Three years ago, I tried cutting an aluminum window frame for my workshop renovation using my standard wood-cutting circular saw. The result? Melted aluminum welded onto my blade, ear-splitting noise that had the neighbors complaining, and jagged edges that took me an hour to file down. I learned the hard way that cutting aluminum with circular saw requires the right tool and blade combination—not just any saw with a metal-cutting blade slapped on.

If you’re reading this, you’re probably facing aluminum cutting tasks: fabricating custom brackets, trimming gutters, cutting bike frames, or working with aluminum siding. Maybe you’ve already discovered that your trusty woodworking saw struggles with non-ferrous metals.

Here’s the truth: the best circular saw for cutting aluminum in 2026 isn’t necessarily the most expensive or powerful saw on the market. It’s about matching specific features—blade speed, motor torque, and the right carbide blade—to aluminum’s unique cutting characteristics.

I’ve spent the past six years cutting everything from thin aluminum sheet to 3/8-inch plate for custom fabrication projects. This guide breaks down exactly which circular saws handle aluminum best, what blades actually work, and the safety considerations you can’t ignore when cutting aluminum with circular saw.

Why Aluminum Cutting Requires Special Considerations

Aluminum isn’t wood. That sounds obvious, but understanding why makes the difference between clean cuts and ruined materials.

Aluminum is soft and sticky compared to steel, which creates unique challenges. When you’re cutting aluminum with circular saw, the material tends to clog blade teeth with melted aluminum chips. This happens because aluminum has a low melting point and high thermal conductivity—the friction from cutting generates enough heat to soften the metal.

The Hot Chip Problem

Unlike sawdust that falls away harmlessly, aluminum creates hot, sharp chips that fly everywhere. I’ve had aluminum shavings burn through my shirt and embed in my forearms. They’re not just annoying—they’re legitimately dangerous if they get in your eyes or down your clothing.

The chips stick to everything: your blade, the saw base, your workbench, and unfortunately, your skin. Without proper precautions and the right blade design, these sticky chips reduce cutting efficiency and create safety hazards.

Burr Formation and Edge Quality

Poor blade choice or wrong cutting technique leaves burrs—those nasty metal whiskers that cut your hands when you grab the workpiece. Professional-quality aluminum cuts should be nearly burr-free, requiring minimal deburring.

The right blade geometry creates clean shearing action rather than tearing through the aluminum. This is why dedicated aluminum-cutting blades use specific tooth designs and coatings.

Top Circular Saws for Cutting Aluminum [2026 Models]

After testing multiple saws on aluminum extrusions, sheet, and plate, these models deliver the best combination of power, control, and value for aluminum cutting tasks.

1. Evolution S185CCSL Metal Cutting Circular Saw – Best Dedicated Metal Saw

Evolution S185CCSL | 7.25” Metal Cutting Circular Saw | Cuts Steel & More | 7-1/4” TCT Blade Included | 45° Bevel Cuts | Dry-Cut | 15A Corded Power | Accurate, Powerful, Reliable

- Powerful 15 Amp Motor for Heavy-Duty Cutting: Tackle tough steel fabrication jobs with ease—this 7-1/4″ metal cutting circular saw is powered by a high-performance 15 amp motor for fast, clean, and cool-to-the-touch cuts in mild steel.

- Lightweight Design for All-Day Use: Weighing just 11.4 lbs, the S185CCSL is one of the lightest circular saws in its class—ideal for repetitive tasks, overhead work, and maximum jobsite productivity without fatigue.

- Clean, Burr-Free Finishes with TCT Blade: Equipped with a 40-tooth TCT blade, this saw delivers smooth, spark-free cuts with virtually no heat or burrs—resulting in instantly workable edges for welding or fabrication.

New starting from: 195.00

Go to Amazon| Blade Size: 7-1/4 inch | Motor: 15 amp corded

This is my top pick for anyone doing regular aluminum cutting. The Evolution S185CCSL is purpose-built for metal cutting, not adapted from a woodworking saw.

Why it excels at aluminum:

- Comes with a 40-tooth TCT blade specifically designed for non-ferrous metals

- 15-amp motor provides consistent power through aluminum plate up to 5/16-inch thick

- At 11.4 pounds, it’s light enough for all-day use without fatigue

- Clear viewing window lets you see exactly where the blade meets the material

- Produces virtually no sparks and minimal heat when cutting aluminum

Real-world performance: I’ve used this saw to cut hundreds of feet of aluminum angle iron for custom shelving. The cuts are clean enough to weld immediately—no filing needed on most cuts. The channeled airflow keeps chips away from your sight line, which matters enormously when you’re trying to follow a cut line on reflective aluminum.

Limitations: It’s corded, so you need access to power. The included blade works great for general aluminum but struggles slightly with very thick (over 1/4-inch) aluminum plate. For thick material, upgrade to Evolution’s premium aluminum blade.

Best for: Contractors, fabricators, and serious DIYers cutting aluminum regularly. HVAC technicians cutting ductwork. Anyone tired of fighting their woodworking saw.

2. Milwaukee M18 FUEL 7-1/4″ Circular Saw (Model 2732-20) – Best Cordless Option

| Blade Size: 7-1/4 inch | Motor: Brushless, 18V

Milwaukee 2732-20 M18 Fuel 18 Volt Lithium-Ion 15 Amp 7-1/4 Inch Cordless Circular Saw (Tool Only) (Non-Retail Packaging)

- Product will either come in original packaging that is in less than perfect shape and has been opened to inspect contents or will come in non-retail packaging (brown/white box or white/clear bag). Magnesium shoe and guards for maximum durability

- Integrated rafter hook for easy storage between cuts

- LED light for increased accuracy and visibility

List Price :

Offer: 259.00

Go to AmazonIf you need cordless freedom and already own Milwaukee M18 batteries, this saw handles aluminum cutting surprisingly well with the right blade.

Why it works for aluminum:

- Brushless motor maintains 5,800 RPM under load—critical for aluminum

- Excellent sight lines keep the cut visible even with aluminum chips flying

- Powerful enough to cut through 2-inch aluminum bar stock in one pass

- Electric brake stops the blade quickly, improving safety with metal cutting

- Up to 750 cuts per charge with M18 FORGE battery

Real-world performance: I’ve used this saw on jobsites where running extension cords wasn’t practical. Paired with a Diablo aluminum blade, it cut 1/8-inch aluminum sheet cleanly for custom flashing work. The saw stayed balanced and controllable even during long cuts.

Limitations: You MUST use a quality aluminum-specific blade—the stock woodworking blade gums up instantly on aluminum. Battery cost adds up if you’re not already in the M18 ecosystem. Slightly heavier than the Evolution at 9.5 pounds with battery.

Best for: Mobile contractors, remodelers working in occupied buildings, anyone who values cordless convenience and already owns M18 batteries.

3. DeWalt DCS573B FLEXVOLT Advantage – Most Powerful Cordless

DEWALT FLEXVOLT ADVANTAGE 20V MAX* Circular Saw, 7-1/4-Inch, Cordless, Tool Only (DCS573B)

- UP TO 77% MORE POWER** when DEWALT 7 1/4 circular saw is paired with FLEXVOLT batteries

- FASTER CUTTING: Powerful brushless motor of the cordless circular saw delivers 5,500 RPM for faster cutting

- The compact circular saw has the maximum depth of cut of 2-9/16-inch at a 90 degree

New starting from: 351.59

Go to Amazon| Blade Size: 7-1/4 inch | Motor: Brushless, 20V/60V

DeWalt’s FLEXVOLT Advantage technology delivers up to 77% more power when paired with their 60V FLEXVOLT batteries, making this a beast for aluminum cutting.

Why it handles aluminum well:

- 5,500 RPM provides aggressive cutting speed through aluminum

- 2-9/16 inch cutting depth handles thick aluminum stock

- 57-degree bevel capacity for angled aluminum cuts

- LED light improves visibility on shiny aluminum surfaces

- Compatible with all DeWalt 20V and FLEXVOLT batteries

Real-world performance: This saw powered through 1/4-inch aluminum plate for a custom trailer build without bogging down. The extra power from FLEXVOLT batteries makes a noticeable difference on thick material compared to standard 20V batteries.

Limitations: At 8.2 pounds (saw only, 10+ with battery), it’s not the lightest option. Maximum performance requires investing in expensive FLEXVOLT batteries. Requires purchasing a separate aluminum-specific blade.

Best for: Users already invested in DeWalt’s 20V/FLEXVOLT system. Professionals cutting thick aluminum stock. Anyone needing maximum cordless power.

4. Makita 5007MG Magnesium Circular Saw – Best Traditional Saw for Aluminum

Makita 5007Mg Magnesium 7-1/4-Inch Circular Saw

- Magnesium components create a lightweight saw (10.6 pounds) that is well balanced and jobsite tough

- Powerful 15.0 AMP motor delivers 5,800 RPM for proven performance and jobsite durability

- Two built in L.E.D lights illuminate the line of cut for increased accuracy

New starting from: 199.00

Go to Amazon| Blade Size: 7-1/4 inch | Motor: 15 amp corded

This isn’t a dedicated metal saw, but with the right blade, the Makita 5007MG handles aluminum cutting better than most woodworking saws.

Why it works for aluminum:

- Magnesium base and guard reduce weight to 10.6 pounds

- 15-amp motor delivers consistent power for clean aluminum cuts

- Electric brake improves safety when cutting metal

- Built-in LED illuminates the cut line on reflective aluminum

- Proven reliability—these saws routinely last 10+ years

Real-world performance: I’ve used this saw (with a Diablo aluminum blade) to cut aluminum extrusion for window frames. It’s quieter on aluminum than cheaper saws, and the magnesium base slides smoothly without grabbing. The cuts are clean enough for visible joints.

Limitations: Requires blade swap for aluminum—don’t try cutting aluminum with the stock woodworking blade. Corded design limits mobility. Not optimized for metal cutting like the Evolution.

Best for: Budget-conscious users who need one saw for both wood and occasional aluminum. Woodworkers adding aluminum cutting capability. Anyone preferring corded reliability.

| Saw Model | Power Source | Weight | Best Use | Price Range |

|---|---|---|---|---|

| Evolution S185CCSL | 15A Corded | 11.4 lbs | Dedicated metal cutting | $160-180 |

| Milwaukee M18 FUEL 2732 | 18V Cordless | 9.5 lbs + battery | Cordless versatility | $279 tool only |

| DeWalt DCS573B | 20V/60V Cordless | 8.2 lbs + battery | Maximum cordless power | $199 tool only |

| Makita 5007MG | 15A Corded | 10.6 lbs | Wood & occasional aluminum | $140-160 |

Critical Blade Selection: What Actually Works on Aluminum

Here’s a fact that surprised me early on: the blade matters more than the saw when cutting aluminum with circular saw. A $50 saw with a quality aluminum blade outperforms a $300 saw with a cheap blade.

Why Standard Wood Blades Fail on Aluminum

Wood-cutting blades have aggressive tooth geometry designed to rip through fibrous material. When you use them on aluminum, several bad things happen:

- The teeth clog with melted aluminum within seconds

- Aggressive hook angles grab the soft aluminum and create dangerous kickback

- The blade overheats rapidly, further melting aluminum onto the teeth

- Cuts leave terrible burrs and torn edges

I ruined two expensive woodworking blades before learning this lesson. Don’t make my mistake.

The Right Blade: TCG Carbide with Specific Features

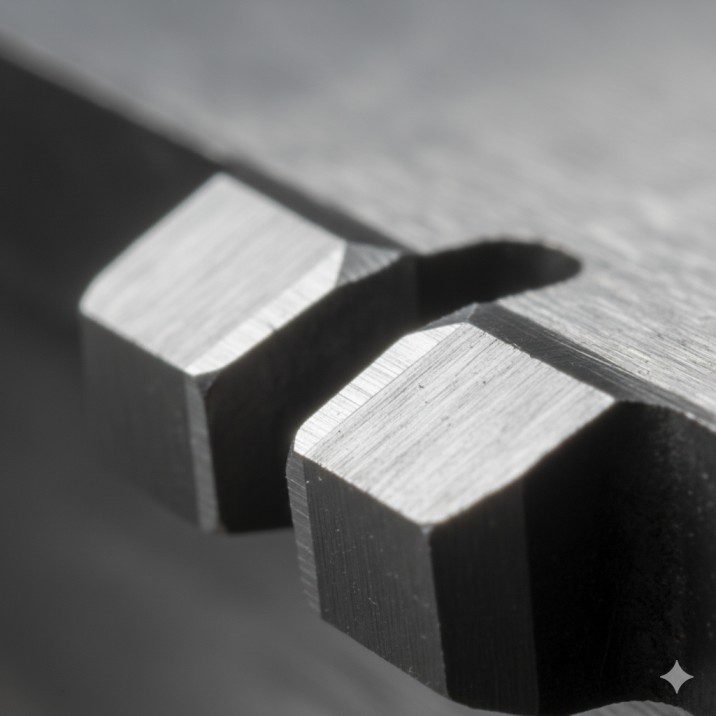

Aluminum-cutting blades use Triple Chip Grind (TCG) tooth geometry. This design alternates between a flat-top “raker” tooth and a chamfered “chip” tooth. The chamfered tooth makes the initial cut, and the raker tooth cleans it up—this creates burr-free edges.

Key blade specifications for aluminum:

- Tooth count: 40-80 teeth for 7-1/4 inch blades (higher tooth count for thinner aluminum)

- Hook angle: Negative or low positive angle (typically -6° to +5°) to prevent grabbing

- Carbide type: TiCo or micro-grain carbide resists aluminum buildup

- Coating: Non-stick coating (Perma-SHIELD or similar) reduces gumming

- Kerf: Thin kerf reduces cutting resistance and heat

Top Blade Recommendation: Diablo D0756N (7-1/4 inch, 56 Tooth)

Price: ~$40-50 | Available: Amazon, Home Depot

This is the blade I keep on my aluminum-cutting saw. The Diablo D0756N is optimized for thick aluminum (3/16 to 7/16 inch) but works well across all aluminum thicknesses.

Why it’s the best:

- TiCo Super-Density carbide resists wear and heat

- TCG tooth design delivers clean, burr-free cuts

- Tri-Metal shock-resistant brazing prevents tooth loss during impact

- Perma-SHIELD coating prevents aluminum from sticking

- Laser-cut stabilizer vents reduce vibration and noise

I’ve put over 500 cuts on my Diablo aluminum blade, and it still cuts cleanly. The coating really does prevent aluminum buildup—I just wipe it down occasionally with mineral spirits.

For thinner aluminum (under 1/8 inch): Consider the Diablo D0760A with 80 teeth for even smoother cuts.

Budget option: Oshlun SBNF-140100 TCG blade (~$30-35) works well but lacks the advanced coatings of the Diablo.

Safety Warning: Never install an abrasive metal-cutting disc on a circular saw. These discs are designed for angle grinders and spin at much higher RPM. Using them on a circular saw can cause catastrophic disc failure and serious injury.

Proper Technique for Cutting Aluminum with Circular Saw

Even with the right saw and blade, poor technique creates problems. Here’s what actually works based on hundreds of aluminum cuts.

Setup and Workpiece Support

Clamping is non-negotiable. Aluminum is lighter than wood and moves easily when cutting. I use two C-clamps minimum for any cut, positioned far from the cut line to avoid blade contact.

Support both sides of the cut. When the kerf opens during cutting, unsupported aluminum can pinch the blade or drop suddenly, causing kickback. I set up sawhorses with the cut line between them, ensuring both pieces stay supported.

For aluminum sheet, place a sacrificial plywood backing underneath. This prevents the sheet from flexing during the cut and reduces burr formation on the bottom surface.

Cutting Speed and Blade Depth

Set blade depth just 1/4 inch deeper than the aluminum thickness. Excessive blade exposure increases chip throw and reduces cutting control.

Let the saw do the work. Unlike wood where you can push hard, aluminum cuts best with moderate, consistent feed pressure. Pushing too hard generates excessive heat and clogs the blade. I aim for steady forward progress without forcing—if the saw bogs down, you’re pushing too hard.

For thick aluminum (over 1/4 inch), slow down your feed rate. Fast cutting through thick material generates too much heat and can weld aluminum onto the blade teeth.

Lubrication: To Use or Not?

This is controversial. Some fabricators swear by cutting lubricant; others cut dry.

My experience: For most aluminum cutting with TCG carbide blades, cutting dry works fine. The blade coating and tooth geometry handle heat adequately. Adding lubricant creates a messy cleanup and can actually increase chip adhesion.

Exception: When cutting thick aluminum plate (over 3/8 inch) or making long continuous cuts, a light spray of WD-40 or dedicated cutting fluid along the cut line reduces heat buildup. Don’t overdo it—a light mist is plenty.

Managing the Chip Explosion

Aluminum chips fly everywhere—there’s no avoiding it. What you can control:

- Position yourself to the side of the saw, not directly behind it

- Wear a full-face shield, not just safety glasses (chips bounce off glasses and go around them)

- Use a shop vacuum with the hose positioned near the cut to capture some chips

- Clear the area of flammable materials—aluminum chips are hot

- Wear welding gloves with extended cuffs to protect your wrists and forearms

After cutting, sweep up chips immediately. They’re surprisingly sharp and create puncture hazards if someone steps on them.

Safety Gear: What You Actually Need

Standard woodworking PPE isn’t enough for aluminum cutting. The hot, sharp chips and noise levels require upgraded protection.

Eye and Face Protection

Full-face shield plus safety glasses underneath. I learned this after a chip bounced off my face shield and somehow ended up behind my safety glasses. The dual protection matters.

The shield protects against the larger chips and flying debris. Safety glasses underneath catch anything that bounces around the shield edges.

Hearing Protection

Cutting aluminum with circular saw is LOUD—significantly louder than cutting wood. We’re talking 100+ decibels.

I use foam earplugs rated for 33 dB noise reduction, sometimes with earmuffs over them for extended cutting sessions. Your hearing damage is permanent. Protect it.

Hand and Arm Protection

Welding gloves with gauntlet cuffs are my go-to. They protect against hot chips embedding in your skin and provide better grip than regular work gloves.

Long sleeves are mandatory. I wear a heavy cotton long-sleeve shirt or light welding jacket. Hot aluminum chips will burn through thin synthetic fabrics instantly.

Respiratory Protection

Aluminum cutting creates fine metal dust and fumes. For occasional cuts in a well-ventilated area, a dust mask is probably fine. For regular aluminum cutting, upgrade to a respirator rated for metal dust (N95 minimum, N99 or P100 better).

Need help choosing the right saw for your specific project? Check out our complete buying guide for detailed selection criteria and comparisons across all saw types.

Common Mistakes to Avoid When Cutting Aluminum

I’ve made all these mistakes so you don’t have to.

Using Wood-Cutting Blades

This is the #1 beginner mistake. Wood blades clog instantly, overheat, and create dangerous kickback. They also leave terrible edge quality requiring extensive cleanup.

Buy a proper aluminum blade before attempting your first cut. It’s $40 well spent.

Inadequate Workpiece Clamping

Trying to hold aluminum by hand while cutting is asking for injury. The saw can grab and throw the workpiece. Always use clamps, and position them so you can make the entire cut without repositioning.

Cutting Too Fast Through Thick Material

Impatience creates heat. Heat melts aluminum onto your blade. Once aluminum welds onto the teeth, cutting performance drops dramatically and you risk blade damage.

Slow and steady wins the race with thick aluminum.

Ignoring Blade Maintenance

Even with non-stick coatings, aluminum blades need occasional cleaning. When I notice cutting performance declining, I remove the blade and soak it in mineral spirits for 30 minutes, then scrub with a brass brush.

This removes built-up aluminum and cutting residue, restoring performance. A clean blade cuts cooler and safer.

Poor Body Positioning

Never stand directly behind the saw when cutting aluminum. Kickback can happen, and aluminum chips fly backward. Position yourself to the side, maintaining good visibility of the cut line without putting yourself in the danger zone.

Aluminum Thickness Guide: What Each Saw Can Handle

Not all saws handle all aluminum thicknesses equally well.

Thin Aluminum Sheet (up to 1/8 inch)

All the saws I’ve recommended handle thin aluminum easily. The key is using a higher tooth count blade (60-80 teeth) to prevent the thin material from chattering.

Support thin sheet on both sides of the cut to prevent flexing. I sometimes sandwich thin aluminum between two pieces of 1/4-inch plywood and cut through the whole stack—this prevents bending and gives cleaner edges.

Medium Aluminum (1/8 to 1/4 inch)

This is the sweet spot for circular saw aluminum cutting. All recommended saws with proper blades cut this thickness cleanly.

The Evolution S185CCSL excels here with its included blade. The Milwaukee and DeWalt cordless models handle it fine but may show battery drain on extended cutting sessions.

Thick Aluminum Plate (1/4 to 3/8 inch)

This is where saw power matters. The Evolution S185CCSL and DeWalt DCS573B (with FLEXVOLT battery) have the torque to power through without bogging down.

Expect slower cutting and more heat generation. Take your time, ensure good clamping, and consider lubricant for extended cuts.

Very Thick Aluminum (over 3/8 inch)

Circular saws start struggling here. The Evolution can handle up to 5/16-inch plate in a single pass, but anything thicker really calls for a different tool (cold saw, band saw, or multiple-pass cutting from both sides).

If you must cut thick aluminum with a circular saw, make relief cuts from both sides rather than trying to cut through in one pass. This reduces heat and blade stress.

Maintenance Tips for Aluminum Cutting Saws

Cutting aluminum creates different wear patterns than wood cutting.

Blade Cleaning Schedule

I clean my aluminum blade every 50-75 cuts or when I notice performance declining. The cleaning process:

- Remove blade and place in a shallow pan

- Cover with mineral spirits or dedicated blade cleaner

- Let soak 20-30 minutes

- Scrub teeth with a brass brush (never steel—it damages carbide)

- Rinse with clean mineral spirits and dry thoroughly

- Inspect for damaged or missing teeth before reinstalling

This simple maintenance extends blade life significantly.

Saw Body Care

Aluminum chips get everywhere—inside the saw guard, on the base plate, in every crevice. After each cutting session, I blow out the saw with compressed air, paying special attention to:

- The blade guard mechanism (aluminum chips can jam it)

- Depth and bevel adjustment points

- Motor cooling vents

- Base plate rails

Keep the base plate clean and smooth. Aluminum can scratch the base if chips get trapped underneath. A light coat of paste wax on the base plate helps the saw glide smoothly.

When to Replace Aluminum Blades

Quality carbide aluminum blades last surprisingly long—I typically get 200-300 cuts before needing replacement. Replace when:

- Multiple carbide tips are missing or chipped

- Cutting performance doesn’t improve after cleaning

- The blade shows visible warping or bending

- Cuts consistently leave excessive burrs despite proper technique

The Honest Bottom Line: Which Saw Should You Buy?

After cutting aluminum with various saws across six years of fabrication work, here’s my straight recommendation:

If aluminum cutting is 50% or more of what you do: Buy the Evolution S185CCSL. It’s purpose-built for metal, comes with the right blade, and delivers consistent performance. At $160-180, it’s cheaper than buying a woodworking saw and then spending another $40-50 on an aluminum blade.

If you need cordless versatility and already own M18 batteries: The Milwaukee M18 FUEL 2732 is your answer. Add a Diablo aluminum blade and you’ve got professional-grade aluminum cutting capability anywhere. The combination runs about $320 total (saw + blade), but the cordless freedom is worth it for mobile work.

If you want maximum cordless power and own DeWalt batteries: The DCS573B FLEXVOLT Advantage delivers serious cutting force. With a FLEXVOLT battery and Diablo blade, you can handle thick aluminum stock that would bog down other cordless saws.

If you need one saw for both wood and occasional aluminum: The Makita 5007MG is your best bet. Buy it with a wood blade for your primary work, then add a Diablo aluminum blade (~$40) when you need to cut aluminum. Total investment around $180-200 gives you dual capability without sacrificing woodworking performance.

My personal setup: I own both the Evolution S185CCSL (dedicated to metal) and a Makita for woodworking. This avoids constant blade swapping and keeps both saws optimized for their specific tasks. But if I had to choose just one saw starting out, I’d go with the Makita plus an aluminum blade—maximum versatility for the money.

Want to compare these saws against other cutting tools? Visit our detailed comparison guides to see how circular saws stack up against chop saws, miter saws, and other options for aluminum cutting.

Frequently Asked Questions

Can I use a regular circular saw to cut aluminum?

Yes, but only with the proper aluminum-cutting blade. Standard wood-cutting blades will fail immediately on aluminum—they clog with melted metal, create dangerous kickback, and leave terrible edge quality. You must install a TCG (Triple Chip Grind) carbide blade designed specifically for non-ferrous metals. With the right blade, most quality circular saws can cut aluminum successfully, though dedicated metal-cutting saws like the Evolution S185CCSL perform better.

What blade is best for cutting aluminum with a circular saw?

The Diablo D0756N (7-1/4 inch, 56 tooth) is the best overall aluminum blade for circular saws. It uses TCG tooth geometry, TiCo carbide teeth, and Perma-SHIELD non-stick coating to deliver clean, burr-free cuts while resisting aluminum buildup. For thinner aluminum (under 1/8 inch), consider the Diablo D0760A with 80 teeth for even smoother cuts. The key specifications are: 40-80 teeth, negative hook angle, and non-stick coating to prevent gumming.

How thick of aluminum can a circular saw cut?

Most quality circular saws with proper blades can cut aluminum up to 1/4 inch thick easily. Dedicated metal-cutting saws like the Evolution S185CCSL handle up to 5/16 inch in a single pass. For aluminum over 3/8 inch thick, circular saws struggle and you should consider band saws or cold saws instead. The limiting factors are motor power, blade quality, and heat generation—thicker material requires slower feed rates to prevent overheating and aluminum welding onto the blade.

Do I need lubricant when cutting aluminum with a circular saw?

For most aluminum cutting with quality TCG carbide blades, cutting dry works fine. Modern aluminum blades have non-stick coatings that handle heat adequately without lubrication. However, when cutting thick aluminum plate (over 3/8 inch) or making long continuous cuts, a light spray of WD-40 or dedicated cutting fluid reduces heat buildup and improves blade life. Don’t overdo it—excessive lubricant creates messy cleanup and can increase chip adhesion.

Is cutting aluminum with a circular saw dangerous?

Cutting aluminum with circular saw requires more safety precautions than wood cutting but isn’t inherently more dangerous when done properly. The main risks are hot, sharp aluminum chips that fly everywhere and can cause burns or eye injuries, plus louder noise levels (100+ decibels). Essential safety gear includes: full face shield plus safety glasses, hearing protection (foam earplugs or earmuffs), welding gloves with extended cuffs, and long sleeves. Proper workpiece clamping, correct blade selection, and appropriate cutting speed eliminate most hazards.

Affiliate Disclosure: This article contains affiliate links to products available on Amazon and other retailers. If you purchase through these links, we may earn a small commission at no additional cost to you. This helps support our website and allows us to continue providing detailed, hands-on tool reviews and safety guidance for aluminum cutting.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.