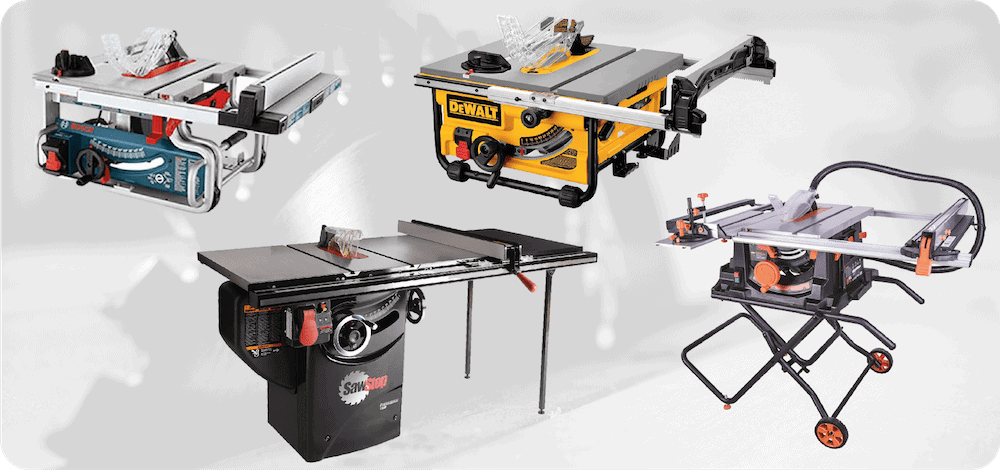

How to choose a Table Saw – the central tool in almost all cabinetmaking shops is the Table Saw, probably the most useful single tool the average woodworker is going to have, because the work it does serves as a base for everything that comes afterward, performing multiple tasks during any woodworking project from the first rough cuts to precision joinery. The fact that the table saw is so central to most woodworking projects means that it is one of the most important buying decisions that you will make. Add to that the fact that even the less expensive table saws tend to cost a good few hundred dollars means that you need to make the right choice – you will probably be living with it a long time. There are 3 main types of table saw – benchtop (or Jobsite), contractor, and cabinet saw, and the first decision that you need to make is what size table saw is right for your needs and budget.

Benchtop or Jobsite Table Saws

These are the smallest and least expensive type of table saw and tend to be defined by their compact size, lightweight, and easy portability, as well as the fact that they all use universal motors. They are the obvious choice for anyone looking for mobility as the number one requirement, so they will appeal to woodworkers who have a limited amount of space in their shop and have to store their tools after each use, or to carpenters and contractors who want a table saw that they can take with them to the job site. Once you’ve enjoyed the benefits of a table saw in your workshop, the last thing you want is to leave it behind when you go on-site.

These are the smallest and least expensive type of table saw and tend to be defined by their compact size, lightweight, and easy portability, as well as the fact that they all use universal motors. They are the obvious choice for anyone looking for mobility as the number one requirement, so they will appeal to woodworkers who have a limited amount of space in their shop and have to store their tools after each use, or to carpenters and contractors who want a table saw that they can take with them to the job site. Once you’ve enjoyed the benefits of a table saw in your workshop, the last thing you want is to leave it behind when you go on-site.

The major disadvantage of benchtop table saws is their limited rip capacity which is the obvious result of their compact size. The largest table top that you are likely to find on one of these saws is on a saw like the Dewalt DW744XRS which has a 26-1/2-inch x 19-1/4-inch table surface. However, to combat this small size, all the best table saws of this type have telescoping fence rails which extend the rip capacity to in excess of 24 inches – the Dewalt DW744XRS extends to 24-1/2 inches and the Bosch 4100-09 extends to 25 inches. This figure is critical, particularly to contractors, as anything over 24 inches means that you can rip a full-sized sheet of plywood in half. The rip fences on these saws are very good, locking down at both sides of the table for complete stability along the whole length of the cut and, in the case of Dewalt saws, using rack and pinion gearing to give accurate adjustment.In order to keep these table saws compact and keep the weight down these table saws also use universal motors of the sort used in other power tools such as routers and drills, which are less powerful and noisier than the induction motors used in contractor and cabinet saws.

PROS

- Lightweight and easy to carry

- Compact with a small footprint allows for easy storage

- Mobile – many models are available with a rolling or folding stand

- Affordable – you can pick up a quality saw for $300 to $600

CONS

- Less power

- Noisy universal motors

- The small table makes it harder to cut sheet stock or longboards

- Limited rip capacity

Contractor Saws

Contractor Saws are the next category up from benchtop table saws. The two main factors that differentiate them from benchtop saws are their larger table tops and the use of more powerful induction motors.In addition to their larger table tops – a typical contractor saw like the Grizzly G0661 has a tabletop 27-inches x 44-inches – contractor saws have cast iron table tops. The benefit of using cast iron for any kind of woodworking machinery table top is that it absorbs vibration much better than aluminum table tops, and makes the whole saw that much more stable. The downside of course is that it is much heavier, and although some models come with an integrated mobile base which makes them easier to move around the shop, they are too heavy to be lifted by one person. Contractor saws use induction motors which are more powerful than the universal motors used in benchtop table saws, and power tends to be around 2 HP on these saws. You can also run an induction motor all day long if you want to, which you can’t do with a universal motor as it will soon burn out.

Contractor Saws are the next category up from benchtop table saws. The two main factors that differentiate them from benchtop saws are their larger table tops and the use of more powerful induction motors.In addition to their larger table tops – a typical contractor saw like the Grizzly G0661 has a tabletop 27-inches x 44-inches – contractor saws have cast iron table tops. The benefit of using cast iron for any kind of woodworking machinery table top is that it absorbs vibration much better than aluminum table tops, and makes the whole saw that much more stable. The downside of course is that it is much heavier, and although some models come with an integrated mobile base which makes them easier to move around the shop, they are too heavy to be lifted by one person. Contractor saws use induction motors which are more powerful than the universal motors used in benchtop table saws, and power tends to be around 2 HP on these saws. You can also run an induction motor all day long if you want to, which you can’t do with a universal motor as it will soon burn out.

PROS

- Cast iron tops absorb vibration

- Powerful induction motors

- Larger tables support a large stock

- Some models have a built-in mobile base

CONS

- Open stand can make dust collection difficult

- 2-hp models may require a dedicated 20-amp circuit for best performance

- Too heavy for one man to lift

Cabinet Saws

Cabinet Saws are the ultimate top-of-the-range table saw, and in all those areas where bigger is better, a cabinet saw is the way to go.

Cabinet Saws are the ultimate top-of-the-range table saw, and in all those areas where bigger is better, a cabinet saw is the way to go.

The table saw of choice for woodworking professionals who have the space in their workshop and the budget to pay for it, a cabinet saw gives you maximum capacity, power and longevity – but at a price that not everyone can afford or justify.

Cabinet Saws are the heaviest, sturdiest and most accurate type of table saw. They have the most powerful induction motors and may require a dedicated 220-volt electrical outlet. Cabinet saws are the best for cutting sheet stock because of their large tables with big extension wings. Because they are the top of the range, they also have the best safety features such as riving knives, blade guard systems and blade brakes, as well as the most efficient dust-control capabilities.

You can easily pay upwards of $3,000 for a quality cabinet saw and you need to be able to justify that expenditure. However, if you are a woodworking professional with enough space and money, a cabinet saw will soon become the permanent centerpiece of your workshop that will last as long as you do, and will let you tackle any project with ease.

PROS

- As much power as you could ever want

- Handles the largest stock with ease

- Lasts a lifetime

CONS

- Much higher cost

- Heavy with large footprint means these saws are only really suitable as a permanent fixture

- May require a dedicated power circuit