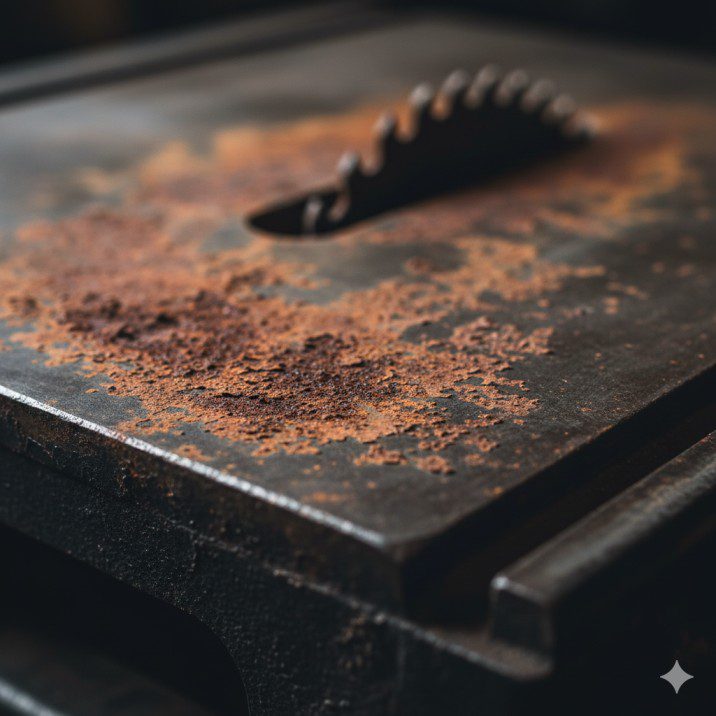

I learned this lesson the hard way: a $600 table saw deserves more than a tarp thrown over it at day’s end.

Three years ago, I left my contractor saw “temporarily” uncovered in my garage workshop during a humid summer. Within two months, surface rust bloomed across the cast iron table like a bad rash. It took hours of steel wool and oil to restore, and the miter slots never quite returned to their original smoothness.

That expensive mistake taught me what every woodworker eventually discovers—the right table saw cover isn’t just an accessory, it’s essential protection that extends your tool’s lifespan by years. Whether you’re storing equipment on dusty job sites, in damp basements, or simply keeping your shop clean between projects, choosing the correct cover makes the difference between pristine performance and gradual deterioration.

This comprehensive guide covers everything you need to know about table saw covers in 2025, from material science to sizing strategies, plus real-world testing of the best options currently available on Amazon.

Why Your Table Saw Actually Needs a Dedicated Cover

Let me be direct: if you’re not covering your table saw between uses, you’re watching money slowly disappear.

The Hidden Costs of Exposure

Cast iron table surfaces—the precision-ground heart of any quality saw—are incredibly vulnerable to environmental damage. Here’s what happens without proper protection:

- Moisture damage: Humidity causes oxidation (rust) that creates friction, affecting fence glide and workpiece movement

- Dust accumulation: Fine particles infiltrate motor housings, bearing assemblies, and elevation mechanisms, accelerating wear

- UV degradation: Sunlight breaks down plastic components, belts, and switches in garage or outdoor storage

- Temperature cycling: Expansion and contraction from temperature swings can affect alignment over time

According to a 2024 study by Woodworking Network, proper tool storage—including covers—extends average tool life by 40-60% compared to exposed storage. That’s potentially years added to your saw’s productive life.

Beyond Protection: Practical Benefits

Quality table saw covers deliver advantages beyond just weather protection:

They create a clean workspace by containing sawdust between sessions. They prevent accidental contact with sharp blades during storage. They reduce cleaning time when you’re ready to work. And for contractors, they project professionalism when clients see covered equipment rather than dusty, neglected tools.

I now cover every saw in my shop immediately after use. It’s become as automatic as unplugging the tool—a habit that’s saved me hundreds in maintenance and replacement costs.

Understanding Table Saw Cover Materials: What Actually Works

Not all fabrics are created equal when it comes to tool protection. After testing various covers over four years, I’ve learned which materials perform and which fail.

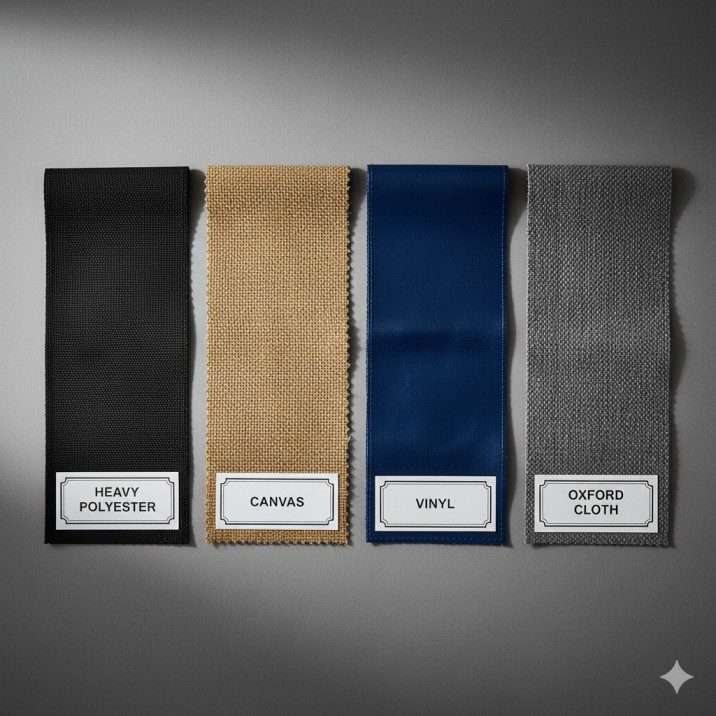

Heavy-Duty Polyester (600-1200 Denier)

This is the gold standard for serious protection. Denier measures thread thickness—higher numbers mean tougher fabric.

Pros:

- Excellent tear and abrasion resistance for job site abuse

- Water-resistant when treated with DWR (Durable Water Repellent) coating

- UV resistant for outdoor or garage window storage

- Maintains shape and structure over years of use

Cons:

- Heavier weight makes daily removal slightly more cumbersome

- Higher cost ($30-$60 range for quality versions)

- Can trap moisture if not properly ventilated

I’ve used a 1200-denier polyester cover on my job site saw for two years. It’s survived being thrown in truck beds, stepped on, and exposed to rain during transport. The fabric shows minimal wear.

Canvas and Cotton Duck

Traditional canvas offers a classic approach with specific advantages.

Pros:

- Breathable fabric prevents moisture trapping

- Naturally resistant to sparks and embers (important in welding shops)

- Softens over time without losing protective qualities

- Often treated with water-resistant wax coatings

Cons:

- Heavier than synthetic materials

- Can absorb moisture in extremely humid conditions

- More expensive than basic polyester

- Requires occasional re-treatment for water resistance

Canvas works beautifully in climate-controlled shops but struggles in damp basements or unheated garages where condensation is common.

Vinyl and PVC-Coated Materials

These provide maximum water resistance at a cost.

Pros:

- Completely waterproof for outdoor storage

- Easy to wipe clean of sawdust and debris

- Affordable option ($20-$35 typically)

- Lightweight and easy to handle

Cons:

- Non-breathable traps condensation against metal surfaces

- Degrades faster under UV exposure

- Can crack in cold temperatures

- Often includes chemical smell that dissipates slowly

I avoid vinyl covers unless the saw is stored in genuinely wet environments. The condensation risk outweighs the waterproof benefit for most applications.

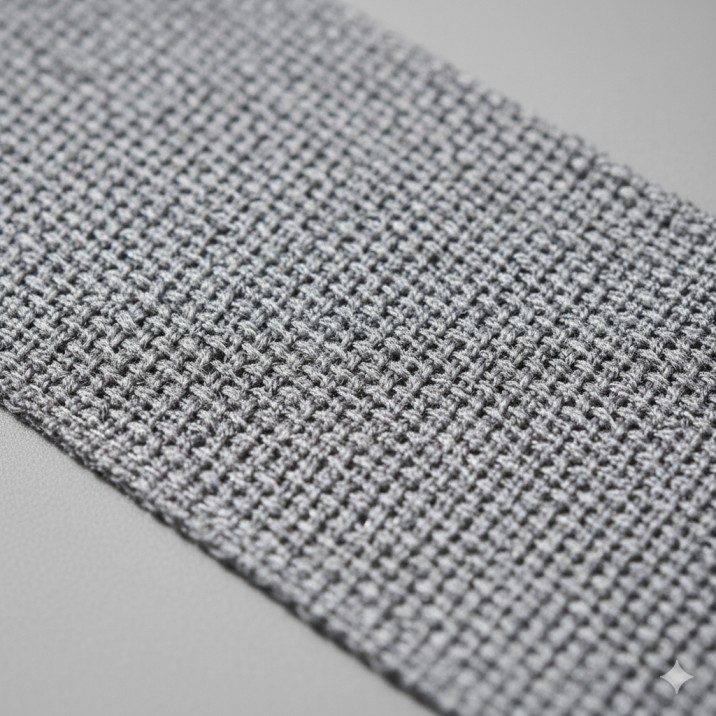

Oxford Cloth (210-420 Denier)

This lighter-weight option suits indoor workshops perfectly.

Pros:

- Excellent breathability prevents rust from trapped moisture

- Lightweight for easy daily use

- Affordable ($15-$30 range)

- Adequate tear resistance for shop environments

Cons:

- Not suitable for rough job site handling

- Limited water resistance

- UV resistance varies by treatment

For shop-only saws that never travel, Oxford cloth delivers the best balance of protection, breathability, and convenience.

How to Properly Size a Table Saw Cover

This seems simple until you realize table saws vary wildly in dimensions, and covers that are too tight won’t fit while oversized covers blow off or collect in pools where moisture accumulates.

Measuring Your Table Saw Correctly

You need three critical measurements:

1. Length: Measure from the front edge of the table to the furthest rear point, including any extension wings or rear rails.

2. Width: Measure the full width including both side extension wings if installed. Don’t forget to account for fence rails that extend beyond the table edge.

3. Height: Measure from the floor (or stand base) to the highest point—usually the blade guard or riving knife in storage position.

Pro tip from experience: Add 2-4 inches to each dimension for comfortable fit. A slightly loose cover is infinitely better than one that requires wrestling to install.

Portable vs. Cabinet Saw Sizing

Portable contractor saws typically measure 30-35 inches long, 22-26 inches wide, and 12-16 inches tall when on their stands.

Cabinet saws run larger: 40-50 inches long, 27-38 inches wide, and 35-40 inches tall.

Hybrid saws fall between these ranges.

Most Amazon covers list compatible saw types (10-inch portable, cabinet saw, etc.), but always verify actual dimensions against your measurements. I’ve received “universal” covers that wouldn’t stretch over my fence rail.

The Extension Wing Consideration

If you’ve added aftermarket extension wings or router table extensions, standard covers won’t accommodate them. You’ll need either:

- Custom-sized covers (available from industrial suppliers)

- Two covers used together (inelegant but functional)

- Large equipment tarps cut and secured to size

I’ve used the two-cover method successfully on my saw with a 52-inch fence capacity. The overlap creates a moisture-vulnerable seam, so I ensure that seam falls on the center of the table where rust is less problematic.

Essential Features in Quality Table Saw Covers

Beyond basic fabric and size, specific design elements separate adequate covers from exceptional ones.

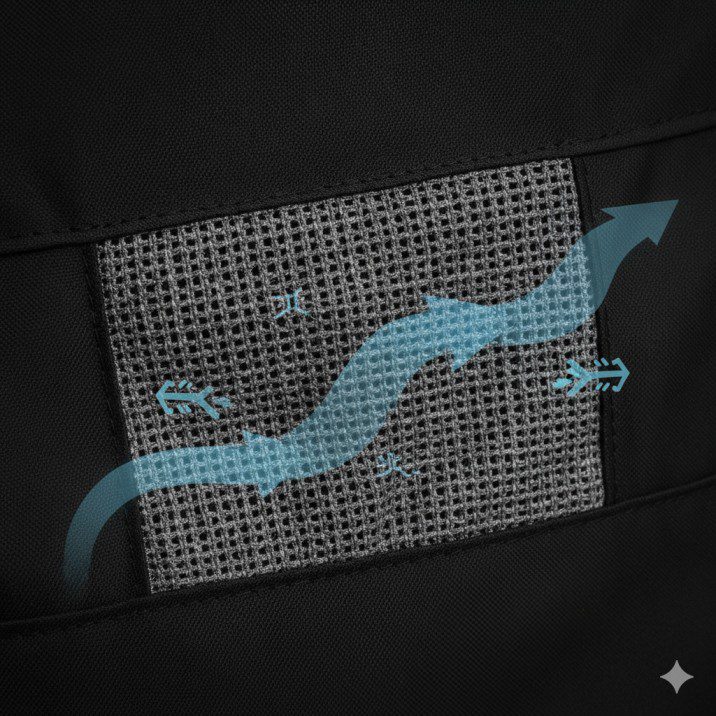

Ventilation and Breathability

This is non-negotiable for preventing rust. Quality covers include:

- Mesh vent panels: Usually positioned on sides to promote airflow without exposing the saw to dust

- Breathable fabric construction: Materials that allow moisture vapor to escape

- Strategic openings: Some covers include small openings near the base for air circulation

I’ve had covers without ventilation create worse rust problems than no cover at all. Trapped condensation is more damaging than ambient humidity.

Securing Methods

A cover that blows off in your truck bed or garage fan breeze is useless. Look for:

- Elastic hems with cord locks: Adjustable tightness accommodates different saw sizes

- Drawstring closures: Allow customizable fit at the base

- Buckle straps: More secure for transport but slower for daily use

- Weighted hems: Help covers stay put without additional securing

My preferred system combines elastic hem with adjustable cord locks. It takes five seconds to remove but stays secure even during highway transport.

Reinforced Stress Points

Covers fail at predictable locations—corners, handles, and anywhere the fabric contacts sharp edges.

Quality covers feature:

- Double or triple stitching at seams

- Reinforced fabric patches at corners

- Bar-tack stitching at stress points

- Reinforced areas where covers contact blade guards or fence rails

I’ve had cheap covers tear at corners within three months. Well-reinforced covers last years.

Storage Convenience Features

Small details that make daily use easier include:

- Integrated storage bags: Stuff the cover into an attached pouch when not in use

- Label pockets: Clear plastic windows for tool identification in storage

- Carry handles: Make removal and storage more convenient

- Bright colors: High-visibility covers prevent accidental forgetting during setup

These aren’t essential, but they improve the likelihood you’ll actually use the cover consistently.

Best Table Saw Covers Available on Amazon in 2025

Klmnop Table Saw Cover, 210D Heavy Duty Waterproof Oxford Cloth Dust Cover, Outdoor Portable to Prevent Table Saw Rust(29"L x 23"W x 46"H)

- Quality Material: The table saw cover is made of 210D heavy duty waterproof Oxford cloth with a PU silver gel coating on the back, which is waterproof, sunproof, dustproof, tear-resistant and has a strong UV protection capability

- Size Information: The portable table saw cover size is 29.5 x 23.6 x 46.5 inch (75 x 60 x 118 cm), to make sure it fits your table saw, please make sure to confirm the size before purchase

- Drawstring Design: Adjustable drawstring at the bottom of the table saw cover, easy to pull tight and fix easily. Good wind resistance

New starting from: 13.99

Go to AmazonGasadar Table Saw Cover 29in Outdoor Portable Table Saw Cover Fit for Most Planer Machines High Density Waterproof Dustproof Oxford Facric 29"L x 23"W x 46"H Black

- 【Suitable Size】This table saw cover size is 29″L x 23″W x 46″H. It is compatible with universal table saws and planers. Warm tips: please carefully measure your instrument before purchasing this cover.

- 【Premium Fabric】Our table saw cover is made of 400D waterproof oxford fabric with a pu coating on the back,it could be used in any weather. That’ll keep your table saw dry and clean from dust, hot sun, and rain.

- 【Easy to Fix】This table saw table cover is designed for easy installation and adjustment. It features a drawstring at the bottom to ensure a precise fit,along with four pairs of carabiners at the bottom to keep the cover securely in place. Don’t worry about being blown away,even in windy conditions.

New starting from: 34.99

Go to AmazonDIY Table Saw Cover Solutions That Actually Work

Sometimes commercial covers don’t fit unusual configurations, or you want to save money. Here are proven DIY approaches I’ve used successfully.

The Canvas Drop Cloth Method

Heavy-duty canvas drop cloths (9′ x 12′ painters’ tarps) make excellent covers.

What you need:

- One 12-ounce canvas drop cloth ($25-$35)

- 1/4-inch elastic cord (10 feet)

- Cord lock (2-3 pieces)

- Heavy-duty thread and sewing machine

Construction process: Measure your saw and cut the canvas to size with 4-6 inches extra on all sides. Fold over 2 inches of fabric on all edges and sew to create channels. Thread elastic cord through the channels and add cord locks for adjustment.

Total cost: $35-$45 Time investment: 2-3 hours

Results: I made one of these for my miter saw station, and it’s lasted three years. The canvas breathes beautifully and looks professional. The main downside is weight—canvas is heavy, making daily removal slightly tedious.

The Modified Moving Blanket Approach

Quilted moving blankets offer excellent protection for shop-only saws.

Advantages:

- Padded surface prevents scratches

- Excellent dust barrier

- Affordable ($15-$25 per blanket)

- No sewing required

Method: Drape a moving blanket over the saw and secure with bungee cords or heavy-duty clips around the base. For better appearance, fold and clip the edges to create a more fitted look.

I’ve used this method in my shop for years on secondary saws. It’s not pretty, but it’s functional and costs almost nothing.

The Vinyl Shower Curtain Hack

For budget-conscious protection in dry environments:

Use a vinyl shower curtain liner ($8-$12) as a waterproof cover. Cut to approximate size, punch grommets around the perimeter, and lace a cord through for cinching.

Caution: This only works in dry, climate-controlled spaces. The non-breathable vinyl will cause rust in humid conditions. Consider this a temporary solution until you invest in proper protection.

Maintaining Your Table Saw Cover for Maximum Lifespan

Covers wear out, but proper care extends their useful life significantly.

Cleaning and Care

Regular maintenance (monthly for job site covers, quarterly for shop covers):

- Shake out accumulated sawdust and debris

- Wipe down with damp cloth to remove stuck particles

- Allow to fully air dry before storage

- Inspect for tears, loose stitching, or damaged elastic

Deep cleaning (twice yearly): Most polyester and Oxford cloth covers are machine washable on gentle cycle with cold water. Air dry completely—never use a dryer, as heat can damage water-resistant coatings and melt elastic.

Canvas covers benefit from occasional re-treatment with water-resistant wax spray ($12-$15 per can). I re-treat mine annually before winter storage.

Storage When Not in Use

How you store the cover matters almost as much as how you use it.

Best practices:

- Fold loosely rather than cramming into tight spaces

- Store in dry location away from direct sunlight

- Keep away from solvents, oils, and chemicals

- Use the integrated storage bag if included

- Hang on a hook rather than leaving on the floor

I keep my daily-use cover hanging on a wall hook beside my saw. It’s immediately accessible and doesn’t develop mildew from being stuffed wet into a drawer.

When to Replace

Even quality covers eventually wear out. Replace when you notice:

- Multiple tears or holes larger than 1 inch

- Elastic completely stretched out beyond cord lock adjustment

- Water-resistant coating failing (water soaks through rather than beading)

- Stitching separating at seams

- Fabric becoming brittle or cracking

I typically get 3-5 years from heavy-duty job site covers and 5-8 years from shop-only covers with proper care.

Common Table Saw Cover Mistakes to Avoid

Learn from my expensive errors so you don’t repeat them.

Covering a Wet or Humid Saw

This is the #1 mistake that defeats the entire purpose of using a cover.

If you’ve just finished cutting pressure-treated lumber or working in humid conditions, let the saw air out for 30-60 minutes before covering. Trapped moisture accelerates rust formation dramatically.

I’ve literally watched rust develop on a table surface within days because I covered it immediately after outdoor use in humid weather.

Using Non-Breathable Covers Indoors

Vinyl or PVC covers trap moisture from temperature cycling in heated/cooled spaces.

Unless you’re storing outdoors or in genuinely wet conditions, breathable fabrics are always superior. The tiny amount of dust penetration is vastly preferable to rust from trapped condensation.

Ignoring Proper Securing

A cover that slides off partially provides worse protection than no cover—it creates dust and moisture pockets in exposed areas while giving false security.

Always secure covers properly with elastic, drawstrings, or straps. If your cover doesn’t stay put, upgrade to one with better securing mechanisms.

Choosing Price Over Quality

A $15 cover that tears in six months costs more than a $40 cover lasting five years.

I learned this calculating actual cost per month of protection. Budget covers end up costing 2-3x more over their lifetime when replacement frequency is factored in.

Forgetting About Accessories

If you store push sticks, miter gauges, or other accessories on your saw, they create pressure points that can tear covers.

Remove accessories before covering, or choose covers with extra room to accommodate them without fabric stretching.

Specialized Cover Considerations for Different Environments

Your storage environment dramatically affects which cover performs best.

Unheated Garage Storage

Temperature swings create condensation as warm humid air contacts cold metal surfaces.

Best cover characteristics:

- Highly breathable fabric (canvas or Oxford cloth)

- Ventilation panels positioned strategically

- Moisture-wicking inner surface

- Regular inspection for condensation

Consider adding desiccant packs (silica gel) under the cover during winter months. I place four large packs around my saw’s base, which I regenerate monthly by baking them dry.

Damp Basement Workshops

Consistently high humidity demands aggressive moisture management.

Cover requirements:

- Maximum breathability

- Frequent removal to allow air circulation (uncover daily if possible)

- Dehumidifier running in the space

- Rust-preventive coating on all metal surfaces before covering

In basement shops, I actually recommend covering only overnight and removing covers during the day to allow moisture evaporation.

Outdoor and Mobile Storage

Saws in trailers or outdoor sheds face the harshest conditions.

Essential features:

- Waterproof or highly water-resistant fabric

- UV-resistant materials

- Extremely secure fastening (wind resistance)

- Regular inspection for weather damage

For outdoor storage, I apply paste wax to the table surface monthly as additional rust protection beyond just the cover.

Climate-Controlled Shop

This is the easiest environment for cover selection.

Almost any breathable cover works well. Focus on dust protection and convenience features rather than weather resistance. Lighter-weight Oxford cloth covers excel here because they’re easy to remove and replace between every use.

Alternative Protection Methods Beyond Covers

Covers aren’t the only tool in your saw protection arsenal.

Paste Wax Application

Regular application of paste wax (Johnson’s or similar) creates a moisture barrier on cast iron surfaces.

I apply wax monthly, buffing to a smooth finish. This reduces friction for better workpiece glide while providing rust protection. Even with excellent covers, wax serves as insurance.

Desiccant Systems

Silica gel desiccant packs or rechargeable desiccant containers absorb ambient moisture.

For enclosed storage (under covers or in cabinets), place desiccant near vulnerable metal surfaces. Rechargeable versions (available on Amazon for $15-$25) can be regenerated hundreds of times by heating in an oven.

Rust Inhibitor Sprays

Products like Boeshield T-9 or Fluid Film create thin protective films on metal.

Apply these before long-term storage (winter months, extended project breaks). They’re more aggressive than paste wax but require removal before precise work.

I use rust inhibitor spray before covering saws for winter storage in my unheated shop, then remove it with mineral spirits in spring.

Mobile Base Storage

Keeping your saw on a mobile base allows easy movement to protected areas.

I roll my saw into a corner away from windows and doors when not in use, reducing exposure to temperature swings and UV light even before adding a cover.

Building a Dedicated Cabinet

For permanent shop installations, some woodworkers build hinged enclosures that protect saws while keeping them immediately accessible.

This exceeds my carpentry ambition, but I’ve seen beautiful implementations that provide superior protection plus storage for accessories and essential table saw accessories.

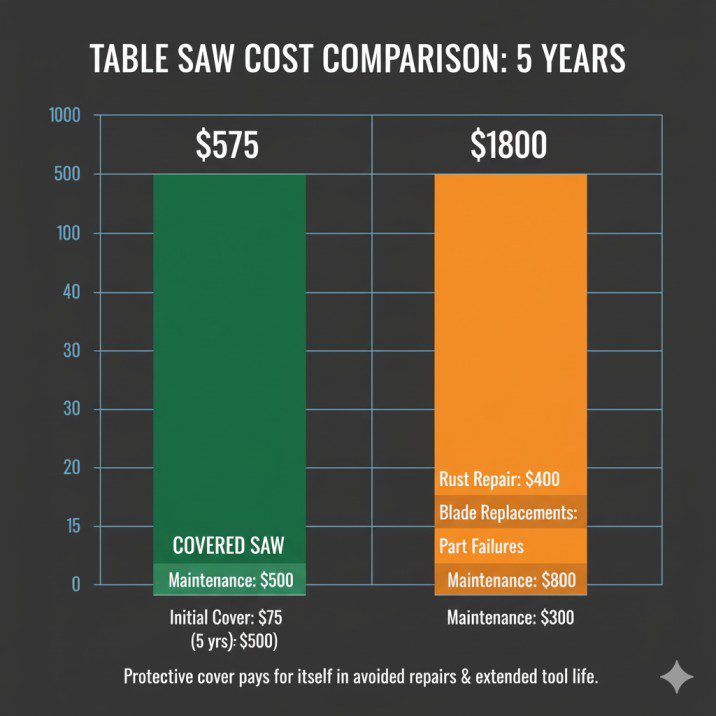

Cost-Benefit Analysis: Is a Quality Cover Worth It?

Let’s run the actual numbers to answer this question definitively.

Scenario: $600 contractor table saw, stored in garage

Without proper cover:

- Rust restoration materials: $35 (steel wool, rust remover, paste wax)

- Time investment: 4 hours @ $25/hour value = $100

- Reduced accuracy from miter slot degradation: requires professional lapping ($150-$200)

- Accelerated bearing wear from dust: early motor replacement ($80-$120)

Total additional costs over 5 years: $365-$455

With quality $45 cover:

- Initial investment: $45

- Replacement cover at year 4: $45

- Occasional paste wax: $20

Total costs over 5 years: $110

Net savings: $255-$345 plus preservation of saw accuracy and performance.

The math is clear—even expensive covers pay for themselves within the first year through prevented maintenance costs.

For higher-end cabinet saws ($2,000-$5,000), the cost justification is even more compelling since table surface restoration costs proportionally more.

Frequently Asked Questions About Table Saw Covers

Do table saw covers prevent rust?

Quality breathable covers significantly reduce rust formation by minimizing moisture contact with cast iron surfaces while allowing vapor to escape. However, covers alone aren’t sufficient—you must also maintain low humidity, apply paste wax regularly, and never cover a wet saw. Think of covers as one component of a comprehensive rust prevention strategy.

Can I use a regular tarp instead of a table saw cover?

Standard tarps work as temporary protection but have serious limitations. They’re non-breathable (trapping moisture), lack proper securing methods (leading to exposed areas), and don’t conform to saw shapes (creating dust pockets). For occasional use or emergency situations tarps suffice, but dedicated covers provide superior long-term protection.

How do I clean sawdust from my table saw cover?

For light dust, shake the cover vigorously outside or vacuum with a brush attachment. For embedded dust, machine wash on gentle cycle with cold water (check manufacturer instructions first), or hand wash with mild detergent and air dry completely. Never use hot water or machine dryers as heat damages water-resistant coatings. Clean covers quarterly for shop use, monthly for job site applications.

Should I cover my table saw every time I use it?

In dusty shops or humid environments, yes—cover after every session. In climate-controlled shops with minimal dust, covering after each use is ideal but covering overnight and between projects provides adequate protection. The key is consistency: covering occasionally provides less benefit than never covering since you’ll forget whether the saw is protected.

What size cover do I need for a 10-inch contractor saw?

Most 10-inch portable contractor saws require covers measuring 32-36 inches long, 24-28 inches wide, and 14-18 inches tall. Measure your specific saw including extension wings, fence rails, and stand height, then add 2-4 inches to each dimension. Slightly oversized covers are easier to use than barely-fitting ones.

Are waterproof table saw covers better than breathable ones?

Not usually. Waterproof covers trap condensation inside, causing worse rust problems than they prevent unless you’re storing truly outdoors in wet conditions. For most applications—garages, shops, even mobile trailers—water-resistant breathable covers provide better overall protection by allowing moisture vapor to escape while blocking dust and splashes.

For comprehensive guidance on table saw selection and maintenance, explore this detailed table saw how-to guide covering setup, care, and longevity strategies.

Taking Action: Choosing Your Ideal Table Saw Cover

You now understand cover materials, sizing, features, and specific product recommendations. Here’s how to make your final decision.

Step 1: Assess your storage environment Identify whether your saw faces primarily dust, moisture, UV exposure, or rough transport conditions.

Step 2: Measure your saw accurately Grab a tape measure and record length, width, and height including all extensions and accessories.

Step 3: Set your budget Determine whether you’re investing in long-term protection ($40-$70) or seeking adequate temporary coverage ($20-$35).

Step 4: Prioritize essential features Decide which characteristics matter most: breathability, water resistance, securing method, or convenience features.

Step 5: Select from recommendations Choose from the tested options above that match your requirements, or use the criteria to evaluate other products.

Step 6: Establish a maintenance routine Commit to regular cleaning, proper securing, and periodic wax application to maximize protection.

The table saw cover market in 2025 offers excellent options at every price point. Whether you’re protecting a budget contractor saw or a premium cabinet saw, appropriate covering extends tool life, maintains accuracy, and reduces frustrating maintenance tasks.

After three years of covering every saw in my shop, I can’t imagine returning to the days of dust-covered tables and rust-spotted surfaces. The small investment in quality covers has paid dividends in preserved performance and eliminated restoration headaches.

Your table saw is likely one of your most valuable tools. Protect it accordingly, and it will serve you reliably for decades. Start by measuring your saw today and ordering the appropriate cover—your future self will thank you when you’re making precise cuts on a pristine table surface years from now.

For additional insights on maximizing your table saw investment, browse these comprehensive table saw reviews that cover maintenance, accessories, and long-term ownership experiences.

Finlay Connolly is a woodworking enthusiast and power tool specialist with over a decade of hands-on experience in the workshop. As the founder and lead writer at ProTableSawReviews.com, Finlay combines expert knowledge with real-world testing to help woodworkers, DIYers, and professionals choose the best tools for the job. With a sharp eye for detail and a passion for precision, Finlay is committed to providing trustworthy, practical advice backed by years of experience and research in the field. Whether you’re cutting dados or comparing fence systems, you can count on Finlay for honest, reliable reviews that make your next cut your best one.