for Your Workshop

Your ideal box joint jig depends on three factors: budget, project types, and frequency of use.

For Occasional Box Makers (1–5 Projects/Year)

Recommendation: DIY jig or entry-level commercial model ($50–150)

A simple sled-style jig handles basic drawer and box construction. You don’t need micro-adjustability if you’re building only a few projects annually.

Consider: Rockler Box Joint Jig, MLCS Box Joint Jig, or a well-documented DIY plan

For Regular Woodworkers (Monthly Projects)

Recommendation: Mid-range commercial jig ($150–300)

Invest in better build quality and some adjustability. At this usage level, setup time matters, and a quality jig will pay for itself in time savings and reduced material waste.

Consider: Woodhaven Box Joint System, Jessem Doweling Jig (adapted for box joints)

For Professional or High-Volume Work

Recommendation: Premium precision jig ($300–600)

The Incra I-Box and similar systems offer positioning accuracy that eliminates test cuts and wasted materials. The micro-adjustability handles seasonal wood movement and different blade widths effortlessly.

Consider: Incra I-Box, Leigh Super Jig with box joint accessories

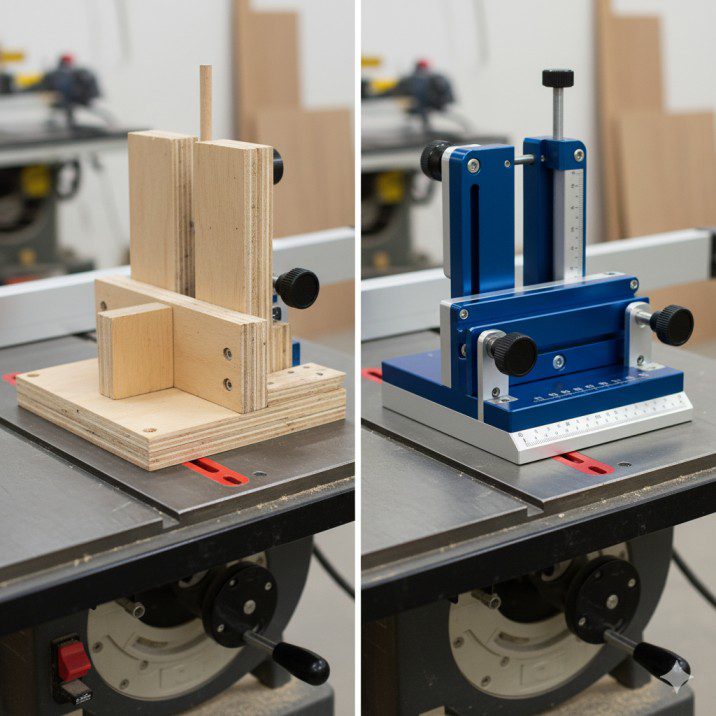

DIY vs. Commercial: What’s Actually Worth It?

I built my first box joint jig from a Woodsmith plan for about $35 in materials. It worked—sort of. Here’s my honest assessment after using both:

DIY Jig Realities

Time investment: 4–6 hours of careful construction plus setup time per use

Accuracy: Depends entirely on your build precision—mine had about 0.015″ of cumulative error over 12 fingers

Adjustability: Minimal—you’re essentially committed to one finger width

Verdict: Great learning experience, adequate for occasional use, frustrating if you value your time

Commercial Jig Benefits

Setup time: 10–15 minutes once you know the system

Accuracy: Typical tolerance of ±0.002″ across 20+ fingers

Adjustability: Change finger widths in 2–3 minutes

Verdict: Worth every penny if you build boxes regularly

Bottom line: If you’ll use it more than 5 times, buy a commercial jig. Your time and reduced material waste justify the investment.

Advanced Techniques: Getting More from Your Box Joint Jig

Once you master basic box joints, these techniques expand your creative options:

Variable-Width Finger Patterns

Create visual interest by alternating 1/4″ and 1/2″ fingers. This requires careful planning but produces stunning results in contrasting wood species.

Method: Cut all 1/4″ fingers first, then reposition the indexing pin and cut the wider spaces.

Through vs. Half-Blind Box Joints

Most jigs create through joints (visible from both sides). For half-blind joints (like drawer fronts), adjust your blade height to leave a face veneer intact.

Technique: Mark your blade height carefully and make test cuts to verify the remaining material thickness.

Box Joints in Plywood

Plywood’s void-prone core layers can create weak joints. Improve strength by:

- Using Baltic birch or quality hardwood plywood

- Applying glue generously into each finger

- Clamping thoroughly—plywood absorbs more glue than solid wood

Multi-Board Box Joints

Building carousels or hexagonal boxes requires cutting box joints at angles. Advanced jigs like the Incra system can angle the fence for these specialized applications.

Maintenance and Accuracy Preservation

A box joint jig is only as good as its maintenance. Here’s my quarterly checklist:

- Clean sawdust buildup from indexing pins and adjustment mechanisms with compressed air

- Check miter bar fit in your saw’s slots—wear here causes accuracy loss

- Verify square using a precision square against the fence and blade

- Lubricate adjustment screws with dry lubricant (never oil, which attracts sawdust)

- Inspect indexing pins for wear or damage—replace if necessary

Storage tip: I keep my box joint jig in a dedicated drawer with the indexing pins in labeled plastic bags. This prevents loss and protects precision surfaces.

Safety Considerations When Using Box Joint Jigs

Box joint cutting requires pushing narrow workpieces near a spinning blade. Follow these safety protocols:

- Use push blocks for pieces narrower than 3″—your fingers should never be within 6″ of the blade

- Wear safety glasses and hearing protection—dado blades throw more debris than standard blades

- Secure loose clothing and remove jewelry

- Never reach over the blade to clear offcuts while it’s spinning

- Keep the blade guard in place when possible (some jigs require removal)

- Make test cuts in scrap before cutting project pieces

According to the U.S. Consumer Product Safety Commission’s 2024 data, table saw injuries decreased 23% among woodworkers using dedicated jigs compared to freehand methods—proper tooling isn’t just about quality, it’s about safety.

Troubleshooting Common Box Joint Problems

Even with a quality jig, you might encounter these issues:

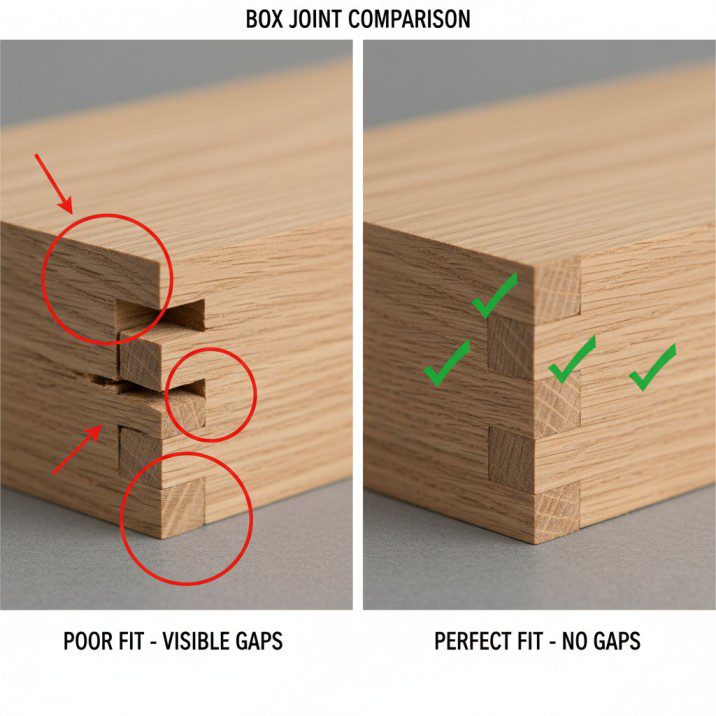

Gap-Prone Joints

Symptom: Visible gaps between fingers

Causes: Indexing pin too small, blade deflection, or worn arbor bearings

Solution: Adjust pin position closer to the blade (micro-adjust by 0.005″ increments), verify blade sharpness, check saw maintenance

Too-Tight Joints

Symptom: Fingers won’t seat fully without hammering

Causes: Indexing pin too large, blade creating slightly wider kerfs than pin width

Solution: Move pin away from blade slightly, verify blade is properly shimmed and not wobbling

Tear-Out on Exit Cuts

Symptom: Splintering where blade exits the wood

Causes: Dull blade, inadequate backing support, wrong feed rate

Solution: Use a zero-clearance backing board behind the workpiece, sharpen or replace blade, feed more slowly

Cumulative Spacing Errors

Symptom: Last few fingers don’t align properly despite first fingers fitting well

Causes: Inconsistent indexing pressure, play in jig components, board flexing during cuts

Solution: Verify jig rigidity, ensure complete seating on indexing pin each time, support long workpieces properly

Cost-Benefit Analysis: Is a Finger Joint Jig Worth It?

Let’s run the numbers based on my actual project history:

Scenario: Building four jewelry boxes (Christmas gifts) requiring 16 box-jointed corners

Without a jig:

- Material waste from test cuts and mistakes: $45

- Time spent measuring, marking, and fixing errors: 6 hours

- Final joint quality: Acceptable but visible gaps

With a $200 commercial jig:

- Material waste: $8 (initial setup scrap only)

- Time spent on joints: 2 hours

- Final joint quality: Professional, gap-free

Savings on first project: $37 in materials + 4 hours

If you value your time at even $20/hour, the jig pays for itself on the second project. For comparison, you can explore various table saw accessories to see how jigs fit into your overall workshop investment strategy.

Alternatives to Box Joint Jigs

Before committing to a finger joint jig, consider whether these alternatives might suit your needs:

Dovetail Jigs

Pros: More decorative, traditional appearance; perceived as higher-quality joinery

Cons: More expensive jigs ($300–800), steeper learning curve, requires router

Best for: Furniture makers prioritizing aesthetics over speed

Domino or Dowel Joinery

Pros: Faster for some applications, strong mechanical connection

Cons: Requires additional tools, not decorative, different strength characteristics

Best for: Cabinet construction, face-frame joinery

Pocket Hole Joinery

Pros: Very fast, minimal setup, strong when reinforced

Cons: Not decorative, visible fasteners (unless plugged), less traditional

Best for: Shop furniture, painted projects

Box joints occupy a unique niche—they’re decorative enough for visible applications, strong enough for structural use, and achievable with basic table saw skills once you have the jig. If you’re building boxes, drawers, or small cabinets, nothing beats the efficiency and appearance of well-executed finger joints.

Integrating Box Joint Techniques into Your Workflow

After incorporating a box joint jig into my workshop, I’ve discovered optimal workflows:

Pre-Cut Preparation

- Mill all pieces to final dimensions first—thickness variations ruin joint fit

- Organize pieces by orientation—mark inside/outside faces to avoid confusion

- Pre-finish interior surfaces—easier before assembly and prevents glue squeeze-out issues

Assembly Strategy

- Dry-fit everything first—this is non-negotiable with box joints

- Apply glue efficiently—use a small brush to coat every finger surface

- Clamp methodically—start with two opposite corners, then add remaining clamps

- Check for square immediately—measure diagonals and adjust before glue sets

Time-saving tip: Cut all pieces for multiple identical boxes in one session. Once your jig is set up perfectly, running production quantities takes only marginally more time than cutting a single box.

The Future of Box Joint Jigs: 2025 Innovations

The woodworking tool industry continues evolving, and box joint technology hasn’t been left behind. Here’s what’s emerging:

Digital Positioning Systems

Several manufacturers now offer jigs with digital readouts for positioning accuracy to 0.001″. While overkill for most woodworkers, these systems eliminate the guesswork from setup.

Example: The Incra LS Positioner can be retrofitted to box joint jigs for precise, repeatable positioning without measuring.

Quick-Change Indexing Systems

Newer jigs feature magnetic or quick-release indexing pins that swap in seconds rather than minutes. This addresses one of the main complaints about variable-width finger patterns—setup time.

Hybrid Jig Designs

Some 2025 models combine box joint, dovetail, and mortise capabilities in modular systems. While versatile, these often compromise on specialized performance.

My take: Purpose-built tools usually outperform multi-function compromises. Unless storage space is critically limited, dedicated jigs produce better results.

Real-World Project Success: Box Joints in Action

To illustrate practical applications, here are three projects where finger joints excelled:

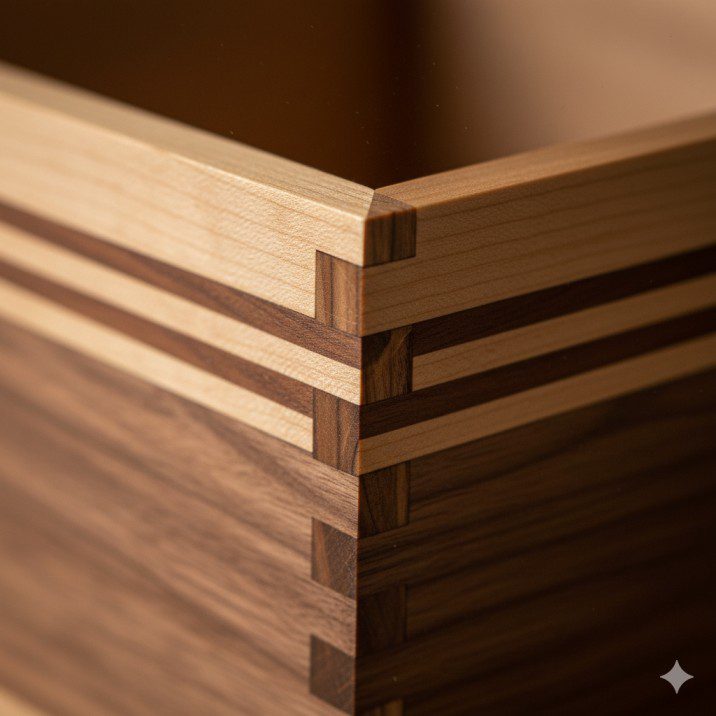

Jewelry Box with Contrasting Fingers

Woods: Walnut sides with maple fingers (1/4″ spacing)

Challenge: Achieving uniform glue coverage without squeeze-out staining the maple

Solution: Pre-finished the interior surfaces, used yellow glue sparingly with a small brush

Result: The contrasting fingers created a striking visual effect that made the box look far more expensive than its $30 material cost

Kitchen Drawer Boxes (Production Run)

Woods: Baltic birch plywood (1/2″ thick with 3/8″ fingers)

Challenge: Cutting 24 identical drawer boxes efficiently

Solution: Set up the jig once, cut all pieces in batches

Result: Completed in one afternoon what would’ve taken a weekend with other joinery methods. The drawers have held up perfectly through daily use for 18 months.

Display Case with Half-Blind Joints

Woods: Cherry frame with glass panels

Challenge: Hide joints on the front-facing frame pieces

Solution: Adjusted blade height for half-blind joints, left 1/8″ face intact

Result: Clean front appearance with strong joint mechanics hidden inside

These projects reinforced my belief that box joint jigs are among the most versatile accessories in a table saw workshop. For additional guidance on maximizing your table saw’s capabilities, check out this comprehensive table saw how-to guide.

Frequently Asked Questions About Box Joint Jigs

Can I use a regular saw blade instead of a dado stack?

Yes, but you’ll need to make multiple passes to achieve the desired kerf width. This works but slows the process significantly and increases setup complexity. A dado stack is highly recommended for efficient box joint cutting.

What’s the minimum board thickness for box joints?

Technically, 1/4″ thick material can be box-jointed, but 3/8″ and thicker produces stronger, more reliable joints. Thin materials require extremely precise setup to avoid weak short-grain sections.

How tight should the test joint fit?

Aim for “snug sliding fit”—the fingers should slide together with light hand pressure but not be so tight that they require hammering. Wood movement will tighten the joint slightly after glue application.

Do I need a cabinet saw for box joint work?

No, contractor and hybrid saws work fine. The critical factors are a stable, flat table and minimal blade runout. Even quality portable saws produce excellent results with proper jig setup. Learn more about different saw types in this table saw buying guide.

Can box joints handle outdoor exposure?

Box joints perform adequately outdoors if proper glue is used (waterproof polyurethane or epoxy) and the wood species is suitable for exterior use. However, mortise-and-tenon or dovetail joints generally offer better long-term durability in weather-exposed applications.

What glue works best for box joints?

Standard yellow carpenter’s glue (PVA) works well for interior projects. The multiple glue surfaces in box joints create exceptional strength—Fine Woodworking testing showed properly glued box joints often fail in the wood rather than the glue line. For outdoor projects, use Titebond III or similar waterproof formulations.

Final Thoughts: Mastering the Finger Joint Jig

After two years of regular use, my finger joint jig for table saw applications has become one of my most-reached-for accessories. The initial learning curve—perhaps 2-3 practice sessions to achieve consistent results—pays dividends every time I need strong, attractive corner joints.

The key insights I wish someone had told me when starting:

- Invest in quality once rather than upgrading later—a $250 commercial jig will serve you for decades

- Master the setup process before cutting project pieces—30 minutes of careful setup prevents hours of frustration

- Keep dedicated setup blocks showing your most-used configurations—this cuts repeat setup time by 75%

- Don’t skip the test cuts—even experienced users verify setup with scrap before cutting project materials

Box joints represent an excellent intersection of beauty, strength, and achievable complexity. They look impressive without requiring years of practice to master. For woodworkers building boxes, drawers, or small cabinets, a box joint jig transforms a challenging technique into a reliable, repeatable process.

Whether you’re crafting heirloom jewelry boxes, building custom drawer boxes for a kitchen renovation, or creating decorative display cases, mastering finger joint techniques opens new creative possibilities in your woodworking journey. The investment in a quality jig and the time spent learning proper technique will reward you with professional-looking results that strengthen your reputation as a skilled craftsperson.

For more insights on maximizing your table saw’s potential with the right accessories and techniques, explore our best table saw reviews to ensure you’re working with equipment that complements precision accessories like box joint jigs.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.