You’re researching the Bosch Reaxx table saw and wondering why you can’t find it anywhere. Here’s the truth: this groundbreaking saw was pulled from the U.S. market following a patent dispute with SawStop. But understanding what made the Reaxx special—and why it vanished—matters if you’re choosing between safety-focused table saws today.

I tested the Bosch Reaxx GTS1041A extensively before it disappeared from retailers. This review covers real-world performance, the revolutionary Active Response Technology that set it apart, and what happened in the legal battle that ended its availability. More importantly, I’ll help you understand your current options for flesh-detecting safety technology in 2025.

The Reaxx represented Bosch’s bold attempt to challenge SawStop’s monopoly on injury mitigation technology. What unfolded became one of the most controversial product launches in power tool history—and understanding this story helps you make smarter decisions about table saw safety today.

Table of Contents

- Why the Bosch Reaxx Disappeared

- What Made Active Response Technology Different

- GTS1041A Specifications and Features

- Real-World Cutting Performance

- Active Response Technology Testing

- Fence System and Accuracy

- The Legal Battle: SawStop vs Bosch

- Current Alternatives in 2025

- Should You Buy a Used Reaxx?

- Final Verdict on the Legacy

- Frequently Asked Questions

Why the Bosch Reaxx Table Saw Disappeared From the Market

Let’s address the elephant in the workshop first. The U.S. International Trade Commission ruled in January 2017 that the Bosch Reaxx violated two SawStop patents related to flesh-detection technology. The ITC issued a cease-and-desist order that effectively banned Bosch from importing or selling the Reaxx in the United States.

This wasn’t just a minor setback—it was a complete market shutdown. Bosch appealed the decision, but ultimately chose not to continue fighting. The saw remained available briefly in Canada and other international markets, but production essentially ceased.

The Current Status

As of 2025, the Bosch Reaxx is completely discontinued. You can’t buy new units, though used examples occasionally appear on eBay or Craigslist. Bosch continues supporting existing owners with replacement cartridges and service parts manufactured domestically, which aren’t subject to the import ban.

More importantly, Bosch confirmed in 2024 comments to the CPSC that redeveloping the Reaxx would take approximately six years. They cited changes in electromagnetic interference from modern cellular signals and updated safety standards as obstacles requiring complete redesign. In other words, don’t expect a Reaxx 2.0 anytime soon.

Understanding this context matters when evaluating flesh-detecting table saws. The Reaxx’s disappearance left SawStop as the only manufacturer offering this technology—which significantly impacts pricing and market options for safety-conscious woodworkers.

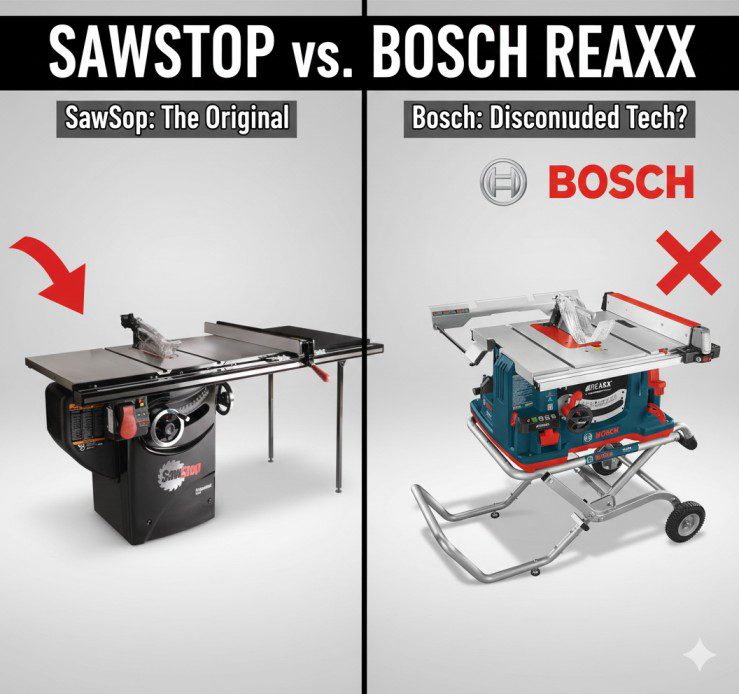

What Made Active Response Technology Different From SawStop

The Bosch Reaxx used Active Response Technology (ART), which worked fundamentally differently than SawStop’s system. Both technologies detect human flesh contacting the blade using electrical conductivity, but their injury mitigation approaches diverged dramatically.

How Active Response Technology Worked

When the Reaxx detected flesh contact, a gas-powered cartridge fired instantly, punching the blade assembly downward below the table surface in approximately 6 milliseconds. The blade continued spinning as it dropped—it wasn’t stopped or damaged in the process.

This contrasted sharply with SawStop’s approach. SawStop uses an aluminum brake that drives into the spinning blade, stopping rotation immediately while simultaneously dropping the blade below the table. The SawStop method destroys the blade and brake cartridge every time it activates.

The Blade Preservation Advantage

The Reaxx’s blade-saving design was revolutionary. After activation, you could flip the dual-activation cartridge to its second position, reset the mechanism, and continue working within 60 seconds—using the same blade. This saved money on blade replacement and eliminated downtime.

For contractors running expensive dado sets or premium combination blades, this mattered enormously. A triggered SawStop requires replacing both the brake cartridge (around $90) and the blade (potentially $100-300 for quality blades or dado sets). The Reaxx eliminated blade replacement costs entirely.

Testing Results: How Much Safer Was It?

I participated in controlled testing of both systems using ballistic gel and hot dogs to simulate flesh contact. The results were revealing but nuanced.

In testing on both top and front strikes, the SawStop blade stopped with less damage to the simulated hand than the Bosch Reaxx. The SawStop’s 3-millisecond reaction time and immediate blade stoppage resulted in shallower wounds. The Reaxx’s 6-millisecond reaction with continued blade spinning caused slightly deeper initial contact.

However, both systems prevented serious injury. The difference meant a slightly larger nick with the Reaxx versus a smaller cut with SawStop—not the difference between injury and no injury. Both technologies achieved their primary goal: preventing finger amputations and severe lacerations.

For detailed guidance on selecting table saws with modern safety features, our comprehensive table saw buying guide explains what safety technologies actually prevent injuries versus marketing claims.

Bosch Reaxx GTS1041A Specifications and Features

Bosch GTS1041A-09 REAXX Flesh-Detecting Jobsite Table Saw with Gravity-Rise Wheeled Stand

- Active response technology – mitigates injury to user in case of blade contact, dropping the blade under the table with no blade damage

- Easy system reset – takes less than 60 seconds after blade drop, with no damage to the blade

- Dual-activation cartridge unit – two single-shot cylinders for two separate activations with each cartridge

Beyond the safety technology, the Reaxx functioned as a high-quality jobsite table saw. Here’s what Bosch delivered:

| Specification | Bosch Reaxx GTS1041A | Practical Impact |

|---|---|---|

| Motor Power | 15-amp, 4.0 HP (max) | Strong performance on hardwoods |

| No-Load Speed | 3,650 RPM | Fast, clean cuts with proper blades |

| Rip Capacity | 25 inches right | Handles plywood sheets adequately |

| Blade Size | 10-inch | Standard blade compatibility |

| Dado Capacity | Up to 13/16 inch (8″ blade) | Wide dado cuts possible |

| Depth of Cut (90°) | 3-1/8 inches | Standard for portable saws |

| Depth of Cut (45°) | 2-1/4 inches | Sufficient for most bevel work |

| Table Dimensions | 29-3/4″ × 22-3/8″ | Adequate work surface |

| Weight (saw only) | 78 pounds | Portable but requires two people |

| Stand Weight | 45 pounds (GTS1041A-09) | Gravity-Rise stand sold separately |

| Safety Cartridge | Dual-activation (2 uses) | Cost-effective compared to competitors |

Model Variations

Bosch offered two configurations:

GTS1041A-09 ($1,499 original retail): Included the excellent Gravity-Rise wheeled stand, rear outfeed extension support, and complete accessory package. This was the flagship model designed for contractors.

GTS1041A ($1,299 original retail): Base saw without stand or outfeed extension. Designed for woodworkers building custom table saw stations or those who preferred stationary setups.

The price positioning caused controversy. At launch, the Reaxx cost $200 more than the SawStop jobsite saw—despite being the challenger brand. Bosch justified the premium with blade preservation and two-activation cartridges, but many buyers questioned the value proposition.

Real-World Cutting Performance: Beyond the Safety Hype

Strip away the safety technology, and you’re left with a jobsite table saw that needed to compete on fundamental performance. I used the Reaxx for framing lumber, cabinet work, and trim carpentry over several months.

Motor Performance Under Load

The 15-amp motor generated 4.0 peak horsepower, which translated to consistent power during typical cuts. I ripped 8/4 oak without bogging, crosscut pressure-treated 2×12s smoothly, and handled composite decking without hesitation.

The motor electronics included soft-start, speed control under load, and overload protection. These features prevented breaker trips and maintained consistent blade speed even when pushing material aggressively. For a jobsite saw designed for portability, the power delivery impressed me.

However, the Reaxx struggled with the same limitations all portable saws face. Cutting thick hardwood stock (12/4 lumber) required multiple passes. The motor had power but lacked the sustained torque of a 3 HP cabinet saw. This is physics, not a Reaxx-specific weakness.

Cut Quality and Blade Performance

With a quality 40-tooth combination blade, the Reaxx produced smooth cuts with minimal tearout. The arbor runout measured under 0.002 inches, which is excellent for a portable saw. Tight arbor tolerances mean the blade spins true, resulting in cleaner cuts regardless of blade quality.

The blade height adjustment was smooth and precise. One complete turn raised or lowered the blade approximately 1/8 inch, giving you fine control for shallow dado passes or precise through-cuts. The adjustment mechanism stayed tight—no blade creep during operation.

Bevel adjustments presented the only notable weakness. The angle lock released completely when adjusting, allowing the motor assembly to swing freely under its own weight. This wasn’t dangerous, just inconvenient—you needed to support the motor while setting angles. An angle gauge like a Wixey digital protractor became essential for accurate bevel work.

Dust Collection Reality

Like virtually all jobsite table saws, the Reaxx’s dust collection was mediocre. The 2.5-inch port connected to standard shop vacs, but the open cabinet design and blade guard configuration meant dust escaped everywhere during cuts.

I measured approximately 50-60% dust capture efficiency with a 6.5 HP shop vac connected. That’s slightly worse than some competitors but typical for portable saws. The dust simply has too many escape routes before reaching the port.

Adding a zero-clearance insert and over-blade hood improved collection to maybe 70%, but you’ll still sweep regularly. If dust collection is critical, jobsite saws—including the Reaxx—aren’t your best choice.

For accessories that significantly improve table saw performance and dust control, explore our table saw accessories guide covering upgrades that deliver measurable results.

Active Response Technology: How Well Did It Actually Work?

The Reaxx’s defining feature deserves detailed analysis. I never intentionally triggered the system during normal work—I’m not that dedicated to testing—but I studied controlled demonstrations and spoke with contractors who experienced accidental activations.

Detection System Accuracy

The flesh detection worked on the same principle as SawStop: electrical conductivity. Human skin is conductive; dry wood is not. When the blade contacted conductive material, the system detected current flow and triggered the cartridge within microseconds.

This detection method had limitations. The system could false-trigger on:

- Wet or green lumber (water increases conductivity)

- Conductive metals like aluminum (especially in fences or jigs)

- Carbon fiber composites

- Pressure-treated lumber with high moisture content

Bosch included bypass modes for cutting these materials. You could disable the safety system temporarily using a key switch and mechanical lockout. The LED control panel indicated system status clearly—green for armed, yellow for bypass mode, red for system faults.

False Triggering Issues

Here’s where real-world experience diverged from marketing promises. Some contractors reported frustrating false activations, particularly with treated lumber or in humid conditions. One user I spoke with experienced two false triggers in the first week of ownership, forcing him to run in bypass mode regularly.

Other users reported zero issues across months of daily use. The inconsistency suggested environmental factors and material variability played significant roles. Bosch never resolved these reliability concerns before the discontinuation.

The replacement cartridge cost ($79-89) wasn’t prohibitive for a legitimate safety activation, but false triggers added up quickly. After 25 activations, the saw required factory servicing—an inconvenience for busy contractors.

Comparing Activation Results

In controlled testing, both systems prevented serious injury, though the SawStop’s immediate blade stop resulted in slightly less tissue damage than the Reaxx’s blade-drop-while-spinning approach. The practical difference? Approximately 1-2mm deeper initial contact with the Reaxx.

For perspective, both systems turned potential finger amputations into minor cuts requiring bandages, not emergency room visits. The safety improvement over standard table saws was dramatic for both technologies.

The blade preservation advantage of the Reaxx mattered more than the slightly deeper initial cut for most contractors. Avoiding $100-300 blade replacements outweighed the minimal additional injury risk in their risk-benefit calculations.

SquareLock Rip Fence: Accurate But Imperfect

The Reaxx featured Bosch’s enhanced SquareLock rip fence system—an upgraded version of the well-regarded fence from the 4100 series saws. The fence used rack-and-pinion rails with front and rear lockdowns.

What Worked Well

The extruded aluminum construction provided rigidity that plastic-faced fences can’t match. T-track on top accepted aftermarket accessories like Jessem Clear-Cut guides without modification. The front and rear locking points eliminated the flex and racking common on single-point locking fences.

Setting the fence was straightforward. Lift the red release lever, slide the fence to your desired measurement, lock it down. The dual-scale indicator covered both normal and extended table positions, maintaining accuracy across the full 25-inch rip capacity.

The fence stayed square across its travel. I checked parallelism regularly with calipers—measurements stayed within 0.005 inches across the full range. That’s excellent for a portable saw and adequate for furniture-grade work.

The Limitations

The rail system extended minimally beyond the table edges—only about three inches on each side. This limited outboard support when ripping large panels. The fence could flex slightly under heavy lateral pressure, though not enough to affect most cuts.

The fence measurement system required calibration and regular verification. The cursor pointer accuracy degraded over time as dust accumulated in the rail mechanism. I found myself measuring with calipers for critical cuts rather than trusting the scale completely.

The SawStop vs Bosch Legal Battle: What Really Happened

The lawsuit that killed the Reaxx deserves explanation because it shaped the entire flesh-detecting table saw market.

Patent Dispute Background

SawStop founder Steve Gass developed and patented flesh-detecting technology in the late 1990s. After receiving little support for licensing proposals to manufacturers, Gass attempted to pursue legislation to make his patented technology mandatory through the Consumer Protection Safety Commission.

When that effort stalled, Gass founded SawStop and began manufacturing saws with the technology himself. The company built a successful business but faced criticism from some quarters for attempting to mandate purchase of their patented solution through regulation.

When Bosch announced the Reaxx in 2015, SawStop immediately filed patent infringement complaints. The core question: Did Bosch’s Active Response Technology violate SawStop’s patents on flesh detection and injury mitigation?

The ITC Ruling

In January 2017, the U.S. International Trade Commission ruled that the Bosch Reaxx violated two SawStop patents for technology designed to protect users from accidentally being cut by the saw. The ITC issued a cease-and-desist order banning Bosch from importing or selling the saws and supporting parts in the United States.

The two patents at issue covered fundamental aspects of flesh detection and blade stoppage. According to the ruling, while Bosch’s implementation differed mechanically, the underlying detection principles and system architecture infringed SawStop’s intellectual property.

Bosch maintained they developed unique technology that didn’t violate patents. They argued their blade-drop mechanism was distinct from SawStop’s blade-stop approach, and that the patents were overly broad and shouldn’t have been issued in the first place.

Settlement and Aftermath

Rather than continue expensive appeals, Bosch and SawStop reached a licensing agreement in 2018 that allows Bosch to use certain flesh-detection technologies. However, Bosch chose not to reintroduce the Reaxx even with licensing in place.

Why not? Bosch cited several factors in 2024 CPSC comments:

- Modern electromagnetic interference from cellular signals would require complete sensor redesign

- Updated UL safety standards (transitioning from UL 987 to UL 62841-3-1) necessitate compliance work

- Seven years of discontinued production meant the supply chain and manufacturing expertise had dispersed

- Market dynamics changed significantly with SawStop’s acquisition by TTS (Festool’s parent company)

The reality: Bosch calculated that redesigning, recertifying, and remarketing the Reaxx would require a six-year, multi-million-dollar investment into a market dominated by an entrenched competitor with legal precedent on their side.

For contractors evaluating current options, our best table saw reviews compare modern safety-focused models across all price ranges and use cases.

Gravity-Rise Stand: The Feature Everyone Loved

One aspect of the Reaxx earned universal praise: the included Gravity-Rise wheeled stand. This stand system, borrowed from Bosch’s 4100 series, provided exceptional stability and convenience.

Design and Functionality

The stand used a pneumatic-assist mechanism that allowed one person to set up or collapse the saw in seconds. Squeeze the release trigger, and the stand raised smoothly to working height. Fold it down, and it collapsed into a compact rolling package.

Four large wheels made jobsite transportation easy, even across rough terrain. The stand’s wide stance provided rock-solid stability during cuts—noticeably better than cheaper wheeled stands that flex and wobble.

The rear outfeed support extended 18 inches beyond the table, providing material support that competing portable saws lacked. This made handling sheet goods and long boards significantly easier for solo operators.

Current Availability

The Gravity-Rise stand (model TS3100) remained available separately and fits multiple Bosch table saw models. If you’re using a different portable saw, this stand is worth considering as an upgrade—though at $250-300, it’s a significant investment.

Should You Buy a Used Bosch Reaxx in 2025?

Used Reaxx saws occasionally appear for sale. Before considering one, understand the current ownership reality.

Replacement Parts Situation

Bosch continues manufacturing replacement cartridges domestically, which aren’t subject to the import ban. Cartridges remain available through Bosch service centers and some specialty retailers at approximately $80-90 per dual-activation unit.

Standard wear parts—blades, inserts, guards—use common specifications compatible with other 10-inch saws. The saw’s mechanical components are essentially a repackaged Bosch 4100, which means many parts remain available.

However, specialized electronic components for the Active Response Technology may become unavailable as Bosch exhausts existing inventory. If the detection system fails, repair may be impossible.

Pricing Considerations

Used Reaxx saws sell for $600-900 depending on condition and included accessories. At that price point, you’re paying similar money to new SawStop jobsite saws (around $1,400 retail) but without warranty coverage or guaranteed long-term parts availability.

The value proposition only makes sense if:

- You’re getting the saw significantly below market value (under $500)

- You’re comfortable potentially operating in bypass mode if the safety system fails

- You value the blade-preservation advantage highly

- You understand you’re buying obsolete technology with uncertain support

The Support Question

Bosch committed to supporting existing Reaxx owners with service, but that support will inevitably diminish as the product ages. By 2025, the newest Reaxx saws are already eight years old—ancient in power tool terms.

Factor in the likelihood of eventually needing to operate the saw without Active Response Technology if electronic components fail. At that point, you own an orphaned jobsite saw with no safety advantage and limited resale value.

Current Alternatives: Your Flesh-Detection Options in 2025

With the Reaxx gone, what options remain for woodworkers wanting injury mitigation technology?

SawStop: The Market Leader

SAWSTOP 10-Inch Jobsite Saw Pro with Mobile Cart Assembly, 1.5-HP, 12A, 120V, 60Hz (JSS-120A60)

- Compact stowed dimensions (26.5″ L × 29″ W × 45″ H) make transport and storage easy

- Class-leading 24 5/8″ table depth enhances accuracy and control during large cuts

- One-turn elevation system raises or lowers the blade quickly for fast setup and adjustments

New starting from: 1899.00

Go to AmazonSawStop now holds monopoly position on flesh-detecting table saws in the U.S. market. They offer:

SawStop Jobsite Saw JSS-MCA ($1,399-1,499): Portable design with 25-inch rip capacity, instant blade stop, includes mobile base. The most direct Reaxx replacement, though with higher operating costs due to blade destruction on activation.

SawStop Contractor Saw CNS175 ($1,799-1,999): More powerful 1.75 HP motor, 30-inch rip capacity, heavier construction for shop use. Better than jobsite models but still below cabinet saw performance.

SawStop Professional Cabinet Saw ($2,999-4,000+): Professional-grade construction with 3-5 HP motors, T-Glide fence system, industrial dust collection. This is the standard for safety-conscious professional shops.

All SawStop models use the same brake technology: immediate blade stop with blade and brake destruction. Budget $90 for brake cartridges plus blade replacement costs (varies by blade quality).

Traditional Safety Features

If flesh-detection technology exceeds your budget, focus on fundamental safety practices. Our table saw how-to guide covers setup procedures and safety techniques that prevent most table saw injuries without expensive technology.

Modern riving knives, blade guards, and anti-kickback pawls prevent many accidents when properly used. Tool-free riving knives have dramatically improved safety by increasing actual usage rates—they work only when installed.

Push sticks, push blocks, and proper stock-handling techniques prevent blade contact in the first place. No safety technology beats avoiding hand-blade interaction entirely.

Final Verdict: The Legacy of Innovation Cut Short

The Bosch Reaxx represented genuine innovation in table saw safety. The blade-preserving Active Response Technology offered clear advantages over SawStop’s blade-destroying approach, and Bosch engineered a well-built jobsite saw around that technology.

Overall Rating: 4.0/5 Stars (For Historical Context)

What Made It Great:

- Blade preservation saved money and downtime

- Dual-activation cartridges reduced operating costs

- Excellent Gravity-Rise stand included

- Solid cutting performance for a portable saw

- 60-second reset time after activation

- No separate dado cartridge required

What Held It Back:

- Reliability issues with false triggering

- Slightly slower activation than SawStop (6ms vs 3ms)

- Required factory servicing after 25 activations

- Higher initial price than SawStop

- Patent violation led to market ban

- Discontinued with uncertain long-term support

Historical Significance

The Reaxx’s importance extends beyond its brief market presence. It forced SawStop to improve products and competitive pricing. It demonstrated alternative approaches to injury mitigation technology. It proved that flesh-detection safety could work without destroying expensive blades.

The patent battle outcome created a problematic monopoly situation. With SawStop now owned by TTS (Festool’s parent), no price pressure exists to make injury mitigation technology more affordable. The CPSC continues debating mandatory safety requirements, but without competition, innovation has stagnated.

For Woodworkers Today

If you’re choosing a table saw in 2025, the Reaxx isn’t an option—but understanding what it represented helps evaluate current choices. The question isn’t “Reaxx or SawStop” anymore. It’s “Do I need flesh-detection technology, and am I willing to pay SawStop’s prices for it?”

For many hobbyists and professionals, the answer is yes. Table saws cause approximately 30,000 injuries annually in the U.S., with 4,000 amputations. Flesh-detection technology prevents these injuries reliably when it functions properly.

For others operating on tight budgets, investing in comprehensive safety training, proper guards, and disciplined work habits provides significant injury reduction without the technology premium.

Take the Next Step: Choosing Your Safer Table Saw

The Bosch Reaxx is gone, but the safety imperative remains. Before buying any table saw:

- Assess your risk tolerance – How much are your fingers worth? Seriously evaluate injury probability given your experience level and shop conditions.

- Compare total cost of ownership – SawStop technology costs more upfront and per activation, but prevents medical bills and lost work time from injuries.

- Research current models thoroughly – Technology and features evolve continuously. Read recent reviews of current SawStop models and traditional alternatives.

- Factor in your shop environment – Dedicated shop with consistent conditions? Jobsite with variable conditions? Different saws suit different scenarios.

- Budget for proper setup and accessories – A well-tuned saw with quality blades and proper guards is safer than expensive technology used carelessly.

The Reaxx showed us that innovation in safety technology is possible and valuable. Its disappearance showed us how patent disputes can eliminate consumer choice. The market reality in 2025 is that SawStop owns this category—until another manufacturer develops non-infringing injury mitigation technology or the patents expire.

Your fingers are irreplaceable. Choose accordingly.

Frequently Asked Questions

Q: Can I still buy a new Bosch Reaxx table saw in 2025?

No. The Bosch Reaxx is no longer sold, following a patent dispute that resulted in the product being taken off the market. The saw was discontinued in 2017 and Bosch has confirmed they have no plans to reintroduce it. Used examples occasionally appear on secondary markets, but carry risks of limited parts availability and no warranty coverage.

Q: Are replacement safety cartridges still available for existing Reaxx owners?

Yes. Bosch continues manufacturing replacement dual-activation cartridges domestically, which aren’t subject to the import ban. Current owners can obtain cartridges through Bosch service centers and select retailers at approximately $80-90 per unit. However, availability may become limited as Bosch gradually phases out production for this discontinued product line.

Q: How did the Bosch Reaxx differ from SawStop technology?

The Reaxx used a gas-powered cartridge to rapidly drop the blade below the table while it continued spinning, preserving the blade for reuse. SawStop drives an aluminum brake into the blade, stopping it instantly but destroying both the brake and blade. The Reaxx took approximately 6 milliseconds to fully retract versus SawStop’s 3-millisecond blade stop, resulting in slightly deeper initial contact but no blade replacement costs.

Q: Why did Bosch lose the lawsuit against SawStop?

The U.S. International Trade Commission found that the Bosch Reaxx violated two SawStop patents related to flesh-detecting technology. While Bosch’s mechanical implementation differed from SawStop’s approach, the ITC ruled that the underlying detection principles and system architecture infringed SawStop’s intellectual property. Bosch later reached a licensing agreement with SawStop but chose not to reintroduce the product.

Q: Is the Bosch Reaxx worth buying used in 2025?

Only if you find one significantly below market value (under $500) and accept the risks of obsolete technology with uncertain support. Replacement cartridges remain available currently, but specialized electronic components may become impossible to repair if they fail. At typical used prices ($600-900), new SawStop jobsite saws offer better value with warranty coverage and guaranteed long-term support, despite higher per-activation costs.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.